DOI: 10.11817/j.ysxb.1004.0609.2020-35743

稀土铈掺杂石墨烯对7050铝合金微弧氧化膜层结构与性能的影响

宗 玙1, 2,宋仁国1, 2,花天顺1, 2,蔡思伟1, 2

(1. 常州大学 材料科学与工程学院,常州 213164;

2. 常州大学 江苏省材料表面科学与技术重点实验室,常州 213164)

摘 要:采用微弧氧化(MAO)技术,以硅酸盐为主要电解液成分,通过加入稀土元素铈以及石墨烯添加剂,在7050高强铝合金表面制备微弧氧化膜层。利用扫描电镜(SEM)、体视显微镜、X射线衍射仪(XRD)、摩擦磨损试验机以及电化学工作站研究微弧氧化陶瓷膜层的形貌、粗糙度、相组成和元素分布以及耐磨性和耐蚀性。结果表明:同时加入4 g/L CeO2和10 g/L的石墨烯制备的复合膜层表面微孔尺寸明显降低,结构致密,耐磨性较好,粗糙度最低(1516.03 nm),膜层主要由α-Al2O3和γ-Al2O3组成。且此时的复合膜层自腐蚀电位最大,自腐蚀电流最小,耐腐蚀性最佳。

关键词:7050高强铝合金;微弧氧化;稀土元素;石墨烯;复合膜层

文章编号:1004-0609(2020)-04-0782-11 中图分类号:TG171 文献标志码:A

7050高强铝合金具有密度小、强度高、加工性能好以及焊接性能好等特点,是重要的轻质高强结构材料,已经被广泛地应用于航空工业以及民用工业等领域[1-3]。但是,由于7xxx系铝合金化学性质活泼,会发生点蚀、晶间腐蚀、应力腐蚀以及剥落腐蚀[4-7],其耐蚀性差极大地限制了它的进一步应用。近年来,人们对提高铝及其铝合金的耐蚀性展开了大量的研究,发现通过阻碍其与外界环境接触来进行表面改性是一种很好的方法[8-9]。

微弧氧化(Micro-arc oxidation, MAO),又称等离子体电解氧化,是在阳极氧化基础上发展起来的一种表面改性技术,是通过电解液和相应的电参数相结合,在Al、Mg等金属及其合金的表面依靠弧光放电所产生的瞬时高压作用,生长出以基体金属氧化物为主的陶瓷层[10]。微弧氧化工艺简单,生产效率高,基本无排放,因而是一种环保型表面处理技术。

在微弧氧化过程中,电解液尤为重要。铝合金微弧氧化研究较多的是以硅酸钠为基础的电解液体系,研究中发现,单一的硅酸钠体系制备的氧化膜层组成单一,无法满足特殊环境下对铝合金结构材料耐腐蚀性和硬度等性能的要求[11-13]。氧化铈具有较高的氧化性,能够在铝合金表面形成具有良好的耐腐蚀性能的氧化膜层[14]。石墨烯由于其优良的热、电性能,近十年来在技术和工程领域引起了人们极大的兴趣,常被用来防止腐蚀与氧化[15]。因此,本文作者通过在硅酸钠电极液中添加氧化铈(CeO2)和石墨烯(GE)来制备复合涂层从而提高7050高强铝合金微弧氧化膜层的性能。同时借助扫描电镜、体视显微镜、X射线衍射仪(XRD)、摩擦磨损实验机以及电化学工作站进行表征微弧氧化陶瓷膜层的表面形貌、粗糙度、相组成、耐磨性和耐蚀性。

1 实验

1.1 微弧氧化陶瓷膜层制备

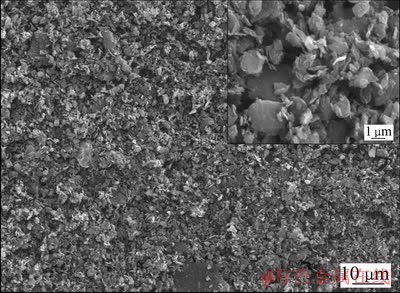

试验采用的是7050高强铝合金试样,其化学成分列于表1中。试验所采用的石墨烯粉末微观形貌图如图1所示。石墨烯固体粉末呈薄片状,利于其在溶液中的分散。

通过线切割将板材加工成15 mm×25 mm×2 mm的试样,分别经500、800、1200号砂纸打磨试样,用无水乙醇超声清洗后用去离子水冲洗干净并干燥。配置微弧氧化溶液Na2SiO3为10 g/L,KOH为2 g/L,CeO2为4 g/L,十二烷基苯磺酸钠为3 g/L,石墨烯浓度为10 g/L。先将十二烷基苯磺酸钠加入适量去离子水溶解,然后将固体石墨烯加入上述溶液中,采用超声波超声分散20 min,再依次加入Na2SiO3、KOH、CeO2,将配置好的溶液机械搅拌20 min,使得石墨烯在溶液中分散均匀。

本试验中的微弧氧化设备主要由微弧氧化电源、自制搅拌系统、电解槽组成,试样和不锈钢棒分别作为阳极和阴极。氧化时间为25 min,电流密度为7 A/dm2。

1.2 性能测试及组织观察

1) 采用JSM-6510扫描电子显微镜微弧氧化膜的表面组织进行观察,采用体视显微镜研究膜层表面轮廓形貌,并在每个测试试样的表面随机测试5个点,取平均值作为膜层表面粗糙度的值。

2) 采用X射线粉末衍射仪测定膜层相组成,其中扫描角度为2θ,电压为40 kV,电流为100 mA。

3) 采用CFT-1型材料表面性能综合测试仪进行摩擦磨损试验,对磨材料为Si3N4,加载载荷为1.96 N,电机转速为500 r/min,采用往复滑动模式,磨痕半径为3 mm,运行时间为20 min,磨损介质为空气,磨损完后对磨损试样进行观察分析。

4) 采用CS350电化学工作站测试试样的耐腐蚀性,其中所用的辅助电极为铂电极(Pt),饱和甘汞电极(SCE)为参比电极,测试的样品为工作电极,腐蚀介质为3.5%(质量分数)的NaCl溶液。交流阻抗的扫描范围为1×10-1~1×105 Hz,所取得振幅为10 mV,每种情况下重复试验3~5次,保证其可靠性和可重复性。

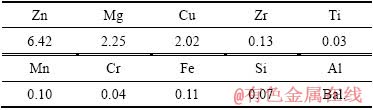

表1 7050铝合金基体的化学成分

Table 1 Chemical composition in weight percent of 7050 aluminum alloy substrate (mass fraction, %)

图1 石墨烯固体粉末的微观形貌图

Fig. 1 Morphology of solid powders of graphene

2 结果与分析

2.1 微弧氧化膜层宏观形貌与显微组织

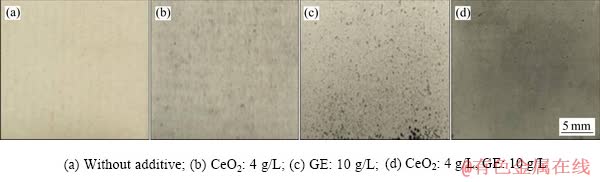

图2所示为不同电解液添加剂条件下7050高强铝合金为微弧氧化膜层的宏观形貌图。从图2中可以看出,当添加4 g/L的CeO2时,试样的表面呈现银色(见图2(a))。当在电解液中添加10 g/L的石墨烯时,试样表面呈现明亮的银灰色,且表面出现黑色颗粒物(见图2(b))。当在电解液中同时添加10 g/L的石墨烯和4 g/L的CeO2制备复合涂层,此时试样表面呈现暗灰色(见图2(c))。

图2 不同电解液添加剂条件下7050高强铝合金MAO膜层的宏观形貌图

Fig. 2 Morphologies of MAO coatings under different electrolyte additives

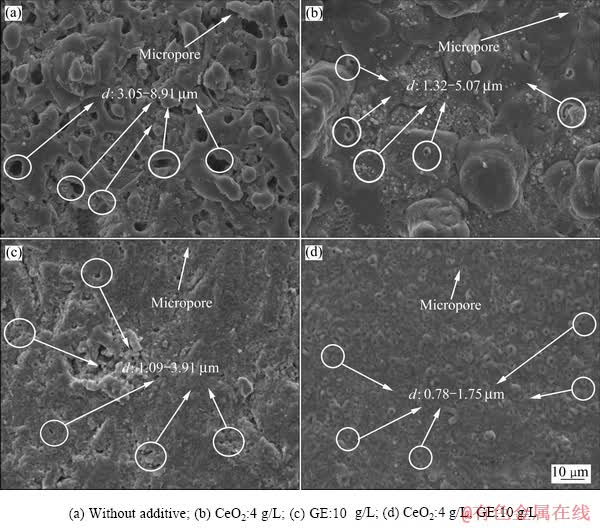

图3 不同电解液添加剂条件下7050高强铝合金MAO膜层的微观形貌

Fig. 3 Micro-morphologies of MAO coatings under different electrolyte additives

图3所示为不同电解液添加剂条件下7050高强铝合金MAO膜层的微观形貌像。从图3中可以看出,微弧氧化膜层表面是由许多类似于“火山堆”状的物质堆积而成,这是由于放电通道中反应所生成的气体压力和放电压力被升高,导致部分熔融氧化铝从放电通道“喷射”而出,经电解液的激冷作用,快速凝固堆积,在陶瓷层内部的熔融氧化物从放电微孔喷射—凝固[16],如图圆圈所示。且从图3(a)中可以看出,MAO膜层的微孔直径较大,在3.05~8.91 μm之间,孔径尺寸变化大,表面比较粗糙,为2444.89 nm,这是由于MAO膜层表面薄弱区域的连续击穿放电导致了微孔尺寸的增大和扩展。当在电解液中添加4 g/L的CeO2时,如图3(b)所示,微弧氧化膜层表面由喷射物沉积形成的颗粒的量逐渐减少,而形成的微孔逐渐增多,孔径直径变化尺寸在1.32~5.07 μm之间,粗糙度为2106.74 nm,较无添加MAO膜层的粗糙度减小。这是由于微弧氧化通道是由单次或几次放电形成的,微弧氧化膜层表面放电的通道越密,通道的孔径越小,反映了微弧氧化过程中放电的程度越弱。而CeO2的加入,能有效地降低微弧氧化过程中放电的剧烈程度,提高微弧氧化过程中放电的频次[17]。当在电解液中加入10 g/L的石墨烯时,孔径尺寸变化在0.25~1.56 μm之间,且此时的粗糙度为1857.69 nm。这是由于石墨烯浓度的加入,使得电解液的电导率升高,在电源恒流的工作模式下,加载到膜层两端的电压升高,但由于放点火花数量的急剧增加,导致单火花放电的持续时间变短和自身体积变小。因此单火花放电所产生的热能仅能熔融部分在膜层与基体界面处形成新的氧化物,导致在陶瓷层表面形成的微颗粒和微孔尺寸变小,进而使得陶瓷层表面粗糙度降低[18]。当在电解液中同时加入4 g/L的CeO2和10 g/L的石墨烯时,如图3(d)所示,表面微孔更加浓密细小,微孔尺寸达到最低,在0.78~1.75 μm之间,此时粗糙度为1516.03 nm。由此可知,稀土元素铈和石墨烯的结合能有效地减小微孔的尺寸以及降低表面粗糙度,从而制备出较光滑致密的复合涂层。

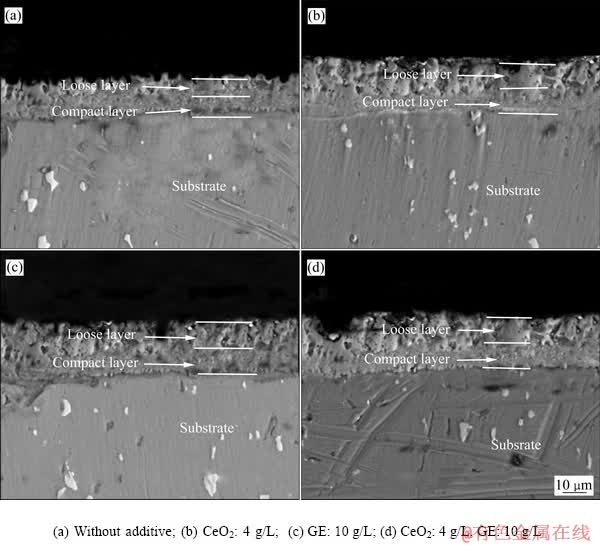

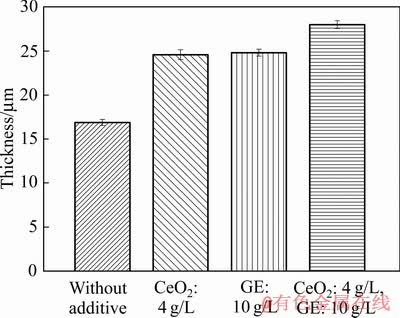

图4所示为不同电解液添加剂时MAO膜层截面形貌。图5所示为不同电解液添加剂时由涡流涂层测厚仪测得的MAO膜层的厚度图。从图4中可以看出,微弧氧化膜层是由内部致密层和外部疏松层所组成,且膜层与基体界面并无断裂现象。当在电解液中添加4 g/L的CeO2时,此时的膜层厚度明显比没有添加剂时厚度增加,与添加10 g/L的石墨烯的厚度没有明显差异。当在电解液中同时加入4 g/L的CeO2和10 g/L的GE制备复合涂层时,此时的膜层厚度达到最高,对提高耐腐蚀性有显著的改善作用。

图4 不同电解液添加剂条件下7050高强铝合金MAO膜层的截面形貌

Fig. 4 Cross-section morphologies of MAO coatings under different electrolyte additives

图5 不同电解液添加剂条件下7050高强铝合金MAO膜层的膜厚

Fig. 5 Thickness of MAO coatings under different electrolyte additives

2.2 微弧氧化膜层元素分布及相组成

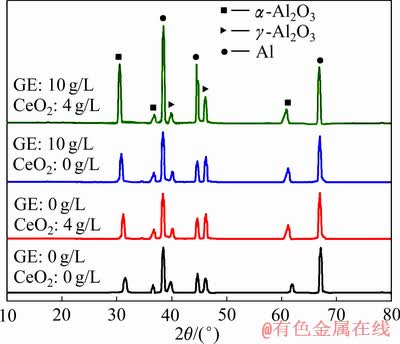

图6所示为不同电解液添加剂时MAO膜层的XRD谱。从图6中可以看出,微弧氧化膜层主要是由α-Al2O3和γ-Al2O3组成。微弧氧化膜层形成过程可用下列反应式[19]表示:

Al→Al3++3e (1)

Al3++3O2→Al2O3 (2)

Al2O3(熔融非晶态)→γ-Al2O3→α-Al2O3 (3)

对铝合金微弧氧化膜层的相分析表明,最初形成的Al2O3是非晶态的,但在高温下会发生如下变化:

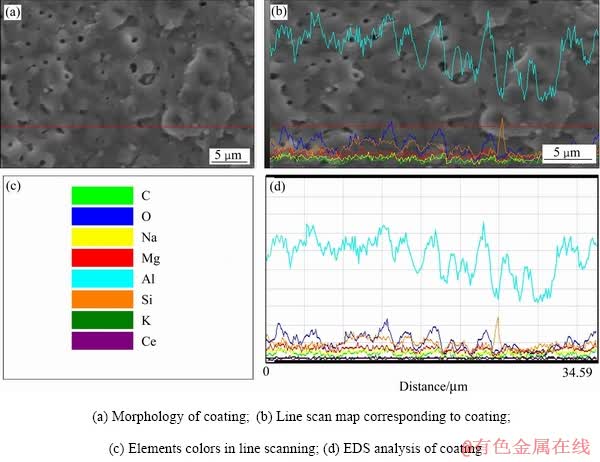

从图中还能发现,当电解液添加剂为CeO2:4 g/L、GE:10 g/L时,α-Al2O3、γ-Al2O3的峰增大。此图中并未发现C物相和稀土元素Ce的峰,这可能是由于膜层中石墨烯和稀土元素Ce含量很少的缘故。图7所示为不同电解液添加剂时MAO膜层的线扫描分析。从图7中可以看出, Al、O元素是微弧氧化膜层主要元素,发生了氧化反应。基体中的Mg元素含量基本保持不变。另外,观察到C、Ce、Na、K等元素的变化,这些元素均来自电解液添加剂,说明添加剂元素已进入到了膜层的微孔中。

图6 不同电解液添加剂条件下7050高强铝合金MAO膜层的XRD谱

Fig. 6 XRD patterns of MAO coatings under different electrolyte additives

2.3 微弧氧化膜层的耐磨性

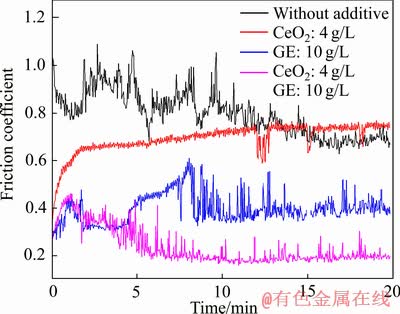

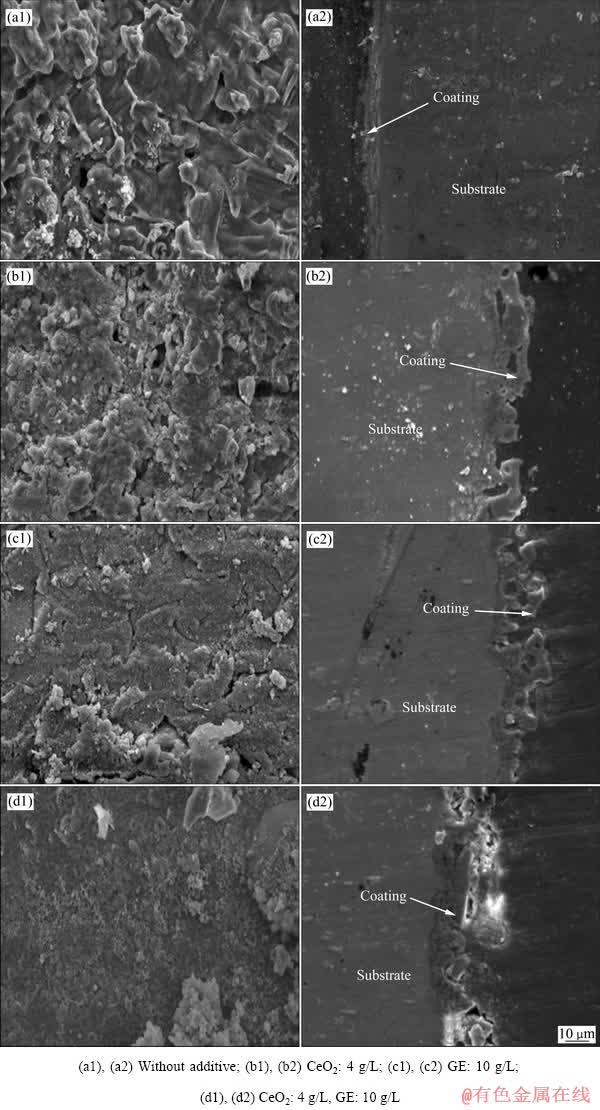

图8所示为不同电解液添加剂条件下MAO膜层摩擦因数随时间的变化。图9所示为磨痕的低倍以及高倍微观形貌图。从图8中可以看出,在摩擦磨损的初始阶段,摩擦因数很快增大,这是由于疏松层很快被破坏。当膜层的外层被磨穿后,含有坚硬相的内层与对磨材料相接触,摩擦因数发生变化。微弧氧化膜层的致密层及其坚硬的相产生的影响较大。从图9中可以看出,当未加入任何添加剂时,此时的摩擦因数变化幅度较大,在0.7~1.0之间,结合图9(a)分析,由于此时的膜厚较低,结构疏松,当用Si3N4陶瓷球滑动时,膜层很容易被打破,膜层表面出现大量磨屑。当在电解液中加入添加剂时,摩擦因数明显减小,膜层的表面受损程度降低,磨屑量减少。当同时加入CeO2和GE制备复合涂层,此时摩擦因数达到最低,稳定在0.2左右,结合图9(d)观察,膜层表面较为光滑,几乎无磨屑产生,这是由于CeO2和GE的同时加入,膜层的微孔直径明显减小,膜层结构更加致密,膜厚较大,α-Al2O3、γ-Al2O3坚硬相的含量增加,从而使得耐磨性较好。

2.4.1 浸泡实验

图7 在电解液中添加4 g/L的CeO2、10 g/L的GE时膜层的形貌及EDS谱

Fig. 7 Morphology and EDS spectra of coating with adding 4 g/L CeO2 and 10 g/L GE into electrolyte

图8 MAO膜层摩擦因数随时间的变化

Fig. 8 Changes of friction coefficient of MAO coating with time

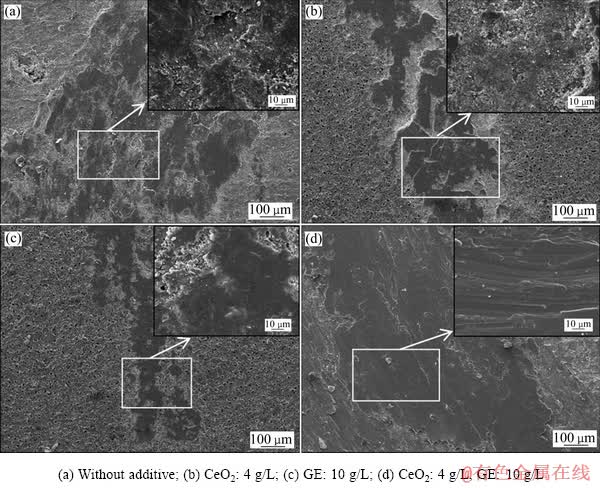

图10所示为不同电解液添加剂条件下MAO膜层在3.5%NaCl(质量分数)溶液中浸泡552 h腐蚀测试后的微观和截面形貌。从图10(a1)~(d1)中可以看出,试样表面大部分已被腐蚀产物覆盖,这是由于此时NaCl溶液通过疏松层通道侵入膜层内部,大量的疏松层以及少量的致密层溶解到腐蚀液中形成腐蚀产物,且随着浸泡时间的增长,腐蚀产物疏松,一部分堆积在疏松层孔洞的一些腐蚀产物被膜层致密层的腐蚀产物挤出,掉落到腐蚀溶液中,另一部分逐渐堆积到膜层表面。并且从图中可以看出,当未在电解液中加入任何添加剂时,膜层孔洞开阔,腐蚀严重,如图10(a1),而在电解液中同时加入CeO2和GE后,膜层表面孔洞明显减小,如图10(d1)。从图10(a2)~(d2)中可以看出,膜层截面孔洞逐渐延伸向铝合金基体,同时,裂纹的出现为NaCl进入到基体表面提供了通道。进一步观察可以发现,图10(a2)中基体有局部腐蚀现象,且膜层表面裂纹众多,说明膜层有剥落的现象,膜厚也明显降低。而在电解液中加入添加剂并经过相同时间腐蚀后,此时的膜厚相对较高,如图10(b2)、(c2)所示,当在电解液中同时加入CeO2和GE后,经过相同时间的腐蚀膜层厚度依旧最高,且截面裂纹明显减少。可以看出,稀土Ce掺杂石墨烯所制备的复合涂层可以有效地提高耐腐蚀性。

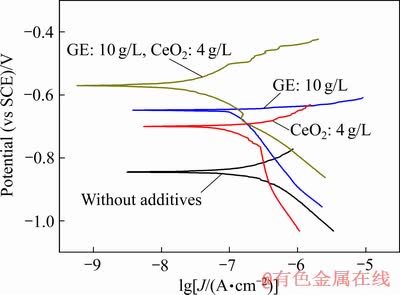

2.4.2 动电位极化测试

图11所示为不同电解液添加剂条件下MAO膜层在3.5%NaCl(质量分数)溶液中浸泡552 h的动电位极化曲线。一般来说,较高的自腐蚀电位(φcorr)和较小的自腐蚀电流(Jcorr)对应于较低的腐蚀速率和较好的耐腐蚀性。由图11可以看出,经过相同时间的腐蚀,复合涂层的自腐蚀电位最高,相对于未加入添加剂时的自腐蚀电位提高了约30 mV,自腐蚀电流也减小了一个数量级。这是由于复合涂层的致密性相对较好,膜层较厚,从而阻挡NaCl腐蚀的性能较好。LIM等[20] 研究了在硅酸盐电解液中添加CeO2所制备的PEO涂层的腐蚀性能,研究发现,CeO2具备较高的化学稳定性以及耐腐蚀性能。而石墨烯可降低表面微孔的孔径尺寸并部分封堵放电通道,使得腐蚀性离子沿放电通道渗入陶瓷层的机会降低;另一方面,由于含碳陶瓷层的厚度增加,腐蚀性离子在陶瓷层内部渗透的阻力增加,因此,石墨烯的加入可以提高膜层的耐腐蚀性[21]。

图9 MAO膜层的磨痕的微观形貌

Fig. 9 Micro graphs of wear marks of MAO coatings

图10 不同电解液添加剂条件下MAO膜层在3.5%NaCl溶液中浸泡552 h的表面和截面微观形貌

Fig. 10 Surface morphologies((a1)-(d1)) and cross-section morphologies((a2)-(d2)) of MAO coating immersed in 3.5% NaCl solution for 552 h under different electrolyte additives

图11 不同电解液添加剂条件下MAO膜层在3.5%NaCl溶液中浸泡552 h的动电位极化曲线

Fig. 11 Dynamic potential polarization curves of MAO coating immersed in 3.5% NaCl solution for 552 h under different electrolyte additives

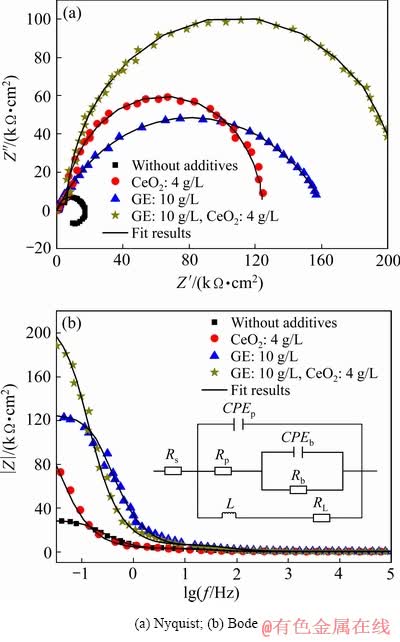

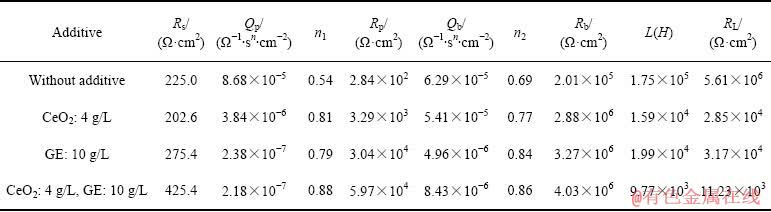

2.4.2 阻抗谱分析

为了进一步评价耐腐蚀性,对不同电解液添加剂条件下经过3.5%NaCl(质量分数)溶液中浸泡552 h的MAO膜层进行了阻抗谱分析,拟合电路如图12所示。表2所列为相应的等效电路数据。从图12中可以看出,中高频范围内出现了容抗弧,这是由于电荷发生了转移,当同时添加CeO2和GE时,容抗弧的半径最大,说明此时的膜层拥有很高的耐腐蚀性。当未加入任何添加剂时,低频范围内出现了感抗弧,这表明此时的铝合金基体发生了点蚀现象[22]。从表2中可以发现,疏松层的电阻(Rp)要小于致密层的电阻(Rb),说明膜层的抗腐蚀性能主要取决于致密层的抗腐蚀性。而在电解液中同时添加4 g/L的CeO2和10 g/L石墨烯所制备的复合涂层Rb数值明显高于其他膜层的Rb数值,且Rp数值也明显较高,进一步说明此时复合涂层的耐腐蚀性最好。

图12 不同电解液添加剂条件下MAO膜层在3.5%NaCl溶液中浸泡552 h的Nyquist图和Bode图

Fig. 12 Nyquist and Bode diagrams of MAO coatings immersed in 3.5% NaCl solution for 552 h under different electrolyte additives

表2 不同电解液添加剂条件下7050高强铝合金MAO膜层在3.5%NaCl溶液中浸泡552 h的等效电路参数

Table 2 EIS fitting parameters of MAO coatings immersed in 3.5% NaCl solution for 552 h under different electrolyte additives

3 结论

1) 7050高强铝合金MAO陶瓷膜层表面呈多孔状,通过在电解液中加入添加剂,其孔径尺寸明显降低,当同时加入4 g/L的CeO2和10 g/L的石墨烯制备复合涂层时,孔径尺寸达到最低,在0.78~1.75 μm之间,此时粗糙度最低,为1516.03 nm,致密性最好。

2) 铝合金的微弧氧化膜主要是由α-Al2O3、γ-Al2O3组成。当同时加入4 g/L的CeO2和10 g/L的石墨烯制备复合涂层时,α-Al2O3、γ-Al2O3的峰值增大。

3) 摩擦磨损实验表明,复合涂层的耐磨性最好,摩擦因数最低,稳定在0.2左右。

4) 浸泡腐蚀实验和电化学测试表明,经过552 h的NaCl腐蚀后,复合涂层的膜层表面孔洞最小,致密性最高,自腐蚀电位最高为-0.570 V,自腐蚀电流最低为7.40×10-10 A/cm2,耐腐蚀性最佳。

REFERENCES

[1] 郝建民, 魏小旖, 陈永楠, 陈 宏. 1060铝合金微弧氧化黑色陶瓷膜显色特性及着色处理[J]. 表面技术, 2014, 43(1): 44-49.

HAO Jian-min, WEI Xiao-yi, CHEN Yong-nan, CHEN Hong. Color characteristic and formation mechanism of black ceramic coating by micro-arc oxidation on1060 aluminum alloy[J]. Surface Technology, 2014, 43(1): 44-49.

[2] 陈小明, 宋仁国, 李 杰. 7xxx系铝合金的研究现状及发展趋势[J]. 材料导报, 2009, 23(2): 67-70.

CHEN Xiao-ming, SONG Ren-guo, LI Jie. Current research status and development trends of 7xxx series aluminum alloys[J]. Materials Review, 2009, 23(2): 67-70.

[3] HO Y H, VORA H D, DAHOTRE N B. Laser surface modification of AZ31B Mg alloy for bio-wettability[J]. Journal of Biomaterials Applications, 2015, 29(7): 915-928.

[4] SILVA G, RIVOLTA B, GEROSA R, DERUDI V. Study of the SCC behavior of 7075 aluminum alloy after one-step aging at 163℃ [J]. Journal of Materials Engineering and Performance, 2013, 22(1): 210-214.

[5] HOLOROYD N J, SCAMANS G M. Stress corrosion cracking in Al-Zn-Mg-Cu aluminum alloys in saline environment[J]. Metallurgical and Materials Transactions A, 2013, 44(3): 1230-1253.

[6] QI Wen-juan, QI Xing, SUN Bin, WANG Chao, SONG Ren-guo. Study on electrochemical corrosion of 7050 aluminum alloy[J]. Materials Performance, 2017, 56(11): 58-61.

[7] FADEE H, JAVIDI M. Investigation on the corrosion behaviour and microstructure of 2024-T3 Al alloy treated via plasma electrolytic oxidation[J]. Journal of Alloys and Compounds, 2014, 604: 36-42.

[8] 庄俊杰, 张晓燕, 孙 斌, 宋仁国, 李 海. 微弧氧化对7050铝合金腐蚀行为的影响[J]. 工程科学学报, 2017, 282(10): 1532-1539.

ZHUANG Jun-jie, ZHANG Xiao-yan, SUN Bin, SONG Ren-guo, LI Hai. Microarc oxidation coatings and corrosion behavior of 7050 aluminum alloy[J]. Chinese Journal of Engineering, 2017, 282(10): 1532-1539.

[9] 王美玲, 周 飞, 丁红燕, 戴振东. 不同环境条件下铝合金微弧氧化陶瓷膜的摩擦磨损性能[J]. 中国有色金属学报, 2007, 27(8): 1266-1272.

WANG Mei-ling, ZHOU Fei, DING-Hong-yan, DAI Zhen-dong. Tribological properties of ceramic coating prepared by micro-arc oxidation for aluminum alloys in various environments[J]. The Chinese Journal of Nonferrous Metals, 2007, 27(8): 1266-1272.

[10] TREVINYO E, GARZA-MONTES-DE-OCA N F, PEREZ A, HERNANDEZ-RODRIGUEZ M A L, HERNANDEZ A J, COLAS R. Wear of an aluminium alloy coated by plasma electrolytic oxidation[J]. Surface and Coatings Technology, 2012, 206: 2213-2219.

[11] HUSSEIN R O, NORTHWOOD D O, NIE X. The effect of processing parameters and substrate composition on the corrosion resistance of plasma electrolytic oxidation (PEO) coated magnesium alloys[J]. Surface and Coatings Technology, 2013, 237(12): 357-368.

[12] 庄俊杰, 宋仁国, 项 南, 卢俊鹏, 宋若希. 6063铝合金微弧氧化膜层的腐蚀行为研究[J]. 腐蚀科学与防护术, 2017, 29(5): 492-498.

ZHUANG Jun-jie, SONG Ren-guo, XIANG Nan, LU Jun-peng, SONG Ruo-xi. Corrosion behavior of micro-arc oxidation coatings formed on 6063 aluminum alloy[J]. Corrosion Science and Protection Technology, 2017, 29(5): 492-498.

[13] NAKAMURA A, OUE S, KOGA H, NAKANO H. Formation behavior of phosphoric acid-based chemical conversion films containing alkaline earth metals on magnesium alloy[J]. Materials Transactions, 2017, 58(7): 1007-1013.

[14] 蒋百灵, 时惠英. LY12铝合金微弧氧化膜层的形成与生长机制[J]. 中国有色金属学报, 2010, 20(10): 1949-1954.

JIANG Bai-ling, SHI Hui-ying. Formation and growth mechanism of microarc oxidation coating on LY12 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1949-1954.

[15] 祁 星, 宋仁国, 祁文娟, 金骥戎, 王 超, 李 海. PH值对7050铝合金膜致应力和应力腐蚀敏感性的影响[J]. 材料工程, 2016, 44(5): 86-92.

QI Xing, SONG Ren-guo, QI Wen-juan, JIN Ji-rong, WANG Chao, LI Hai. Influence of PH values on passive film-induced stress and susceptibility to stress corrosion cracking in 7050 aluminum alloy[J]. Journal of Materials Engineering, 2016, 44(5): 86-92.

[16] 易传贵, 王 瑞, 王安平, 史鸿威, 任常飞. 稀土铈对 2A12 铝合金微弧氧化膜性能的影响[J]. 热加工工艺, 2015, 44(6): 115-118.

YI Chuan-gui, WANG Rui, WANG An-ping, REN Chang-fei. Effect of cerium on properties of ceramic coating prepared by micro-arc oxidation on 2A12 Al alloy[J]. Hot Working Technology, 2015, 44(6): 115-118.

[17] JIANG Dan, ZHOU Huan, WAN Shan, CAI Guang-yi, DONG Ze-hua. Fabrication of superhydrophobic coating on magnesium alloy with improved corrosion resistance by combining micro-arc oxidation and cyclic assembly[J]. Surface and Coatings Technology, 2018, 339(2): 155-166.

[18] GAO Y H, GUAN S K, CHEN J, WANG L G, ZHU S J, HU J H, REN Z W. Fabrication and characterization of rod-like nano-hydroxyapatite on MAO coating supported on Mg-Zn-Ca alloy[J]. Applied Surface Science, 2011, 257(6): 2231-2237.

[19] FENG Chang-jie, HU Shui-lian, JIANG Yuan-fei, ZHOU Yan. Effects of micro-arc oxidation of Ti6Al4V alloy on adhesion property to electroless Ni-P-ZrO2 composite platings and their wear resistance[J]. Rare Metal Materials and Engineering, 2013, 42(12): 2427-2432.

[20] LIM T S, RYU H S, HONG S H. Electrochemical corrosion properties of CeO2-containing coatings on AZ31 magnesium alloys prepared by plasma electrolytic oxidation[J]. Corrosion Science, 2012, 62: 104-111.

[21] 鲁 成, 王 青, 梁 军, 彭振军, 刘百幸. 铝合金黑色微弧氧化陶瓷膜的生长过程[J]. 中国有色金属学报, 2015, 25(12): 3430-3438.

LU Cheng, WANG Qing, LIANG Jun, PENG Zhen-jun, LIU Bai-xing. Forming process of black micro-arc oxidation coatings on aluminium alloys[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3430-3438.

[22] SEYFOORI A, MIRDAMADI S H, KHAVANDI A, SEYED RAUFI Z. Biodegradation behavior of micro-arc oxidized AZ31 magnesium alloys formed in two different electrolytes[J]. Applied Surface Science, 2012, 261: 92-100.

Microstructure and properties of rare earth CeO2-doped graphene composite coatings prepared by MAO on AA7050

ZONG Yu1, 2, SONG Ren-guo1, 2, HUA Tian-shun1, 2, CAI Si-wei1, 2

(1. School of Materials Science and Engineering, Changzhou University, Changzhou 213164, China;

2. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164, China)

Abstract: The ceramic coatings were prepared on the surface of 7050 high strength aluminum alloy by micro-arc oxidation process in a silicate electrolyte added with rare earth element cerium or graphene. The surface morphology, roughness, phase composition and distribution of elements, wear resistance and corrosion resistance were analyzed by the scanning electron microscope (SEM), surface profilometer, X-ray diffractometer (XRD), friction-abrasion tester, electrochemical workstation, respectively. The results show that the micro-pore size of the composite coatings which mainly consists of α-Al2O3, γ-Al2O3 decreases and the compactness obviously improves with the simultaneous addition of 4 g/L CeO2 and 10 g/L graphene to the electrolyte. In addition, the roughness is the lowest (1516.03 nm) as well as the wear resistance is significantly improved. The corrosion is the best that the corrosion potential of the coating is the maximum and the corrosion current is the minimum.

Key words: 7050 high strength aluminum alloy; micro-arc oxidation; rare earth; graphene; composite coating

Foundation item: Project(51871031) supported by the National Natural Science Foundation of China

Received date: 2019-04-08; Accepted date: 2019-06-27

Corresponding author: SONG Ren-guo; Tel: +86-519-86330069; E-mail: songrg@hotmail.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51871031)

收稿日期:2019-04-08;修订日期:2019-06-27

通信作者:宋仁国,教授,博士;电话:0519-86330069;E-mail:songrg@hotmail.com