文章编号:1004-0609(2013)S1-s0456-06

热处理对Ti-22Al-25Nb合金显微组织演变及显微硬度的影响

王 伟1,曾卫东1,薛 晨1,梁晓波2,张建伟2

(1. 西北工业大学 凝固技术国家重点实验室,陕西 西安 710072;

2. 北京钢铁研究总院 高温材料研究所,北京 100081)

摘 要:对Ti-22Al-25Nb锻造棒材进行热处理,观察不同固溶和时效温度下合金的显微组织,研究其演化规律,并根据显微硬度评价该合金的基本性能。结果表明:合金的显微组织主要取决于热处理工艺。在980 °C以下进行固溶处理,合金的显微组织包括等轴α2相、围绕α2镶嵌的O相、板条O相以及B2基体;在980 °C以上进行固溶处理,显微组织主要包括等轴O相以及B2基体。在不同温度下时效,板条O相的尺寸及形态发生明显变化:在840 °C时效析出O相的板条粗最大,在760 °C效析出O相的板条最细小。不同温度下时效的显微硬度与热处理温度满足线性变化关系。

关键词:Ti2AlNb基合金;热处理;组织演变;显微硬度

中图分类号:TG146.2 文献标志码:A

Effect of heat treatment on microstructural evolution and micro-hardness of Ti-22Al-25Nb orthorhombic alloy

WANG Wei1, ZENG Wei-dong1, XUE Chen1, LIANG Xiao-bo2, ZHANG Jian-wei2

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Beijing Iron & Steel Research Institute, Beijing 100081, China)

Abstract: The forged Ti-22Al-25Nb alloy was heat treated, and the microstructures under different solution treatments and aging times were observed and the evolution was studied. The basic properties of the alloy were evaluated based on the hardness. The results show that the microstructure of the alloy is mainly depended on heat treatment schedule. Equiaxed α2 grains, rim O around α2, and equiaxed O and B2 matrix could be obtained after the samples were solution treated below 980 °C, while equiaxed α2 grains and B2 matrix existed when the samples were solution treated above 980 °C. The aging temperature is very important for the size and morphology of acicular O phase. The largest precipitate size occurred at 840 °C and the finest size was displayed at 760 °C. Experimental and statistical analysis show linear relationship between micro-hardness and the temperature of heat treatment.

Key words: Ti2AlNb based alloys; heat-treatment temperature; microstructural evolution; microhardness

Ti2AlNb基合金是20世纪90年代初开发出的一类新型金属间化合物材料,具有较高的比强度、高断裂韧性、高蠕变抗力、低热膨胀系数、无磁性和阻燃性能好等优点,在未来的航空航天领域具有广阔的应用前景[1-2]。该合金属于三元体系,相变关系极为复杂,微观组织随热机械加工工艺制度的变化非常敏感[3]。随着热加工工艺制度的不同,Ti2AlNb基合金可能包含α2相(有序密排六方相,基于Ti3Al的DO19结构)、 O相(有序正交相,基于Ti2AlNb的Cmcm空间群)、B2相(有序体心立方相)中的两相或三相,而各个相所起的作用又各不相同。因此,有效地控制合金中的微观组织变化及系统地认识其演变规律就显得格外重要。Ti2AlNb基合金主要通过锻造工艺成形,后经固溶处理和时效处理获得所需性能相对应的组织。合金的热变形以及后续的热处理是改善合金力学性能的主要手段[4-5],本文作者研究了等温锻后热处理工艺对Ti-22Al-25Nb合金组织和显微硬度的影响。

1 实验

实验所用Ti-22Al-25Nb合金为北京钢铁研究总院提供的铸锭,该铸锭通过真空自耗-凝壳-自耗工艺制备,化学成分如表1所列。将原始铸锭在B2/β单相区开坯,然后在三相区经过三墩三拔之后改锻成型,原材料的显微组织如图1所示。

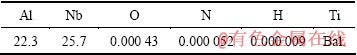

表1 Ti-22Al-25Nb合金的化学成分

Table 1 Chemical composition of Ti-22Al-25Nb alloy (molar fraction, %)

在锻造后的棒材上用线切割截取尺寸为14 mm× 14 mm×12 mm的试样。在(α2+B2)两相区和(α2+B2+O)三相区选用不同的固溶处理温度,研究固溶处理对初生α2/O相形貌、含量和尺寸的影响。并将940 °C固溶处理之后的试样在(O+B2)两相区内选择不同的时效温度,研究时效处理对合金组织的影响。本研究所采用的热处理制度如表2所列。用扫描电子显微镜(SEM)附带背散射(BSD)进行微观组织分析,采用X射线衍射(XRD)技术分析显微组织的物相结构,采用差热分析(DTA)仪研究材料的相转变温度,采用显微硬度评价材料的性能,显微硬度的测试条件为载荷4.9 N,保压时间10 s。

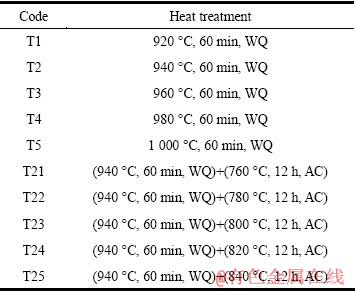

表2 Ti-22Al-25Nb合金的热处理制度

Table 2 Heat treatment procedure of Ti-22Al-25Nb alloy

2 结果与分析

2.1 锻造后Ti-22Al-25Nb合金的组织分析

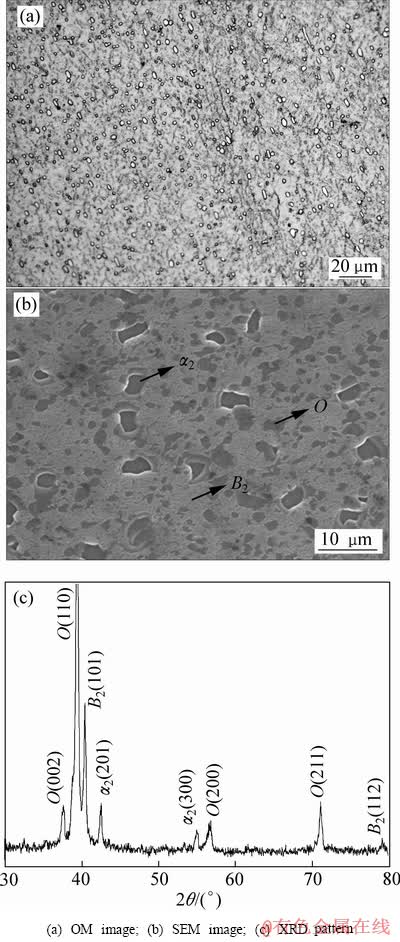

图1所示为Ti-22Al-25Nb合金在改锻之后的显微组织和XRD谱。从图1可以看出,在晶界上已经部分析出等轴组织,对比SEM像,该等轴颗粒为α2相或O相,并且在等轴颗粒附近弥散分布着针状的魏氏O相,该组织十分细小以至于在光学显微镜下无法辨别。在二次电子像中略显浮凸,颜色较深的黑色颗粒为α2相,颜色较浅的灰色等轴颗粒为O相,颜色最亮的为B2基体。XRD分析进一步证明了三墩三拔后合金的组织状态为α2+B2+O三相组织。

图1 原材料的显微组织及XRD谱

Fig. 1 Microstructures and XRD pattern of as-received Ti-22Al-25Nb

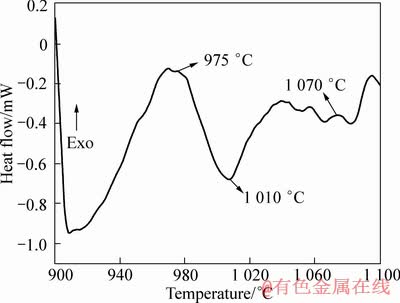

图2 Ti-22Al-25Nb合金的DTA曲线

Fig. 2 DTA curves of Ti-22Al-25Nb alloy

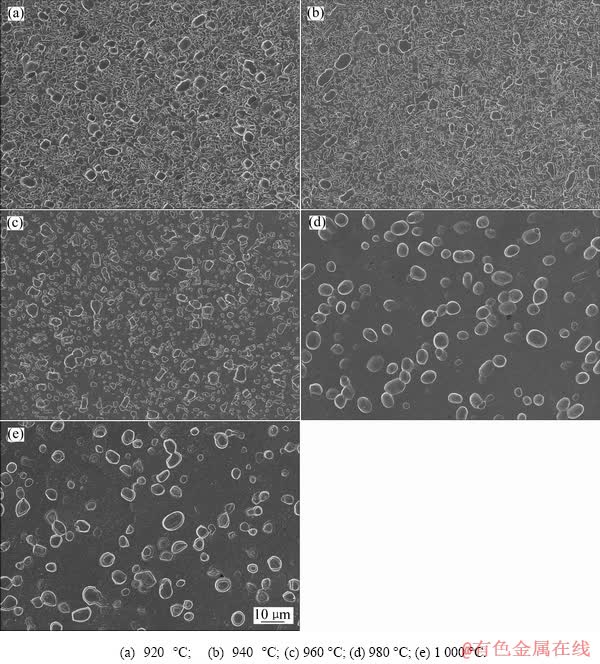

图3 不同固溶温度下Ti-22Al-25Nb合金的显微组织

Fig. 3 Microstructures of solution-treated specimens at different solution-treatment temperatures

2.2 Ti-22Al-25Nb合金相变温度的确定

合金的相变温度对于制定合适的热处理工艺,得到理想的显微组织及性能具有非常重要的意义。本实验中采用差热分析法确定Ti-22Al-25Nb合金的相变温度。根据差热分析法,结合MURALEEDHARAN等[6]和GOGIA等[7]对Ti2AlNb合金相演变的研究,可以得出B2/B2+α2的转变温度高于1 060 °C。DTA曲线在975 °C有一个放热峰,根据参考文献[6]中的相图分析可知该温度为B2+α2+O/O+B2的转变温度。用切线法得到DTA曲线中的第二个吸热峰为1 010 °C,该温度为B2+α2+O/B2+α2的转变温度。在1 040~1 080 °C范围内,曲线出现波动,这主要与合金组织的不稳定性有关。综上所述,合金的相转变温度为 TB2>1 060 °C, 1 010 °C< <1 060 °C, 1 010 °C <

<1 060 °C, 1 010 °C < <975 °C, T(O+B2)<975 °C。

<975 °C, T(O+B2)<975 °C。

2.3 固溶处理对Ti-22Al-25Nb合金显微组织的影响

图3所示为合金在920、940、960、980、1 000 °C下固溶处理60 min后的微观组织形貌。从图3可以看出,随着固溶温度的升高,O相板条逐渐变短、变粗。当固溶温度为920 °C(图3(a))时,更多的O相从B2基体中析出,细小的O相板条转变成等轴的O相颗粒,O相的体积分数大约为46.99%。另有一部分α2相存在,成为O相的形核点,等轴的O相附着在的α2相周围,形核并长大,形成rim O相[5]。根据DTA分析可知,该温度区间应该为O+B2两相区,不存在α2相。该α2相是在高温等温锻的过程中形成的,极其稳定。原因在于:在低温下α2相的扩散动力非常低,很难转变成O相。在940 °C固溶后(图3(b)),少量的α2相转变成B2或O相。等轴的O相连在一起,在O相转变为B2的过程中,板条宽度增加,长宽比减小[8]。等轴的rim O相变薄,O相的体积分数为32.14%。当固溶温度升高到960 °C(图3(c))后,更多的等轴O相转变成为B2基体,rim O相变得更薄,更多的板条O相转变为长宽比接近的板条,O相的体积分数减小到8.69%。固溶温度升高到980 °C(图3(d))以上,合金的组织形态与在固溶温度为980 °C以下的完全不同,合金中板条O相已经发生静态再结晶并完全球化。图3(c)中细小的等轴颗粒溶解到B2基体中,此时合金的组织主要由等轴的α2/O相以及B2基体组成。固溶温度升到到1 000 °C(图3(e))时,合金中α2相的体积分数增加到15.59%,O相的体积分数减小到2.53%。

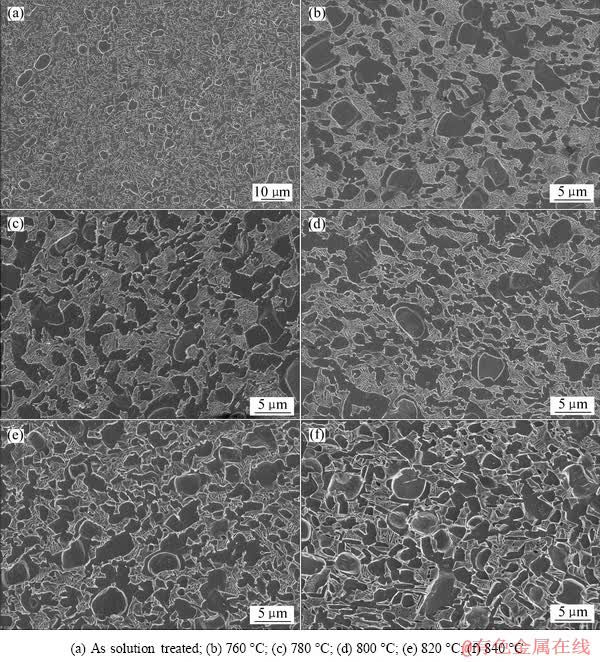

2.4 时效处理对Ti-22Al-25Nb合金显微组织的影响

为了更好地研究合金的显微组织演变规律,将940 °C固溶后的试样在O+B2两相区在不同温度下进行时效,其显微组织如图4所示。由图可知,该合金主要是由等轴状的α2/O相以及板条状的O相组成的复合组织。组织中的O相板条有两种形态:一种为粗大的、短棒状的O相板条;另一种为细小的针状O相板条。比较940 °C固溶处理和时效处理组织,总体形貌没有明显的变化,只是在B2基体上析出了十分细小的针状O相。细小的针状O相板条主要是在时效过程中从B2基体中析出的,板条宽度大约为0.1 μm,长度小于1 μm,总体积分数约为10%。析出的针状O相主要分布在等轴α2/O颗粒和短棒状的O相之间,排列杂乱无章[6]。粗大的、短棒状的O相板条是在固溶时形成,宽度大约为1 μm,长度为2~4 μm。与在940 °C固溶 (图4(a))的组织状态相比,板条状O相的尺寸明显增加,说明在时效过程中板条O相有长大趋势。通过940 °C固溶和不同温度时效的组织形貌可知,等轴状的α2/O相的颗粒尺寸不受时效温度的影响,而板条状的O相以及B2相的体积分数却随时效温度的升高变化很大。时效温度为840 °C时,析出的针状O相最粗,时效温度为760 °C时,析出的针状O相最细小。随着时效温度的升高,O相板条的宽度增加。这为后面设计Ti-22Al-25Nb合金的显微组织提供了一种思路,即通过固溶处理来调节初生等轴O相的尺寸及体积分数,通过不同温度以及冷却速率调节析出的细小的二次板条O相。

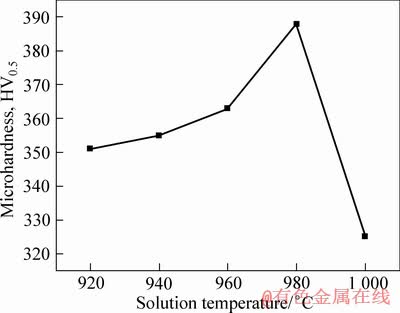

2.5 热处理对Ti-22Al-25Nb合金显微硬度的影响

硬度是最经常应用的、快速评价材料力学性能的基本属性之一[9]。图5为不同温度固溶处理后,合金显微硬度的变化。从图中可以看出,随着固溶温度的升高,合金的硬度先升高后降低。硬度的变化主要与材料的显微组织分布有关,即α2相、O相以及B2相的体积分数和形态。LI等[10]研究了Ti2AlNb合金显微组织对拉伸性能的影响,结果表明:B2相具有比α2相及O相更高的强度。因此,于不同温度固溶处理之后合金的显微硬度与硬度最高的B2相的显微硬度变化规律是一致的。在980 °C固溶处理,B2相的体积分数最高,因而显微硬度最高;在1 000 °C固溶处理,B2相的体积分数降低,其硬度也降低。

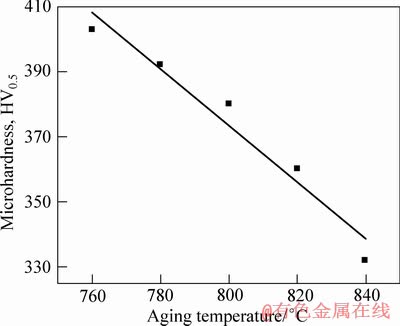

在940 °C固溶处理后,不同温度时效合金的显微硬度变化如图6所示。在相同的固溶温度下合金的显微硬度随着时效温度的提高而降低。940 °C固溶后于840 °C时效合金的显微硬度最低,约为332 HV0.5, 760 °C时效合金的显微硬度值最高,约为403 HV0.5。

采用线性拟合的方法建立显微硬度与时效温度之间的关系,合金的显微硬度与时效温度满足线性关系: ,其中T为温度。在金属和钛合金中存在着4种不同的硬化机制,即固溶强化、位错强化、晶界强化和析出强化。在Ti-22Al-25Nb合金中,α2相, B2相以及O相之间存在着不同的强化机制。而在940 °C固溶,于不同温度时效后的组织差异主要表现在析出的细小O相不同,因此,在此时效过程中O相的析出强化起主导作用。

,其中T为温度。在金属和钛合金中存在着4种不同的硬化机制,即固溶强化、位错强化、晶界强化和析出强化。在Ti-22Al-25Nb合金中,α2相, B2相以及O相之间存在着不同的强化机制。而在940 °C固溶,于不同温度时效后的组织差异主要表现在析出的细小O相不同,因此,在此时效过程中O相的析出强化起主导作用。

图4 940 °C固溶处理后不同温度时效的Ti-22Al-25Nb合金显微组织

Fig. 4 Microstructures of 940 °C, 1 h solution-treated Ti-22Al-25Nb alloy and then aged at different temperatures

图5 固溶温度对Ti-22Al-25Nb合金显微硬度的影响

Fig. 5 Effect of solution temperature on microhardness of Ti-22Al-25Nb alloy

图6 不同时效温度对Ti-22Al-25Nb显微硬度的影响

Fig. 6 Effect of aging temperature on microhardness of Ti-22Al-25Nb alloy

3 结论

1) Ti-22Al-25Nb合金的相转变温度为:TB2>1 060 °C, 1 010 °C< <1 060 °C, 1 010 °C<

<1 060 °C, 1 010 °C< <975 °C, 和T(O+B2)<975 °C。

<975 °C, 和T(O+B2)<975 °C。

2) 在980 °C以下固溶处理过程中,O相板条发生溶解,数量减少,形状变短、变粗。在980 °C以上固溶处理,板条O相发生静态球化,全部转变为等轴颗粒。

3) 940 °C固溶处理后在不同温度时效,针状二次O相会再次从B2基体中析出,并且时效温度越高,析出的二次O相尺寸越粗大,时效温度越低析出的针状O相尺寸越细小。

4) 不同温度时效之后合金的显微硬度主要与O相的析出强化作用有关,并且显微硬度与时效温度之间满足线性关系。

REFERENCES

[1] BANEJEE D, GOFIA A K, NANDI T K, JOSHI V A. A new ordered orthorhombic phase in Ti3Al-Nb alloy[J]. Acta Metall, 1988, 36(4): 871-882.

[2] 司玉峰, 孟丽华, 陈玉勇. Ti2AlNb基合金的研究进展[J]. 宇航材料工艺, 2006, 3: 10-13.

SI Yu-feng, MENG Li-hua, CHEN Yu-yong. Research development of Ti2AlNb-based alloy[J]. Aerospace Materials and Technology, 2006, 3: 10-13.

[3] 王邵丽, 曾卫东, 马 雄, 孙 宇, 黄建余. 固溶温度对 Ti-22Al-25Nb 合金微观组织的影响[J]. 热加工工艺, 2009, 38(8): 106-109.

WANG Shao-li, ZENG Wei-dong, MA Xiong, SUN Yu, HUANG Jian-yu. Effect of solution temperature on microstructure of Ti-22Al-25Nb alloy[J]. Material and Heat Treatment, 2009, 38: 106-109.

[4] GOGIA A K, NANDY T K, BANERJEE D, CARISEY T, STRUDELB J L, FRANCHETC J M. Microstructure and mechanical properties of orthorhombic alloys in the Ti-Al-Nb system[J]. Intermetallics, 1998, 6: 741-748.

[5] 梁晓波, 程云君, 张建伟, 李世琼. 热处理对β锻造Ti-22AI-25Nb合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s611-s615.

LIANG Xiao-bo, CHENG Yun-jun, ZHANG Jian-wei, LI Shi-qiong. Effects of heat treatment on microstructure and properties of β-forged Ti-22Al-25Nb alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s611-s615.

[6] MURALEEDHARAN K, BANERJEE D, BANERJEE S, LELE S. The α2-to-O transformation in Ti-Al-Nb alloys[J]. Phil Mag, 1995, 71: 1011-1036.

[7] GOGIA A K, NANDY T K, MURALEEDHARAN K, BANERJEE D. The effect of heat treatment and niobium content on the room temperature tensile properties and micro-structure of Ti3Al-Nb Alloys[J]. Materials Science and Engineering A, 1992, 159: 73-86.

[8] 张 艺, 刘俊友, 张建伟. β锻造Ti-22Al-25Nb合金的组织转变与拉伸性能[J]. 中国有色金属学报, 2008, 18(1): 30-35.

ZHANG Yi, LIU Jun-you, ZHANG Jian-wei. Microstructure transition and tensile properties of Ti-22Al-25Nb intermetallic alloy forged in β-phase zone[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 30-35.

[9] BRANDL E, SCHOBERTH A, LEYENS C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM)[J]. Materials Science and Engineering A, 2012, 532 : 295-307.

[10] LI Shi-qiong, MAO Yong, ZNANG Jian-wei, LI Jun-tao, CHENG Yun-jun, ZHONG Zeng-yong. Effect of microstructure on tensile properties and fracture behavior of intermetallic Ti2AlNb alloys[J].Transactions of Nonferrous Metals Society of China, 2002, 12 (4): 582-585.

(编辑 方京华)

基金项目:凝固技术国家重点实验室开放课题资助项目(35-TP-2009);教育部博士点基金资助项目(20116102110015)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:曾卫东,教授,博士;电话:029-88494298,E-mail:zengwd@nwpu.edu.cn