高密度脉冲电流处理对Ti2AlNb基合金板材的增塑作用

来源期刊:中国有色金属学报(英文版)2013年第1期

论文作者:宋辉 王忠金 赫晓东

文章页码:32 - 37

关键词:Ti2AlNb基合金板材;脉冲电流处理;塑性;晶粒细化;组织;形核速率;相变

Key words:Ti2AlNb-based alloys; electropulsing treatment; plasticity; grain refinement; microstructure; nucleation rate; phase transformation

摘 要:为了优化Ti-22Al-27Nb基合金板材的塑性,研究了高密度脉冲电流(Jmax=6.80~7.09 kA/mm2, tp=110 μs)处理对Ti-22Al-27Nb合金板材力学性能和组织的影响。应用扫描电子显微镜(SEM)观察了试样的微观组织和形貌变化,应用单向拉伸试验对不同状态试样的力学性能进行了测试。结果表明,高密度脉冲电流处理能够细化Ti-22Al-27Nb合金板材的晶粒,促进塑性的提高。具有细小而均匀显微组织的试样表现出最好的塑性,其伸长率可达到19.4%。对晶粒细化的机制进行了分析,相变过程中形核率的加快和极短的脉冲电流处理时间是晶粒细化的主要原因。

Abstract: In order to optimize the ductility of orthorhombic Ti2AlNb-based alloys sheet, Ti-22Al-27Nb sheet was treated by high density electropulsing (Jmax=6.80-7.09 kA/mm2, tp=110 μs) under ambient condition. Microstructures were observed by SEM, and the tensile properties were also studied using uniaxial tension tests. The experimental results show that electropulsing can refine the microstructures of Ti-22Al-27Nb sheets. The specimen with the fine and homogeneous microstructures has good plasticity, and its elongation reaches 19.4%. The mechanism about the effect of electropulsing treatment on the microstructure of Ti-22Al-27Nb sheets was discussed. It was thought that the increase in nucleation rate during phase transformation and a very short treating time were regarded as the main reasons of producing smaller grains and increase in the plasticity by electropulsing.

Trans. Nonferrous Met. Soc. China 23(2013) 32-37

Hui SONG1, Zhong-jin WANG2, Xiao-dong HE1

1. School of Astronautics, Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 5 December 2011; accepted 4 May 2012

Abstract: In order to optimize the ductility of orthorhombic Ti2AlNb-based alloys sheet, Ti-22Al-27Nb sheet was treated by high density electropulsing (Jmax=6.80-7.09 kA/mm2, tp=110 μs) under ambient condition. Microstructures were observed by SEM, and the tensile properties were also studied using uniaxial tension tests. The experimental results show that electropulsing can refine the microstructures of Ti-22Al-27Nb sheets. The specimen with the fine and homogeneous microstructures has good plasticity, and its elongation reaches 19.4%. The mechanism about the effect of electropulsing treatment on the microstructure of Ti-22Al-27Nb sheets was discussed. It was thought that the increase in nucleation rate during phase transformation and a very short treating time were regarded as the main reasons of producing smaller grains and increase in the plasticity by electropulsing.

Key words: Ti2AlNb-based alloys; electropulsing treatment; plasticity; grain refinement; microstructure; nucleation rate; phase transformation

1 Introduction

In order to reduce the mass of aircraft and spacecraft, the light structural materials with high strength, high stiffness, high modulus and good creep resistance have received considerable attention in recent years. Ti2AlNb-based alloy is one of the most promising materials for high-temperature structural applications because of its low density, high yield strength and excellent high temperature performance [1,2]. However, the complicated fabrication process and the control influence of composition and heat treatment strongly influenced the practical application of Ti2A1Nb-based alloys [3]. Because of the mechanical property of Ti-Al-Nb alloy is very sensitive to the composition and microstructure [4,5], numerous studies had been focused on improving its mechanical property by microstructure controlling using heat-treatment. ZHANG et al [6] studied the microstructure transition of Ti-22Al-25Nb intermetallic alloy forged in the β-phase zone during different heat treatments. MAO et al [7] used various thermo-mechanical processing to optimize the ductility and strength of the orthorhombic alloy. In order to optimize the microstructure, PENG et al [8] proposed a complex processing method: prior heat treatment was applied to obtaining a fine and homogenous O/B2 lath structure, followed by thermo-mechanical processing at a suitable temperature.

Although the above-mentioned thermo-mechanical processing methods have been fruitful, it is still significant to seek a new method for improving the formability of Ti2AlNb based alloys because heat treatments in different phase fields can produce different microstructures, depending on the heat treatment schedule, Ti2AlNb-based alloys may obtain various constituent phases, including B2, α2 and O phases.

Many studies have indicated that high density electropulsing can influence the behaviors of materials due to its unique characteristic. Through the electropulsing treatment, new nanometer-sized lamellar β-Ti was produced in Ti-6Al-4V, originally with the fully equiaxed α-Ti and intergranular β-Ti phases [9]. The electropulsing can increase the nucleation rate by the decrease of the thermodynamic barrier during recrystallization or phase transformation (liquid–solid, solid-state). Furthermore, because the electropulsing time is very short, the new grains have no enough time to grow. So ultrafine-grained microstructure [10,11] and nano-phases [12,13] could be formed in the conventional coarse-grained low-carbon steel and polycrystalline Cu-Zn alloy by applying high current electropulsing. The experimental results showed that the electropulsing is an effective method for improving the mechanical properties [14,15] and machinability [16,17] of metal materials.

In the present work, a study on the effect of electropulsing on microstructure transition and properties of Ti2AlNb-based alloys assumes even greater significance, since the conventional thermo-mechanical processing, such as forging, extrusion, rolling as well as heating is not required, so the process of electropulsing is simpler than conventional one.

2 Experimental

The experimental material used in this study was Ti2AlNb-based alloys sheet with 1.0 mm in thickness. The chemical composition of the test material determined using EDS (energy dispersive spectrometer) was Ti-22Al-27Nb (mole fraction, %). With electro- discharge machining (EDM), blanks from the Ti2AlNb- based alloys sheet were machined into flat dog-bone geometry specimens with a gage length of 19.0 mm, a width of 6.0 mm and a thickness of 1.0 mm.

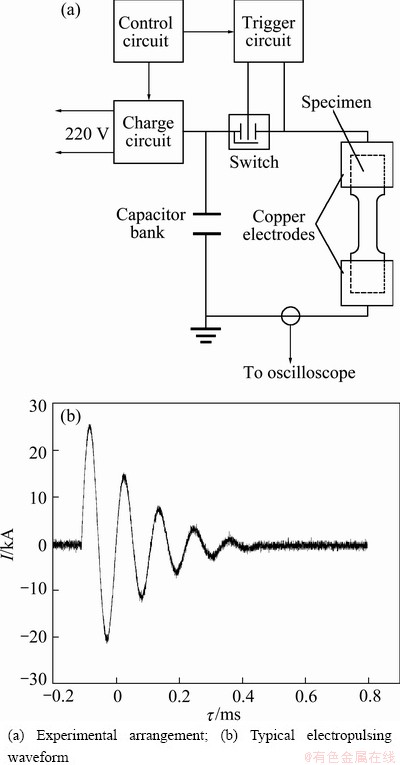

The electropulsing treatments were performed under ambient conditions with a capacitor bank discharge. The experimental arrangement for the electropulsing treatment (EPT) is shown in Fig. 1(a). The specimen is joined with discharge circuit by copper electrodes, whereafter capacitor banks are charged. By triggering circuit, high density electropulsing is produced to pass through specimen. The waveform of electropulsing is detected by a Rogowski coil and a TDS3012 digital storage oscilloscope (TektronixInc., Beaverton, OR, USA). It is a damped oscillation wave (see Fig. 1(b)).

All specimens were divided into four groups (A-D): the original specimens A is not subjected to electropulsing treatment, which was employed as the compared specimen; specimens B, C and D were subjected to high density electropulsing treatment (EPT). Each specimen was only treated once by one electropulse, namely, the electric current pulse applied in this study was a single high density electropulse. The duration of an electropulse was about 800 μs, the pulse period tp was 110 μs. For specimens B, C and D, the maximum current densities were 6.8, 6.95 and 7.09 kA/mm2, respectively.

Tensile tests at room temperature were conducted to examine the mechanical properties on a MTS 810 test machine. The tensile speed was 1.0 mm/min. The yield strength was specified as a strain of 0.2% (ε=0.002). The ultimate strength was the stress that a material can withstand when subjected to tension, which is the maximum stress on the stress—strain curve.

The sample used in the microstructure investigation was conventionally polished, and then chemically etched with Kroll’s reagent. The microstructures were investigated by SEM (scanning electron microscopy).

Fig. 1 Schematic of electropulsing treatment (EPT) experiment

3 Results and discussion

3.1 Mechanical properties

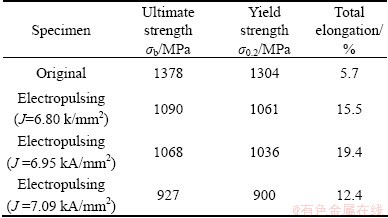

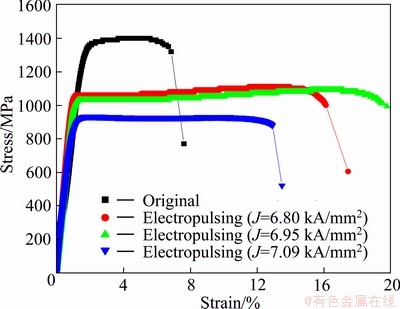

The experimental data for the room temperature tensile properties of Ti-22Al-27Nb sheet is provided in Table 1. Typical stress—strain curves are shown in Fig. 2. The room temperature tensile strength of the original specimen is 1378 MPa, the yield strength is 1304 MPa, while the elongation is 5.7%.

Table 1 Experimental data of Ti-22Al-27Nb sheet with 1.0 mm in thickness

The mechanical properties of Ti-22Al-27Nb sheet were changed obviously after electropulsing. Compared with the original specimen, the strength values of the electropulsing specimens were decreased, but the ductilities were increased significantly. For specimen treated using electropulsing of 6.80 kA/mm2, the tensile strength is 1090 MPa, the yield strength is 1061 MPa, while the elongation is 15.5%. When the maximum current density for electropulsing is 6.95 kA/mm2, the specimen has the highest elongation, reaches 19.4%, and exhibits almost the same high strength as electropulsing specimen B. Despite the fact that with the further increasing of maximum current density to 7.09 kA/mm2, the mechanical properties of the electropulsing specimen have decreased slightly, but plasticity levels were still high in comparison with original specimen. The above results show that the plasticity of Ti-22Al-27Nb sheet can be improved by electropulsing, which is beneficial to its workability.

Fig. 2 Typical stress—strain curves of Ti-22Al-27Nb sheet

3.2 Analysis of microstructure

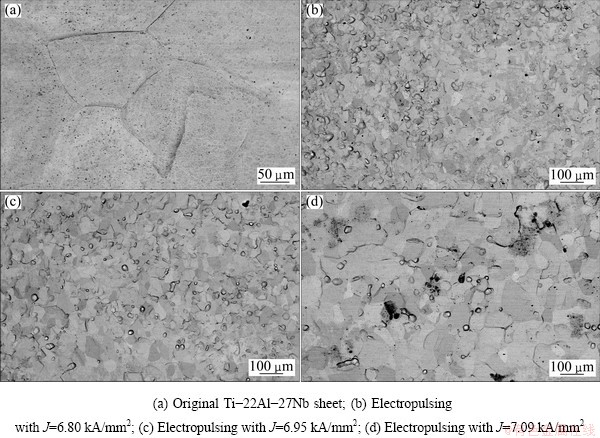

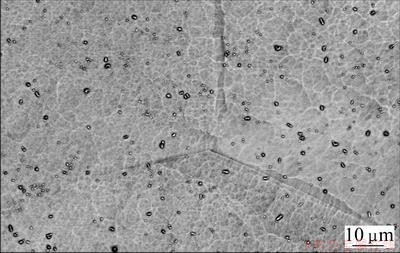

The BSE (back scattered electron)/SEM images of Ti-22Al-27Nb alloy sheet with different treatments are shown in Figs. 3 and 4. In these back scattered electron (BSE) images, according to Nb content in constituent phases, the dark contrast is α2, the bright contrast is B2 phase, and the gray contrast is O phase [8].

Fig. 3 BSE (back scattered electron)/SEM images of Ti-22Al-27Nb sheet

Fig. 4 BSE (back scattered electron)/SEM image of typical local microstructures of original Ti-22Al-27Nb sheet

The microstructures of original specimen are shown in the Fig. 3(a) and Fig. 4, which consists of coarse grains O phase and fine α2 and B2 phases, and the dominate microstructure is larger coarse O phase (see Fig. 3(a)). In terms of the room temperature tensile behavior, coarse O phase provided low elongation to failure. After electropulsing with J=6.80 kA/mm2, O phase became the equiaxed grain and was very fine (see Fig. 3(b)). With the increase of maximum current density, the microstructures became more homogeneous. When the maximum current density for electropulsing was 6.95 kA/mm2, the principal microstructure was fine and homogeneous equiaxed O+B2 phase (see Fig. 3(c)). The experimental results of the room temperature showed that this fine and homogeneous equiaxed O+B2 phase microstructures has the best plasticity. For specimen treated with J=7.09 kA/mm2, the principal microstructure still was the two-phase structure of O and B2 (see Fig. 3(d)), but the diameter of grains is larger than that of specimens C (J=6.95 kA/mm2), which results in the decrease in mechanical properties.

3.3 Discussion

In order to change the microstructure of the metal alloy by a conventional heating treatment, a long-time heating is required at a certain temperature. According to the above experimental results, fine grain microstructure can be obtained in a very short time by electropulsing. So the electropulsing treatment should not be considered simply as a conventional heating treatment. Electropulsing has an effect that a conventional heating treatment does not have.

The mechanism about the effect of electropulsing treatment on the microstructure of materials and their properties is not very clear now; the possible reasons are the electron wind effect, and the Joule heating effect. The average temperature rise of the specimen by Joule heating is written as

(1)

(1)

where I is the amplitude of pulse; tp is the pulse period; t is the corresponding duration; S is the cross-sectional area of the specimen; γ, ρ and c are the electrical resistivity, the density and the specific heat of the experimental material, respectively. For Ti2AlNb sheet, γ=2.0×10-6Ω·m, ρ=4.85×103 kg/m3, c=650 J/(kg·°C).

According to this expression, the average temperature rise values for the electropulsed specimens with the maximum current density of 6.8, 6.95 and 7.09 kA/mm2 are 1364, 1425 and 1483 °C, respectively. According to the Ti-22Al-xNb phase diagram, the phase transformation of O→β/B2 takes place during the heating.

Different from the conventional heating, the electropulsing is a nonequilibrium process, and the heating rate of electropulsing is very high (the rate is about 106 °C/s here). A large overheating can be obtained for a material during the solid-state phase transformations under high-rate (rapid) heating, and the nucleation rate will be enhanced with the increased overheating [18].

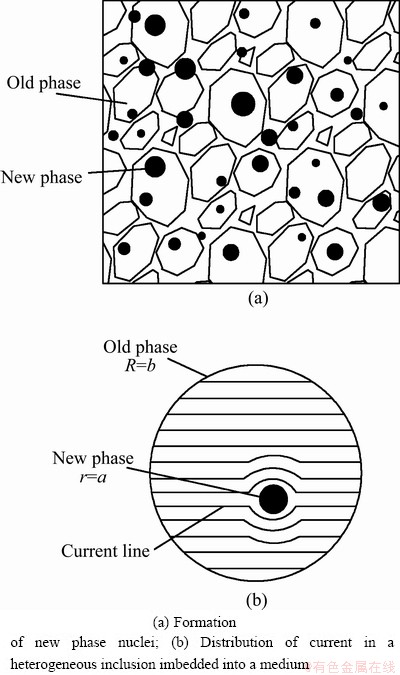

On the other hand, electropulsing itself can increase the nucleation rate by decreasing the thermodynamic barrier during phase transformation. Electric current affects the dynamics of phase transition by three mechanisms. One is associated with a change in the configuration of an electric current by the difference in electric conductivity of the new phase and the host medium [19]. If the electric conductivities of the nucleus of the new phase and the host medium are different, the configuration of the electric current will be redistributed after the formation of the new phase [19].

Assume for simplicity that the formation of a nucleus with radius a and conductivity σ1 inside an old phase with radius b and conductivity σ2, and b>> a (Fig. 5). The energy change, ΔWe, which arises due to additional work induced by the change of the electric current configuration during the formation of a nucleus of a new phase, is written as [20]

(2)

(2)

Because  , the expression for the free energy change ΔWe can be represented as

, the expression for the free energy change ΔWe can be represented as

(3)

(3)

where J0(r) and Jn(r) are the densities of electric current before and after formation of the nucleus, respectively.

According to Eq. (3), ΔWe can be represented as [20,21]

(4)

(4)

where μ is the magnetic susceptibility;  is a geometric factor that depends on the parameters of nucleus and medium;

is a geometric factor that depends on the parameters of nucleus and medium;  is a factor that depends on the electrical properties of nucleus and medium; ΔV is the volume of a nucleus.

is a factor that depends on the electrical properties of nucleus and medium; ΔV is the volume of a nucleus.

Fig. 5 Schematic illustration of phase transform

The electrical conductivity of an intermetallic compound is, in general, relatively small compared with metals because after an intermetallic compound is formed, the atoms combining metallic bond give place to covalent one, and electron concentration is reduced [22]. Namely, σβ=σ1>σO=σ2 (σB2=σ1>σO=σ2), according to Eq. (4), ξ(σ1, σ2)<0. Due to b>> a, thus g(a, b)>0, one can know ΔWe>0.

According to classical nucleation theory, the average number of stable spherical nucleus is given by [20,21]

(5)

(5)

where k is the Boltzmann constant; T is the thermodynamic temperature; Wc is the thermodynamic barrier in forming a spherical nucleus with critical radius; W0 is the free energy of a current-free system. Because ΔWe<0, Wc in a current-carrying system is lower than that in a current-free system, the average number of stable nucleus n can be increased in a current-carrying system. Furthermore, because the electropulsing time is very short, the new grains have no enough time to grow. So smaller grains can be obtained finally.

4 Conclusions

1) The plasticity of Ti-22Al-27Nb sheet can be improved; its highest elongation reaches 19.4%. It is beneficial to its workability.

2) The microstructures of Ti-22Al-27Nb sheets are refined significantly by the electropulsing. The fine and homogeneous microstructures can be obtained. An increase in the nucleation rate during the phase transformation and a very short treating time were regarded as main reasons of producing smaller grains by electropulsing.

3) The electropulsing treatment is an effective method to improve the plasticity of Ti-22Al-27Nb sheets.

Acknowledgements

The authors are great grateful to Prof. Jing-dong GUO and Bao-quan WANG of Institute of Metal Research, Chinese Academy of Sciences (CAS) for their help in the electropulsing treatment experiments.

References

[1] GERMANN L, BANERJEE D,  J Y, STRUDEL J L. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide [J]. Intermetallics, 2005, 13: 920-924.

J Y, STRUDEL J L. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide [J]. Intermetallics, 2005, 13: 920-924.

[2] CHENG Yun-jun, LI Shi-qiong, LIANG Xiao-bo, ZHANG Jian-wei. Effect of deformed microstructure on mechanical properties of Ti-22Al-25Nb alloy [J]. Transaction of Nonferrous Metals Society of China, 2006, 16: s2058-s2061.

[3] SI Yu-feng, CHEN Yu-yong, LIU Zhi-guang, KONG Fan-tao. Influence of yttrium on microstructure and properties of Ti-23Al-25Nb alloy after heat treatment [J]. Transaction of Nonferrous Metals Society of China, 2006, 16: s849-s853.

[4] KE Y B, DUAN H P, SUN Yan-ran. Effect of yttrium and erbium on the microstructure and mechanical properties of Ti-Al-Nb alloys [J]. Materials Science and Engineering A, 2010, 528: 220-225.

[5] LI Shi-qiong, MAO Yong, ZNANG Jian-wei, LI Jun-tao, CHENG Yun-jun, ZHONG Zeng-yong. Effect of microstructure on tensile properties and fracture behavior of intermetallic Ti2AlNb alloys [J]. Transaction of Nonferrous Metals Society of China, 2002, 12(4): 582-586.

[6] ZHANG Yi, LIU Jun-you, ZHANG Jian-wei. Microstructure transition and tensile properties of Ti-22Al-25Nb intermetallic alloy forged in β-phase zone [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 30-35. (in Chinese)

[7] MAO Yong, LI Shi-qiong, ZHANG Jian-wei, PENG Ji-hua, ZOU Dun-xu, ZHONG Zeng-yong. Study on microstructure and mechanical properties of Ti-22Al-20Nb-7Ta intermetallic alloy [J]. Acta Metallrugica Sinica, 2000, 36(2): 135-140. (in Chinese)

[8] PENG J H, MAO Y, LI S Q, SUN X F. Microstructure controlling by heat treatment and complex processing for Ti2AlNb based alloys [J]. Materials Science and Engineering A, 2001, 299: 75-80.

[9] ZHANG W, WU B, ZHAO W S, LI D X, SUI M L. Formation of novel β-Ti martensites in Ti-6Al-4V under an electric-current-pulse heat treatment [J]. Materials Science and Engineering A, 2006, 438-440: 320-323.

[10] ZHOU Y Z, ZHANG W, WANG B Q, GUO J D. Ultrafine-grained microstructure in a Cu-Zn alloy produced by electropulsing treatment [J]. J Mater Res, 2003, 18(8): 1991-1997.

[11] ZHOU Y Z, ZHANG W, WANG B Q, HE G H, GUO J D. Grain refinement and formation of ultrafine-grained microstructure in a low-carbon steel under electropulsing [J]. J Mater Res, 2002, 17(8): 2105-2111.

[12] ZHANG W, SUI M L, HU K Y, LI D X. Formation of nanophases in a Cu-Zn alloy under high current density electropulsing [J]. J Mater Res, 2000, 15(10): 2065-2068.

[13] ZHOU Y Z, ZHANG W,SUI M L, LI D X, HE G H, GUO J D. Formation of a nanostructure in a low-carbon steel under high current density electropulsing [J]. J Mater Res, 2002, 17(5): 921-924.

[14] GUO Xiao-nan, SHEN Yi-fu, ZHOU Yi-zhou, HE Guan-hu, ZHOU Ben-lian. Effect of a single high current density electropulsing on the mechanical properties of H62 [J]. Chinese Journal of Materials Research, 1999, 13(1): 73-75. (in Chinese)

[15] CUI J P, SUI M L, CUI Y Y, LI D X. Ductile TiAl alloy with lamellar structure formed by rapid heating [J]. J Mater Res, 2008, 23(4): 949-953.

[16] SONG Hui, WANG Zong-jin, GAO Tie-jun. Effect of high density electropulsing treatment on formability of TC4 titanium alloy sheet [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(1): 87-92.

[17] WANG Z J, SONG H. Effect of high density electropulsing on microstructure and mechanical properties of cold-rolled TA15 titanium alloy sheet [J]. Journal of Alloys and Compounds, 2009, 470, 522-530.

[18] ZHU H L, MARUYAMA K, MATSUDA J. Microstructural refinement mechanism by controlling heating process in multiphase materials with particular reference to γ-TiAl [J]. Applied Physics Letters, 2006, 88: 131908-131910.

[19] DOILINSKY Y, ELPERIN T. Peculiarities of coexistence of phases with different electric conductivities under the influence of electric current [J]. Materials Science and Engineering A, 2000, 287: 219-226.

[20] DOILINSKY Y, ELPERIN T. Thermodynamics of phase transitions in current-carrying conductors [J]. Phys Rev, 1993, B47: 14778-14785.

[21] WANG X L, GUO J D, WANG Y M, WU X Y, WANG B Q. Segregation of lead in Cu-Zn alloy under electric current pulses [J]. Applied Physics Letters, 2006, 89: 061910-061913.

[22] ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang, GUO Jian-ting, WAN Xiao-jing, FENG Ti. Intermetallic compounds for structural application [M]. Beijing: National Defence Industry Press, 2001: 486. (in Chinese).

宋 辉1,王忠金2,赫晓东1

1. 哈尔滨工业大学 航天学院,哈尔滨 150001;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:为了优化Ti-22Al-27Nb基合金板材的塑性,研究了高密度脉冲电流(Jmax=6.80~7.09 kA/mm2, tp=110 μs)处理对Ti-22Al-27Nb合金板材力学性能和组织的影响。应用扫描电子显微镜(SEM)观察了试样的微观组织和形貌变化,应用单向拉伸试验对不同状态试样的力学性能进行了测试。结果表明,高密度脉冲电流处理能够细化Ti-22Al-27Nb合金板材的晶粒,促进塑性的提高。具有细小而均匀显微组织的试样表现出最好的塑性,其伸长率可达到19.4%。对晶粒细化的机制进行了分析,相变过程中形核率的加快和极短的脉冲电流处理时间是晶粒细化的主要原因。

关键词:Ti2AlNb基合金板材;脉冲电流处理;塑性;晶粒细化;组织;形核速率;相变

(Edited by Hua YANG)

Foundation item: Project (50875061) supported by the National Natural Science Foundation of China; Project (20092302110016) supported by the Specialized Research Fund for the Doctoral Program of Higher Education of China

Corresponding author: Zhong-jin WANG; Tel: +86-451-86413365; Fax: +86-451-86413786; E-mail: wangzj@hit.edu.cn

DOI: 10.1016/S1003-6326(13)62425-5