DOI:10.19476/j.ysxb.1004.0609.2019.12.02

喷射成形高强Al-Zn-Mg-Cu合金的高应变速率塑性变形行为

杨雨童1,罗 锐1,程晓农1,陈乐利1,桂 香1,王 威1,张 桢2,高仕渊2

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 江苏豪然喷射成形合金有限公司,镇江 212009)

摘 要:利用Gleeble-3500型热力模拟试验机对挤压态喷射成形Al-Zn-Mg-Cu系高强铝合金进行高应变速率下的热压缩试验,系统研究了材料在变形温度350~450 ℃,高应变速率1~20 s-1条件下的高温塑性变形行为。考虑绝热温升因素影响,采用外推法修正材料的流变应力曲线,以此构建材料本构模型;基于动态材料模型(dynamic materials model,DMM)构建材料的热加工图,并确定不同变形条件区域内的微观组织特征。结果表明:该合金流变应力曲线呈现典型的动态回复特征;随着应变速率的升高绝热温升现象愈发明显;材料热加工图和不同变形区域组织特征表明,该合金存在3个危险加工区间分别为350~420 ℃、1~3 s-1,350~390 ℃、7~20 s-1和425~450 ℃、2~20 s-1,应避免在危险区间加工,防止出现失稳和开裂现象。存在2个安全加工区间350~370 ℃、4~7 s-1和395~425 ℃、14~20 s-1,应优先选择在该热加工窗口区域进行热加工。

关键词:喷射成形;Al-Zn-Mg-Cu合金;高应变速率;热变形

文章编号:1004-0609(2019)-12-2700-09 中图分类号:TG146.2 文献标志码:A

喷射成形是一种先进的快速凝固材料制备技术,采用该工艺制备的高强Al-Zn-Mg-Cu合金相比于传统铸造工艺具有更加优异的综合力学性能,经热挤压和时效处理后,其σb超过740 MPa,大幅超过相应美国军标[1]。目前,该合金已成功应用于国防军工、国家重大项目关键部件的制造。现阶段该材料的研究热点主要集中在力学性能、热处理工艺以及焊接工艺上[2-3],对其热加工性能的研究虽有过相关报道[4],但由于相关试验参数的限制,研究仅局限于较低应变速率条件,这难以满足制定该材料热加工工艺的需要。在实际工业生产中材料锻造后失稳倾向严重,因此,为降低生产成本、控制产品质量和进一步提高材料性能,有必要对其高应变速率下的高温塑性变形行为进行系统性的研究。

有研究表明[5],材料在高应变速率下进行热变形时,内部产生的大量形变热无法及时向外传递,易于发生绝热温升现象,此时的流变曲线无法真实反映材料在设定温度下的变形抗力,因此,必须考虑绝热温升因素的影响,从而建立更加精确的本构模型及热加工图。热加工图是一种基于DMM,能够宏观描述金属材料在热变形过程中流变行为、热加工性与变形参数关系的技术[6],可用于预测和改善材料可加工性能、控制材料热变形组织及材料热加工工艺设计等多种用途。目前,加工图技术已被广泛应用于高温合金[7]、奥氏体不锈钢[8]、铝合金[9]、镁合金[10]等多种材料,并得到有效验证。因此,可利用该技术研究喷射成形高强Al-Zn-Mg-Cu合金的高温塑性变形行为。

本文作者利用Gleeble热力模拟试验机,对挤压态喷射成形高强Al-Zn-Mg-Cu合金进行高应变速率的热压缩试验,利用外推法对流变曲线进行绝热温升修正,基于Arrhenius关系构建了合金在高应变速率下的本构方程,基于DMM构建材料的热加工图,并确定不同变形条件区域内的微观组织特征,研究了挤压态Al-Zn-Mg-Cu合金的热变形行为,为制定其热加工工艺提供科学理论依据。

1 实验

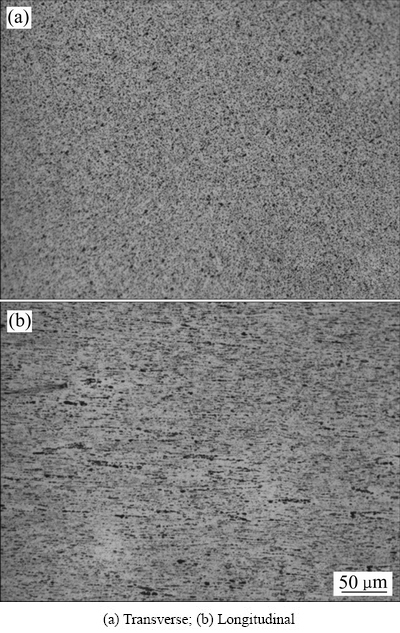

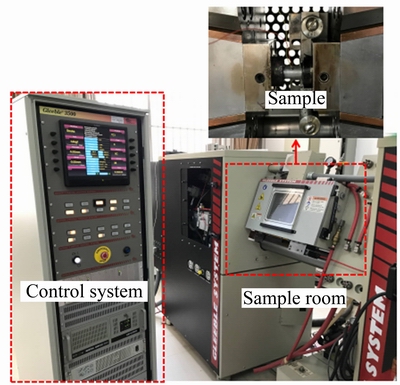

实验用喷射成形高强Al-Zn-Mg-Cu合金由江苏豪然提供,喷射沉积材料经热挤压处理(挤压比为9:1),材料化学成分(质量分数,%)见表1。其原始组织如图1所示,图1(a)为横向截面图,可见挤压后原始晶界消失,组织致密化,第二相呈均匀分布,图1(b)为纵向剖面图,可见第二相沿挤压方向呈方向性分布。将材料沿挤压棒轴向加工成d 10 mm×15 mm的圆柱体,在Gleeble-3500热力模拟试验机上进行等温恒应变速率热压缩试验,如图2所示。压缩时在试样两端粘贴石墨片,起润滑作用,防止发生鼓肚效应,以10 ℃/s的速率将试样加热至变形温度,保温30 s后进行压缩变形,变形温度设定为350~450 ℃,应变速率分别为1 s-1、5 s-1、10 s-1、20 s-1,真应变为0.8,热变形后立即用高速气流淬火以保留高温变形组织。为避免试样内部孔洞缺陷造成的不确定性,每个试样进行3次热模拟试验。将压缩试样沿轴向剖开,经抛光腐蚀后制成金相试样,腐蚀剂为Keller试剂,随后观察显微组织。

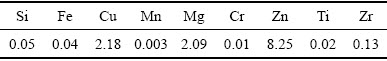

表1 实验用材料化学成分

Table 1 Chemical Composition of experimental steel (mass fraction, %)

图1 挤压态喷射成形高强Al-Zn-Mg-Cu合金原始组织

Fig. 1 Microstructures of extrusion high strength Al-Zn-Mg-Cu alloy by spray forming

图2 Gleeble热力模拟热压缩示意图

Fig. 2 Schematic diagram of thermal compression by using Gleeble thermal simulation machine

2 结果与分析

2.1 流变应力曲线

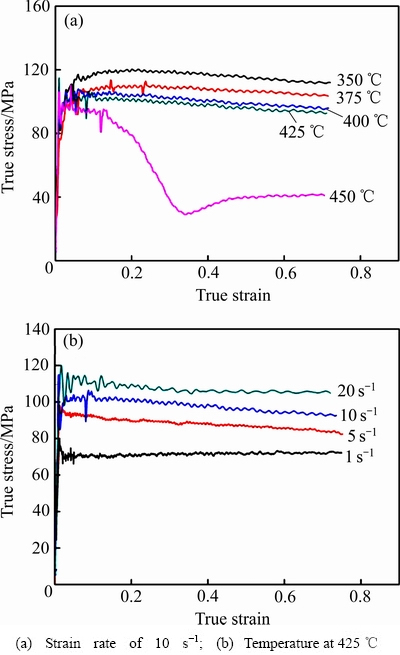

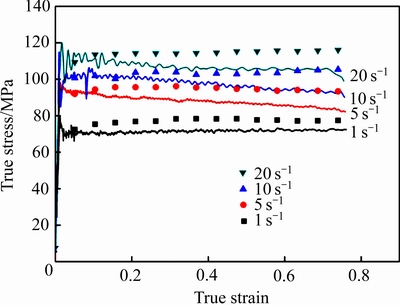

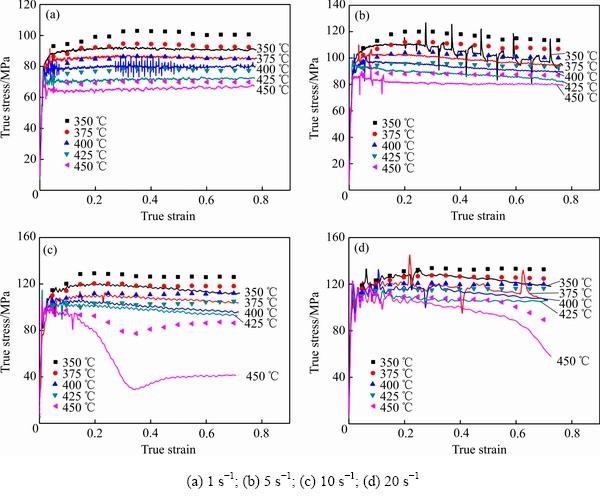

图3所示为挤压态喷射成形高强Al-Zn-Mg-Cu合金在不同变形参数下的流变应力曲线。由图3可知:其流变曲线均呈现典型的动态回复特征,这是由于该合金是一种高层错能的金属,热变形过程中难以形成层错,这有利于位错的束集和交滑移等作用的进行,位错在滑移面间转移使异号位错相互抵消,位错密度下降导致畸变能达不到发生动态再结晶所需要的能 量[11],因此,高层错能金属热变形时以动态回复为主。在流变应力曲线上则表现为变形初期位错密度迅速增加引起加工硬化从而导致应力迅速增加至峰值,随后硬化作用与动态回复的软化作用达到平衡,使流变应力趋于稳定状态。当应变速率为10 s-1时不同变形温度的流变曲线如图3(a)所示,可知随变形温度的升高,材料变形抗力降低,当温度增加至450 ℃时,试样在压缩过程中碎裂,导致流变曲线在应变量为0.2时迅速下降,随后趋于稳定。当变形温度为425 ℃时,不同应变速率的流变曲线如图3(b)所示。由图3(b)可知:随应变速率的增加,材料变形抗力呈上升趋势。

2.2 绝热温升修正

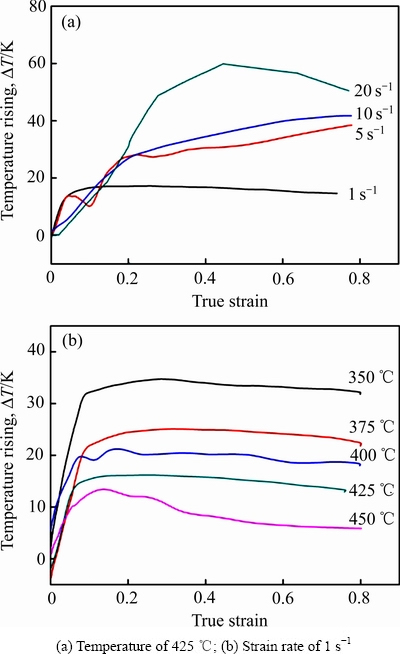

当变形温度为425 ℃、应变速率为1 s-1时,变形抗力随应变量增加呈平稳状态,当应变速率增加至5 s-1、10 s-1、20 s-1时,随应变量增加,流变曲线均呈现略微下降趋势,这可能是由于绝热温升现象导致的。

图3 材料在各变形参数下的流变应力曲线

Fig. 3 Flow stress curves of alloy obtained under different deformation conditions

有研究表明,在热变形过程中,部分塑性变形功转化为形变热[12],通常由于材料中心变形较为剧烈,因此,产生较多的形变热,若热量不能及时传递出去,将致使材料内部温度显著升高,这就导致实际变形温度高于试验设定温度的现象出现,从而产生绝热温升效应。在较低应变速率(<1 s-1)下变形时,形变热有足够时间通过对流和辐射等方式耗散,绝热温升现象可忽略不计[13]。当应变速率较高时(>5 s-1),变形时间短,而产生的形变热增加,导致形变热无法及时向外传递,因此绝热温升现象较低应变速率变形时更加明显。

图4所示为不同变形条件下设定温度与实测温度间的关系。由图4(a)可以看出,当应变速率为1 s-1时实测温度先迅速增加,后随应变量增加趋于稳定,温升约为15 ℃。当应变速率为5 s-1、10 s-1时,温度随应变量增加呈持续上升趋势。当应变速率增加至20 s-1时,绝热温升现象十分显著,温升近60 ℃。同时可以发现,当变形温度一定时,随应变速率的升高,绝热温升现象愈发显著。由图4(b)可以看出:温升值随变形温度的升高而降低,这是由于试样高温变形时与环境温差较大,散热较快从而使绝热温升现象减弱。

图4 不同变形条件下,设定温度与实测温度之间的关系

Fig. 4 Relationship between setting temperature and measured temperature under different deformation conditions

因此,在425 ℃变形,应变速率为1 s-1时,虽有绝热温升现象,但温度保持平稳趋势,而在高应变速率(>5 s-1)下变形时,材料实际变形温度持续上升,强度逐渐降低,流变应力水平下降,这就是导致图3(b)中高应变速率(>5 s-1)变形时流变曲线呈持续下降趋势的原因。此时的流变曲线并不能真实地反映材料在该变形条件下的变形抗力,因此,为提高后期建立高应变速率下的本构模型及热加工图的准确性,有必要对材料的流变应力曲线进行绝热温升修正。

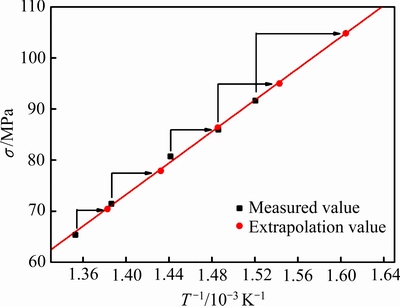

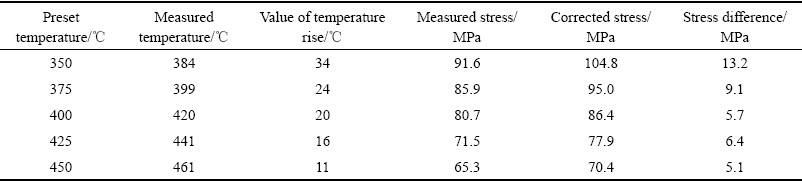

相关研究表明,材料在高应变速率下热变形时的绝热温升效应,导致流变曲线失真现象可通过外推法对其进行修正[14]。外推法是对某一应变量下的实测应力和实测温度进行σ—1/T的一元线性拟合,在该拟合直线上外推到试验设定温度并得出其对应的应力,该值则为考虑绝热温升效应修正后的流变应力。本文基于外推法,对不同应变量(0.05~0.75,间隔0.05)下的流变应力分别进行σ—1/T的一元线性拟合并修正其流变应力。图5所示为应变量0.25时应变速率1 s-1、不同实测变形温度的σ—1/T一元线性拟合。由图5可以看出:σ与1/T的线性关系明显,相关系数达0.9943,因此使用外推法有较高的准确性。对每一实测温度下的应力外推至设定温度,并获得其相对应的应力。表2所列为应变量0.25、应变速率1 s-1温升修正结果。由表2可以看出:经过外推法修正后,应力均有不同程度的提高,同时可发现随着变形温度的下降,应力差值更加明显。

图5 当应变量0.25、应变速率1 s-1时σ与T-1之间的线性关系

Fig. 5 Linear relationship between σ and T-1 at strain 0.25 and strain rate 1 s-1

图6 变形温度425 ℃时的流变真应力-真应变曲线

Fig. 6 Corrected true stress-true strain curves at deformation temperature of 425 ℃

图6所示为使用外推法修正后变形温度425 ℃时不同应变速率时的流变曲线。由图6可知:绝热温升修正后流变应力均有不同程度的上升,在高应变速率 (>5 s-1)下变形的流变曲线不再呈下降趋势,呈现出典型的动态回复型曲线特征。图7所示分别为应变速率1、5、10、20 s-1时不同变形温度时的流变曲线修正图对比,可知经绝热温升修正后,材料变形抗力提高5~15 MPa。经过绝热温升修正后的流变曲线能够更加真实地反映材料在不同变形条件下的塑性变形特征,提高了后续构建喷射成形高强Al-Zn-Mg-Cu合金的本构模型和热加工图的准确性。

2.3 本构模型的构建

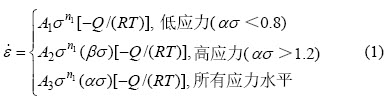

通常σ(流变抗力)与T(变形温度)、 (应变速率)三者之间的关系可用基于Arrhenius[15]关系构建的本构方程来描述,可分为以下3种情况:

(应变速率)三者之间的关系可用基于Arrhenius[15]关系构建的本构方程来描述,可分为以下3种情况:

式中:A1、A2、A3、n、n1、 和β为材料常数;Q为热变形激活能,kJ/mol;R为摩尔气体常数,J/(mol·K);T为热力学温度,K;且有

和β为材料常数;Q为热变形激活能,kJ/mol;R为摩尔气体常数,J/(mol·K);T为热力学温度,K;且有 =β/n1关系存在。本文采用适用于所有应力水平双曲正弦形式修正方程来构建喷射成形高强Al-Zn-Mg-Cu合金的本构方程,σ取应变量为0.2时绝热温升修正后的应力。

=β/n1关系存在。本文采用适用于所有应力水平双曲正弦形式修正方程来构建喷射成形高强Al-Zn-Mg-Cu合金的本构方程,σ取应变量为0.2时绝热温升修正后的应力。

ZENER等[16]发现可用一个Z参数来描述变形温度和应变速率之间的关系(Zener-Hollomon参数):

(2)

(2)

表2 应变量0.25、应变速率1 s-1时的流变应力温升修正结果

Table 2 Flow stress correction for temperature rising of 1 s-1 when ε=0.25

图7 高应变速率热变形经修正后的流变真应力-真应变曲线

Fig. 7 Corrected true stress-true strain curves with high strain rates

Z参数综合反映材料在不同变形条件下的热变形行为,通常Z越小材料发生动态再结晶程度越大。由式(1)和式(2)可知流变应力σ与Z参数有如下关系:

(3)

(3)

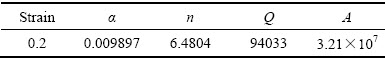

对上述各式进行变形、联立并通过线性拟合计算得出绝热温升修正后应变量0.2时的材料常数,如表3所示。

表3 应变量0.2时的材料常数

Table 3 Material constants when true strain of 0.2

将上述材料常数代入传统Arrhenius关系构建的本构方程,得出喷射成形高强Al-Zn-Mg-Cu合金在变形温度350~450 ℃、应变速率1~20 s-1范围内的本构方程如下式所示:

(4)

(4)

式(4)可反映喷射成形高强Al-Zn-Mg-Cu合金的本构行为,并为解决实际生产过程中的不同变形条件下的塑性成型问题提供有效的依据。

2.4 热加工图的构建

为了能够更加直观地描述材料在热加工过程中的热加工性能与变形参数之间的内在联系,PRASAD 等[17]最早提出了DMM并在此基础上发展出加工图理论。通过构建材料的热加工图,可直观反映出材料在一定变形条件范围内的安全区和失稳区,从而为材料热加工工艺的优化提供科学理论依据。

DMM理论将热加工工件看作一个非线性能量耗散体,并用下式表示耗散功率P与耗散量G、耗散协量J三者之间的关系:

(5)

(5)

式中: 表示等效应力;

表示等效应力; 为等效应变速率。用功率耗散因子η来表示材料微观组织演变所耗散能量与消耗总能量的比值,如下式所示:

为等效应变速率。用功率耗散因子η来表示材料微观组织演变所耗散能量与消耗总能量的比值,如下式所示:

(6)

(6)

式中:m为应变速率敏感因子。一般认为当功率耗散值η较高时往往对应着材料最佳热加工性能区,以 为坐标平面,绘制相应应变量下的η等值曲线图即为功率耗散图。

为坐标平面,绘制相应应变量下的η等值曲线图即为功率耗散图。

为了避免将材料在失稳变形区进行加工,KUMAR基于最大熵产生率的原理和塑性流变理论提出了失稳判据:

<0 (7)

<0 (7)

式中: 为失稳参数,当

为失稳参数,当 小于零时系统会产生局部流变或形成流变失稳,微观组织上则表现为产生局部塑性流动或绝热剪切带等现象。以

小于零时系统会产生局部流变或形成流变失稳,微观组织上则表现为产生局部塑性流动或绝热剪切带等现象。以 为坐标平面,绘制某一应变量下的流变失稳区域即为流变失稳图。将同一应变量下的功率耗散图和流变失稳图相叠加即为热变形加工图,通过热加工图可直观地发现功率耗散峰值区域并判断其是否与流变失稳区域相重叠,从而更加准确地确定材料的热加工窗口。

为坐标平面,绘制某一应变量下的流变失稳区域即为流变失稳图。将同一应变量下的功率耗散图和流变失稳图相叠加即为热变形加工图,通过热加工图可直观地发现功率耗散峰值区域并判断其是否与流变失稳区域相重叠,从而更加准确地确定材料的热加工窗口。

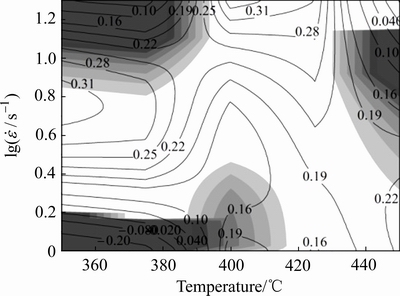

基于DMM理论利用绝热温升修正后的流变曲线构建Al-Zn-Mg-Cu合金热加工图,图8所示为材料在应变量0.6时的热加工图,图中用等高线表示功率耗散值并在线上标明数值大小,用阴影部分表示流变失稳区域,阴影颜色越深则表示此区域流变失稳倾向越大。可以看出图中存在2个热加工窗口区域,其中区域①位于350~370 ℃、4~7 s-1,区域②位于395~425 ℃、14~20 s-1。图中分布着大面积的流变失稳区域,主要位于350~420 ℃低应变速率、350~390 ℃高应变速率和425~450 ℃中高应变速率附近,这是应避免进行热加工的区域。变形试样的外观观察表明,在425~450 ℃中高应变速率区域的试样均出现严重的表面裂纹和开裂现象。

图8 喷射成形高强Al-Zn-Mg-Cu合金应变量0.6时的热加工图

Fig. 8 Process map of spray forming high strength Al-Zn-Mg-Cu alloy at true strain of 0.6

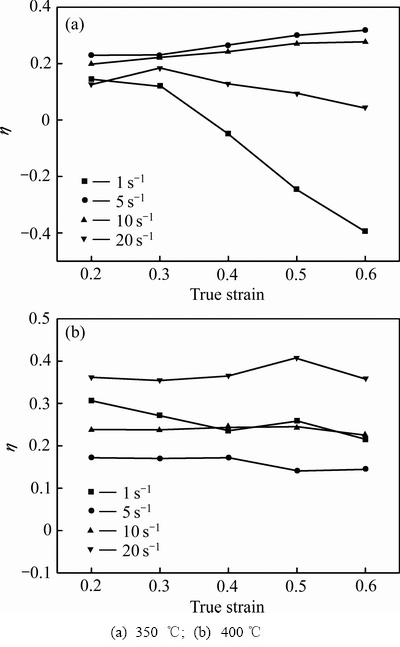

为直观观察应变量增加导致的功率耗散变化趋势,绘制出不同变形条件下功率耗散与应变量关系,如图9所示。由图9(a)可知:在350 ℃、1 s-1和350 ℃、20 s-1变形时,随应变量增加,η逐渐降低说明变形程度的增加导致了合金加工难度上升。在350 ℃、5 s-1和350 ℃、10 s-1变形时,η逐渐升高,应变量达0.6时功率耗散峰值达0.3。由图9(b)可知,在400 ℃、20 s-1变形时,随变形量增加,η始终高于0.3,这说明该变形参数处于稳定的功率耗散峰值区域。

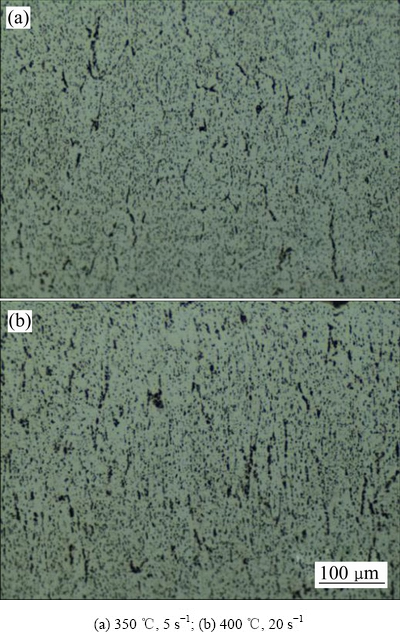

为验证热加工图的准确性,还需进一步结合微观变形组织进行判定。图10所示为不同变形条件下Al-Zn-Mg-Cu合金的显微组织。图10(a)、图10(b)分别为功率耗散峰值区域①和区域②处的显微组织。由图10可以看出:该区域组织原始晶界消失,依稀可见网络化的第二相,2个区域均发生了动态回复现象,同时观察变形后宏观试样无明显开裂等失效现象,因此,该区域是适合进行热变形及后续处理的热加工窗口。

图9 不同温度时不同变形条件下功率耗散值与应变量关系

Fig. 9 Relationship between η and true strain at different deformation temperatures and different

图10 应变量0.6时功率耗散峰值区域的显微组织

Fig. 10 Typical microstructures in peak power dissipation at true strain of 0.6

图11 失稳变形区450 ℃、20 s-1的显微组织

Fig. 11 Microstructures of unstable deformation zone at (450 ℃, 20 s-1)

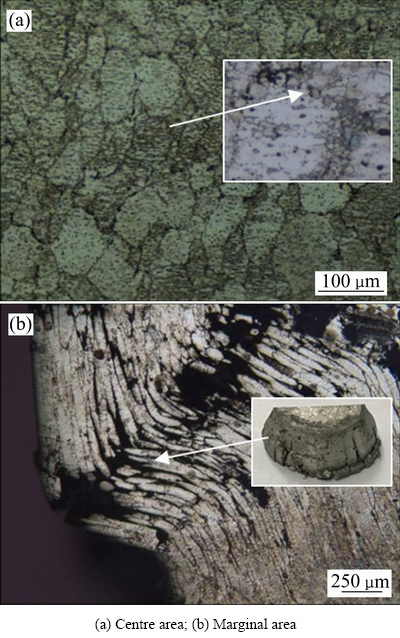

图11(a)和(b)所示分别为450 ℃、20 s-1变形后试样心部区域和边缘区域的显微组织。图11(a)及局部放大图可以看到粗大的等轴状晶粒和晶界周围分布的细小的再结晶晶粒,这是典型的连续性动态再结晶组织,由于材料在变形过程中,位错非均匀分布形成封闭胞壁,在较高温度下构造出低角度晶界,同时由于变形速率较大,形成的胞壁更加细小,在后续变形中位错不断向小角度晶界处聚集导致亚晶界取向差继续增大,最终演变为大角度晶界从而产生细小的再结晶晶粒。由图11(b)可以看到:在高速变形条件下,处于自由变形区域的组织来不及发生动态回复和再结晶,依然呈现为原始晶粒伸长方向的长条状晶粒,在试样鼓出的过程中出现沿晶开裂导致试样失效。因此,该区域是不适合进行热加工的危险区域,制定热加工工艺时应注意避开该区域。

3 结论

1) 热压缩试验表明,喷射成形高强Al-Zn-Mg-Cu合金在不同变形条件下的流变曲线均呈现动态回复型特征。

2) 材料在高应变速率下变形时出现了显著的绝热温升现象,利用外推法对不同变形条件下的流变曲线修正后,材料的变形抗力均发生不同程度的提高。

3) 基于双曲线正弦Arrhenius关系构建了材料在高应变速率下变形时的本构模型为

4) 基于DMM构建了喷射成形高强Al-Zn-Mg-Cu合金的热加工图,结合不同区域显微组织和试样宏观外形观察表明,材料有2个的热加工窗口为350~ 370 ℃、4~7 s-1和395~425 ℃、14~20 s-1,应避免在350~420 ℃、1~3 s-1,350~390 ℃、7~20 s-1和425~450 ℃、2~20 s-1区域进行热变形,防止出现流变失稳和开裂现象。

REFERENCES

[1] 李先聚, 杨 杰, 张 豪, 张 捷, 张 荻. 喷射成形7055铝合金的显微组织和力学性能[J]. 中国有色金属学报, 2007, 17(12): 1987-1992.

LI Xian-ju, YANG Jie, ZHANG Hao, ZHANG Jie, ZHANG Di. Microstructure and mechanical properties of 7055 Al alloys by spray forming[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(12): 1987-1992.

[2] 夏 浩. 工业级规格喷射成形7055铝合金的组织演变与力学性能[D]. 兰州: 兰州理工大学, 2013: 27-34.

XIA Hao. Microstructure evolution and mechanical properties of industrial level 705 5 aluminum alloy extrusion by spray forming[D]. Lanzhou: Lanzhou University of Technology, 2013: 27-34.

[3] 陆正萍. 喷射成形超高强度铝合金搅拌摩擦焊接头组织性能研究[D]. 镇江: 江苏科技大学, 2015: 27-28.

LU Zhen-ping. Study on microstructures and properties of spray formed ultra high strength aluminum alloys joint by friction stir welding[D]. Zhenjiang: Jiangsu University of Science and Technology, 2015: 27-68.

[4] 陈 刚. 超高强铝合金Al-12Zn-2.4Mg-1.2Cu热变形特性及应用研究[D]. 太原: 中北大学, 2016: 93-119.

CHEN Gang. Study on thermal deformation characteristics and application of the Al-12Zn-2.4Mg-1.2Cu ultra high strength aluminum alloy[D]. Taiyuan: North University of China, 2016: 93-119.

[5] SON K T, KIM M H, KIM S W, LEE J W, HYUN S K. Evaluation of hot deformation characteristics in modified AA5052 using processing map and activation energy map under deformation heating[J]. Journal of Alloys & Compounds, 2018, 740: 96-108.

[6] LI Peng-wei, LI Hui-zhong, HUANG Lan, LIANG Xiao-peng, ZHU Ze-xiao. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(8): 1677-1688.

[7] 罗 锐, 程晓农, 郑 琦, 朱晶晶, 王 皎, 刘 天, 陈 光, 杨 乔. 新型含铝奥氏体耐热合金Fe-20Cr-30Ni- 0.6Nb-2Al-Mo的动态再结晶行为[J]. 材料导报, 2017, 31(18): 136-140.

LUO Rui, CHENG Xiao-nong, ZHENG Qi, ZHU Jing-jing, WANG Jiao, LIU Tian, CHEN Guang, YANG Qiao. Dynamic recrystallization behavior of an alumina-forming austenitic alloy Fe-20Cr-30Ni-0.6Nb-2Al-Mo[J]. Materials Review, 2017, 31(18): 136-140.

[8] 卓秀秀, 徐桂芳, 袁 圆, 罗 锐, 程晓农. 0Cr17Mn- 17Mo-3NiN奥氏体不锈钢的热变形行为及热加工图[J]. 机械工程学报, 2017, 53(22): 74-80.

ZHUO Xiu-xiu, XU Gui-fang, YUAN Yuan, LUO Rui, CHENG Xiao-nong. Hot deformation behavior and processing map of 0Cr17Mn17Mo3NiN austenitic stainless steel[J]. Journal of Mechanical Engineering, 2017, 53(22): 74-80.

[9] PENG Jian, WANG Yong-jian, ZHONG Li-ping, PENG Long-fei, PAN Fu-sheng. Hot deformation behavior of homogenized Al-3.2Mg-0.4Er aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(4): 945-955.

[10] HADADZADEH A, WELLS M A. Analysis of the hot deformation of ZK60 magnesium alloy[J]. Journal of Magnesium and Alloys, 2017, 5(4): 369-387.

[11] 王少阳. 7075铝合金热变形的动态再结晶规律研究[D]. 合肥: 合肥工业大学, 2012: 14-17.

WANG Shao-yang. Research on dynamic recrystallization behavior of 7075 aluminum alloy during hot deformation[D]. Hefei: Hefei University of Technology, 2012: 14-17.

[12] AHADI A, TAHERI A K, TAHERI K K. The effect of deformation heating on restoration and constitutive equation of a wrought equi-atomic NiTi alloy[J]. Journal of Materials Engineering & Performance, 2012, 21(4): 516-523.

[13] PINHEIRO I P, BARBOSA R, CETLIN P R. The relevance of dynamic recrystallization in the hot deformation of IF steel at high strain rates[J]. Materials Science and Engineering A, 2007, 457(1/2): 90-93.

[14] LI L, ZHOU J, DUSZCZYK J. Determination of a constitutive relationship for AZ31B magnesium alloy and validation through comparison between simulated and real extrusion[J]. Journal of Materials Processing Technology, 2006, 172(3): 372-380.

[15] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[16] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[17] PRASED Y V R K. Moeling of dynamic material behavior in hot deformation: forging of Ti-242[J]. Metallurgical and Materials Transactions A, 1984, 15(10): 1883-1892.

Plastic deformation behavior of spray formed high-strength Al-Zn-Mg-Cu alloy at high strain rate

YANG Yu-tong1, LUO Rui1, CHENG Xiao-nong1, CHEN Le-li1, GUI Xiang1, WANG Wei1, ZHANG Zhen2, GAO Shi-yuan2

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. Jiangsu Haoran Spray Forming Alloy Co., Ltd., Zhenjiang 212009, China)

Abstract: The thermal compression test of extruded spray formed Al-Zn-Mg-Cu high strength aluminum alloy at high strain rate was performed on Gleeble-3500 thermo-mechanical simulator. The high temperature plastic deformation behavior of the material at deformation temperature of 350-450 ℃ and high strain rate of 1-20 s-1 was systematically studied. Considering the influence of adiabatic heating, the flow stress curve of material was corrected by extrapolation, and the material constitutive model was constructed. The processing maps were constructed based on the dynamic material model, and the microstructure characteristics in different deformation conditions were determined. The results show that the flow stress curves of the alloy exhibit typical dynamic recovery characteristics. With the increase of strain rate, the adiabatic temperature rise becomes more obvious. The processing maps and the microstructure characteristics of different deformation regions show that there are three hazardous processing zones at (350-420 ℃, 1-3 s-1), (350-390 ℃, 7-20 s-1) and (425-450 ℃, 2-20 s-1) which should be avoided to prevent the occurrence of instability and cracking in the hazardous area. There are two safe processing zones, (350-370 ℃, 4-7 s-1) and (395-425 ℃, 14-20 s-1) which should be selected for hot working.

Key words: spray forming; Al-Zn-Mg-Cu alloy; high strain rate; hot deformation

Foundation item: Project(BE2017127) supported by Jiangsu Province Key Research and Development Program (Industry Prospects and Common Key Technologies), China

Received date: 2018-05-30; Accepted date: 2018-08-27

Corresponding author: LUO Rui; Tel: +86-18796000354; E-mail: luoruiweiyi@163.com

(编辑 龙怀中)

基金项目:江苏省重点研发计划(产业前瞻与共性关键技术)( BE2017127)

收稿日期:2018-05-30;修订日期:2018-08-27

通信作者:罗 锐,讲师,博士;电话:18796000354;E-mail:luoruiweiyi @163.com