DOI:10.19476/j.ysxb.1004.0609.2018.06.03

喷射成形7055铝合金的热变形行为和加工图

王向东1,潘清林1,熊尚武2,刘丽丽1,张豪3,范曦3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 轻合金研究院,长沙 410083;

3. 江苏豪然喷射成形合金有限公司,镇江 212004)

摘 要:通过高温热压缩实验研究喷射成形7055铝合金的热变形行为,实验温度为340~480 ℃,应变速率为0.001~1 s-1。结果表明:该合金在变形过程中的流变应力随着温度升高和应变速率的降低而降低,在480 ℃时会出现失稳现象。变形过程中的主要软化机制为动态回复和动态再结晶,其中低温时,动态回复占主导地位,随着温度升高,软化机制逐步转变为动态再结晶,再结晶晶粒的尺寸随着温度的升高而增大。基于动态材料模型和极化互惠模型,结合热变形中的组织演变,确定该合金在应变量为0.7时的适宜加工范围为:温度范围400~420 ℃,应变速率0.01~0.1 s-1,此时对应的动态材料模型加工图能量耗散效率超过33%,极化互惠模型加工图内在加工参数在65%~70%之间。

关键词:喷射成形7055铝合金;加工图;动态材料模型;极化互惠模型

文章编号:1004-0609(2018)-06-1101-10 中图分类号:TG146.2 文献标志码:A

7xxx铝合金由于具备高强度、高韧性、高比强度以及不错的腐蚀性能被广泛应于在航空航天、先进武器设备和轨道交通等领域中[1-3]。近年来,随着对加工过程和热处理工艺的不断优化,7055铝合金的性能得到进一步提高[4-8]。通过喷射成形工艺制备的合金,通常由细小的等轴晶(10~100 μm)细化的金属间弥散相(0.5~15 μm)以及第二相组成。这些固溶体和中间相可以在随后的加工和热处理过程中抑制晶粒的长大,进一步优化力学性能,此外,还可以有效缩短或避免均匀化[9]。除了在细化晶粒方面的优势外,喷射成形技术还可以带来成分与组织的均匀性,提高加工工艺的灵活性等[10]。热加工工艺对喷射成形7055铝合金的性能有着极其重要的影响,因此,研究热变形行为对其加工工艺的确定、变形中组织的演变以及性能的提高都有着密不可分的关系[11]。

合金的热变形过程非常复杂。在这个过程中,常常伴随着动态回复(DRV)、动态再结晶(DRX),也会存在一些失稳行为,比如孔洞的形成以及断裂行为的发生。这些现象的发生通常与加工工艺有着密不可分的关系,无论是温度、变形速率还是变形量,都会对合金的组织演变产生影响,从而影响其各项性能[12]。相应地,热变形过程中的组织演变也会通过加工参数的形式呈现出来。热加工图是基于原子模型(AM)、动态材料模型(DMM)和极化互惠模型(PRM)等构建的,通过分析热加工图可以会加深对热变形行为的认识。其中,Raj图(AM)[13]可以有效呈现不同热变形行为发生的边界条件,从而预测在不同热加工参数下的变形行为;然而,合金对加工参数的响应比较复杂,限制了这个模型的应用。动态材料模型则因为可以将材料与模拟系统建立有效联系而得到广泛应用。FENG等[14]通过DMM热加工图确定了均匀化Al-Zn-Mg-Cu-Zr的动态再结晶和动态回复区域。WU等[15]则通过DMM热加工图研究了Al-Zn-Mg-Er-Zr的动态回复区域和失稳区。然而,DMM的变形历史依赖性被忽略,可能是DMM存在的问题。极化互惠模型(PRM)则将变形历史这一因素考虑在内,同时将材料的速率依赖性作为主要特征来构建加工图,PRM热加工图的一大特点为失稳区与合理加工区充分分开,因此,在钛合金的加工中得到很好的应用[16]。

本文作者研究喷射成形Al-Zn-Mg-Cu-Zr合金在不同加工条件下的热变形行为,结合DMM和PRM加工图,通过组织观察,确定两种加工图与软化机制和失稳行为的关系,以期确定合适的加工工艺,避免该合金在热加工过程中发生失稳行为。

1 实验

1.1 实验材料

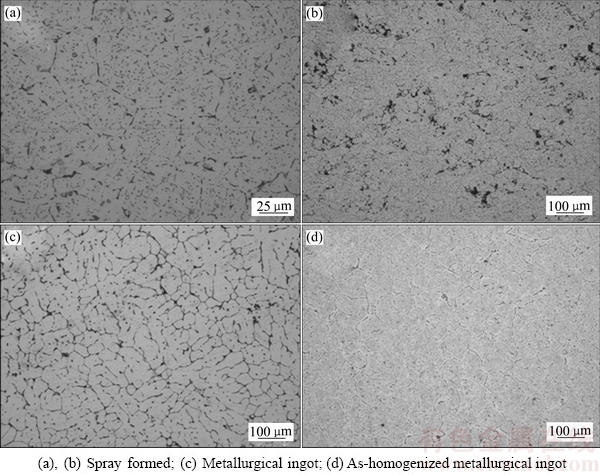

实验所用合金是由江苏豪然喷射成形有限公司制备,其实际成分为Al-7.91Zn-1.98Mg-2.42Cu-0.12Zr(质量分数,%)。不同铸造方式制备的7055铝合金的显微组织如图1所示。由图1(a)可知,其晶粒为均匀、细小、直径不到50 μm的等轴晶,内部存在着细小的第二相,通过低倍金相显微镜观察可知(见图1(b)),晶界处有部分孔洞。通过EDX分析,合金元素Zn、Mg和Cu主要在晶界处富集。而采用传统铸造方式制备的7055铝合金,原始晶粒为等轴晶和枝晶(见图1(c)),在均匀化处理后直径大约为100 μm(见图(1(d))。

合金的热压缩实验是在Gleeble-3500热模拟试验机上进行,热压缩试样为经过致密化的喷射成形样品,试样为d 10 mm×15 mm的圆柱体。变形温度分别为340、370、410、450和480 ℃,应变速率为0.001、0.01、0.1和1 s-1。热压缩之前,试样以2 ℃/s 的速率升温到设定温度,保温3 min以确保材料内部各处的温度均匀,随后进行热压缩实验,待真应变量达到0.8后,立即用20 ℃的冷水淬火,以保留热压缩结束时的组织。

1.2 加工图理论

1.2.1 DMM加工图理论

图1 不同铸造方式制备的7055铝合金的显微组织

Fig. 1 Microstructures of 7055 aluminum alloys prepared by different casting methods

动态材料模型是由PRASAD等提出,被广泛应用在高温热变形行为的分析中[13]。在DMM模型中,加工图是由能量耗散图和失稳图叠加而成,而热变形可以视为能量耗散的过程,被试样吸收的能量则由两部分组成:一部分称为耗散因子(G),为塑性变形所消耗的能量,其中大部分以热量的形式散失,少部分则以晶格缺陷的方式储存。另一部分称为耗散协调因子(J),为变形过程中微观组织变化消耗的能量,与不同的冶金过程有关,例如:动态再结晶、动态回复和变形引起的相变等。所以,总能量P可以表达为[17]

(1)

(1)

在一定的温度和应变下,流变应力可以用下列公式描述

(2)

(2)

式中:K是与温度和结构有关的参数;m是应变速率敏感因子,可以表达为

(3)

(3)

应变速率敏感因子在构建加工图中起到至关重要的作用,利用实验所得数据,通过插值法得到应力值的二维矩阵,在此基础上,通过梯度下降函数,根据公式(3)计算出在不同点的应变速率敏感因子m[11]。

因此,在给定的条件下,组织消耗功率J可以通过以下方程表示:

(4)

(4)

对于理想的线性耗散,其应变速率敏感因子m=1,耗散协调因子J得到最大值,其最大值为 。而对于非理想的线性耗散,则需要用能量耗散系数η表示,η的值与材料的组织演变有关,其表达式为

。而对于非理想的线性耗散,则需要用能量耗散系数η表示,η的值与材料的组织演变有关,其表达式为

(5)

(5)

在DMM模型中,材料的失稳判据是基于最大熵产率, 为失稳参数,表达式为[18]

为失稳参数,表达式为[18]

<0 (6)

<0 (6)

可以看出,在失稳参数为负值时,材料的热变形过程中发生失稳。

1.2.2 极化互惠模型

在极化互惠模型中,基于塑性变形的准则,试样在加工过程中吸收的能量可以分为互补的两部分:硬化能量 和耗散能量

和耗散能量 。考虑到变形历史和应变的作用,应变速率和应力之间的关系可以表达为[19]

。考虑到变形历史和应变的作用,应变速率和应力之间的关系可以表达为[19]

(7)

(7)

式中:S是流变应力, 为应变速率。如果能量以公式(7)所表达的方式分布,则内在热加工参数(

为应变速率。如果能量以公式(7)所表达的方式分布,则内在热加工参数( )可以通过硬化能量

)可以通过硬化能量 的形式,表达为

的形式,表达为

(8)

(8)

可以看出,硬化能量的最小值 。与此同时,基于耗散能量依赖于应变历史的假设,通过极化互惠处理,流变应力表达为:

。与此同时,基于耗散能量依赖于应变历史的假设,通过极化互惠处理,流变应力表达为:

(9)

(9)

式中: 和C是与应变历史相关的函数;

和C是与应变历史相关的函数; 为应变。当

为应变。当 仅仅与应变历史有关而与应变速率及其历史无关时,

仅仅与应变历史有关而与应变速率及其历史无关时, 的本构方程为

的本构方程为

(10)

(10)

式中:E1可以为任意的具体应变值;Smin则为在这一任意值E1下流变应力的最小值。通过对应变速率和应力之间的极化互惠处理,可以得到以下方程

(11)

(11)

式中: 为应变速率敏感因子,材料的内在热加工参数则可以表达为

为应变速率敏感因子,材料的内在热加工参数则可以表达为

(12)

(12)

2 结果与讨论

2.1 流变行为

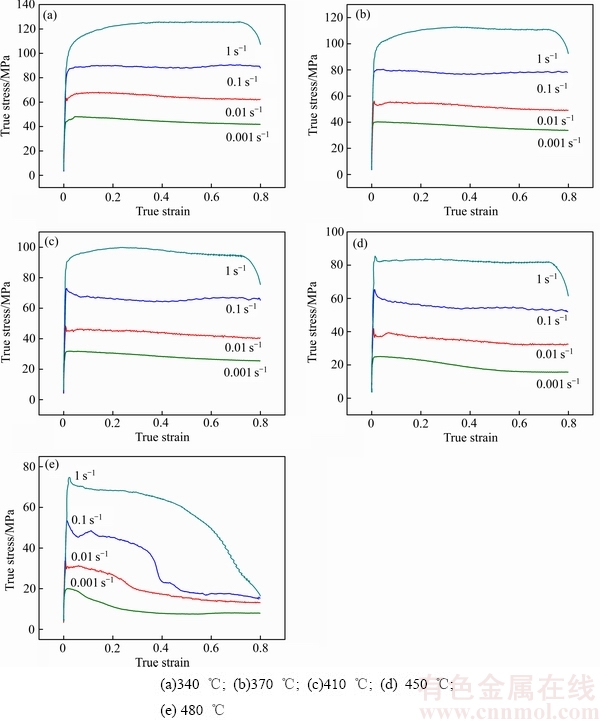

喷射成形7055铝合金的真应力-真应变曲线如图2所示。由图2可知,真应力随着变形温度的提高和应变速率的降低而降低。当温度低于450 ℃,在应变初期(真应变量小于0.1),真应力随着应变过程的进行急剧上升,在达到峰值后,会保持稳定或者出现小幅度的下降。真应力的变化可以通过位错密度来说明,热压缩开始后,随着应变量的增加,能量积累,激活位错的移动,因此,位错密度急剧增加,位错塞积后,出现加工硬化现象,使真应力急剧上升。与此同时,在外界压力下,移动位错同样也会与晶胞内和位错墙中的位错发生相互作用,产生位错偶极,当大量位错塞积,产生亚晶界,发生动态回复。当贮存的能量达到了最大值,与此同时耗散速率低至临界值,会发生动态再结晶。动态回复和动态再结晶的发生则可以全部或者部分抵消加工硬化的作用。当在480 ℃下变形时,该合金的真应力-真应变曲线出现变化:真应力在达到峰值后,随即出现明显下降。真应力的急剧下降是由失稳行为引起的。

如图2(a)所示,合金的应力应变曲线平滑,没有出现尖峰。可以推断出,在340 ℃下变形,不会发生DRX,此时,DRV为主要的软化机制。随着温度的升高,出现峰值的曲线数目增加,由此可以推断,温度提高有利于DRX过程的发生。而在热变形过程中,最有效的能量消耗方式为断裂产生的自由界面[20],随着大量能量的散失,引起真应力的显著下降,如图2(e) 所示。

图2 在不同温度下热压缩变形实验合金的真应力-应变曲线

Fig. 2 True stress-true train curves of experiment alloy at different temperatures

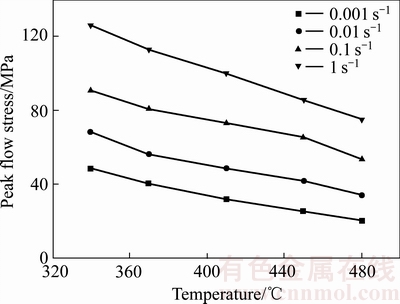

变形温度以及应变速率对峰值应力的影响如图3所示。由图3可知,变形温度和应变速率对峰值应力有很大影响,峰值应力随着变形温度的增加或应变速率的降低而减小。随着变形温度的升高,合金内原子的平均动能增加,原子间的相互作用增强,合金形变时的热激活作用加强,促进了位错的相互作用和软化行为的发生。当应变速率提高时,合金内的能量积累加快,促进了位错的运动,而变形时间会相应减短,导致位错有充足的时间和能量进行攀移和交滑移,位错湮灭和重排不充分;并且晶粒长大过程就是“大吞并小”的过程,因此,在更高变形速率的条件下,晶粒无法有效合并长大,软化机制弱化,使真应力值增加[21]。

2.2 加工图

2.2.1 DMM加工图

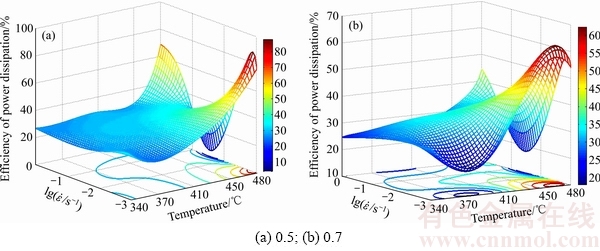

图4所示为喷射成形7055铝合金在真应变量为0.5和0.7时的三维能量耗散图。由图4可以看出,能量耗散效率有两个峰值区域,其中心分别为(480 ℃,1 s-1)和(480 ℃,0.001 s-1)。最小值则出现在两个峰值区之间,其中心在(480 ℃,0.01 s-1)左右。通常,能量耗散效率高意味着合金在该区域加工可以获得较好的性能。KAI等[22]的研究表明,当能量耗散效率超过0.3时,主要的软化机理为DRX。通过能量耗散图,可以看出在400 ℃以上加工,DRX过程占据主导。

图3 变形温度和应变速率对合金峰值应力的影响

Fig. 3 Effects of deformation temperature and strain rate on peak flow stress during hot compression of experimental alloy

图4 喷射成形7055铝合金在不同真应变时的三维能量耗散图

Fig. 4 3D maps of power efficiency of dissipation at different true strains

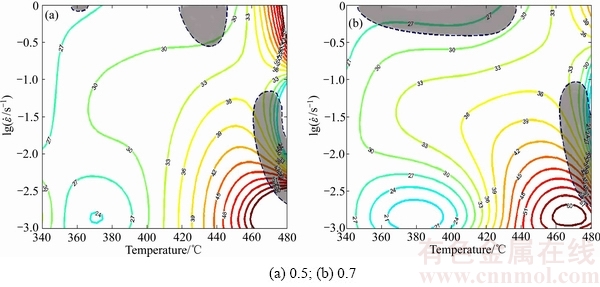

图5 合金在不同真应变下的DMM加工图

Fig. 5 DMM processing maps of experimental alloy at different true strains

合金在真应变为0.5和0.7时的加工图如图5所示,图中的等高线代表能量耗散效率,阴影部分为失稳区。由图5可以看出,随着真应变的增加,失稳区的面积有增大趋势,失稳区主要在加工图上部的高速热变形区和右侧的高温热变形区。两图中的能量耗散效率则基本相似,但随着应变的增加,低温区的效率值有不同程度的提高,而在高温区域,能量耗散效率则有不同程度的降低。从加工图中可以看出,温度超过450 ℃以及应变速率超过0.55 s-1,不适合该合金的加工。

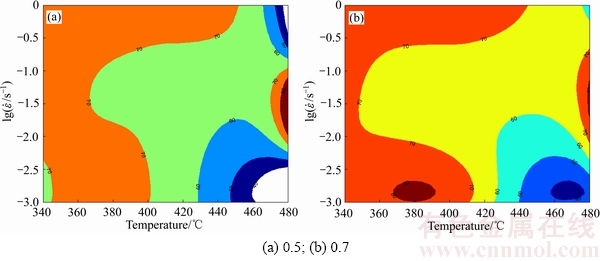

2.2.2 PRM加工图

图6所示为喷射成形7055铝合金在真应变0.5和0.7时的PRM加工图。图中的区域与加工过程中的变形机理可以对应起来。RAJAGOPALACHARY等[16]通过对钛合金的研究,得出以下结论:当内在加工参数在0.8~1时,发生的典型微观现象为断裂、剪切带、动态应变时效以及晶粒的长大等;当处于0.7~0.8时,主要发生动态再结、动态回复和孔洞的形成;当处于0.5至0.7之间时,发生动态回复、动态再结晶、晶界钉扎和织构软化;当小于0.5时,发生超塑性现象。由图6可知,该合金在480 ℃和0.01~0.1 s-1区域变形时,内在加工参数出现峰值,超过0.8,该峰值对应的现象为断裂;内在加工参数在370~390 ℃和0.001~0.004 s-1区域也存在峰值(见图6(b)),说明在该应变下合金出现动态应变硬化现象。而在(480 ℃,0.001 s-1)和(480 ℃,1 s-1)时,内在加工参数出现最小值,前者对应在高速应变的条件下发生断裂,后者对应在在低速条件下发生DRX和晶粒的长大。通过PRM加工图,可以得出在480 ℃下加工容易出现失稳现象,这些加工区应该避免。

2.3 组织演变

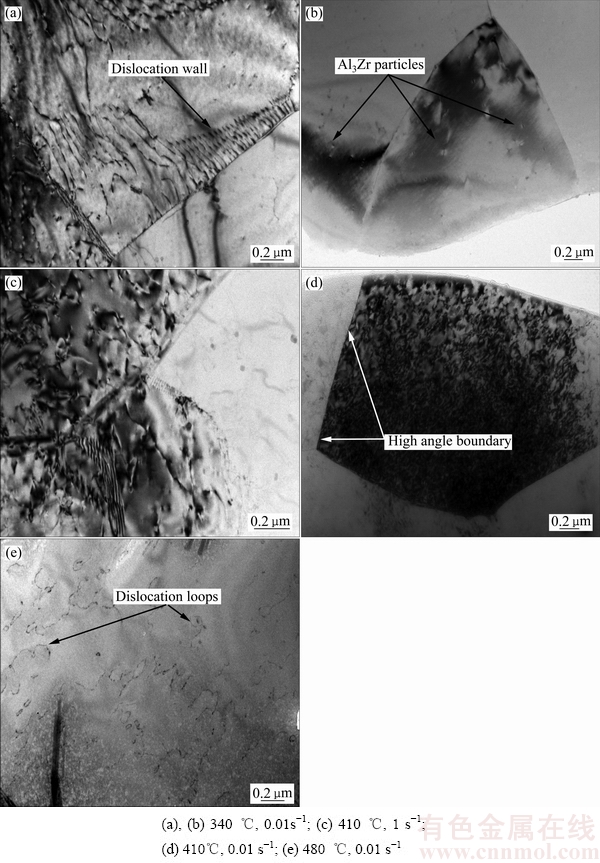

喷射成形7055铝合金在不同变形条件下的TEM像如图7所示。当合金变形条件为(340 ℃,0.01 s-1) 时,可见许多纳米级Al3Zr粒子呈弥散分布 (见图7(a)和(b)),这些Al3Zr粒子对位错和亚晶界有着强烈的钉扎作用,可以有效延缓变形中的动态回复过程以及阻碍动态再结晶过程的发生,使该合金发生再结晶的温度提高,应变速率降低[23]。同时,可以观察到大量的位错缠结,主要形成位错墙存在于晶界处。在此温度下,由于位错的湮灭和重组,亚晶界形成,DRV发生并且占主导地位。当温度升高,变形条件为(410 ℃,0.01 s-1)时,位错的交滑移过程增强,亚晶界可以吸收大量位错并形成大角度晶界,晶界平滑,这样有利于晶界在外加应力下移动,促进了再结晶过程的发生。KNIPLING等[24]发现,在400~425 ℃中,弥散分布的Al3Zr粒子的体积分数会有明显的下降,同样有利于动态再结晶过程的形核。当变形条件为(480 ℃,0.01 s-1)时,只存在少量的位错环。这是由于,在较高的温度下,容易激活位错的运动,位错间的相互作用增强,加剧了位错的湮灭,而第二相粒子可以钉扎部分位错,从而形成位错环。

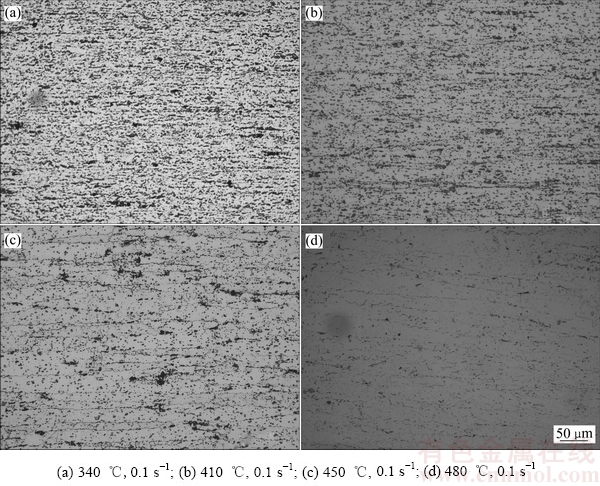

图8所示为喷射成形7055铝合金在不同变形条件下的金相组织。由图8可知,变形过程中,晶粒在垂直于压缩方向被拉长。当变形条件为(340 ℃,0.1 s-1)时,晶界较为平滑(见图8(a)),这时的软化机制为动态回复。在变形条件为(410 ℃,0.1 s-1)时,存在大量的再结晶晶粒(见图8(b)),没有明显的缺陷。动态再结晶是主要软化机制,在DMM加工图中对应的能量耗散效率为33%,在PRM加工图中对应的内在加工参数在0.6~0.7,与加工图所指示的动态再结晶区域吻合。当变形条件为(450 ℃,0.1 s-1)时,可以观察到晶粒尺寸较410 ℃时有所增大(见图8(c)),这是因为随着温度的升高,原子的扩散能力增强,有利于位错和晶界的移动。此外,可以看出大部分再结晶晶粒位于晶界处,少部分晶粒位于晶内,这是由于动态再结晶主要在晶界形核,只有少部分会在晶内形核。当变形条件为(480 ℃,0.1 s-1)时,晶粒尺寸进一步增大,在晶界处仍可以看到再结晶晶粒(见图8(d))。

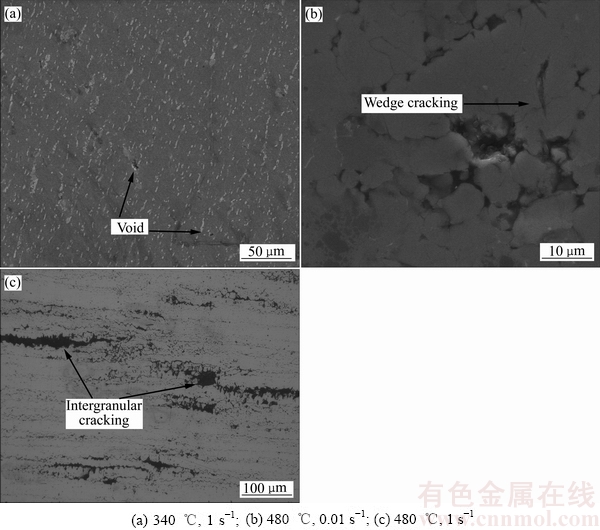

此外,喷射成形7055铝合金在热压缩过程中出现了不同程度的失稳现象,如图9所示。由图9可知,该合金在(340 ℃,1 s-1)、(480 ℃,0.01 s-1)和(480 ℃,1 s-1)时,分别会出现孔洞、楔形断裂和沿晶断裂等失稳行为(依次见图9(a)~(c))。变形条件为(340 ℃,1 s-1)时,较软的铝基体绕过较硬的第二相粒子,将会产生更大的变形量,导致在第二相粒子周围出现更强的加工硬化作用和应力;当应力值积累到足够大时,界面就会破裂,产生孔洞,孔洞的产生将会引起加工性能的下降,甚至会引起断裂。变形条件为(480 ℃,0.01 s-1)时,相对应的DMM加工图中能量耗散效率最低,并处于PRM加工图中的峰值区域,此时将会产生楔形断裂。这是由于一定的应力作用于三角晶界处时,相邻的晶界将会产生滑移,产生微裂纹,当晶界的扩散能力较弱,不能够有效修复裂纹,引起楔形断裂,楔形断裂一般在较高温度和中间速率下发生。而变形条件为(480 ℃,1 s-1)时,由于变形时间较短,晶界迁移不充分,导致晶界断裂,从而使能量大量耗散,DMM加工图中呈现峰值。

图6 合金在不同真应变下的PRM加工图

Fig. 6 PRM processing maps of experimental alloy at different true strains

图7 实验合金在不同变形条件下的TEM像

Fig. 7 TEM images of experimental alloy deformed under different conditions

通过结合DMM加工图和PRM加工图的分析,观察该合金的组织演变。可以看出,在低温时,由于能量耗散效率较低,流变应力较大,不利于合金的加工;而当温度最高时,则容易出现断裂现象,同样不利于加工。DRX可以有效抑制局部失稳的发生,因此在喷射成形7055铝合金热变形过程中需要尽可能的考虑动态再结晶区域。通过DMM加工图,合金在较高温度和较低的应变速率下加工,这样有利于DRX过程。过高的温度下变形将会在很大程度上使晶粒进一步长大,低温DRX变形可以得到相对细化的晶粒,可以为合金的热处理奠定基础。

图8 合金在不同变形条件下的金相组织

Fig. 8 OM images of experimental alloy deformed under different conditions

图9 合金在不同变形条件下的失稳现象

Fig. 9 Unsafe behaviors of studied alloy under various conditions

3 结论

1) 喷射成形7055铝合金在热变形过程中,其峰值应力随着温度的升高或应变速率的降低而逐渐降低。

2) 通过DMM加工图分析可知,在能量耗散效率低于0.3时,主要发生动态回复,当能量耗散效率超过0.3时,动态再结晶成为主要软化机制。合适的加工参数为:温度400~420 ℃,应变速率0.01~0.1 s-1。

3) Al3Zr粒子的存在能够抑制动态回复和动态再结晶的发生。

4) 在热压缩过程中会有失稳状态发生:低温高速变形时会有孔洞形成,高温时则会发生断裂。

REFERENCES

[1] 舒文祥. Mg和Cu元素调控的7xxx系铝合金凝固特性及强韧化机理研究[D]. 北京: 北京科技大学, 2016.

SHU WEN-xiang. Solidification characteristics and strenghtening-toughening mechanisms of 7xxx Al alloys with tailored Mg and Cu elements[D]. Beijing: University of Science and Technology of Beijing, 2016.

[2] RAO A C U, VASU V, GOVINDARAJU M, SRINADH K V S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1447-1471.

[3] ROMETSCH P A, ZHANG Y, KNIGHT S. Heat treatment of 7xxx series aluminium alloys—Some recent developments[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2003-2017.

[4] FENG Di, ZHANG Xin-ming, LIU Sheng-dan, WU Ze-zheng, TAN Qi. Rate controlling mechanisms in hot deformation of 7A55 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 28-35.

[5] 冯 迪, 张新明, 刘胜胆. 非等温回归再时效对7055铝合金中厚板的厚向组织及性能均匀性的影响[J]. 中国有色金属学报, 2015, 25(11): 3000-3010.

FENG Di, ZHANG Xin-ming, LIU Sheng-dan. Effect of non-isothermal retrogression and re-ageing on through-thickness homogeneity of microstructure and properties in 7055 aluminum alloy medium thick plate[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3000-3010.

[6] ZHOU Song, WANG Lei, XIE Li-yang, HUI Li, XU Liang. Effect of T7951 secondary aging treatment on crack propagation behavior of 7055 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(4): 938-944.

[7] 李 晨, 李志辉, 黄树晖, 李锡武, 闫宏伟, 刘红伟, 张永安, 熊柏青. 7055铝合金多道次热变形及固溶处理中的组织演变[J]. 材料热处理学报, 2015, 36(12): 55-60.

LI Chen, LI Zhi-hui, HUANG Shu-hui, LI Xi-wu, YAN Hong-wei, LIU Hong-wei, ZHANG Yong-an, XIONG Bo-qing. Microstructure evolution of 7055 aluminum alloy during multi-pass hot deformation and solution treatment process[J]. Transactions of Materials and Heat Treatment, 2015, 36(12): 55-60.

[8] 祝令状, 李忠华, 张 桢, 周小军. 喷射成形7055铝合金热变形行为模拟[J]. 航空材料学报, 2016, 36(1): 18-25.

ZHU Ling-zhuang, LI Zhong-hua, ZHANG Zhen, ZHOU Xiao-jun. Hot deformation simulation of spray formed 7055 aluminum alloy[J]. Journal of Aeronautical Materials, 2016, 36(1): 18-25.

[9] SINGER A. Principles of spray rolling of metals[J]. Metals Materials, 1970, 4(6): 246-250.

[10] SCHREIBER J M, OMCIKUS Z R, EDEN T J, SHARMA M M, CHAMPAGNE V, PATANKAR S N. Combined effect of hot extrusion and heat treatment on the mechanical behavior of 7055 AA processed via spray metal forming[J]. Journal of Alloys and Compounds, 2014, (617): 135-139.

[11] 祝令状. 喷射成形7055铝合金热变形行为研究[D]. 镇江: 江苏大学, 2016.

ZHU Ling-zhuang. Study on hot deformation behavior of spray formed 7055 aluminum alloy[D]. Zhenjiang: Jiangsu University, 2016.

[12] LIN Yong-cheng, CHEN Xiao-min. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working[J]. Materials and Design, 2011, 32: 1733-1759.

[13] RAJ R. Development of a processing map for use in warm-forming and hot-forming processes[J]. Metallurgical Transactions A, 1981, 12(6): 1089-1097.

[14] FENG Di, ZHANG Xin-ming, LIU Sheng-dan, DENG Yun-lai. Constitutive equation and hot deformation behavior of homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr alloy during compression at elevated temperature[J]. Materials Science and Engineering A, 2014, 608: 63-72.

[15] WU H, WEN S P, HUANG H, GAO K Y, WU X L, WANG W, NIE Z R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy[J]. Journal of Alloys and Compounds, 2016, 685: 869-880.

[16] RAJAGOPALACHARY T, KUTUMBARAO V V. Intrinsic hot workability map for a titanium alloy IMI685[J]. Scripta Materialia, 1996, 35(3): 311-316.

[17] FAN Cai-he, PENG Ying-biao, YANG Hai-tang, ZHOU Wei, YAN Hong-ge. Hot deformation behavior of Al-9.0Mg-0.5Mn-0.1Ti alloy based on processing maps[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 289-297.

[18] JIANG He, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei, YAO Zhi-hao. Hot deformation characteristics of alloy 617B nickel-based superalloy: A study using processing map[J]. Journal of Alloys and Compounds, 2015, (647): 338-350.

[19] KUTUMARAO V, RAJAGOPALACHARY T. Recent developments in modeling the hot working behavior of metallic materials[J]. Bulletin of Materials Science, 1996, 19(4): 677-698.

[20] REDDY G J, SRINIVASAN N, GOKHALE A A, KASHYAP B P. Processing map for hot working of spray formed and hot isostatically pressed Al-Li alloy (UL40)[J]. Journal of Materials Processing Technology, 2009, 209(18/19): 5964-5972.

[21] LI B, PAN Q L, YIN Z M. Characterization of hot deformation behavior of as-homogenized Al-Cu-Li-Sc-Zr alloy using processing maps[J]. Materials Science and Engineering A, 2014, 614: 199-206.

[22] KAI Xi-zhou, CHEN Cun, SUN Xia-fei, WANG Chun-mei, ZHAO Yu-tao. Hot deformation behavior and optimization of processing parameters of a typical high-strength Al-Mg-Si alloy[J]. Materials & Design, 2016, 90: 1151-1158.

[23] KNIPLING K E, DUNAND D C, SEIDMAN D N. Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during aging at 450–600 ℃[J]. Acta Materialia, 2008, 56(6): 1182-1195.

[24] KNIPLING K E, DUNAND D C, SEIDMAN D N. Precipitation evolution in Al-Zr and Al-Zr-Ti alloys during isothermal aging at 375–425 ℃[J]. Acta Materialia, 2008, 56(1): 114-127.

Hot deformation behavior and processing map of spray formed 7055 aluminum alloy

WANG Xiang-dong1, PAN Qing-lin1, XIONG Shang-wu2, LIU Li-li1, ZHANG Hao3, FAN Xi3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Light Alloys Research Institution, Central South University, Changsha 410083, China;

3. Hao-ran Co. Ltd., Jiangsu, Zhenjiang 212004, China)

Abstract: The hot deformation behavior of spray formed 7055 aluminum alloy was studied by a series of isothermal compression tests at different temperatures ranging from 340 ℃ to 480 ℃ and strain rates varying from 0.001 s-1 to 1 s-1. The results show that the flow stress decreases with increasing temperature and deceasing strain rate, and the instable behaviors occurs at 480 ℃. The main softening mechanisms are dynamic recovery and dynamic recrystallization. The dynamic recovery occurs at low temperature and it turns to dynamic recrystallization as temperature increases. The grain size increases with increasing temperature. Based on dynamic materials model, polar reciprocity model and microstructure evolution, the appropriate processing conditions for this alloy are in the strain rate range of 0.01–0.1 s-1 and deformation temperature range of 400–420 ℃, with power efficiency over 33% and intrinsic workability parameter of 65%–70%, respectively.

Key words: spray formed 7055 aluminum alloy; processing map; dynamic materials model; polar reciprocity model

Foundation item: Project(XXXX-K2008-6) supported by the Special Materials Project of National Large Aircraft Engineering, China

Received date: 2017-04-07; Accepted date: 2017-06-20

Corresponding author: PAN Qing-lin; Tel: +86-731-88830933; E-mail: PQL1964@yeah.net

(编辑 何学锋)

基金项目:国家大飞机工程材料专项(XXXX-K2008-6)

收稿日期:2017-04-07;修订日期:2017-06-20

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail: PQL1964@yeah.net