DOI:10.19476/j.ysxb.1004.0609.2017.04.008

涂碳铝箔在锂硫电池中的应用

李 涛1, 2,洪 波1,曹华伟2,刘业翔1,闫霄林1,黄子欣2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 深圳好电科技有限公司,深圳 518057)

摘 要:利用导电炭黑和导电石墨两款碳材料制作涂碳铝箔,将其作为锂硫电池正极的集流体,考察箔材种类对电极性质和电池性能的影响规律。结果表明:所制作的涂碳铝箔具有“点-面”结合的导电架构,其不仅可以改善硫电极的导电性,而且有利于增强活性物质与集流体的粘结性、抑制电解液对铝箔的腐蚀。涂碳铝箔可以显著降低电池的极化阻抗,维持稳定的充放电平台。相比使用传统铝箔,使用涂碳铝箔的电池的活性物质利用率更高,循环性能更为优异,经0.2C充放电循环40次后,其放电容量达到602 F/g,容量保持率为77.7%。

关键词:锂硫电池;导电碳;涂碳铝箔;集流体;电化学性能

文章编号:1004-0609(2017)-04-0732-07 中图分类号:TM912.9;O646 文献标志码:A

当前,锂离子电池已成为手机、电脑等移动式电子设备的首选电源,并且在电动汽车、可再生能源利用以及智能电网等新兴领域具有广阔的应用前景。但是,受电极材料比容量的限制[1],商品化锂离子电池仍未能突破250 W·h/kg的能量密度瓶颈,难以满足高能量密度的使用需求。而单质硫比容量可达到1675 mA·h/g,将其与金属锂配对构成的锂硫电池,理论比能量更是高达2600 W·h/kg[2],近年来已引起世界范围内的广泛重视。

锂硫电池大多采用表面光滑的铝箔作正极集流体,该箔材对活性物质的粘附力有限,电池接触阻抗较大,部分活性物质在循环期间还可能发生脱落而导致性能衰减。而且这种传统铝箔由于长期与电解液接触而易被腐蚀[3],影响电化学性能的稳定,并引起电池自放电[4]。为此,研究者们尝试将其他一些金属或碳基材料替代传统铝箔,如泡沫镍、泡沫碳、多孔碳纸、活性炭纤维布、碳纳米管等[5-8]。这些集流体在粘附活性物质、抑制电解液腐蚀、改善电池性能等方面具有积极作用,但是要么制作复杂、成本较高,要么难以实现大面积加工成型,且有些材料的导电性相比铝箔存在一定的差距。因此,有必要进一步探寻更为合适且易于制作的集流体材料。

本文作者采用简单易控的表面刮涂技术,将导电炭黑和导电石墨二者混合均匀后,涂覆于传统铝箔上,制作出一种结构特别的涂碳铝箔材料。考察该涂碳铝箔及其所构建电极的剥离强度、电阻率等性质,并与传统铝箔比较,探讨箔材种类对锂硫电池电化学性能的影响。研究结果表明,该涂碳铝箔有助于减少电池极化、提高电池容量、稳定电池性能,且制作简单、使用方便,因此,在锂硫电池中具备良好的应用前景。

1 实验

1.1 涂碳铝箔制作

将导电炭黑(Super P, Timcal)和导电石墨(KS-6, Timcal)按质量比5:1加入去离子水中,并添加一定量的聚丙烯酰胺(Alfa)作粘结助剂,采用高速分散机(DSP)充分混合,制成粘度约150 mPa·s、固含量约10%的导电浆料。利用平板式实验涂布机(DSP),将导电浆料均匀涂覆于表面经过处理的光滑铝箔上,真空干燥12 h后得到涂碳铝箔。

1.2 电极制备与电池组装

将75%(质量分数)的升华硫(Alfa, 99.5%)和25%的导电炭黑在玛瑙研钵中充分混合,制得的粉末倒入密封的不锈钢罐中,置于管式炉中经155 ℃高温处理12 h,紧接着在250 ℃保温2 h,随后自然冷却,得到硫/碳复合材料。

将硫/碳复合材料、导电炭黑SP和聚偏氟乙烯(PVDF, HSV900)按质量比8:1:1在N-甲基吡咯烷酮(NMP, 科密欧)中充分混合,利用实验涂布机,将所得浆料分别涂覆于涂碳铝箔和传统铝箔上。所制得的硫电极片在60 ℃下真空干燥12 h。

在充满氩气的手套箱中,将硫电极片、多孔隔膜(Celgard 2400)和金属锂片以三明治形式层叠,滴加电解液后组装成CR2025扣式电池。电解液组成为1 mol/L的二(三氟甲基磺酰)亚胺锂(LiTFSI, Aldrich)和0.1 mol/L的硝酸锂(LiNO3, Acros)同时溶解于乙二醇二甲醚(DME, Acros)和1,3-二氧戊环(DOL, Alfa)的混合溶剂中(体积比为1:1)。

1.3 理化性质与电化学性能测试

采用数字四探针测试仪(ST2258C)测量铝箔和硫电极的电阻率,每个条件测量3次,取平均值。采用万能材料试验机(Instron5540)测量极片的剥离强度,剥离速率为300 mm/min。采用扫描电镜(SEM, FTSU8010)观察箔材与电极的表/截面形貌。

采用LAND充放电仪(CT2001A)对锂硫电池进行恒流充放电测试,充放电电流为0.2C,电压窗口为1.7~2.8 V。采用电化学工作站(CHI604E)测试电池的循环伏安(CV, 扫描速率0.1 mV/s)和电化学阻抗图谱(EIS, 频率范围0.1 Hz~100 kHz,振幅±5 mV)。

在手套箱中拆解循环后的锂硫电池,取出其中的硫电极用DME溶剂清洗,干燥2h后转移至扫描电镜系统,与未循环的硫电极对比,分析极片循环前后的形貌变化。

2 结果与讨论

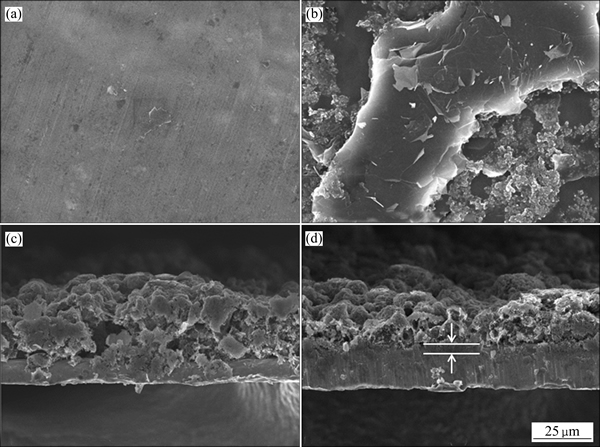

图1(a)和(c)所示分别为传统铝箔的表面形貌和使用传统铝箔的电极截面图。从图1(a)和(c)中可以看到,传统铝箔表面平整光滑,成分单一,使用该箔的电极片仅由活性层和铝箔层两部分构成。而实验制作的涂碳铝箔(见图1(b))表面明显被两类物质覆盖,一类是较大尺寸的片状石墨,另一类是纳米尺寸的炭黑颗粒。片状石墨与球形炭黑均匀分布、紧密接触,构成一种“点-面”结合的导电架构。因此使用涂碳铝箔的电极片除了活性层和铝箔层外,在两者之前还存在一层薄薄的涂碳层(如图1(d)所示)。

图1 传统铝箔和涂碳铝箔的表面和截面形貌

Fig. 1 Surface((a), (b)) and cross section((c), (d)) morphologies of common Al foil((a), (c)) and carbon-coated Al foil((b), (d))

表1所列为采用两款箔材制备的电极片的剥离强度测试结果。表中数据指的是极片单位面积所能承受的压力,表征了二者之间的结合力。对于传统铝箔制作的电极,活性物质从铝箔上分离下来的强度仅0.09 N/cm,说明二者之间的结合力较弱,这是由于传统铝箔表面过于平整、光滑所致。而铝箔表面附上涂碳层后,剥离强度突然增大至3.35 N/cm。涂碳铝箔表面大量的碳材料形成富孔且粗糙的表面构造,这可以增大活性物质与集流体的接触面积,为活性物质的稳定附着提供有利条件,从而改善了活性物质与集流体之间的粘结性。

表1 电极片剥离强度测试结果

Table 1 Adhesion strength of electrode material to foil

表2所列为两款箔材及所制备极片的电阻率。传统铝箔表面在自然条件下会形成氧化铝钝化膜[9],该膜对铝箔的导电性有所影响,因此所测得的电阻率较高,达到28.17 Ω·cm。在铝箔上涂覆硫材料等制成电极后,由于活性物质颗粒之间以及活性物质与铝箔之间产生接触电阻,电阻率进一步增大。与之相比,涂碳铝箔的电阻率骤然下降至5.25 Ω·cm,同时,使用涂碳铝箔制作的电极的电阻率明显低于传统铝箔的。这一方面是由于在涂碳铝箔的制作过程中需要预先采用酸溶液去除铝箔表面氧化膜(削薄铝箔),直接改善铝箔基体的导电性。另一方面涂碳铝箔引入的涂碳层,同样具有良好的导电性、支持电子的快速传递。此外,由表1可知,涂碳层增强了活性物质与集流体之间的结合力,这也有利于减少两者的接触电阻[10]。

表2 箔材和电极片的电阻率测试结果

Table 2 Electrical resistivity of foil and sulfur electrode

将不同箔材构造的电极组装成锂硫电池进行CV测试,其结果如图2所示。电池在扫描过程中出现了两个还原峰和一个氧化峰,其中C1及C2分别代表了单质硫向可溶多硫化物进而向不溶Li2S2/Li2S的转变,A1代表硫化物向氧化态Li2S8或S的转变[11]。与采用传统铝箔的电池相比,使用涂碳铝箔的电池的两个还原峰电位正移,而氧化峰电位负移,说明该电池的极化程度更小、氧化还原可逆性更好,这归因于涂碳铝箔对电极导电性的改善。

图2 锂硫电池使用不同箔材做集流体的循环伏安曲线

Fig. 2 Cyclic voltammograms of Li-S cells using different foils as current collector

图3 传统铝箔和涂碳铝箔锂硫电池的充放电曲线

Fig. 3 Charge-discharge curves of Li-S cell using common Al foil(a) and carbon-coated Al foil(b)

不同箔材制作的锂硫电池的充放电曲线如图3所示。电池放电曲线上的两个放电平台与CV曲线上的两个还原峰对应。随着循环的进行,传统铝箔电池的内部极化在不断增大,导致放电平台逐步下降、充电平台逐步上升,这可能是由于传统铝箔受到电解液腐蚀所致,随着循环的进行,这种腐蚀程度加剧。而涂碳铝箔电池的充放电平台在循环期间基本保持平稳。涂碳层在一定程度上能够对基体铝箔起到保护作用,阻断电解液和铝箔的接触,抑制电解液对铝箔的腐蚀[12],从而提高铝箔乃至整个电池的电化学稳定性。

进一步分析锂硫电池的循环性能(见图4),与传统铝箔电池相比,涂碳铝箔电池在整个循环期间具有更高的放电容量,同时循环稳定性良好,经过40次循环后,电池仍保留602 mA·h/g的容量,容量保持率达到77.7%。涂碳铝箔不仅改善了电极的导电性,而且增强了活性物质与集流体的粘结性(抑制活性物质从电极上脱落),这些因素使得更多的硫材料能够在循环期间持续保持电化学活性,因此活性物质的利用率高。当然,涂碳层能够抑制电解液对铝箔的腐蚀、减少腐蚀引起的电化学极化和性质不稳定等问题,这应该也是电池循环性能得以改善的重要原因。

图4 锂硫电池使用不同箔材做集流体的循环性能

Fig. 4 Cycle performances of Li-S cells using different Al foils as current collector

将不同箔材构成的硫电极循环前后的表面形貌进行观察对比,其结果如图5所示。循环前的传统铝箔电极(见图5(a))为多孔形貌,但是经循环后(见图5(b)),其孔洞空间基本上被一些不溶颗粒物所占据(电极厚度似乎也有所增加),多孔特征不再明显,且形貌看上去不够均一。这主要是由反应产生的Li2S2和Li2S等产物不均匀沉积在电极上所致[13]。而涂碳铝箔电极循环后(见图5(d))仍保留有一定的孔隙结构,整体形貌也较为规整。涂碳铝箔由于对活性物质具有较好的粘附性,有助于减少充放电过程中不溶产物的无序堆积。同时,涂碳铝箔对电极导电性的改善,也有利于电荷快速传递给整个电极,降低了在局部形成非活性区域的可能性[14],因此,不溶产物在电极表面的分布相对更为均匀。

图5 使用传统铝箔和涂碳铝箔硫电极循环前和循环后的表面形貌

Fig. 5 Surface morphologies of sulfur cathode with common Al foil((a), (b)) and carbon-coated Al foil((b), (d)) before((a), (c)) and after((b), (d)) cycles

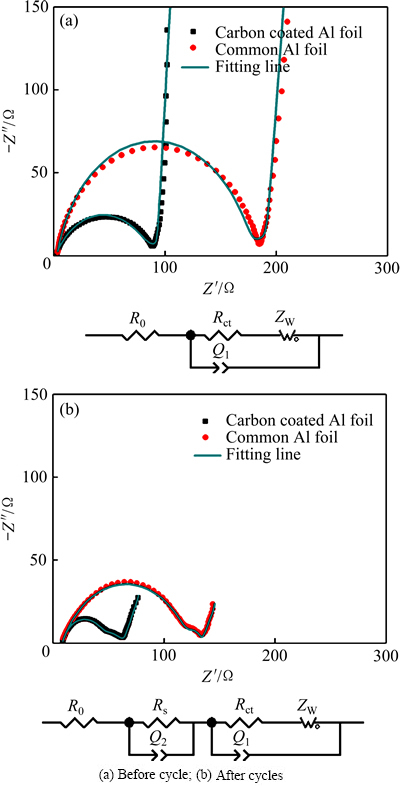

使用不同箔材的锂硫电池的EIS谱见图6。循环前的阻抗图谱由高频区半圆和低频区斜线组成,前者代表电荷转移阻抗(Rct),后者与锂离子在电极中的扩散有关[15]。而循环后的阻抗图谱在高频区新增了一个半圆,其代表了电极/电解液的界面层阻抗(Rs)。表3所列为依据等效电路图拟合得到的阻抗数据。在循环前,涂碳铝箔电池的R0和Rct值均小于传统铝箔电池的,说明导电涂碳层对于减少电极电阻、促进电荷在电极上的转移确实有帮助。电池经循环后Rct明显减小,可能是电解液在电极中的持续浸润增加了活性反应区域,电池内部的电化学环境得到了改善所致[16]。相比传统铝箔,使用涂碳铝箔的电池亦具有相对更低的Rs值,这应该与硫电极表面形貌与状态的改善有关(如图5所示)。

图6 锂硫电池使用不同箔材做集流体的电化学阻抗谱和等效电路图

Fig. 6 Impedance plots and equivalent circuit of Li-S cells using different Al foils as current collector

表3 根据等效电路图拟合得到的阻抗数据

Table 3 Fitted resistances data from equivalent circuit

3 结论

1) 片状石墨与球形炭黑构建的涂炭铝箔具有 “点-面”结合的导电架构。相比传统铝箔,该涂炭铝箔不仅增强硫电极电导,而且提高了活性物质与集流体之间的结合强度。

2) 传统铝箔致使电池极化严重,而涂碳铝箔能够减少极化阻抗,提高氧化还原可逆性,同时改善不溶产物在电极上的分布状态。

3) 锂硫电池使用制作的涂碳铝箔后,活性物质的利用率得到提高,放电容量优于传统铝箔电池,且循环性能稳定,经0.2C循环40次后,电池的容量保持率达到77.7%。

REFERENCES

[1] MANTHIRAM A. Materials challenges and opportunities of lithium ion batteries[J]. The Journal of Physical Chemistry Letters, 2011, 2: 176-184.

[2] LIANG Ji, SUN Zhen-hua, LI Feng, CHENG Hui-ming. Carbon materials for Li-S batteries: Functional evolution and performance improvement[J]. Energy Storage Materials, 2016, 2: 76-106.

[3] KAZAZI M, VAEZI M R, KAZEMZADEH A. Improving the self-discharge behavior of sulfur-polypyrrole cathode material by LiNO3 electrolyte additive[J]. Ionics, 2014, 20(9): 1291-1300.

[4] RYU H S, AHN H J, KIM K W, AHN J H, CHO K K, NAM T H. Self-discharge characteristics of lithium/sulfur batteries using TEGDME liquid electrolyte[J]. Electrochimica Acta, 2006, 52(4): 1563-1566.

[5] CHUNG S H, MANTHIRAM A. Lithium-sulfur batteries with superior cycle stability by employing porous current collectors[J]. Electrochimica Acta, 2013, 107: 569-576.

[6] CHUNG S H, MANTHIRAM A. Nano-cellular carbon current collectors with stable cyclability for Li-S batteries[J]. Journal of Materials Chemistry A, 2013, 1(34): 9590-9596.

[7] CHUNG S H, MANTHIRAM A. Low-cost, porous carbon current collector with high sulfur loading for lithium-sulfur batteries[J]. Electrochemistry Communications, 2014, 38: 91-95.

[8] KIM H, LEE J T, YUSHIN G. High temperature stabilization of lithium-sulfur cells with carbon nanotube current collector[J]. Journal of Power Sources, 2013, 226: 256-265.

[9] 刘 松, 侯宏英, 胡 文, 刘显茜, 段继祥, 孟瑞晋. 锂离子电池集流体的研究进展[J]. 硅酸盐通报, 2015, 34(9): 2562-2568.

LIU Song, HOU Hong-ying, HU Wen, LIU Xian-xi, DUAN Ji-xiang, MENG Rui-jin. Research progress of current collectors for Li-ion batteries[J]. Bulletin of the Chinese Ceramic Society, 2015, 34(9): 2562-2568.

[10] 邓龙征, 吴 锋, 高旭光, 谢海明, 杨智伟. 涂碳铝箔对磷酸铁锂电池性能影响研究[J]. 无机化学学报, 2014, 30(4): 770-778.

DENG Long-zheng, WU Feng, GAO Xu-guang, XIE Hai-ming, YANG Zhi-wei. Effects of coating carbon aluminum foil on the battery performance[J]. Chinese Journal of Inorganic Chemistry, 2014, 30(4): 770-778.

[11] ZHANG K, QIN F, LAI Y, LI J, LEI X, WANG M, LU H, FANG J. Efficient fabrication of hierarchically porous graphene-derived aerogel and its application in lithium sulfur battery[J]. ACS Applied Materials & Interfaces, 2016, 8(9): 6072-6081.

[12] DOBERDO I, LOFFLER N, LASZCZYNSKI N, CERICOLA D, PENAZZI N, BODOARDO S, KIM G T, PASSERINI S. Enabling aqueous binders for lithium battery cathodes-carbon coating of aluminum current collector[J]. Journal of Power Sources, 2014, 248: 1000-1006.

[13] HE Min, YUAN Li-xia, ZHANG Wu-xing, HU Xian-luo, HUANG Yun-hui. Enhanced cyclability for sulfur cathode achieved by a water-soluble binder[J]. The Journal of Physical Chemistry C, 2011, 115(31): 15703-15709.

[14] 刁 岩, 谢 凯, 洪晓斌, 熊仕昭. Li-S电池硫正极性能衰减机理分析及研究现状概述[J]. 化学学报, 2013, 71(4): 508-518.

DIAO Yan, XIE Kai, HONG Xiao-bin, XIONG Shi-zhao. Analysis of the sulfur cathode capacity fading mechanism and review of the latest development for Li-S battery[J]. Acta Chim Sinica, 2013, 71(4): 508-518.

[15] LU Hai, YUAN Yan, HOU Zhen-zhong, LAI Yan-qing, ZHANG Kai, LIU Ye-xiang. Solvate ionic liquid electrolyte with 1,1,2,2-tetrafluoroethyl 2,2,2-trifluoroethyl ether as a support solvent for advanced lithium–sulfur batteries[J]. RSC Advances, 2016, 6: 18186-18190.

[16] LI Qiang, ZHANG Zhi-an, ZHANG Kai, FANG Jing, LAI Yan-qing, LI Jie. A simple synthesis of hollow carbon nanofiber-sulfur composite via mixed-solvent process for lithium-sulfur batteries[J]. Journal of Power Sources, 2014, 256: 137-144.

Application of carbon-coated aluminum foil for Li-S secondary batteries

LI Tao1, 2, HONG Bo1, CAO Hua-wei2, LIU Ye-xiang1, YAN Xiao-lin1, HUANG Zi-xin2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Shenzhen Perfect Power Technology Co., Ltd., Shenzhen 518057, China)

Abstract: The carbon-coated aluminum (Al) foil was prepared by mixing two conductive carbon materials (carbon black+graphite) and studied as a current collector of Li-S battery. The effects of foil type on the electrode properties and cell performance were investigated. The results show that the carbon-coated Al foil possesses a point-surface combined conductive framework between active material layer and Al foil layer, which not only improves the conductivity of the sulfur electrode, but also enhances the adhesion of active material to current collector and inhibits the corrosion of the electrolyte to Al substrate. When using carbon-coated Al foil, the cell polarization is significantly reduced and stable charge-discharge platform is maintained. Compared to common Al foil, the carbon-coated Al foil favors more utilization of active material and more excellent cycle performance. The retained capacity reaches 602 F/g and capacity retention is 77.7% for the cell loading carbon-coated Al foil after 40 cycles at rate of 0.2C.

Key words: lithium sulfur battery; carbon-coated aluminum foil; current collector; electrochemical performance

Foundation item: Project(51474243) supported by the National Natural Science Foundation of China; Project (JCYJ20120618164543322) supported by Shenzhen Strategic Emerging Industry Development Special Funds, China

Received date: 2016-10-12; Accepted date: 2017-03-17

Corresponding author: HONG Bo; Tel: +86-731-88830474; E-mail: bop_hong@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51474243);深圳市战略性新兴产业发展专项资金(JCYJ20120618164543322)

收稿日期:2016-10-12;修订日期:2017-03-17

通信作者:洪 波,博士;电话:0731-88830474;E-mail: bop_hong@163.com