文章编号:1004-0609(2008)12-2158-08

GH742y合金凝固偏析行为

潘晓林1, 2,孙文儒2,杨树林2,郭守仁2,李 战3,杨洪才1,胡壮麒2

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 中国科学院 金属研究所,沈阳 110016;

3. 沈阳理工大学 机械工程学院,沈阳 110168)

摘 要:采用组织分析和差热分析相结合的方法系统研究GH742y合金的凝固偏析行为和铸态组织形成规律。GH742y合金枝晶偏析严重,组织析出复杂:Cr、Co、W、V和Al偏析于枝晶干,而Nb、Ti和Mo等元素在枝晶间的富集导致一次和二次γ′相、(γ+ γ′)共晶、MC碳化物、M6C碳化物、Laves相和δ相的析出;稀土元素La和Ce的偏析导致Ni5Ce相和富氧硫稀土相的枝晶间析出。相分计算表明,严重的元素偏析以及大量富Nb和Ti相的析出是σ相和μ相等有害TCP相析出的主要原因。GH742y合金的凝固顺序为:γ基体、MC碳化物、一次γ′相、(γ+ γ′)共晶、Laves相、Ni5Ce相和M6C碳化物。

关键词:镍基高温合金;偏析;铸态组织;凝固

中图分类号:TG 132.3 文献标识码: A

Solidification and segregation behavior of GH742y alloy

PAN Xiao-lin1, 2, SUN Wen-ru2, YANG Shu-lin2, GUO Shou-ren2, LI Zhan3, YANG Hong-cai1, HU Zhuang-qi2

(1. School of Material & Metallurgy, Northeastern University, Shenyang 110004, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

3. School of Mechanical Engineering, Shenyang University of Science and Technology, Shenyang 110168, China)

Abstract: The solidification, segregation and microstructure of GH742y alloy were systematically investigated by microstructure characterization and differential thermal analysis. The as-cast GH742y alloy exhibits severe dendritic segregation and complicated precipitation. Cr, Co, W, V and Al are segregated to the dendritic arm. The primary and secondary γ′ phases, (γ+ γ′) eutectic, MC carbide, M6C carbide, Laves phase and δ phase are precipitated due to the enrichment of Nb, Ti and Mo in the interdendritic region. The Ni5Ce phase and RE-O-S phase are precipitated in the interdendritic region due to the segregation of La and Ce. The phase calculation indicates that the severe segregation and precipitates containing Nb and Ti are the main reasons for the precipitation of TCP phases such as σ phase and μ phase. The solidification sequence of GH742y alloy is as follows: γ matrix, MC carbide, primary γ′, (γ+ γ′) eutectic, Laves phase, Ni5Ce phase and M6C carbide.

Key words: Ni-base superalloy; segregation; as-cast microstructure; solidification

GH742y合金是在GH742合金基础上提高Al、Ti、Nb和W等元素的含量水平发展而成的一种先进镍基高温合金。根据化学成分计算[1],GH742y合金中γ′-Ni3(Al, Ti, Nb)强化相的数量达到45%以上,再加上Co、Cr、W、Mo和V等元素的固溶强化以及B、La、Ce和Mg等元素的晶界强化,使其具有很高的强度、 良好的组织稳定性和优异的使用性能,最高工作温度可达800~850 ℃,在一些先进军用和民用发动机中用于制造涡轮盘等关键部件[2]。

由于元素种类的不断增多以及许多微量元素的加入,导致镍基高温合金凝固过程中产生了严重的枝晶偏析,并析出了大量的有害相,严重影响合金的加工和服役行为[3?7]。GH742y合金的合金化程度高,元素偏析倾向大,加工困难,并且由于La和Ce等元素的加入使合金的凝固偏析行为更加复杂。然而有关其凝固过程和铸态组织的报道很少,有待全面和深入研究[8?9]。为了更好地控制GH742y合金的加工工艺和组织性能,满足更高水平的服役要求,本文作者系统研究了GH742y合金的元素偏析、枝晶组织及其凝固过程。

1 实验

采用真空感应炉熔炼GH742y合金10 kg铸锭,配料成分(质量分数,%)为:C 0.06、Cr 11.00、Co 14.25、W 2.50、Mo 4.50、Al 3.05、Ti 2.70、Nb 2.75、V 0.60、B 0.005、La 0.05、Ce 0.01、Mg 0.05和Ni 余量。

综合分析铸锭自心部至边缘枝晶组织、相析出和元素分布情况,并结合差热分析研究合金的凝固行为。差热分析样品尺寸为d 3 mm×3 mm,以10 ℃/min的速度加热到1 450 ℃并保温3 min,然后以10 ℃/min的速度冷却,升温和降温过程中充氩气保护。

利用金相显微镜(OM)和扫描电镜(SEM)观察组织形貌,用电子探针(EPMA)和X射线能谱分析(EDS)确定枝晶偏析和析出相成分,用X射线衍射(XRD)和透射电镜(TEM)对析出相进行种类分析和形貌观察。

2 结果与分析

2.1 铸态组织分析

GH742y合金的低倍铸态组织如图1(a)所示,呈明显的枝晶结构。由图1(b)可以看出,灰白色区域(Ⅰ区)为枝晶干,黑色区域(Ⅱ区)和其中的白亮区域(Ⅲ区)为枝晶间。枝晶组织很发达,枝晶间面积很大,局部还析出了大量的第二相(图1(b)),说明铸锭枝晶偏析严重。

图1 铸态GH742y合金枝晶组织及稀土元素的分布

Fig.1 Dendritic microstructures of as-cast GH742y alloy: (a) At lower magnification; (b) At higher magnification; (c) La map corresponding to (b); (d) Ce map corresponding to (b)

GH742y合金中Al、Ti和Nb总含量达到了8.5%,凝固过程中形成过饱和固溶体,所以在冷却过程中析出大量γ′相。图2(a)所示为枝晶干处从γ基体中固态析出的γ′相,主要为球形,平均尺寸为0.15 μm;图2(b)所示为枝晶间处固态析出的γ′相,主要为十字花形,平均尺寸为0.35 μm。由于枝晶间Al、Ti和Nb含量比枝晶干高得多,导致枝晶间处γ′相的尺寸比枝晶干处大得多,形状也复杂得多。

图2 铸态GH742y合金析出相形貌

Fig.2 SEM micrographs of precipitates in as-cast GH742y alloy: (a) γ′ phase at dendrite arm; (b) γ′ phase at interdendritic region; (c) (γ+γ′) eutectic at periphery of ingot; (d) (γ+ γ′) eutectic at center of ingot; (e) Laves phase, M6C carbide and Ni5Ce phase; (f) MC carbide and RE-O-S phase

由于合金铸锭不同部位凝固速度和元素偏析不同,枝晶间(γ+γ′)共晶的析出也表现出明显的差异。铸锭边缘处共晶形貌如图2(c)所示,密集的γ′相析出带之间存在较宽的γ相区。靠近铸锭心部区域的共晶形貌如图2(d)所示,呈典型的葵花状,相排列非常紧密,边缘为大块的椭圆形γ′相,内部为规则的网格型γ-γ′组织。以往文献均把葵花状共晶的两部分作为一个整体,但最新的研究结果表明[10],由于共晶边缘γ′的尺寸和形貌跟内部完全不同,并且共晶边缘γ′按照一定的方向向γ基体生长,说明共晶边缘和内部在凝固过程中发生了不同的反应,边缘为包晶反应L+γ→γ′生成的γ′相,内部为共晶反应L→(γ+γ′)生成的(γ+γ′)共晶。从图3可以看出,葵花状共晶的周围还分布着少量大块的γ′相,这种γ′相为椭圆形,尺寸达到了1~2 μm,其形貌和大小均与枝晶内固态析出的γ′相截然不同,却与共晶边缘的γ′相相同,说明这种γ′相也是包晶反应的产物。

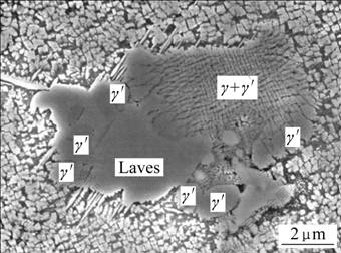

图3 铸态GH742y合金典型凝固组织

Fig.3 Typical solidification microstruture of as-cast GH742y alloy

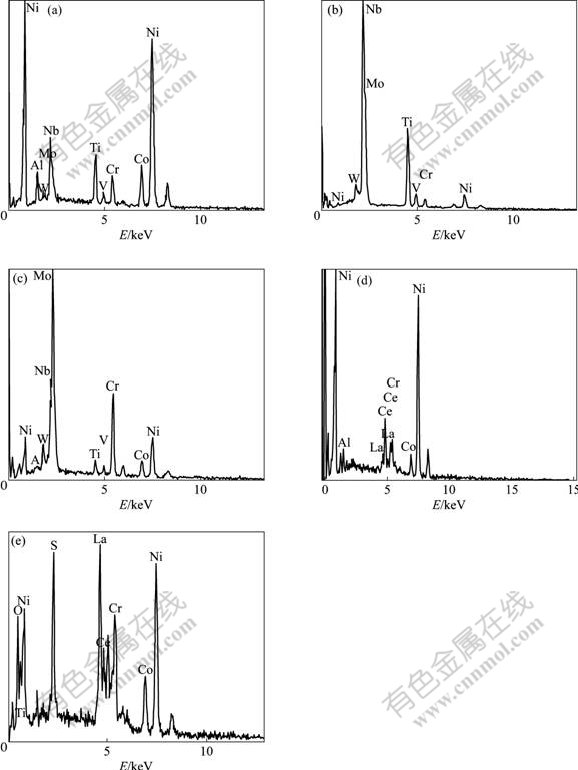

在枝晶间Ⅲ区析出了较多大块状相,形貌如图2(e)所示,尺寸达到几十个μm。该相含有大量的Ni、Co、Nb、Ti等元素(图4(a)),其中Nb和Ti含量要远远高于其在合金的平均成分。图5(a)所示为该相在透

射电镜下的形貌及[001]晶带衍射花样,为Laves相。

图4 铸态GH742y合金析出相能谱

Fig.4 EDX spectras of precipitates in as-cast GH742y alloy: (a) Laves phase; (b) MC carbide; (c) M6C carbide; (d) Ni5Ce phase; (e) RE-O-S phase

图5 铸态GH742y合金析出相TEM形貌及其选区衍射花样

Fig.5 TEM micrographs of precipitates in as-cast GH742y alloy and corresponding selected area diffraction patterns: (a) Laves phase and [001]; (b) MC carbide and [110]; (c) δ phase and [542]; (d) σ phase and [31 0]; (e) μ phase and [ ?342]

?342]

在枝晶间Ⅱ区聚集分布着尺寸较大、棱角分明的块状碳化物相,如图2(f)所示。该相主要由Nb和Ti组成,同时含有少量的Mo、W、V和Cr等元素(图4(b))。该碳化物在透射电镜下的形貌及[110]晶带衍射花样如图5(b)所示,为MC型碳化物。X射线衍射分析表明,铸态GH742y合金的碳化物主要为MC型。但是,在大块的Laves相周围发现另一种类型的碳化物,其析出量比较少,背散射电子像比较亮,如图2(e)所示。该碳化物的成分与MC型碳化物差别很大,含有大量的Mo,还有一定量的Nb、Cr、Ni和W等元素(图4(c)),根据其成分推断,该碳化物为M6C型碳化物。

图1(c)和(d)所示为稀土元素La和Ce在图1(b)中的电子探针面扫描分布。由图可知,La和Ce强烈地偏聚于枝晶间,并且主要以块状析出相的形式存在。这些稀土相一般分布在大块Laves相周围,如图2(e)所示,主要由Ni和Ce组成(图4(d))。由于X射线衍射分析显示,合金中存在Ni5Ce相,因此由成分可以断定此相即为Ni5Ce相。在MC碳化物附近也可以发现少量稀土相,如图2(f)所示。该稀土相中含有大量的O和S等非金属元素(图4(e))。由于稀土元素与O和S等元素生成自由能低,其加入可以大大降低合金中O和S等杂质的含量,改善夹杂物的形貌和分布,达到洁净合金的作用[11]。

透射电镜相分析表明,铸态组织中还存在固态析出的δ相(Ni3Nb)、σ相和μ相等有害拓扑密排相(TCP)。图5(c)所示为δ相的形貌及其[5 4 2]晶带衍射花样。δ相在合金中的含量比较少,主要呈长条状在共晶周围析出;σ相、μ相也在枝晶间析出,σ相呈光滑平直的棒状,而μ相则为表面粗糙的条状,二者形貌及其相应的晶带衍射花样分别见图5(d)和5(e)。由于枝晶间大量富Al、Ti和Nb相的析出,使得γ基体中σ相、μ相形成元素Cr、Co、W和Mo相对含量大大提高,从而导致σ相和μ相的析出。

2.2 元素偏析分析

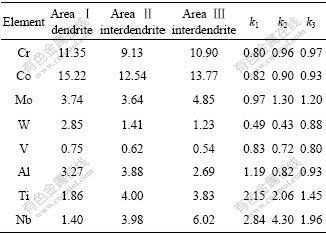

为了确定合金枝晶中元素的偏析程度,用电子探针测定了枝晶干Ⅰ区、枝晶间Ⅱ区和Ⅲ区中元素的含量,并计算了元素偏析系数k,结果见表1,其中k1、k2和k3分别为元素在枝晶间Ⅱ区、Ⅲ区、合金成分与枝晶干Ⅰ区成分的比值。比较k1与k2可以看出,在枝晶间,Al在Ⅱ区富集,Mo在Ⅲ区富集,其它元素Cr、Co、W、V、Ti和Nb在Ⅱ区和Ⅲ区的偏析趋向相同,Cr、Co、W和V贫化,Nb和Ti富集,其中枝晶间Ⅲ区Nb的偏析比Ⅱ区大得多,说明Ⅲ区的元素偏析程度比Ⅱ区更严重。同时可以看出,k2与k3反映的元素偏析趋向是相同的,仅数值不同,因此选用k2来表征GH742y合金元素的偏析程度。元素Cr、Co、W、V和Al的k值小于1,偏聚于枝晶干,为负偏析元素;元素Nb、Ti和Mo的k值大于1,偏聚于枝晶间,为正偏析元素。其中,W和Ti偏析较为严重,Nb的偏析最严重,偏析系数达到了4.30。

表1 元素在铸态GH742y合金枝晶干和枝晶间的分布

Table 1 Distribution of elements in dendritic and interdendritic regions of as-cast GH742y alloy (mass fraction, %)

2.3 凝固过程分析

图6所示为GH742y合金冷却过程中的DTA曲线,曲线上存在4个比较明显的放热峰,分别标记为A、B、C和D。组织分析结果表明,DTA试样的凝固组织主要由γ基体、γ′相、MC碳化物和少量Laves相组成。根据Ni基高温合金的凝固规律[12],A峰为γ奥氏体的形成峰,开始温度为1 348 ℃,其对应的反应为:L→γ。B放热峰较宽,为MC碳化物形成的共晶反应:L→(γ+MC),其开始反应温度为1 288 ℃。C峰温度在1 197~1 167 ℃之间,自C峰后曲线趋于平缓,之后又开始回升,说明C峰是合金最后凝固时的反应,由于DTA试样冷却速度比较快,凝固组织中没有(γ+ γ′)共晶的析出,却可以发现一些Laves相,所以C峰应为Laves相的析出峰。合金凝固之后,当温度降低到γ′相的形成温度时,便固态析出了γ′强化相。DTA曲线上的D峰即为γ′相析出的放热峰,该峰非常宽,从1 108 ℃一直持续到980 ℃,这说明了γ′相析出是一个比较缓慢的过程。

图6 铸态GH742y合金冷却过程的DTA曲线

Fig.6 DTA curve of as-cast GH742y alloy during cooling process

由于GH742y合金铸锭尺寸较DTA试样大得多,凝固速度比较慢,元素偏析严重,所以其凝固组织要复杂得多,除了固态析出γ′相、MC碳化物和Laves相外,还出现了一次析出γ′相、(γ+γ′)共晶、δ相、σ相、μ相、M6C碳化物及Ni5Ce相等。从图3可以看出,Laves相和(γ+γ′)共晶镶嵌在一次析出γ′相之中,说明Laves相和(γ+γ′)共晶的析出均在一次γ′相析出之后。(γ+γ′)共晶分布在靠近枝晶干的区域,而Laves相分布在枝晶间的区域的中心,说明(γ+γ′)共晶是先于Laves相析出的。Ni5Ce相和M6C碳化物在Laves相形成之后析出,因为从其分布来看,这两相均分布在Laves相的周围;从其成分来看,稀土元素几乎不溶于任何相中,在Laves相形成之后只能以一种单独的相存在,而Mo元素是在枝晶间富集的,但在形成的Laves相中含Mo却较少,Laves相的析出使得剩余液体中的Mo大量富集,从而与液体中剩余的少量C形成M6C碳化物。Ni5Ce相和M6C碳化物这些最后凝固的相分布在Laves相周围,而没有分布在(γ+γ′)共晶周围,也说明了(γ+γ′)共晶是在Laves相之前析出的。对于富氧硫稀土相,从其析出位置判断,可能在MC碳化物析出温度附近析出,但由于其数量极少,尚需进一步确定。而δ相、σ相、μ相以及大量的二次析出γ′相则是在合金凝固后从γ固溶体中析出的。

综上所述,GH742y合金的凝固过程为:当γ枝晶首先从液相析出后,由于Nb、Ti和Mo等元素在固液界面前沿富集,随即发生析出γ相和MC碳化物的共晶反应;随着反应的进行,Nb和Ti进一步富集,继而以包晶反应的方式析出一次γ′相;随后发生共晶反应而析出(γ+γ′)共晶;由于Nb和Ti等元素仍然在枝晶间大量富集,从而促使Laves相的析出;最后,由于稀土元素不溶于Laves相,因此在Laves相周围形成了Ni5Ce相,同时剩余的Mo与少量的C形成M6C碳化物,从而结束了合金的凝固。

3 讨论

相分计算[13]是预测合金中是否出现TCP相的一种重要方法,一般来说,镍基变形高温合金的平均电子空位数大于2.45~2.50就可能产生σ相;对于铸造合金,只要平均电子空位数大于2.32就有可能析出σ相,而产生μ相的平均电子空位数比σ相还要低。另外,由于铸态合金中许多微量元素和杂质元素均在枝晶间偏聚,它们的存在可以促进TCP相的析出,所以实际合金中产生σ相和μ相的电子空位数比上述值还要小。

根据GH742y合金成分计算的电子空位数为1.96,这个值要小于镍基高温合金析出σ相和μ相的临界电子空位数。但是,由于合金铸锭存在严重的枝晶偏析,枝晶干Ⅰ区、枝晶间Ⅱ区和Ⅲ区的平均电子空位数计算值分别为1.87、2.15和2.30,可以看出,枝晶间的电子空位数较枝晶干的大得多;再考虑到局部的成分波动,严重偏析区域的电子空位数已超过了σ相和μ相形成的临界电子空位数,从而在枝晶间析出了σ相和μ相。因此,相分计算对于预测铸态GH742y合金TCP相的析出仍然是适用的,但必须考虑元素偏析,其电子空位数应按照合金偏析最严重区域的成分进行计算。

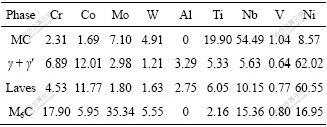

Nb是变形高温合金中非常重要的强化元素,它可同时进入γ固溶体、γ′相和初生MC碳化物[14]。在铸态GH742y合金中,Nb也是偏析最严重的元素,它大量偏析于枝晶间,而且枝晶间很多有害相的存在都与Nb的偏析密切相关。表2所列为枝晶间主要沉淀相的化学成分。从表中可以看出,在MC碳化物、Laves相、M6C碳化物以及(γ+γ′)共晶中均含有大量的Nb,它几乎进入枝晶间所有的相中,因此Nb显著影响GH742y合金的凝固过程。

表2 铸态GH742y合金枝晶间主要析出相化学成分

Table 2 Compositions of main precipitates of as-cast GH742y alloy in interdendritic region (mass fraction, %)

利用热力学平衡相计算对GH169合金和GH706合金中的Nb在液相中的偏析规律进行分析,结果表明[15],Nb在合金中的偏析程度与液固相间的温度差有单调增加的关系,凝固温度区间越宽,Nb的偏析越严重。由DTA分析可知,GH742y合金的初凝温度为1 348 ℃,终凝温度为1 167 ℃,凝固温度区间较宽,终凝温度较低,导致合金中Nb的偏析非常严重。事实上,由于铸锭边缘的凝固速度较快,Nb在边缘的偏析程度比在心部的小得多,凝固组织只有γ基体、γ′相、(γ+γ′)共晶、MC型碳化物等相。由此可见,凝固速度对合金的元素偏析和凝固组织影响很大,加快铸锭的凝固速度,提高合金的终凝温度,可以减轻元素的偏析程度,减少有害相的析出,从而获得良好的铸态组织。

由于GH742y合金的高合金化和添加了大量微量元素导致铸锭偏析十分严重,凝固组织非常复杂,生成了大量的非平衡相,如(γ+γ′)共晶、Laves相、σ相、μ相、δ相、M6C碳化物和Ni5Ce相等,再加上棱角分明聚集分布的大块MC碳化物,这些相都具有热脆性,很容易在热加工过程中形成裂纹源,并且成为裂纹迅速扩展的通道,所以在热加工之前,必须经过高温扩散退火,消除或者改变这些有害脆性相,减轻甚至消除元素偏析,以提高合金的热加工塑性。

4 结论

1) 铸态GH742y合金存在严重的枝晶偏析,Cr、Co、W、V和Al偏析于枝晶干,Nb、Ti和Mo偏析于枝晶间。Nb偏析最严重,W和Ti次之。

2)铸态GH742y合金枝晶干γ基体中析出了大量的γ′相,枝晶间相析出非常复杂,包括一次和二次析出γ′相、MC碳化物、(γ+ γ′)共晶、Laves相、σ相、μ相、δ相、M6C碳化物及Ni5Ce相等。

3) 铸态GH742y合金凝固温度区间为1 348~ 1 167 ℃,各析出相的凝固顺序为γ基体、MC碳化物、一次γ′相、(γ+γ′)共晶、Laves相、Ni5Ce相和M6C碳化物。

REFERENCES

[1] 杨洪才. 沉淀强化镍基高温合金中γ′相数量的计算表达式[J]. 金属学报, 1982, 18(4): 510?514.

YANG Hong-cai. A formula for γ′-phase amounting in precipitation hardening nickel-base superalloys[J]. Acta Metallurgica Sinica, 1982, 18(4): 510?514.

[2] 黄福祥. 涡轮盘用变形高温合金在俄国的发展[J]. 航空材料学报, 1993, 13(3): 49?56.

HUANG Fu-xiang. Development of turbine disk superalloys in Russia[J]. Journal of Aeronautical Materials, 1993, 13(3): 49?56.

[3] ZHU Y X, ZHANG S N, ZHANG T X, ZHANG J H, HU Z Q, XIE X S, SHI C X. A new way to improve the superalloy[C]// Superalloys 1992. New York: The Minerals, Metals & Materials Society, 1992: 145?154.

[4] SUN W R, GUO S R, LU D Z, HU Z Q. Effect of sulfur on the solidification and segregation in Inconel 718 alloy[J]. Materials Letters, 1997, 31(6): 195?200.

[5] WANG A C, LI Y Y, FAN C G, YANG K, LI D F, ZHAO X, SHI C X. Effect of P and Si(Mn) on the solidification segregation in an iron-based superalloy[J]. Scripta Metallurgica et Materialia, 1994, 31(12): 1695?1700.

[6] 郑 亮, 谷臣清, 郑运荣. Ru对铸造镍基高温合金凝固行为的影响[J]. 中国有色金属学报, 2002, 12(6): 1199?1204.

ZHENG Liang, GU Chen-qing, ZHENG Yun-rong. Effect of Ru addition on solidification behavior of cast nickel base superalloy [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1199?1204.

[7] ZHENG L, GU C Q, ZHENG Y R. Investigation of the solidification behavior of a new Ru-containing cast Ni-base superalloy with high W content[J]. Scripta Materialia, 2004, 50: 435?439.

[8] 吴贵林, 王林涛, 赵长虹, 董 健, 金槿秀, 田树森, 庄景云, 邓 群, 杜金辉. GH742Y合金真空自耗锭的偏析及均匀化处理[J]. 钢铁研究学报, 2003, 15(7): 366?371.

WU Gui-lin, WANG Lin-tao, ZHAO Chang-hong, DONG Jian, JIN Jin-xiu, TIAN Shu-sen, ZHUANG Jing-yun, DENG Qun, DU Jin-hui. Segregation and homogenization treatment of GH742Y alloy VAR ingot[J]. Journal of Iron and Steel Research, 2003, 15(7): 366?371.

[9] 邓 群, 杜金辉, 庄景云, 曲敬龙, 赵长虹, 吴贵林, 王照坤. GH742y合金的铸态组织及铸态偏析的改善[J]. 钢铁研究学报, 2007, 19(5): 89?93.

DENG Qun, DU Jin-hui, ZHUANG Jing-yun, QU Jing-long, ZHAO Chang-hong, WU Gui-lin, WANG Zhao-kun. As-cast microstructure and segregation improvement of alloy GH742y[J]. Journal of Iron and Steel Research, 2007, 19(5): 89?93.

[10] D’SOUZA N, DONG H B. Solidification path in third-generation Ni-based superalloys, with an emphasis on last stage solidification[J]. Scripta Materialia, 2007, 56(1): 41?44.

[11] LI D, COSANDEY F, MAURER G E, FOOTE R, TIEN J K. Understanding the role of cerium during VIM refining of nickel-chromium and nickel-iron alloys[J]. Metallurgical Transactions B, 1982, 13(12): 603?611.

[12] SPONSELLER D L. Differential thermal analysis of nickel-base superalloys[C]// Superalloys 1996. New York: The Minerals, Metals & Materials Society, 1996: 259?270.

[13] 郭可信. 高合金钢与高温合金中的相[J]. 金属学报, 1978, 14(1): 73?95.

GUO Ke-xin. Phases in high alloy steels and superalloys[J]. Acta Metallurgica Sinica, 1978, 14(1): 73?95.

[14] ZHAO K, LOU L H, MA Y H, HU Z Q. Effect of minor niobium addition on microstructure of a nickel-base directionally solidified superalloy[J]. Materials Science and Engineering A, 2008, 476(1/2): 372?377.

[15] 董建新, 张麦仓, 曾燕屏. 含铌高温合金液相中铌偏聚行为[J]. 北京科技大学学报, 2005, 27(2): 197?201.

DONG Jian-xin, ZHANG Mai-cang, ZENG Yan-ping. Calculation of Nb segregation behavior in liquid phase for Nb-rich superalloys[J]. Journal of University of Science and Technology Beijing, 2005, 27(2): 197?201

收稿日期:2008-04-11;修订日期:2008-08-29

通讯作者:孙文儒,研究员;电话:024-23971737;E-mail: wrsun@imr.ac.cn

(编辑 陈爱华)