含Ta低Cr高W铸造镍基高温合金中α相的形成与转变

郑 亮

(北京航空材料研究院 先进高温结构材料国防科技重点实验室, 北京 100095)

摘 要: 研究了不同含Ta量低Cr高W铸造镍基高温合金的铸态和1100℃保温500h、 1280℃保温20min~3h热处理后的显微组织以及1100℃, 118MPa条件下的持久性能。 结果表明: 低Cr高W铸造镍基高温合金中添加元素Ta会使共晶γ′相的数量显著增加。 当(Ti+Nb)含量恒定在2.1%(摩尔分数), (Ta+Al)含量达14.4%(摩尔分数)时, 合金凝固后期将形成α(W, Mo) +γ′共晶; 少量α 相不会明显降低合金的持久性能, 但α 相在高于1260℃下固溶处理或在1100℃长时热暴露时是不稳定的, 它会溶解或转变成块状M6C, 从而损伤合金的高温持久性能; Ta是一种有利于提高高温合金高温强度的元素, 但Ta含量应与合金中的Al含量相适应, 须按等摩尔分数原则相互替换; 具有Ni-10Co-1.5Cr-16W-2Mo-1Nb-5Al-4Ta成分的合金性能最佳。

关键词: 镍基高温合金; α 相; 钽; M6C碳化物; 显微组织; 相变 中图分类号: TG132.3; TG113

文献标识码: A

Formation and transformation of α phase in Ta-containing low Cr and high W content cast Ni-base superalloys

ZHENG Liang

(National Key Laboratory of Advanced High Temperature Structural Materials,Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The microstructures of as-cast and specimens heat-treated at 1100℃ for 500h or 1280℃ for 2min-3h and stress ruptured properties at 1100℃, 118MPa for four heats of low Cr and high W content cast Ni-base superalloys were investigated. The results indicate that the addition of element Ta increases the amount of eutectic γ′. (α+γ′) eutectic forms in the later stage of solidification as the amount of Nb and Ti maintains at 2.1%, Ta and Al reaches or exceeds 14.4%(mole fraction). Small amount of α phase does not decrease the stress rupture life obviously. However, α phase is unstable during the period of solid solution heat treatment at 1260℃ or thermal exposure at 1100℃ because of its solid solution or transformation to blocky M6C carbides which result in a deterioration of the stress rupture properties of alloys at elevated temperature. Although tantalum is a beneficial element for increasing the high temperature strength of superalloys, its content should be matched with the suitable Al content. Therefore, the substitution of Ta for Al should follow the principle of equal atomic fraction. The alloy with the composition of Ni-10Co-1.5Cr-16W-2Mo-1Nb-5Al-4Ta possesses the optimum properties.

Key words: Ni-base superalloys; α phase; tantalum; M6C carbides; microstructure; phase transformations

低Cr高W铸造镍基高温合金是一种低成本高承温能力合金, 其等轴晶状态下1100℃的高温持久强度接近第一代单晶高温合金水平, 是燃气涡轮导向叶片和高温模具的候选材料[1]。 但是, 此类合金高温抗氧化能力较差, 应通过合金化途径加以改善。 合金元素Ta被认为是提高合金高温蠕变抗力和抗氧化能力的有效元素[2-6], 早期研制出的一些合金如B-1900和TRW-NASA Ⅵ含Ta量在3%~9%(质量分数)[7, 8]。 近期研发出来的单晶高温合金含Ta量提高至4%~12%(质量分数)[9-11], 由于Ta在合金中的重要作用, 冶金工作者对Ta在合金中的强化作用及其对显微组织及稳定性的影响进行了大量的研究工作[12-14]。 本文作者研究添加Ta的低Cr高W合金时发现当Al、 Ta含量配合不当时, 会在合金凝固后期析出α +γ′共晶, 进而影响合金的组织稳定性和高温持久性能。 本文旨在探明Ta对合金中α相的形成及转变的影响。

1 实验

用真空感应熔炼法制备了4炉不同含Ta量的低Cr高W合金, 其分析成分列于表1。 合金用壳模铸造的方法铸成等轴晶成形试棒, 铸态试棒在1100℃, 118MPa条件下测持久寿命, 各炉试样在1100℃温度下保温500h和1280℃保温20min~3h, 铸态和热暴露后的试样用光学金相、 扫描电镜、 能谱和X射线衍射法确定存在相的种类及成分。 合金中相的萃取采用标准10mL HCl+90mL甲醇+1g酒石酸溶液在3~5V电压下电解约2h。 萃取产物用D8 Advance型X射线衍射仪进行相鉴定。

2 分析与讨论

2.1 α相的形成

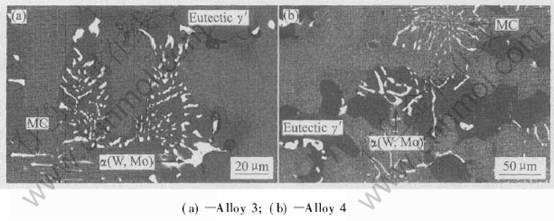

4炉合金铸态下的显微组织如图1所示。 可以看出, 所有合金都是在γ基体上沉淀析出γ′相, 在枝晶间区还存在MC碳化物和(γ+γ′)共晶, 在凝固冷却过程中γ相回溶到γ′相中形成了没有γ相的“光板”共晶γ′相。 此外, 在组织中还偶然可以观察到M3B2相和M6C相。 在3号合金和4号合金的共晶γ′相内部还有条状和小块状相(图1(c)、 (d))。 在扫描电镜背散射图像中, 该相最亮(图2), 反映出该相的平均原子量最高, 其成分列于表2。 由表2可以看出该相主要由W、 Mo组成, 是α(W, Mo)固溶体。 在0.49N负载下, α相的平均维氏显微硬度为4.52GPa。 用10%盐酸+90%甲醇溶液电解溶解掉γ+γ′基体后萃取了3号合金中的微量相, 萃取残留物的X射线衍射结果示于图3。 可见合金微量相中除了MC、 M6C碳化物和M3B2硼化物外, 还存在α(W, Mo)相。

在所研究的4炉合金中, 主要是Al、 Ta含量变化, 其他元素基本不变。 可以看出, α(W, Mo)相的出现与合金中Al、 Ta含量和共晶γ′相数量有关。 在枝晶间距为60~70μm时, 1号合金和2号合金的共晶γ′相数量都在7%(体积分数)左右。 出现α(W, Mo)相的3号合金和4号合金的Al、 Ta含量超过14.4%(摩尔分数), 共晶γ′超过20%(体积分数)(表3)。 4号合金中的Al+Ta含量高于3号合金, 但由于4号合金中W含量较3号合金低, 因而析出的α(W, Mo)相较少。

在高W铸造镍基合金中, 当W含量超过了溶解度极限时, 通常会以树枝晶的形式在合金凝固过程中最先形成, 凝固后γ枝晶干和枝晶间部位均分布有α相[1]。 而在本研究中, α(W, Mo)相处于γ枝晶间的共晶γ′内部, 表明它是在凝固后期形成的。 由于元素Ta和Al是很强的正偏析元素, 又是强γ′形成元素, 在凝固后期的残余液体很快接近γ+γ′共晶成分, 发生L→γ+γ′共晶反应。 因为W和Mo在共晶γ′中的溶解度远比它们在合金中的平均成分低27%~43%(见表4、 表1)和过量的Al+Ta

表1 合金的化学成分

Table 1 Chemical compositions of alloys

图1 铸态合金的显微组织

Fig.1 Microstructures of as-cast alloys

图2 铸态合金的扫描电镜背散射像

Fig.2 BSEI micrographs of as-cast alloys

表2 α(W, Mo)相的能谱成分分析结果

Table 2 Composition of α(W, Mo) phase by EDX analysis (mole fraction, %)

含量促进过量共晶γ′相形成(表3中3号合金和4号合金), 所以剩余液相中的W+Mo浓度显著升高, 含有过饱和W+Mo的残留液体发生L→α(W, Mo)+γ′共晶反应, 在部分大块共晶γ′相内形成

图3 3号合金铸态下萃取微量相的X射线衍射谱

Fig.3 XRD pattern of extracted minor phases in as-cast alloy 3

表3 合金中Al+Ta含量、共晶γ′相数量与α(W, Mo)相数量的关系

Table 3 Relationship between amount of (Al+Ta), eutectic γ′ and α(W, Mo) for different alloys

条状α(W, Mo)相, 这也是为什么只有部分共晶γ′相内部存在α相的原因(见图1(c)、 (d)和图2)。 以往的研究工作证明, 在Ni-Al-W和Ni-Al-Mo系中, 加Ta和Nb可以促进α+γ′共晶形成[15, 16]。 因此, 所研究的合金在γ′相形成元素Ti+Nb的含量固定在2.1%(摩尔分数)条件下, Al+Ta总量不超过13.6%(摩尔分数)就能避免α(W, Mo)固溶体相的析出。 2号合金是以1.6%(摩尔分数)的Ta代替1号合金中1.9%(摩尔分数)的Al, 从1号合金和2号合金的显微组织相近可知, 加Ta的同时应降低等摩尔分数的Al, 否则过量的Ta会促进α+γ′共晶的形成(如3号合金和4号合金)。

2.2 α相的转变

当合金高于1260℃固溶处理时, 部分α(W, Mo)相通过α(W, Mo)+C→M6C反应转变成了M6C碳化物, 部分α(W, Mo)相固溶并聚集长大。 随着温度的升高和时间的延长, 这种转变更加明显。 图4(a)所示为3号合金经过1280℃, 20min处理后的显微组织, 与图2(a)相比, 铸态组织中在共晶γ′相内大量的α(W, Mo)变成了有规则几何形状的M6C相, 剩余少量的α(W, Mo)相聚集成块状。 1280℃, 3h处理后, 形成的块状M6C更多, 尺寸更大, 残存的α相变成球状, 周围被γ相包围(见图4(b))。 从图4背散射电子像的衬度可看出, α相比M6C更亮。

含有α相的合金在1100℃长时间热暴露时,

表4 铸态合金中共晶γ′相的化学成分

Table 4 Chemical composition of eutectic γ′ in as-cast alloys

图4 经1280℃固溶处理不同时间后3号合金的背散射像

Fig.4 BSEI micrographs of alloy 3 after solid-solution heat treatments at 1280℃ for different time

α相的固溶效果不明显, 但仍存在α(W, Mo)+C→M6C的反应, 这样反应主要由于α(W, Mo)相在原位与合金中的碳反应所致。 图5所示为3号合金经1100℃, 500h热暴露后的显微组织。 可以看到, α+γ′共晶中的α相依然保持原貌, 但其0.49N负载下的维氏显微硬度值已由α相的4.52GPa变为9.48GPa。 大块的α相长时间热暴露后只有部分转变为M6C, 中心仍残存有α相, 而边缘已经转变为M6C。 转变的M6C和合金中析出的片状M6C成分相近(表5)。

图5 经1100℃, 500h热暴露后3号合金的显微组织

Fig.5 Microstructure of alloy 3 after 500h thermal exposure at 1100℃

表5列出了1280℃, 3h 固溶处理后析出的块状M6C和残存球状α(W, Mo)相的成分, 同时列出了1100℃, 500h热暴露后剩余α相、 转变的M6C碳化物和析出的片状M6C碳化物成分, 证明所有M6C碳化物的W+Mo总量明显低于α相, 而且含有较高的Ni。 虽然能谱难以定量测定碳含量, 但仍然测到图5中转变的M6C区碳量明显高于α相区, 证明α相向M6C的转变。

在高W铸造镍基高温合金中, 高于1260℃固溶热处理或1100℃长时热暴露时, MC碳化物不稳定, 它会分解并转变成更加稳定的M6C碳化物, 在M6C碳化物周围包覆一层γ′。 其反应符合MC+γ→M6C+γ′。 通过这种反应形成的碳化物通常呈粒状和片状(图5)。 对于含有α相的3号合金和4号合金, 固溶于γ内的碳或MC分解释放出的碳还会与α相直接反应并原位形成M6C。 由于M6C中的金属原子是MC中的6倍, 所以MC分解释放的碳可与6倍的金属原子结合, 使形成的M6C碳化物远比MC多。 这就是高温合金长时使用后碳化物成倍增加的原因[17]。

2.3 α相对高温持久寿命的影响

对4炉铸态合金在1100℃, 118MPa条件下作了持久实验, 结果示于图6。 所有炉次的持久寿命均为两根试棒的平均值。 比较1号合金和2号合金数据可知, 以等摩尔分数的Ta代替Al能提高合金的高温持久寿命。 但当Ta过量时由于形成过量共晶γ′相以及α相使持久寿命呈下降趋势, 由于α

图6 铸态合金在1100℃,118MPa条件下的持久寿命

Fig.6 Stress-rupture life of as-cast alloys under 1100℃ and 118MPa

表5 3号合金经不同热处理后α(W, Mo)相和M6C的成分

Table 5 Compositions of α(W, Mo) and M6C after different solid-solution heat treatments for alloy 3(mass fraction, %)

相并非脆性相, 所以对合金持久寿命损伤不大(3号合金)。 当合金Al+Ta过量并且凝固速度较慢时, 除析出大量共晶γ′和α相外, 还析出较多初生大块M6C时, 则合金持久寿命明显降低(4号合金)。 由于初生M6C碳化物尺寸大且为脆性相, 严重损害合金的持久性能[16]。 从以上显微组织和高温持久寿命看, 1号合金和2号合金是合适的合金成分, 其中2号合金性能最佳。

3 结论

1) 铸造镍基高温合金中添加元素Ta会显著增加共晶γ′的量。 当合金中Ti+Nb量恒定在2.1%(摩尔分数), Ta+Al量达14.4%(摩尔分数)时, 凝固后期会形成α(W, Mo)+γ′共晶, 在共晶γ′内分布着小块或条状的α 相。 小于2%(体积分数)的α 相不会明显降低合金的持久性能。

2) α 相在高于1260℃下固溶处理或在1100℃长时间热暴露时是不稳定的, 它会固溶或转变成块状M6C, 从而明显损伤合金的高温持久性能。

3) Ta是一种有利于提高高温合金高温强度的元素, 但Ta量应与合金中的Al量相适应, 须按等摩尔分数原则相互替换。 具有Ni-10Co-1.5Cr-16W-2Mo-1Nb-5Al-4Ta成分的合金性能最佳。

REFERENCES

[1]Zheng Y R, Li S S, Zheng L, et al. Abnormal phases in high W content nickel base superalloys and phase control[A]. Green K A, Pollock T M, Harada H, et al. Proceedings of Superalloys 2004[C]. Warrendale, Pennsylvania: TMS, 2004. 743-751.

[2]Nathal M V, Ebert L J. The influence of Cobalt, Tantalum, and Tungsten on the elevated temperature mechanical properties of single crystal Nickel-base superalloys[J]. Metallurgical Transactions A, 1985, 16A: 1863-1870.

[3]叶锐曾, 孙金贵, 于文秀, 等. MCrAlx铸造合金中Ta的作用[J]. 金属学报, 1999, 35(Suppl. 2): 316-319.

YE Rui-zeng, SUN Jin-gui, YU Wen-xiu, et al. The role of Tantalum in MCrAlx cast alloys[J]. Acta Metallurgica Sinica, 1999, 35(Suppl. 2): 316-319.

[4]Yang S W. Effect of Ti and Ta on the oxidation of complex superalloys[J]. Oxidation of Metals, 1981, 15(5/6): 375-397.

[5]Barrett C A, Miner R V, Hull D R. The effect of Cr, Al, Ti, Mo, Ta, and Cb on the cyclic oxidation behavior of cast Ni-base superalloys at 1100 and 1150℃[J]. Oxidation of Metals, 1983, 20(5/6): 255-278.

[6]Gobel M, Rahmel A, Schutze M. The isothermal-oxidation behavior of several nickel-base single-crystal superalloys with and without coatings[J]. Oxidation of Metals, 1993, 39(3/4): 231-260.

[7]Colling H E, Quigg R J, Dreshfield R L. Development of Nickel-base superalloy using statistically designed experiments[J]. Trans ASM, 1968, 61: 711-718.

[8]Janowski G M, Heckel R W, Pletka B J. The effects of Tantalum on the microstructure of two polycrystalline nickel-base superalloy B-1900+Hf and Mar-M247[J]. Metallurgical Transaction A, 1986, 17A: 1891-1905.

[9]Getel A D, Duhl A D. Second-generation nickel-base single crystal superalloy[A]. Duhl D N, Maurer G, Antolovich S, et al. Superalloys 1988[C]. Warrendale Pennsylvania: The Metallurgical Society, Inc, 1988. 235-244.

[10]Erickson G L. The development and application of CMSX-10[A]. Kissinger R D, Deye D J, Anton D L, et al. Superalloys 1996[C]. Warrendale, Pennsylvania: TMS, 1996. 35-44.

[11]Harada H, Murakami H. Design of Ni-base Superalloys. In: Saito T eds. Computational Material Design[M]. Berlin: Springer, 1999. 39-67.

[12]Wlodek S T. The stability of superalloys[A]. Fuchs G E, Dannemen K A, Deragon T C. Long Term Stability of High Temperature[C]. Warrendale Pennsylvania: TMS, 1999. 3-39.

[13]Nathal M V, Ebert L J. The influence of cobalt, tantalum, and tungsten on the microstructure of single crystal nickel-base superalloys[J]. Metallurgical Transactions A, 1985, 16A: 1849-1862.

[14]Fuchs G E. Improvement of creep strength of a third generation single-crystal nickel-base superalloy by solution heat treatment[J]. Journal of Materials Engineering and Performance, 2002, 11(1): 19-25.

[15]Jackson M R, Walter J L. Superalloy eutectic composites with the ⅥA refractory elements[A]. Kear B H, Muzyka D R, Tien J K, et al. Superalloys: Metallurgy and Manufacture[C]. Baton Rouge, Louisiana: Claitors Publishing Division, 1976. 341-350.

[16]Bursik J, Broz P, Picha R. Microstructural and phase equilibria study in the Ni-Al-Cr-W system at 1173-1273K[J]. Intermetallics, 2003, 11: 483-490.

[17]Lvova E, Norsworthy D. Influence of service-induced microstructural changes on the aging kinetics of rejuvenated Ni-based superalloy gas turbine blades[J]. Journal of Materials Engineering and Performance, 2001, 10(3): 299-313.

(编辑陈爱华)

收稿日期: 2005-03-07; 修订日期: 2005-06-13

作者简介: 郑 亮(1979-), 男, 助理工程师

通讯作者: 郑 亮, 助理工程师; 电话: 010-62496337; 传真: 010-62456212; E-mail: zheng_liang@tom.com