文章编号:1004-0609(2008)06-1094-06

Mo-Cu复合材料构件激光快速成型工艺

白培康,刘 斌,胡胜亮

(中北大学 材料科学与工程学院,太原 030051)

摘 要:开发了一种激光快速成型制备钼铜复合材料的新工艺,采用水悬浮包覆方法制备激光烧结成型用覆膜钼粉,对覆膜钼粉激光烧结成型工艺进行优化实验。对激光烧结成型件的后处理工艺,包括脱脂、高温烧结与熔渗进行了实验研究,制备钼铜复合材料样件。结果表明:激光烧结成型最佳工艺参数如下,激光功率15 W,扫描速度1 000 mm/s,铺粉厚度0.1 mm,预热温度60 ℃;钼铜复合材料的抗拉强度为383.8 MPa,伸长率为6.6%,可以满足弹箭发动机喷管等高温零部件的实际使用要求。

关键词:钼;铜;复合材料;覆膜钼粉;激光烧结;高温烧结;熔渗

中图分类号:TN 249; TQ 174 文献标识码:A

Laser rapid prototyping process of Mo-Cu composites part

BAI Pei-kang, LIU Bin, HU Sheng-liang

(School of Materials Science and Engineering, North University of China, Taiyuan 030051, China)

Abstract: A novel method for producing Mo-Cu composites part by laser rapid prototyping technology was carried out. Water suspending method was used to prepare polymer-coated molybdenum powder used in selective laser sintering (SLS). The optimization of laser sintering process was experimentally conducted. The post-treatment process of prototyping parts was developed, including debinding, high-temperature sintering and copper melting infiltration. The results show that the optimal parameters are 15 W in laser power, 1 000 mm/s in scanning velocity, 0.1 mm in powder depth and 60 ℃ in preheating temperature. The molybdenum/copper composites samples are obtained, with tensile strength and elongation of molybdenum part of 383.8 MPa and 6.6%, respectively. This method can be used to produce fire-resisting parts of weaponry and aerospace arms.

Key words: Mo; Cu; composites; polymer-coated molybdenum powder; laser sintering; high temperature sintering; melting infiltration

钼是一种蕴藏量极少的战略物资,它具有较高的硬度和脆性,机加工困难,特别是加工成形状复杂、精密部件时效率低、废品多。而钼/铜复合材料在常温和中温下既具有较好的强度、塑形,可加工性好,又有高的电导性和热导性,所以被广泛应用于武器装备及航空、航天等制造业中,如火箭、导弹发动机喷管和喉衬等高温部件[1-2]。

对于形状复杂的高温难熔材料零件,目前多采用粉末冶金结合机械加工的方法制造,存在研制周期长、材料利用率低和成本高等问题[3-5]。金属零件的激光快速成形技术已成为快速成形技术领域的研究热点和发展方向,该项技术根据三维实体的CAD模型,采用激光束对金属粉末进行扫描烧结或熔化堆积的方式,逐层成型,可以方便快捷地制造出形状复杂的金属零件和模具。与传统的制造工艺相比,无需任何硬质工装模具,具有生产周期短、成本低的优势,并且可以灵活地改变设计方案,实现柔性生产,特别适用于传统方法难以成形的复杂零件的多品种、小批量生产[6-9]。

目前,国内外制备难熔复合材料主要采用等静压成型-高温烧结骨架-渗铜工艺,利用该工艺已经成功研制钨铜材料和ZrC/W复合材料。但对于具有耐高温耐烧蚀、高热强性等特殊性能要求的零部件,在制造工艺上还不能完全满足应用要求[10-13]。

国内利用激光快速成形技术制备金属零件的研究主要集中在激光熔敷直接成型技术[12]。有关激光烧结快速成型技术制造难熔金属零件的相关报道甚少,尚未开展激光快速成型制备钼铜复合材料方面的研究。

本文作者对覆膜钼粉的制备方法、激光烧结成型工艺以及成型件后处理技术进行研究,得到满足使用性能要求的钼/铜复合材料样件。

1 实验

1.1 覆膜钼粉的制备

采用水悬浮包覆方法制备了激光烧结成型用覆膜钼粉,具体制备工艺如下。

1) 首先用稀碳酸钠溶液清洗钼粉表面油脂,再用稀盐酸清洗表面氧化物,用清水洗涤,最后用润湿剂进行表面处理,干燥。

2) 包覆溶液制备:将热熔胶、润湿剂、分散剂按一定比例在卤代烃中加热溶解成溶液。

3) 将表面处理后的钼粉放入盛有蒸馏水的反应釜进行加热、搅拌30 min,使金属粉末分散均匀。

4) 将制备的包覆溶液按比例滴入反应釜水中进行搅拌,使之与钼粉混合均匀;然后进行蒸馏,将卤代烃溶剂挥发,经过滤、干燥和过筛得到微细的覆膜钼粉(其粒径分布范围为35~60 μm)。

1.2 激光烧结成型工艺

覆膜钼粉激光烧结成型实验在自行研制的LLS-500D变长线激光快速成型机上进行, 其主要技术参数为。最大成型尺寸d 400 mm×500 mm;成型精度:±0.15 mm;激光功率100 W;激光线束长度0.20~50 mm;激光束最大扫描速度5 m/s;激光线束宽度0.20 mm。

采用正交实验设计方法,对覆膜钼粉激光烧结成型工艺进行了优化实验研究。

1.3 激光成型件后处理工艺

1) 脱脂、预烧结。在真空碳管烧结炉中对覆膜钼粉成型件进行脱脂、预烧结处理。在真空炉中加热到300 ℃保温2~3 h,彻底去除其中的有机覆膜材料;继续升温到1 350 ℃(升温速度不超过200 ℃/h),保温1 h左右,使其具备一定强度。

2) 高温烧结。在高温氢气炉中对预烧结件进行1 900 ℃高温强化烧结,获得多孔钼骨架,烧结后制件收缩明显,密度提高,为熔渗合金化处理作准备。

3) 熔渗。实验所选熔渗金属为纯铜,把高温烧结件和一定比例的电解铜块置入石墨坩埚,在氩气惰性气氛中加热到1 200 ℃并保温2 h,加热使铜块逐渐熔化,铜液慢慢渗入多孔钼骨架中,获得致密的钼渗铜制件[12-13]。最后经过表面处理后即可得到钼铜成品件。

2 结果与讨论

2.1 覆膜钼粉微观形貌

覆膜钼粉中覆膜材料成分配比的依据是在保证成型件基本强度达到的前提下,尽量降低树脂总量,有利于成型件致密度的提高,覆膜材料所占的比例以不超过4%为宜。

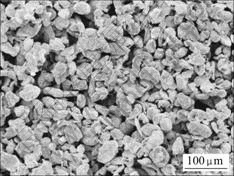

覆膜钼粉的微观形貌如图1所示。由图可知,由于钼粉粒度很小,制备得到的覆膜钼粉由大小不一的形状接近球形的颗粒和多边形颗粒组成,单个颗粒是很多微细纯钼粉经树脂包覆的聚集体,激光烧结成型主要依靠这种聚集体颗粒之间的粘接。通过激光粒度分析测试可知,试样中颗粒统计95%以上的覆膜钼粉粒径范围分布在35~60 μm,粒度大小适于激光烧结加工成型,且粉末流动性好,成型性能优良。

图1 覆膜钼粉微观形貌

Fig.1 Micrograph of polymer-coated Mo powers

2.2 激光烧结成型工艺优化参数

分析表明,激光功率、激光扫描速度、铺粉厚度、预热温度是影响激光烧结成型质量(以烧结密度衡量)的主要因素。对于现有的实验设备,在一定的铺粉条件下,烧结成型质量的影响因素可以表达为[8]

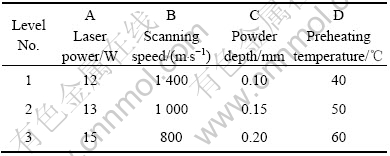

采用正交实验设计方法研究了上述4个参数对激光烧结成型质量的影响关系,以成型件的密度作为主要衡量指标,通过对实验结果进行分析得出最优工艺参数匹配。正交实验因素水平表如表1所列。

表1 正交实验因素水平

Table 1 Factor level of orthogonal experiment

利用方差分析方法对实验结果进行分析,得到各因素方差平方和排序为

SD>SB>SC>SA

可见,各因素的重要性次序为:预热温度、扫描速度、铺粉厚度和激光功率。在A3 、B2、C1、D3参数组合情况下烧结密度值最大,故最优工艺条件为 A3 B2 C1 D3 ,即激光功率15 W,扫描速度1 000 mm/s,铺粉厚度0.10 mm,预热温度60 ℃。在最优工艺条件下进行烧结,成型件坯体密度达到4.3g/cm3。

2.3 激光烧结成型件质量影响因素

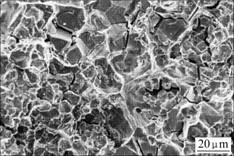

图2所示为覆膜钼粉激光烧结成型件微观形貌。由图可知,覆膜钼粉经激光烧结后,有机树脂在激光加热作用下熔化,将金属颗粒粘结在一起,但所制得零件只是一种坯体,呈低密度多孔状结构,必须经过后处理(脱脂、高温烧结等),才能得到致密的、力学性能满足使用要求的零件。

图2 激光烧结成型件微观形貌

Fig.2 Micrograph of laser sintered part

一般而言,在预热与铺粉条件确定以后,激光功率和扫描速度决定了能量密度的大小,成型件的质量主要取决于激光功率和扫描速度。

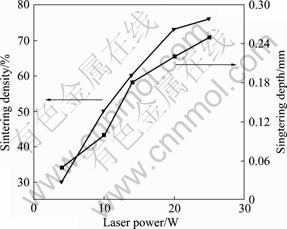

当扫描速度为1 000 mm/s时,激光功率对成型件烧结深度和密度的影响如图3 所示。由图可知,扫描速度一定时,随激光功率增加,烧结深度和烧结密度均增加,主要原因在于输入能量增加后产生的液相 数量增加,在粉粒间隙中流动及润湿粉末颗粒,使得成型件致密度增大,粘结效果增强。但激光功率过大,使得粘结剂一部分发生烧蚀,烧结件强度反而降低,同时使成型件表面粗糙,也容易产生翘曲变形[14]。

图3 激光功率对烧结深度和密度的影响

Fig.3 Influences of laser powers on sintering depth and sintering density

当激光功率为15 W时,扫描速度对烧结深度和密度的影响关系如图4所示。随着扫描速度增大,烧结深度和密度减小。其原因在于扫描速度增大后,能量密度不足,融融液相来不及充分向粉粒间隙中扩散,成型件致密度低,导致烧结深度和烧结密度下降,容易产生分层缺陷。

图4 激光扫描速度对烧结深度和密度的影响

Fig.4 Influences of laser scanning velocities on sintering depth and sintering density

在选择工艺参数时,二者要合理匹配,保证既要得到良好的层内及层间烧结质量,又要尽可能地选择较大的扫描速度来提高加工效率。

2.4 预处理件、高温烧结件微观形貌

图5所示为激光烧结成型件在300 ℃充分脱脂并在1 350 ℃预烧结后的扫描电镜像。由图可知,经过脱脂处理后,金属颗粒间无高分子聚合物存在,表明覆膜钼粉中包覆的有机树脂已经被完全脱除。脱脂后坯体内失去有机树脂的粘结作用,粉末间联结主要靠粉粒间的摩擦力和微小的聚合物联结,其强度极低,十分容易发生变形和破断。

图5 预烧结件的微观形貌

Fig.5 Micrograph of pre-treated part

图6所示为在氢气气氛中经高温烧结后制件的扫描电镜像。由图可知,坯件内部金属粉颗粒已经形成紧密结合,大部分孔隙在烧结过程中消除,部分孔隙已经闭合,工件的致密度得到大幅度提高,经计算相对密度达到了92%以上。材料性能得到改善,强度提高。从图6(a)中可以观察到,金属颗粒熔化粘接在一起,证明在1 900 ℃的高温下实现液相烧结;从图6(b) 中可以观察到烧结件局部颗粒间晶界联结十分紧密,致密化程度得到很大的提高。但是高温烧结后的烧结件内部仍然残留有一小部分空隙,可以通过渗入其它低熔点金属使其性能得到进一步提高。

图6 高温烧结件微观形貌

Fig.6 Micrographs of high-temperature sintered part

2.5 熔渗处理后钼铜件微观组织及其性能

图7所示为熔渗后钼铜复合材料制件的断口形貌。由图可知,高温烧结后的制件,其内部孔隙大量减少,经过熔渗后在钼骨架连通孔隙内渗入大量铜,其组织较为致密,可以观察到Cu相与Mo相已经紧密结合在一起,图中颜色较暗呈块状板结的为Mo相,颜色较亮呈放射状流体态的为Cu相,二相交错分布。Mo相组织有两种,其一为细小卵形的单个晶粒,第二种就是多个晶粒结合在一起的呈多边体形、板条形Mo相组织,而且主要以后者形式存在,作为材料的骨架[15-16]。

图7 熔渗处理后制件的断口形貌

Fig.7 Fractograph of sample after melting infiltration

图8(a)所示为经过熔渗处理后的钼铜喷管制件外形图。由图可知,其表面具有金属光泽,但表面光洁度较差,经过小加工量的表面处理后,即可满足最终精度要求,图8(b)所示为经表面处理后某导弹发动机喷管样件。

`

图8 表面处理前后样件的照片

Fig.8 Photographs of samples before (a) and after (b) surface treatment

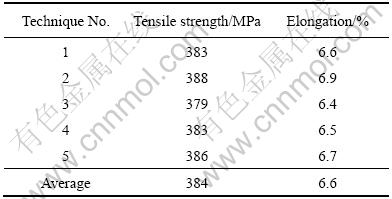

采用电子万能材料实验机CMT-5105A型对钼 铜复合材料制件进行拉伸实验,试样尺寸参照 GB/T228-1987的规定,环境温度为25 ℃,湿度为65%±5%,同一实验进行5次,测试结果如表2所列。从表中可以看出,试样的抗拉强度达到383.8 MPa,伸长率达到6.6%,其力学性能可以满足弹箭发动机喷管等高温零部件的实际使用要求。

表2 钼-铜复合材料制件的力学性能

Table 2 Mechanical properties of molybdenum-copper composites samples

3 结论

1) 采用水悬浮包覆方法制备了激光烧结成型用微细覆膜钼粉, 其粒径分布范围为35~60 μm,具有流动性好,包覆膜层均匀,烧结成型性好的特点。

2) 覆膜钼粉激光烧结成型的最佳工艺参数为:激光功率15 W,扫描速度1 000 mm/s,铺粉厚度0.1 mm,预热温度60 ℃,在此工艺条件下激光烧结成型件密度达到4.3 g/cm3。

3) 对激光烧结成型件的后处理工艺(脱脂、高温烧结、熔渗)进行了实验研究,制备钼铜复合材料样件,其抗拉强度为383.8 MPa,伸长率为6.62%,可以满足使用要求。

REFERENCES

[1] 向铁根. 钼冶金[M]. 长沙: 中南大学出版社, 2002.

XIANG Tie-gen. Molybdenum metallurgy[M]. Changsha: Central South University Press, 2002.

[2] 郭志俊, 张树才, 林 勇, 高 云. 钼在破甲弹上的应用前 景[J]. 中国钼业, 2003, 27(6): 10-15.

GUO Zhi-jun, ZHANG Shu-cai, LIN Yong, GAO Yun. The application foreground of Mo in shaped charge warhead[J]. China Molybdenum Industry, 2003, 27(6): 10-15.

[3] KING D, TANSEY T. Alternative materials rapid tooling[J]. Journal of Materials Processing Technique, 2002, 121(2/3): 313-317.

[4] Kumar S, Chatterjee A N, Saha P. An experimental design approach to selective laser sintering of low carbon steel[J]. Journal of Materials Processing Technique, 2003, 136(1/3): 151-157.

[5] BAI Pei-kang, WANG Wen-feng. Selective laser sintering mechanism of polymer-coated molybdenum powder[J]. Trans Nonferrous Met Soc China, 2007, 17(3): 543-547.

[6] Tolochko N K, Mozzharov S E, Yadroitsev I A. Selective laser sintering and cladding of single-component metal powders[J]. Rapid Prototyping Journal, 2004, 10(2): 88-97.

[7] Das S. Physical aspects of process control in selective laser sintering of metals[J]. Advanced Engineering Materials, 2003, 5(10): 701-711.

[8] BAI Pei-kang, CHENG Jun. Numerical simulation of temperature field during laser sintering of polymer-coated molybdenum powder[J]. Trans Nonferrous Met Soc China, 2006, 16: s603-607

[9] BAI Pei-kang. Study on selective laser sintering of polymer- coated metal powder[C]// Proceedings of the Second International Conference on Rapid Prototyping and Rapid Manufacturing, Beijing: Tsinghua University Press, 2002: 181-185.

[10] TOLOCHKO N K, MOZZHAROV S E, YADROITSEV I A. Balling processes during selective laser treatment of powders[J]. Rapid Prototyping Journal, 2004, 10(2): 78-87.

[11] 张启修, 赵秦生. 钨钼合金[M]. 北京: 冶金工业出版社, 2005.

ZHANG Qi-xiu, ZHAO Qin-sheng. Tungsten and molybdenum metallurgy[M]. Beijing: Metallurgical Industry Press, 2005.

[12] 陈 静, 杨海欧, 杨 健, 黄卫东. 高温合金与钛合金的激光快速成型工艺[J]. 航空材料学报, 2003, 10: 100-103

CHEN Jing, YANG Hai-ou, YANG Jian, HUANG Wei-dong. Laser rapid prototyping process of high-temperature alloy and titanium[J]. Journal of Aerospace Material, 2003, 10: 100-103

[13] NIU H J, CHANG I T H. Liquid phase sintering of M3/2 high speed by selective laser sintering[J]. Scripta Material, 1998, 39(1): 67-72.

[14] 白培康, 方明伦. 包覆不锈钢粉末激光烧结深度的影响因 素[J]. 中国有色金属学报. 2007, 17(6): 940-944

BAI Pei-kang, FANG Ming-lun. Effects of laser processing parameters on sintering depth of polymer-coated stainless steel powder[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 940-944

[15] Kathuria Y P. Microstructuring by selective laser sintering of metallic powder[J]. Surface and Coatings Technology, 1999, 116/119: 643-647.

[16] LIU Bin, CHENG Jun, BAI Pei-kang, WANG Jian-hong. Preparation of Mo/Cu composites by SLS method and its post-treatment techniques[J]. Trans Nonferrous Met Soc China, 2006, 16(S2): 255-259.

基金项目:国家自然科学基金资助项目(50675210);教育部新世纪优秀人才支持基金资助项目(NCET-07-0766)

收稿日期:2008-03-07;修订日期:2008-05-29

通讯作者:白培康,教授,博士;电话:0351-3557443;传真:0351-3557519;E-mail: baipeikang@sohu.com

(编辑 龙怀中)