选择性激光烧结碳化硅及铝合金氧化入渗

徐文武, 史玉升, 黄树槐, 刘锦辉, 程 迪, 郭 婷

(华中科技大学 塑性成形模拟及模具技术国家重点实验室, 武汉 430074)

摘 要: 采用选择性激光烧结和金属直接氧化法相结合的技术, 制备SiC-Al2O3-Al陶瓷基复合材料零件。 研究选择性激光烧结成形碳化硅零件坯体的工艺和脱脂预处理工艺对坯体孔隙率的影响规律, 以及氧化入渗工艺影响因素; 采用扫描电镜、 X射线衍射仪分别对成形好的复合材料进行微观形貌和物相分析。 结果表明: 用选择性激光烧结和金属直接氧化技术相结合的工艺可以直接利用三维图形, 快速成形出复杂形状的SiC-Al2O3-Al复合材料零件; 其陶瓷相和金属相都呈三维网络状分布, SiC、 Al2O3和金属相的体积分数分别为45.1%、 32.7%和18.0%, 孔隙率为4.2%, 抗弯强度为361.2MPa。

关键词: 选择性激光烧结; 金属直接氧化; SiC-Al2O3-Al; 陶瓷基复合材料 中图分类号: TB333

文献标识码: A

Selective laser sintering of SiC and oxidative infiltration of Al-alloys

XU Wen-wu, SHI Yu-sheng, HUANG Shu-huai, LIU Jin-hui, CHENG Di, GUO Ting

(State Key Laboratory of Plastic Forming Simulation and Die and Mould Technology,Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: SiC-Al2O3-Al ceramic matrix composite parts with complex shape can be produced by combination of selective laser sintering(SLS) and directed oxidation of metals (DIMOX). The factors affecting SLS process such as debinding and post-processing of high temperature sintering on open porosity of SiC preform were discussed, the affecting factors of DIMOX process were also studied. The microstructures of the composites were investigated using X-ray diffraction and scanning electron microcopy. The result indicates that three-dimensional objects of SiC-Al2O3-Al ceramic matrix composites can be produced successfully from their CAD models directly by combination of SLS and DIMOX. The ceramic and metals form three dimensional networks. There are 45.1% SiC, 32.7% Al2O3, 18.0% Al and 4.2% porosity in the material, and its bending strength is 361.2MPa.

Key words: selective laser sintering; directed oxidation of metal; SiC-Al2O3-Al; ceramic matrix composite

目前, 陶瓷基复合材料具有熔点高、 强度好、 硬度高、 耐高温、 耐磨以及密度小等优异性能, 广泛应用于国防军工、 航空航天、 医疗、 汽车、 电子、 光学和机械制造等领域[1]。 但陶瓷基复合材料的制备技术(如: 反应烧结、 热压烧结、 泥浆浸渍或渗透、 化学气相沉积或渗透、 高温自蔓延反应、 先驱体浸渍热分解等)都不同程度地存在工艺复杂、 成本高、 难以直接制备复杂形状零件的缺点, 而且陶瓷基复合材料加工困难, 导致其零件制造成本很高, 周期长。

而选择性激光烧结(SLS)技术是一种基于离散堆积成形思想的快速成形技术, 可直接根据实体的CAD模型, 并利用计算机控制激光逐层烧结、 叠加成形复杂形状的原型或零件[2]。 其制造周期短、 成本低、 成形材料广泛, 并已广泛用于机械、 电子、 航空、 航海、 生物医学、 武器、 汽车和医疗等领域[3-4]。 目前, 国外已初步对选择性激光烧结成形碳化硅进行了研究[5], 而国内还没有相关的报道。

金属直接氧化法(DIMOX)是美国Lanxide公司发明的一种全新的制备复合材料的工艺[6-7], 也称Lanxide技术。 其基本原理是熔融金属合金发生氧化反应, 原位生成固体产物骨架为基体并含有金属相的复合材料。 该工艺过程简单, 不需要昂贵的设备, 成本较低, 具有比固态法和传统的液态法潜在的经济性, 且材料的性能可控, 制品具有良好的体积稳定性, 并可以设计最终形成的复合材料的性能及界面结构[8]。 另外, 利用金属晶粒的生长, 合金还可以长入由颗粒、 晶须及纤维构成的填充材料或预型体中[9-10], 可制备新型的陶瓷基复合材料(CMC)和金属基复合材料(MMC), 特别是具有网络陶瓷增强体的复合材料。 这种具有网络陶瓷增强体已成为复合材料增强相的新研究热点[11]。

鉴于选择性激光烧结的直接快速成形复杂零件和金属直接氧化法能制备高性能陶瓷基复合材料的优点, 以及陶瓷基复合材料难以加工的特点, 本文作者利用选择性激光烧结直接成形碳化硅零件坯体, 并结合金属直接氧化法制备具有三维网络联通结构的SiC-Al2O3-Al的陶瓷基复合材料(CMC)零件。

1 实验

1.1 材料及零件制备方法

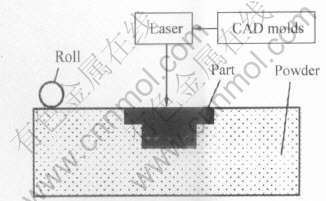

碳化硅初坯在华中科技大学自行研制的HRPS-Ⅱ型SLS成形系统上成形, 其工艺原理如图1所示, 采用50W的CO2激光器, 光斑直径为0.3mm左右。 粉末为小于52μm的黑色碳化硅和粒径小于10μm的4种不同型号的环氧树脂, 其中环氧树脂用做粘结剂, 占总质量的3%。 成形好的零件初坯在普通箱式炉中脱脂后, 升温至1200℃进行预烧, 并保温3h使碳化硅颗粒表层生成SiO2的氧化膜。

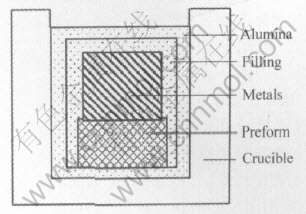

成形好的碳化硅零件坯体在箱式炉中, 直接升温至1200℃, 采用金属氧化生长的方法熔渗铝合金, 保温直至氧化生长完全。 图2所示为改进的Lanxide复合材料的工艺原理, 其中填料用来限制金属氧化生长的方向, 使其只往碳化硅的初坯中生长, 并改善成形件的表面质量[12]; 氧化铝粉防止生长超过零件的边界, 同时为氧化生长提供氧气通道及维持碳化硅零件的形状。

图1 SLS成形工艺原理图

Fig.1 Schematic illustration of SLS processing

图2 Lanxide复合材料的生长工艺

Fig.2 Schematic illustration of Lanxide processing

1.2 测试

采用排水法测量多孔材料的表观密度和孔隙率, 采用德国Zwick/Roell公司的Z010型电子万能力学试验机测试材料的三点抗弯强度, 采用xPert PRO型X射线衍射仪对材料进行物相分析, 并采用Sirion200型扫描电镜分析试样的显微组织及断面形貌, 采用Image-pro plus软件对复合材料的相含量和孔隙率进行分析。

2 结果与讨论

2.1 粘结剂的选择

粘结剂的种类和含量对选择性激光烧结的工艺, 以及成形坯体的性能和脱脂工艺有着很大的影响。 表1所列为4种不同的环氧树脂在相同含量和激光成形参数下的初坯抗弯强度, 其中粘结剂D的抗弯强度最高, 是最佳的选择。

通过适当调整粘结剂的含量可以改变零件坯体的孔隙率。 但是当粘结剂加入量过少时, 无法将

表1 不同粘结剂的成形坯体的抗弯性能

Table 1 Bending strength of SLS samples with different binders

陶瓷颗粒完全粘接起来, 易产生分层现象, 或导致零件初坯强度太低而无法进行后续处理; 加入量过大时, 则使坯体中陶瓷的体积分数过小, 在脱脂去除粘结剂的过程中容易产生开裂、 收缩率大、 变形等缺陷, 因此须选择适量的粘接剂。

2.2 碳化硅坯体孔隙率的影响因素

影响碳化硅坯体孔隙率的因素主要有三方面。 一是粉末本身的性质, 如: 松装密度越大, 成形后的坯体密度越大。 二是热效应, 激光入射能量密度q越大, 粉末吸收的热量越大, 烧结温度高, 使烧结体密度越高。 而影响入射能量密度的工艺参数主要是激光功率W、 扫描速率v、 扫描间距D, 它们之间的关系可通过关系式: q=W/Dv[13]来描述, 所以适当调整工艺参数, 可得到不同的致密度的碳化硅坯体。 另外, 坯体脱脂预烧温度和保温时间也影响坯体的致密度, 预烧温度越高, 保温时间越长, 坯体的致密度越高, 开口孔隙率越低[14]。 三是力效应, 铺粉对粉末产生压力, 提高坯体的致密度; 另外, 激光烧结粉末时, 激光脉冲对粉末有冲击效应, 可以提高坯体的致密度。

通过工艺参数优化后, 在激光功率为15W, 扫描速率为2000mm/s, 扫描间距为0.1mm, 层厚为0.1mm时, 排水法测得碳化硅坯体的表观密度为1.32g/cm3, 孔隙率为58.7%; 脱脂预烧后的表观密度为1.41g/cm3, 孔隙率为54.9%, 开口孔隙率为98.6%, 抗弯强度为0.91MPa。

2.3 金属直接氧化工艺

2.3.1 氧化熔渗温度和保温时间

实验表明, 当熔渗温度低于900℃时, 碳化硅坯体没有发生入渗现象; 当熔渗温度越高, 保温时间越长, 材料的生长厚度值越大, 材料的致密度也随之增加[15]。 但是, 当温度过高时, 会导致大量Al合金挥发而浪费。

2.3.2 预氧化生成SiO2膜对氧化熔渗的影响

铝能与碳化硅反应生成不稳定的化合物Al4C3和Al4SiC4, 这两种化合物易与空气中的水分及氧气反应生成大量气体而产生粉化现象[16]。 预氧化生成的SiO2膜可以与Al发生反应防止化合物Al4C3和Al4SiC4的生成, 有利于熔渗的进行, 缩短入渗孕育期短。 另外, SiO2参与界面反应生成了游离Si, 而游离Si能够改善润湿性[17-18], 界面反应发生所放出的反应热使铝液局部的温度急剧升高, 促进了润湿角θ的降低, 改善了润湿性。 另外, Si元素的存在有助于扩大渗透所需的微观通道, 合金溶液正是通过这些微观通道才源源不断供应到界面层; 微观通道越大, 合金熔液的供应越容易, 渗透也越易于进行[19]。 此外, SiO2膜可避免材料的胞状生长, 促进材料的光滑生长, 从而增加材料的致密度[20]。

2.3.3 镁对氧化熔渗的影响

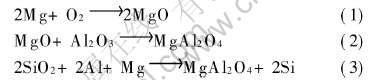

合金中Mg的含量对系统的润湿及渗透均有着非常重要的影响, Mg的主要作用表现在两个方面: 一是可以降低熔铝合金的表面张力; 二是Mg的蒸气压较高, 可破坏铝液表面形成致密的Al2O3保护膜, 氧化熔渗时Mg会发生下列反应:

在熔体表面形成MgO/MgAl2O4双层结构的表面膜, 然后依靠MgAl2O4在Al的浸蚀下不断反应溶解形成熔体传输通道, 通过对氧化入渗的前沿进行X射线衍射分析(图3), 在氧化熔渗的前沿主要是MgAl2O4和SiC的衍射峰, 另外有少量的Al2O3、 Al和Si的衍射峰, 表明氧化入渗前沿MgAl2O4层的存在。 Nagelberg等[21]认为MgAl2O4薄层可以控制Mg离子的扩散, 保护熔融金属持续氧化, 形成非保护性层而不至于使反应终止。 此外, 反应生成的MgAl2O4能改善基体和陶瓷颗粒的结合强度, 从而改善复合材料的力学性能; 但是在一定范围内, 随着Mg含量的增加复合材料的气孔率也有所增加[20]。

2.4 显微组织及断口形貌

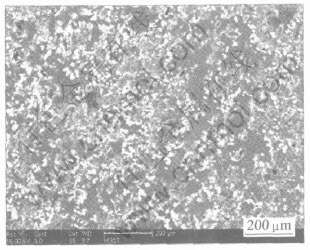

X射线衍射分析结果表明, 熔铝氧化反应渗透合成的SiC-Al2O3-Al复合材料主要有4种相: SiC、 Al2O3、 Al和Si相。 扫描电镜观察结果如图4所示。 深灰色的、 棱角分明的连续相为SiC, 浅灰色的连续相为反应生成的Al2O3, 白色连续相为金属相, 黑色相为孔洞。 氧化生长的Al2O3陶瓷相及金属相成三维连通的网状结构, 另外复合材料中的SiC早在氧化熔渗前已预烧成三维连通的网状结构, 这种形成多相三维连通的网状结构对材料的性能提高非常有利[11]。 通过Image-pro plus软件分析计算得出各相的体积含量为: SiC 45.1%, Al2O3 32.7%, 金属相18.0%, 孔隙率4.2%。 只有少量的孔隙, 表明了氧化生长的致密度高, 孔隙产生的原因主要是由于金属凝固收缩和氧化生长前产生的闭孔。 通过排水法测得其体积密度为3.1g/cm3。

图3 SiC-Al2O3-Al材料生长前沿的X射线衍射谱

Fig.3 XRD pattern of SiC-Al2O3-Al composites on growth front

图4 SiC-Al2O3-Al复合材料的SEM像

Fig.4 SEM image of SiC-Al2O3-Al composites

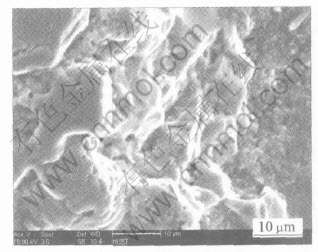

对尺寸为40mm×5mm×4mm的试样进行三点抗弯实验, 其抗弯强度为361.2MPa。 图5所示为复合材料的断口扫描电子显微照片。 由图可见, SiC-Al2O3-Al复合材料的断裂特征与纯陶瓷的脆性断裂不同, 断口区域存在比较明显的韧性撕裂特征, 这主要是SiC-Al2O3-Al复合材料中金属相的增韧作用, 这说明金属相对复合材料起到了增韧作用。 但是, 过多的金属相会影响复合材料的高温性能。 图6所示为制得的外径为50.9mm, 高14.0mm小型叶轮零件。

图5 SiC-Al2O3-Al复合材料的断口形貌SEM像

Fig.5 SEM image of fracture surface of SiC-Al2O3-Al composites

图6 SiC-Al2O3-Al复合材料的零件照片

Fig.6 Photo of part made ofSiC-Al2O3-Al composites

3 结论

1) 用选择性激光烧结技术制备SiC零件坯体和金属直接氧化法技术相结合的方法, 可以直接利用三维图形, 低成本制备出具有较高尺寸精度的复杂形状的零件。 由于不需要模具, 从而节省了模具制作的高成本; 另外, 减少了二次加工, 克服了SiC-Al2O3-Al陶瓷基复合材料难以机械加工的缺点。 实验所制备的复合材料, 其陶瓷相、 金属相都呈三维网络结构, SiC、 Al2O3和金属相的体积分数分别为45.1%、 32.7%、 18.0%, 孔隙率为4.2%, 抗弯强度为361.2MPa。

2) 选择性激光烧结和预处理工艺参数影响SiC预成坯的强度和致密度, 合适的工艺参数可以保证氧化入渗后的致密度和各相的含量。

3) 碳化硅预氧化生成的SiO2膜, 以及硅、 镁合金元素能加快铝合金向碳化硅坯体中氧化生长速率, SiO2膜和单质硅能改善SiC与Al2O3-Al的界面, 防止复合材料的粉化。

REFERENCES

[1]Rosso M. Ceramic and metal matrix composites: Routes and properties[J]. Journal of Materials Processing Technology, 2006, 172(1): 364-375.

[2]Deckard C R. Method and Apparatus for Producing Parts by Selective Sintering[P]. US 4863538, 1989-09-05.

[3]Goodridge R D, Ohtsuki C, Kamitakahara M, et al. Fabrication of bioactive glass-ceramics by selective laser sintering[J]. Key Engineering Materials, 2006, 309-311: 289-292.

[4]肖强伟, 余欢, 徐志峰. 选择性激光烧结技术的发展概况及展望[J]. 国外金属加工, 2005, 26(2): 8-12, 25.

XIAO Qiang-wei, YU Huan, XU Zhi-fen. Development overview and prospect of selective laser sintering[J]. Journal of International Metal Working, 2005, 26(2): 8-12, 25.

[5]Evans R S, Bourell D L, Beaman J J. Rapid manufacturing of silicon carbide composites[J]. Rapid Prototyping Journal, 2005, 11(1): 37-40.

[6]Newkirk M S. Novel Ceramic Materials and Methods of Making Same[P]. EP 0155831A2, 1985-03-15.

[7]Murthy V S R, Rao B S. Microstructural development in the directed melt oxidized (DIMOX) Al-Mg-Si alloys[J]. Journal of Materials Science, 1995, 30(12): 3091-3097.

[8]张明海, 杨刚宾. Lanxide材料及其研究进展[J]. 洛阳工业高等专科学校学报, 2006, 16(1): 5-7.

ZHANG Ming-hai, YANG Gang-bin. Lanxide materials and its researching progression[J]. Journal of Luoyang Technology College, 2006, 16(1): 5-7.

[9]Guerazi M, Drew R A L. Microstructural evolution of silicon carbide/aluminum oxide composites processed by melt oxidation[J]. Journal of Materials Science, 1998, 33(2): 5081-5093.

[10]赵敬忠, 金志浩. Lanxide陶瓷基复合材料的研究进展[J]. 硅酸盐通报, 2002, 21(6): 46-52.

ZHAO Jing-zhong, JIN Zhi-hao. Progress in lanxide ceramic matrix composites[J]. Bulletin of the Chinese Ceramic Society, 2002, 21(6): 46-52.

[11]Sercombe T B, Schaffer G B. Rapid manufacturing of aluminum compoents[J]. Science, 2003, 301(29): 1225-1227.

[12]Michael K. Method of Making Metal Matrix Composite Bodies with Use of A Reactive Barrier[P]. US 005316069A, 1994-05-31.

[13]Nelson J, Vail K, Barlow W, et al. Selective laser sintering of polymer-coated silicon carbide powders[J]. Industrial and Engneering Chemistry Research, 1995, 34(5): 1641-1651.

[14]任淑彬, 叶斌, 曲选辉. 复杂形状SiCp/Al复合材料零件的制备与性能[J]. 中国有色金属学报, 2005, 15(11): 1722-1726.

REN Shu-bin, YE Bin, QU Xuan-hui. Preparation and properties of SiCp/Al composite parts with complex shape[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(11): 1722-1726.

[15]王芬, 林营, 罗宏杰. 直接金属氧化法制备SiCp/Al2O3-Al复合材料的显微结构及工艺因素的研究[J]. 陶瓷学报, 2004, 25(2): 93-97.

WANG Fen, LIN Ying, LUO Hong-jie. Study on the microstructure and process of SiCp/Al2O3-Al composites made by directed metal oxidation[J]. Journal of Ceramics. 2004, 25(2): 93-97.

[16]Sandeep K, Vikarm J. Degradation of Al2O3-SiC-Al composites prepared by the oxidative growth of Al-alloys into SiC particulate[J]. Journal of Materials Science, 1997, 32(17): 4719-4722.

[17]Pechcanul M I, Katz R N, Makhlouf M M. The role of silicon in wetting and pressureless infiltration of SiCp preforms by aluminum alloys[J]. Journal of Materials Science, 2000, 35(9): 2167-2173.

[18]Zulfia A, Hand R J. Role of Mg and Mg+Si as external dopants in production of pure Al-SiC metal matrix composites by pressureless infiltration[J]. Materials Science and Technology, 2000, 16(7-8): 867-872.

[19]Nagelberg A S. Observations on the role of Mg and Si in the directed oxidation of Al-Mg-Si alloys[J]. Journal of Materials Research, 1992, 7(2): 265-268.

[20]林营, 杨海波, 王芬. SiO2氧化层在DIMOX法制备SiCp/Al2O3-Al复合材料中的作用机制[J]. 陕西科技大学学报, 2005, 23(4): 21-24, 32.

LIN Ying, YANG Hai-bo, WANG Fen. Function of SiO2 oxidation layer on SiCp/Al2O3-Al composites prepared by directed metal oxidation[J]. Journal of Shanxi University of Science & Technology, 2005, 23(4): 21-24, 32.

[21]Nagelberg A S, Antolin S. Formation of Al2O3/metal composites by the directed oxidation of molten aluminum-magnesium-silicon alloys[J]. Journal of American Ceramic Society, 1992, 75(2): 455-462.

(编辑陈爱华)

基金项目: 湖北省自然科学基金创新群体资助项目(2004ABC001); 中南大学粉末冶金国家重点实验室开放基金资助项目(200506123102A)

收稿日期: 2006-06-22; 修订日期: 2006-09-22

通讯作者: 史玉升, 教授; 电话: 027-87547042; 传真: 027-87548581; E-mail: wenwuxu@126.com