文章编号:1004-0609(2009)03-0529-09

机械合金化对W-Ti合金组织与性能的影响

王庆相,范志康,杨 怡

(西安理工大学 材料科学与工程学院,西安 710048)

摘 要:以乙醇为过程控制剂,采用机械球磨方法制备W-10%Ti(质量分数)、W-10%TiH2纳米晶W-Ti粉末,晶粒粒径为30~80 nm,粉体经压制后在1 823 K保温烧结80 min得到W-Ti合金。利用X射线衍射、透射电镜和扫描电镜等手段,研究球磨时间对两种粉末及其烧结试样的相组成和微观组织的影响;测量烧结试样的密度和显微硬度。结果表明:机械合金化能够降低烧结温度,提高烧结体的密度,组织均匀且晶粒细小;利用W-TiH2球磨粉制备的W-Ti合金与W-Ti粉相比密度较高且晶粒细小。

关键词:W-Ti合金;机械合金化;密度;显微硬度

中图分类号:TG 146.4 文献标识码:A

Influence of mechanical alloying on structure and properties of W-Ti alloy

WANG Qing-xiang, FAN Zhi-kang, YANG Yi

(School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: W-Ti nanocrystalline alloying powders of 30?80 nm with composition of W-10%Ti (mass fraction) and W-30% TiH2 were prepared by mechanical milling in alcohol media. The W-Ti alloy was prepared by pressing and sintered at 1 823 K for 80 min using W-Ti powders. The phase constituent and microstructure of the powders and alloy billets were analyzed by X-ray diffractometry (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The density and micro-hardness of the alloy billets were also measured. The results show that mechanical alloying is helpful to decrease the sintering temperature and increase the density. The microstructure of the alloys is well-proportioned and the size of crystal is small. The alloy prepared by W-TiH2 powders has higher density than W-Ti powders, and its particle size is finer.

Key words: W-Ti alloy; mechanical alloying; density; micro-hardness

W-Ti合金因为具有稳定的热机械性能、低电子迁移率、高抗腐蚀性能和化学稳定性,已经被成功地用于制备集成电路Al、Cu与Ag布线技术的扩散阻挡层薄膜[1?2];WOx-TiOx、W-Ti-C和W-Ti-N薄膜等也在电致变色材料、耐磨材料和微电子材料方面得到了广泛的研究[3?5],W-Ti薄膜的性能依赖于W-Ti合金靶材的密度、晶粒度和相组成。机械合金化作为一种新工艺已经被应用于很多领域,如制备高密度合金等,该工艺具有均匀混合粉体、细化晶粒、活化烧结和降低烧结温度等优点[6]。当前,W-Ti合金靶材的制备主要以微米级的W粉和Ti粉(或TiH2粉)为原料,利用热压法(包括真空热压和惰性气体热压法)、热等静压法和热爆炸法来合成制备[7?9]。采用这些方法制备的W-Ti合金晶粒粗大、致密度较低,且很难得到单一相的组织,从而影响了W-Ti薄膜的阻挡性能。因此,寻找新的途径制备细晶粒、高致密度的W-Ti合金是目前研究的热点;但当前研究者的工作主要集中在材料制备方法的改进上,有关原始粉末的粒度及其相组成对材料性能的影响研究相对较少。本文作者采用高纯W粉、Ti粉和TiH2粉为原始粉末,采用机械合金化法和真空烧结制备W-10%Ti和W-10%TiH2球磨粉及其烧结材料,研究机械合金化时间对不同混合粉体及其烧结材料组织和性能的影响,对比使用Ti粉和TiH2粉对烧结材料的影响,为制备高性能W-10%Ti合金靶材提供新的途径。

1 实验

1.1 实验原料

实验原料如下:W 粉,纯度大于 99.9 %,平均粒径6 μm,含氧量小于6×10?4;Ti 粉,纯度大于99.9%,平均粒径44 μm,含氧量小于1.7×10?3;TiH2粉,纯度大于99.7 %,平均粒径35 μm,含氧量小于2.0×10?3。

1.2 实验过程

实验过程如下:称取W-10%Ti、W-10%TiH2两种混合粉末进行研究,球磨过程中球料质量比为20?1,研磨球材料为WC硬质合金,加入适量乙醇作为过程控制剂(PCA),密封装罐进行不同时间(0,12,24,48和72 h)球磨,获得 W-Ti和W-TiH2两种粉末。将不同球磨时间的粉末在400 MPa压力下冷压成型,然后放入真空烧结炉中,真空度为5.0×10?2 Pa,1 623~ 1 823 K保温2~3 h。

1.3 材料表征和性能测试

对含Ti或TiH2、不同球磨时间的粉末进行 X 射线衍射分析,以确定物相、晶粒尺寸和微应变等;采用扫描电子显微镜和高分辨透射电镜对粉末和其对应的烧结体形貌进行观察分析。利用阿基米德排水法测量密度,利用显微硬度仪测量显微硬度。XRD使用的是日本岛津制作所的XRD?7000 型X射线衍射仪, 测试条件为Cu Kα 辐射,最大管电压60 kV,最大管流80 mA,扫描速度8 (?)/min;SEM采用的是JSM?6700 F型场发射扫描电镜;高分辨透射电镜的型号为JEM?3010。

2 结果和分析

2.1 球磨后粉体的物相分析

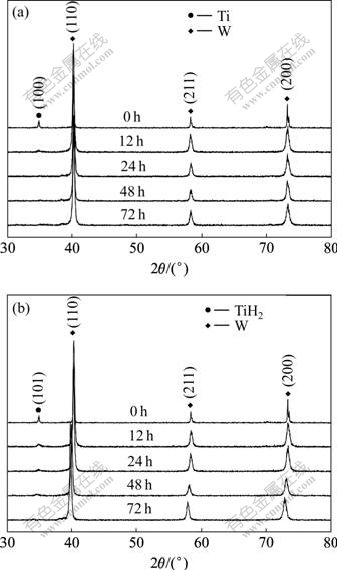

图1所示为粉末经过不同时间球磨后的XRD谱。由图1可知,随着球磨时间的延长,W(JCPDS 47?1319)的衍射峰出现宽化和向低角度偏移,宽化主要是由于晶粒细化和点阵畸变造成的[10],向低角度偏移是由于β-W/Ti固溶体的形成和含量逐渐增加造成的;Ti(JCPDS 44?1294)或TiH2(JCPDS 03?0859)的衍射峰的变化非常不明显,这是因为一方面Ti和W的互溶形成固溶体相;另一方面Ti的原子序数相对较低,且原子散射因子正比于原子序数,随着Ti含量的减少,衍射谱中Ti的衍射峰强度变弱。随着球磨时间的延长,晶体的完整性遭到破坏,使得参与衍射的晶粒减少,从而导致W和Ti的衍射峰高逐渐降低直到Ti的衍射峰消失,这也说明 Ti溶入W 中,形成体心立方相β-W/Ti。

图1 经过不同时间球磨后粉末的XRD谱

Fig.1 XRD patterns of powders after ball-milled for different times: (a) W-Ti; (b) W-TiH2

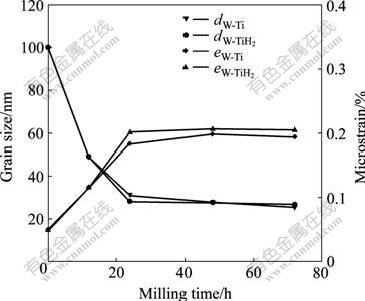

根据衍射峰的宽化度B,由文献[11]中公式: Bcosθ = 0.94λd+4esinθ,可以估算粉末的晶粒尺寸d和点阵畸变e。其中,λ为入射X射线波长,θ为Bragg角,B为衍射峰半高宽。晶粒尺寸及点阵畸变随球磨时间的变化趋势如图2所示,其中初始晶粒度为W粉的晶粒度。从图2可以看出,随着球磨时间的增加,晶粒尺寸逐渐减小,点阵畸变逐渐变大,并且在最初的24 h内晶粒尺寸降幅最快,畸变程度增幅最大。这是因为球磨初期,晶粒内部位错密度增加,引起微观应力升高,而此时晶粒尺寸较大,微观应力不能很好地释放,从而导致微观应变的增加。继续球磨,晶粒尺寸下降缓慢,说明球磨提供的能量不足以再使晶粒细化,粉末的塑性变形量趋于稳定,晶粒内部应变趋于平衡。继续延长球磨时间,即球磨末阶段,颗粒变形程度的增加导致位错密度进一步增加到一定程度时,位错将以降低应变能的组态形式排列,即离开其滑移面而形成弯曲平台,这种多边化排列导致晶粒内长程应力区消失,微观应变稍有降低。由于W-TiH2粉为脆性系其过程中产生的应变强化程度大使应变能要稍高于W-Ti粉,两种混合粉末都发生固溶生成了β-W/Ti固溶体,但W-TiH2粉的合金化程度较低且时间较长。

图2 粉末晶粒尺寸和微应变与球磨时间的关系

Fig.2 Relationships among powders grain size, micro-strain and milling time (e: Micro-strain; d: Grain size)

2.2 球磨后粉体的形貌分析

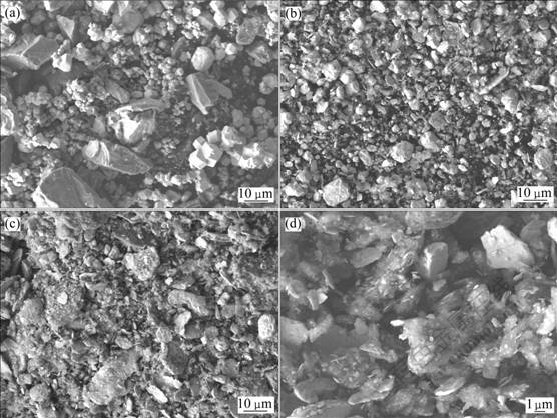

利用SEM对W-Ti和W-TiH2两种粉末球磨不同时间产物的形貌进行了观察。图3(a)和图4(a)所示分别为两种粉末球磨时的形貌。由图可知,W粉为类球形颗粒,而Ti和TiH2粉均为无规则块状颗粒。图3(b)所示为W-Ti粉末球磨24 h后的形貌,球磨初期延性粉末(Ti)在研磨介质的作用下发生严重的塑性变形,而脆性粉末(W)在研磨球的作用下迅速破碎,形成超细粉末,被破碎的W具有很高的表面能,它们团聚在一起或聚集在Ti粉表面以降低系统自由能;包覆在Ti粉表面的超细W颗粒阻碍了Ti粉的延展,加速了Ti粉的断裂,颗粒尺寸在球磨初期迅速减小;图3(c)所示为W-Ti混合粉末球磨48 h后的形貌,颗粒为片层状形貌,聚集情况明显;由于常规手段难以分散粉末的聚集,扫描电镜下观察到的颗粒可能是由更细小的颗粒聚集而成;继续球磨72 h,片层颗粒更多(见图3(d)),尺寸<4 μm。W-Ti粉末属于典型的脆性/韧性体系;W-TiH2则属于脆性/脆性体系,这是因为TiH2是硬脆粉,球磨初期(0~12 h)两种粉末被迅速破碎(见图4(a)),在形成超细粉的同时,由于过程产生的能量使得TiH2缓慢分解生成Ti,因而与W-Ti粉对比,其粒度明显偏小且相对均匀(<1 μm),片层状结构更细小(见图4(d))。粉末在球磨过程中形态和尺寸的变化与晶粒所发生的塑性变形、断裂和焊合互溶现象有关。当球磨时间为12 h时,金属细晶内部的缺陷较少,具有良好的塑性,因此在磨球的冷墩和碾压轧制作用下,晶粒发生了显著的压缩塑性变形,由块状和球状变成了层片状。此后,晶粒在磨球的高速撞击、研磨下发生断裂。晶粒断裂后形成金属表面具有很高的活性,在磨球的作用下重新焊合互溶,经过焊合互溶—断裂—再焊合互溶这样不停的反复循环。随着球磨时间的延长,复合晶粒的塑性变形不断累积,高能球磨在复合颗粒中造成了极大的应力、应变,使其产生大量缺陷。这些缺陷的存在很容易诱发微裂纹,并且由于加工硬化晶粒变得越来越脆,晶粒硬化而发生断裂的频率大大超过晶粒发生冷焊的频率,晶粒被破碎,因此当球磨时间继续增加时颗粒继续减小直到达到一个平衡状态[12]。

图3 不同球磨时间后W-Ti粉末的SEM像

Fig.3 SEM images of W-Ti powder after ball-milled for different times: (a) 0 h; (b) 24 h; (c) 48 h; (d) 72 h

图4 不同球磨时间后W-TiH2粉末的SEM像

Fig.4 SEM images of W-Ti H2 powder after ball-milled for different times: (a) 0 h; (b) 24 h; (c) 48 h; (d) 72 h

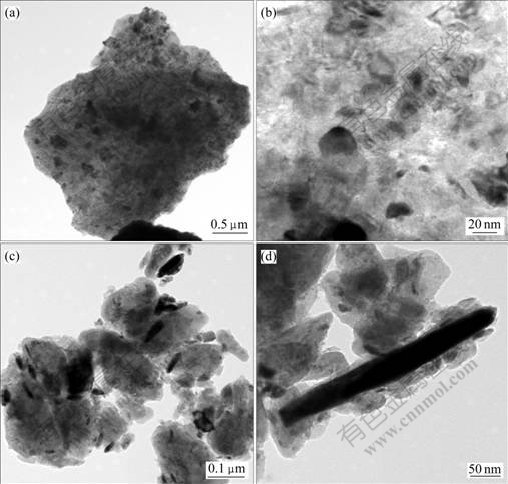

图5所示为W-Ti和W-TiH2粉末球磨48 h后的TEM照片,图5(a)和(b)所示为W-Ti合金粉末的明场像。由图可知,球磨48 h后晶粒已达到纳米级;颗粒主要是片状结构,由浅色区和深色区两种不同颜色的区域组成。图5(c)和(d)所示为W-TiH2合金粉末的明场像。由图可以看出,晶粒已达到纳米级且在颗粒周围分布着很多纳米级小颗粒,还有少量的黑色条状颗粒,片层结构细小(<0.5 μm)。通过对W-Ti合金粉末多晶电子衍射环的分析,能够判断衍射花样为固溶体β-W/Ti,原因是固溶体β-W/Ti和W之间的衍射数据基本上相同,且未发现Ti的衍射环,故判断其为β-W/Ti;其中深色区可能为富Ti固溶体,而浅色区域为富W固溶体。可见Ti和W基本上发生合金化反应生成无限固溶体。W-TiH2除了存在上述的无限固溶体外,其黑色条状组织的多晶衍射环经分析为TiH2,这说明TiH2还没有完全分解与W发生互扩散,合金化还没有完成,这与球磨粉在48 h的XRD结果吻合。

图5 球磨48 h后W-Ti和W-TiH2粉末的TEM像

Fig.5 TEM images of W-Ti and W-TiH2 powders after ball-milled for 48 h: (a), (b) W-Ti; (c), (d) W-TiH2

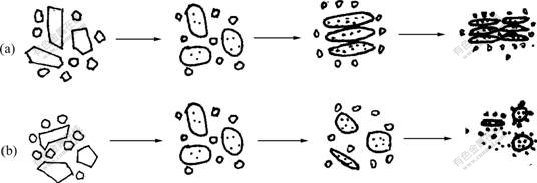

由上述SEM和TEM观察推断,合金粉末形成的可能机理如图6所示。球磨初期,W-Ti和W-TiH2的过程基本上相同,主要是无规则块状Ti或者TiH2颗粒菱角的磨平及球化过程(见图6(a)和(b)中的第一阶段),但由于W-Ti和W-TiH2属于两种不同的粉末体系,因此,在第二阶段的差异较大,脆性/韧性体系的W-Ti混合粉由于W和Ti之间的硬度差别较大,较硬的W颗粒容易进入较软的Ti粉中,形成很多周围密布小颗粒的片层结构复合颗粒,且随着时间的延长,这种片层结构更薄更细,有朝同一方向排布的趋势。而脆性/脆性体系的W-TiH2混合粉主要是颗粒球化变小的过程,在这个过程中仅有很少一部分为层片状结构;球磨足够长时间以后,较大颗粒周围分布着很多纳米级的细小颗粒。

图6 W-Ti和W-TiH2粉末机械合金化示意图

Fig.6 Schematic diagram of mechanical alloying process for W-Ti and W-TiH2 powders: (a) W-Ti; (b) W-TiH2

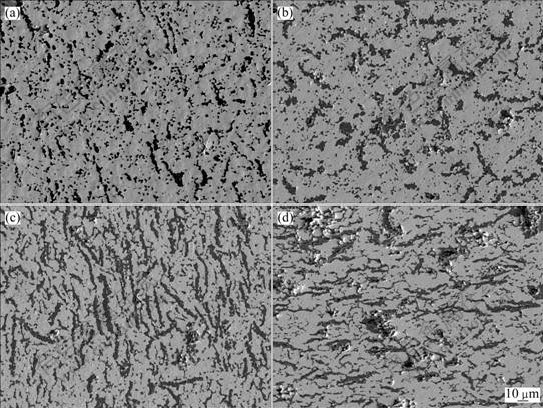

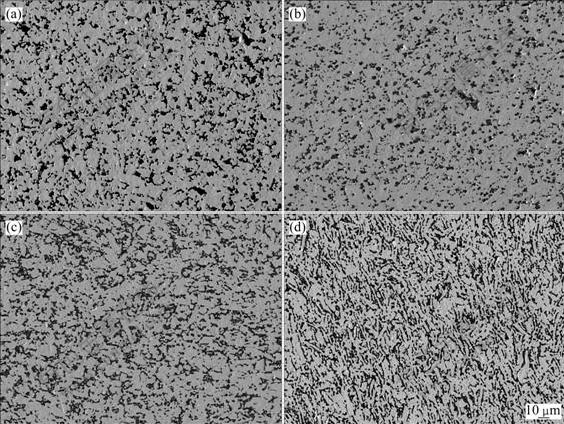

2.3 球磨时间对烧结样组织的影响

采用未球磨的粉体制备的W-Ti合金致密度仅为80%左右,孔隙和孔洞较多;图7和图8所示分别为粉末球磨后压坯烧结组织的SEM像。图7所示为W-Ti粉体球磨不同时间后的烧结组织。由图7可知,烧结组织主要是由浅色区和深色区两种形貌组成,随时间的延长晶粒逐渐减小,由初始的球状组织(见图7(a)和7(b))逐渐转变为长条状组织(见图7(c)和7(d)),长条状组织主要是在球磨过程中由片状组织烧结形成的,孔隙和孔洞较少。经过点能谱分析深色区Ti含量呈逐渐下降的趋势,说明其固溶量越来越多、程度越来越均匀。图7(b)、(c)和(d)中出现了凝固相,尤其是在图7(d)中非常明显,主要是因为晶粒细化到纳米级以后降低了Ti的熔点,使其在烧结温度(1 823 K)时形成了部分液相,液相的形成导致凝固过程中形成细小的孔洞。图8所示分别为W-TiH2粉体球磨不同时间后的烧结组织,与W-Ti粉体的烧结试样相比,该烧结组织也是由浅色区和深色区两种形貌组成,但其颗粒更细小分布更均匀,孔洞少且不存在凝固相。球磨48 h时深色颗粒分布更加均匀且有存在少量条状颗粒(见图8(c)),随着球磨时间的延长(72 h)时,条状组织更加明显。通过对两种不同粉末不同球磨时间的烧结形貌分析,可以看出W-TiH2粉体的烧结性能较好,其组织比较均匀晶粒细小,这与球磨的机理相对应,Ti和TiH2粉的硬度差别较多,球磨后TiH2更容易细化且团聚现象更加明显,使W-TiH2粉体系在烧结后颗粒尺寸相比W-Ti粉体更加细小、均匀,这与SEM和TEM对应的球磨颗粒尺寸的大小关系相对应,且在球磨过程中生成的活性Ti更容易与W固溶生成β相固溶体,同时烧结过程中极少量未合金化的TiH2粉在1 273~ 1 473 K温度范围内真空气氛下能够分解生成Ti增加了扩散的均匀性因而在烧结过程中没有发现凝固相,经过点能谱分析W-TiH2粉体烧结试样随着球磨时间的不同其在深色区中W的固溶量逐渐增多,在72 h时固溶量达到了24.48%。对两种粉末球磨24 h烧结坯进行了线扫描分析(见图9),可见深色区均为Ti含量较多的相且W-Ti烧结试样深色区要大于W-TiH2烧结试样,可见W-TiH2粉末球磨后的粒度更小;通过W-Ti粉末烧结体(见图9(a)和9(b))可以看出,深色区较大且呈现扁平状结构的趋势,而W-TiH2粉末烧结体(见图9(c)和9(d))深色区颗粒较小且分布均匀。

图7 球磨不同时间后W-Ti烧结坯的SEM像

Fig.7 SEM images of W-Ti sintered samples after ball-milled for different times: (a) 12 h; (b) 24 h; (c) 48 h; (d) 72 h

图8 球磨不同时间后W-TiH2烧结坯的SEM像

Fig.8 SEM images of W-TiH2 sintered samples after ball-milled for different times: (a) 12 h; (b) 24 h; (c) 48 h; (d) 72 h

图9 两种粉末球磨24 h烧结坯组织及元素线扫描分析结果

Fig.9 SEM images and line scanning curves of elements for W-Ti and W-TiH2 powders after ball-milled for 24 h: (a), (b) W-Ti; (c), (d) W-TiH2

2.4 球磨时间对烧结密度的影响

不同的混合粉体在不同球磨时间后压坯密度(ρ1)、烧结后的密度(ρ2)和相对密度(μ)如表1所示,根据文献[7]可知W-10%Ti合金的理论密度为14.54 g/cm3。从表1中可以看出,随着球磨时间的延长,所制备的粉末在相同压力下压制的压坯密度逐渐减小,符合粉末越细其压制性能越差的压制规律;而烧结体的密度呈逐渐增大的趋势,这主要是由于晶粒细化有利于烧结密度的增加。W-Ti球磨粉的烧结坯致密度在90%以上,但72 h的球磨粉致密度仅为83.4%,主要原因是烧结时出现了裂缝,导致试样致密度偏低。W-TiH2球磨粉在相同球磨时间的压坯密度和烧结体密度均高于W-Ti球磨粉压坯,致密度最高为99.4%,这是由于W-TiH2球磨后类球形颗粒较多,片层结构细小,压制性能较好;而W-Ti粉球磨后主要为层片状结构,这种结构降低了压制性能,使其密度偏低,经72 h球磨的粉末由于片层结构太多导致了压坯出现了许多微小的裂纹,这种微小的裂纹在烧结过程由于热应力的影响容易导致裂缝的出现,降低致密度。

表1 球磨不同时间的压坯和烧结试样密度

Table 1 Density of sample without sintered and sintered after ball-milled for different times

机械合金化之所以能够降低烧结温度,提高烧结体的密度与晶体之间的扩散有重要的关系。晶体的自扩散能力对晶粒的烧结性能有着重要影响。在金属合金中,扩散既可以在晶内进行,也可以沿颗粒表面、晶界、亚晶界、相界和位错线等进行。由于晶界等缺陷处的晶格畸变较大,能量较高,其扩散激活能要比晶内小,原子易于扩散迁移,因此原子沿晶界等缺陷的扩散比晶内快[13]。密度提高的原因是由于球磨过程中粉体受到冲击而发生变形而细化晶粒并且产生大量晶格缺陷和纳米晶晶界,相当于提供了许多快速扩散的通道,使原子的扩散激活能降低,扩散系数增大;使系统的自由能、原子活性和分布在纳米晶界上的原子数增加从而促进了原子扩散,同时由于球磨使粉末之间的混合达到原子级水平[14],并且根据位错密度(ρd)估算,ρd=3n/d 2 (n为单位面积的位错数,d为晶粒尺寸),未球磨ρd=106~108/cm2,球磨后ρd=1010~1012/cm2,球磨后这些大量存在的缺陷利于原子扩散和物质迁 移[15],因而在烧结过程中原子扩散距离缩短,烧结易于致密化,烧结温度相对降低。

2.5 烧结体硬度的测量

表2所列为球磨不同时间后烧结试样的显微硬度测量结果。由表可以看出,W-Ti球磨粉烧结后其显微硬度先增大后减小。对于W-Ti合金,影响其硬度的因素除了密度和晶粒度外,还包括固溶强化的效果。W-Ti粉球磨24 h后W和Ti固溶强化效果明显且晶粒更加细小,显微硬度相对较高,继续球磨由于生成的片状结构增多,可能会导致孔洞等缺陷的增多,从而导致了显微硬度的下降,尤其是球磨72 h后,片层颗粒导致压坯和烧结坯均产生微小的裂纹,使硬度迅速降低。W-TiH2球磨粉压坯烧结后硬度变化与W-Ti球磨粉烧结坯稍有不同,球磨12 h时硬度最大,而增加球磨时间后其硬度变化不大,分析原因为W-TiH2球磨12 h时,晶粒迅速细化并伴随有固溶强化使硬度最大;当增加球磨时间后晶粒度逐渐细化达到平衡,固溶程度也逐渐均匀,硬度反而有所下降;由此可见,固溶程度均匀性增加反而会导致硬度的下降。

表2 球磨不同时间后烧结试样的显微硬度

Table 2 Micro-hardness of sintered samples after ball-milled for different times

通过组织观察和性能测试发现,采用相同球磨时间时W-TiH2粉末制备的W-Ti合金性能要高,且组织更均匀细小。对于W-Ti粉末体系,由于Ti与O的亲和力较大,其在球磨混合、存放、压制等过程中已被部分氧化,晶界处的孔隙与预烧样的O含量呈正比[15],因此,O含量较高的预烧样经高温烧结后相对密度较低;同时Ti颗粒表面的氧化膜,阻碍了其向 W 中扩散,削弱了固溶强化的效果,并且由于氧化物使晶界的强度降低,容易产生脆性沿晶断裂[16]。对于W- TiH2粉末体系,TiH2的脆性比纯Ti 的大,球磨过程中TiH2颗粒较Ti颗粒粉碎程度大,故经球磨后其粒度较细,经脱氢后形成的 Ti 原子活性较高,易于向W 基体中扩散,强化效果明显,同时生成的氧化物相对较少。因此采用W-TiH2粉制备的W-Ti合金性能略高于W-Ti粉。根据球磨时间对W-TiH2粉末体系制备的合金组织和性能的影响发现,球磨时间为48 h时,组织明显细化且固溶效果较好,而延长时间虽然能够进一步细化组织但也会引入较多杂质并且增加成本,因此,采用W-TiH2粉末制备W-Ti合金球磨最优时间为48 h。

3 结论

1) 用机械球磨制备W-Ti和W-TiH2复合粉体可得到成分均匀,烧结活性高的纳米晶预合金粉。随着球磨时间的延长,晶粒尺寸逐渐下降,点阵畸变也逐渐增大。

2) 随着球磨时间的延长W-Ti合金的致密度不断增加,组织更加均匀细小;机械球磨是提高W-Ti合金的性能,降低烧结温度,提高致密度的有效途径。

3) 采用W-TiH2球磨粉比W-Ti球磨粉制备的W-Ti合金整体性能要好,可以减少氧化和避免烧结过程中液相的产生。

REFERENCES

[1] DIRKS A G, WOLTERS R A M, NELLISSEN A J M. On the microstructure-property relationship of W-Ti-(N) diffusion barriers[J]. Thin Solid Films, 1990, 193/194(1): 201?202.

[2] BHAGAT S, HAN H, ALFORD T L. Tungsten-titanium diffusion barriers for silver metallization[J]. Thin Solid Films,2006, 515(4): 1998?2002.

[3] BUNDALESKI N, PETROVIC S, PERUSKO D, KOVAC J, ZALAR A. Composition of the sputter deposited W-Ti thin films[J]. Applied Surface Science,2008, 254(20): 6390?6394.

[4] SHIEH J, FENG H M, HON M H, JUANG H Y. Tribological behaviour of W-Ti-N sputtered thin films[J]. Surface and Coatings Technology,2005, 200(1/4): 186?188.

[5] CAVALEIRO A, TRINDADE B. Influence of Ti addition on the properties of W-Ti-C/N sputtered films[J]. Surface and Coatings Technology, 2003, 174(9/10): 68?75.

[6] SURYANARAYANA C. Mechanical alloying and milling[J]. Progress in Materials Science,2001, 46(1/2): 1?25.

[7] WICKERSHAM C E. Method of producing tungsten-titanium sputter targets and targets produced thereby: US 685789[P]. 1993.

[8] LO C F. Single phase tungsten-titanium sputter targets and method of producing same: US 630155[P]. 1996

[9] KECSKES L J, HALL I W. Microstructural effects in hot-explosively-consolidated W-Ti alloys[J]. Journal of Material Processing Technology, 1999, 94(2/3): 247?260.

[10] GAFFET E, ABDELLAOUI M, MALHOUROUX-GAFFET N. Formation of nanostructural materials induced by mechanical processing[J]. Material Transactions, JIM, 1995, 36(2): 198?200.

[11] 范 雄. 金属X射线学[M]. 北京: 机械工业出版社, 1989: 119?121.

FAN Xiong. Metal X-ray analysis[M]. Beijing: China Machine Press, 1989: 119?121.

[12] 肖 鹏, 赵玮兵, 梁淑华, 范志康. 机械合金化法制备不同Cr含量的W-Cr纳米合金粉末[J]. 中国有色金属学报, 2007, 17(11): 1780?1782.

XIAO Peng, ZHAO Wei-bing, LIANG Shu-hua, FAN Zhi-kang. Preparation of W-Cr nano alloying powders with different Cr contents by mechanical alloying[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1780?1782.

[13] 冯 端, 师昌绪, 刘治国. 材料科学导论[M]. 北京: 化学工业出版社, 2002: 502?505.

FENG Duan, SHI Chang-xu, LIU Zhi-guo. Introduction to material science[M]. Beijing: Chemical Industry Press, 2002: 502?505.

[14] 范景莲, 黄伯云, 梁淑全, 曲选辉. 纳米晶W-Ni-Fe粉的流变行为和烧结特性[J]. 中南工业大学学报, 2001, 32(1): 66?68.

FAN Jing-lian, HUANG Bai-yun, LIANG Shu-quan, QU Xuan-hui. Rheologic behavior and sintering characteristic of nanocrystal W-Ni-Fe powder[J]. Journal of Central South University of Technology, 2001, 32(1): 66?68.

[15] 范景莲, 曲选辉, 李益民, 刘绍军, 黄伯云. 高能球磨钨基高密度合金超细粉末的烧结[J]. 中南工业大学学报, 1998, 29(5): 450?452.

FAN Jing-lian, QU Xuan-hui, LI Yi-min, LIU Shao-jun, HUANG Bai-yun. Sintering of nanocrystalline tungsten heavy alloy powders prepared by high energy ball milling[J]. Journal of Central South University of Technology, 1998, 29(5): 450?452.

[16] 李玉清, 刘锦岩. 高温合金晶界间隙相[M]. 北京: 冶金工业出版社, 1990: 91?93.

LI Yu-qing, LIU Jin-yan. Grain boundary clearance phase of superalloy[M]. Beijing: Chemical Industry Press, 1990: 91?93.

[17] 张久兴, 刘燕琴, 刘丹敏, 周美玲, 左铁镛. 微量 La2O3对 Mo的韧化作用[J]. 中国有色金属学报, 2004, 14(1): 13?15.

ZHANG Jiu-xing, LIU Yan-qin, LIU Dan-min, ZHOU Mei-ling, ZUO Tie-yong. Toughness of La2O3-doped Mo alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 13?15.

基金项目:国家自然科学基金资助项目(50474012)

收稿日期:2008-08-27;修订日期:2008-12-28

通讯作者:范志康,教授,博士;电话:029-82312773;E-mail: fanzk@xaut.edu.cn

(编辑 龙怀中)