文章编号:1004-0609(2014)01-0053-08

Si添加量对机械合金化Al-12%Sn合金组织与摩擦性能的影响

叶 新,鲁忠臣,曾美琴,胡仁宗,朱 敏

(华南理工大学 材料科学与工程学院,广州 510640)

摘 要:利用机械合金化方法制备出Al-12%Sn-x%Si合金粉末,然后将其压制成型,并进行烧结得到块体合金;运用X线衍射仪(XRD)和扫描电镜(SEM)等研究Si添加量对Al-12%Sn合金组织和性能的影响。结果表明:添加Si使得Al-12%Sn合金中Sn相变得更加细小且均匀分布,并且通过形成Al-Si共晶液相能够有效改善合金的烧结活性,提高合金的致密度;随着合金中Si添加量增加,合金的硬度、强度和塑性都有大幅度提升。此外,添加Si的Al-12%Sn合金的摩擦磨损性能也有较大提高,Si含量为2.5%时,合金具有最优的摩擦性能。

关键词:Al-Sn-Si合金;机械合金化;摩擦性能

中图分类号:TG135 文献标志码:A

Effects of Si addition on microstructure and wear properties of mechanical alloying Al-12%Sn

YE Xin, LU Zhong-chen, ZENG Mei-qin, HU Ren-zong, ZHU Min

(School of Materials Science and Engineering,South China University of Technology, Guangzhou 510640, China)

Abstract: The mechanical alloying (MA) was used to prepare Al-12%Sn-x%Si alloy powders, and then, the bulk alloy was obtained by a combination of cold pressing and conventional powder sintering. The effects of Si addition on the microstructure and properties were investigated by XRD and SEM. The results show that appropriate Si addition can achieve the uniform Sn distribution in Al-12%Sn matrix. It can also effectively facilitate sintering due to the formation of Al-Si eutectic liquid phase, and significantly improve the densification of alloy. With the Si addition increasing, the hardness, strength and ductility enhance obviously. In addition, Si addition can also develop excellent wear properties in Al-12%Sn alloys, furthermore, when the Si addition is 2.5%, Al-12%Sn-2.5%Si has the best wear properties.

Key words: Al-Sn-Si alloy; mechanical alloying; wear properties

Al-Sn、Al-Pb系合金是现代工业上被最广泛应用的滑动轴承材料,但是,随着人们环保意识的增强,含铅类轴承合金由于Pb的毒害作用逐步被淘汰[1]。另一方面,发动机向高速、高载、低能耗和轻量化的方向发展,也对Al-Sn基轴承合金的力学性能和摩擦学等性能提出了更高的要求。中锡轴承铝合金由于具有较高的力学性能、热传导性和较好的耐磨性等诸多优点,近年来得到广泛的重视。

控制Al-Sn合金的显微组织是其获得优异的摩擦学性能的关键,这其中Sn相的大小和弥散程度尤为关键。由于Al和Sn的固溶度非常小可看成互不溶体系,同时,Al和Sn的密度相差较大,用传统的铸造方法制备Al-Sn合金一般会存在比重偏析缺陷,这严重地影响合金的摩擦学性能和承载能力。因此,改善制备工艺或采用新的制备方法,对于提高Al-Sn合金的性能十分重要。近年来,研究人员采用快速凝固法[2]、搅拌铸造法[3]、物理气相沉积[4]、粉末冶金法[5]和强烈塑性变形[6]等方法制备Al-Sn合金,使得其组织有所改善,但是Sn相不均匀,颗粒比较大等缺陷仍然没有完全解决。机械合金化(Mechanical alloying,MA)是一种在固态下实现合金化的方法,可较好地克服互不溶和密度差大等问题,获得均匀弥散的合金组织,这一方法早期成功地应用于Al-Pb合金[7]。最近,LIU等[8]、刘辛等[9]以及赖曲芳等[10]通过机械合金化制备纳米相复合的Al-Sn合金,其中Al相和Sn相的平均晶粒尺寸分别为70~80 nm和30~50 nm,经过450 ℃烧结制得的合金表现出较为优异的摩擦学性能和更高的承载能力。

通过机械合金化制备的Al-Sn合金存在一个较严重的缺陷[11],球磨细化后的Al颗粒容易氧化,在其表面形成一氧化层,氧化层的存在导致烧结过程中液相润湿性差,不利于颗粒之间的冶金结合,使得合金的疲劳强度低,承载能力差,这是进一步提高Al-Sn基轴承合金性能需解决的问题。Si与Al之间存在共晶反应,能促进液相烧结,改善气孔分布和形态,强化颗粒之间的结合。同时,Si可以提高铝基合金的基体强度和耐磨性[12]。FUENTES等[13]通过添加Si来改善Al烧结活性,提高Al的疲劳强度。但对于添加Si对机械合金化制备的Al-12%Sn合金组织和摩擦学性能影响还没有研究。本文作者对此开展研究,以期获得具有高疲劳强度和承载能力以及优异的摩擦学性能的Al-12%Sn-x%Si合金。

1 实验

首先将平均粒度为74 μm的硅粉(纯度99.99%)采用QM-3C高速摆振球磨机进行球磨细化,转速为 1 000 r/min,球磨时间为4 h,钢球和粉末的质量比为20:1,球磨后Si粉平均粒度约为2 μm。然后将平均粒度为25 μm的铝粉(纯度99.95%)和锡粉(纯度为99.99%)以及球磨细化后的硅粉按Al-12%Sn、Al-12%Sn-1.5%Si、Al-12%Sn-2.5%Si、Al-12%Sn- 3.5%Si(质量分数)比例配成混合粉,采用QM-3SP2行星式球磨机进行球磨,转速为300 r/min,球磨时间为40h,钢球和粉末的质量比为15:1。对球磨得到的合金粉末在664 MPa压力下冷压成28 mm×9 mm×3 mm的长方体状和d 24 mm×3 mm的圆片状块体,然后放入CVD(G)-07/50/2高温管式炉中在高纯氩气保护下经550和600 ℃温度烧结,保温时间均为1 h。

用Philips X’ pert MPD型X射线衍射仪(Cu Kα辐射)和Zeiss super 40 场发射扫描电子显微镜分析合金的组织结构。采用GB5163—85(可渗性烧结金属材料密度的测试)进行密度的测量以及致密度的计算。用HVS-1000型数字显微硬度计测合金硬度,载荷为0.49 N,保压时间为10 s,取5个点的平均值。将长方体试样用线切割加工成哑铃状,用Instron 5900电子万能材料试验机测合金的拉伸强度,拉伸速率为0.6 mm/min;压缩样品尺寸为d2 mm×3 mm,压缩速率为0.6 mm/min。滑动磨损试验在M-2000磨损试验机上进行。用线切割将材料切割成10 mm×10 mm×3 mm的试样,磨损面保持光滑平整,对磨环材料为GCr15钢,表面硬度为(58~60)HRC,尺寸为d 45.4 mm×10 mm。试验在干摩擦条件下进行,滑行速度为0.51 m/s,时间1 h。摩擦因数是指试样在磨损载荷的作用下滑动磨损1 h的平均摩擦因数。磨损体积是通过如下关系式[14]计算得出

(1)

(1)

式中:ΔV为磨损体积,B为试样的宽度,b为磨痕的宽度,r为对磨环的半径。

2 结果与分析

2.1 添加Si对MA Al-12%Sn合金烧结性能的影响

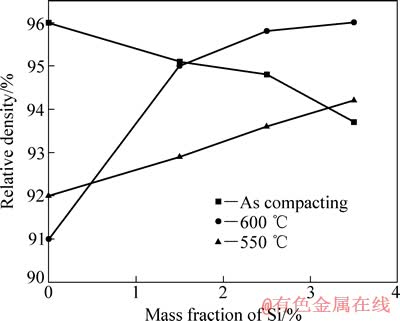

图1所示为合金经压制和在不同温度烧结1 h后Si含量与致密度的关系。由图1可见,随着Si含量的增加,球磨并压制后的合金致密度降低。这是由于Si质硬脆,塑性变形能力差,导致合金粉末的压制性能变差。但是,对于烧结样品而言,未添加Si时,Al-12%Sn(MA)合金烧结后致密度降低,而且温度越高,下降得越厉害,这是由于合金粉末在压制力作用下发生强烈的塑性变形,互相冷焊形成了封闭的空洞,在烧结过程中,封闭的气孔由于正压膨胀使体积增大,导致致密度降低;添加Si后,随着Si含量的增加,合金的致密度明显增加,从而有效改善合金的烧结性能,在600 ℃烧结改善效果尤为明显。这是由于在铝硅合金中,当烧结温度高于共晶温度577 ℃[15]时,Al与Si形成液相破坏Al的氧化膜[13],增加颗粒与颗粒间的接触面积。同时,Si能够降低Al液的表面张力,提高液相的润湿性[16],促进液相烧结。当烧结温度为550 ℃时,由于通过机械合金化获得的纳米晶结构促使Al和Si的共晶温度降低[17],从而在烧结过程中形成少量的液相也有利于提高合金的烧结致密度。由此可见,添加Si的Al-12%Sn(MA)合金在600 ℃时表现较优良的烧结性能,样品发生明显收缩。

图1 Al-12%Sn-x%Si(MA)合金在压制后和经不同温度烧结1 h后Si添加量与致密度的关系

Fig. 1 Relationship between Si addition and relative density Al-12%Sn-x%Si (MA) alloy after compacting and sintering at different temperatures for 1 h

2.2 添加Si对MA Al-12%Sn合金组织结构的影响

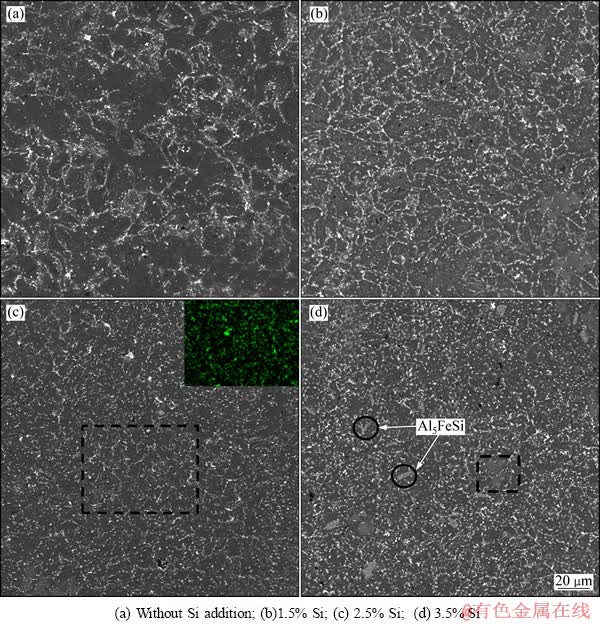

图2所示为Al-12%Sn-x%Si(MA)合金在600 ℃烧结1 h后的SEM像。图像均为背散射电子像,白亮组织对应的是原子序数较大的Sn相,暗黑的区域对应的是原子序数较小的Al基体相,而少部分灰色区域应为富Si相(见图2(d)中虚线框区域)。由图2可见,随着Si含量的增加,Sn相的分布形态明显发生变化。未添加Si时(图2(a)),Al-12%Sn(MA)合金中的Sn相呈网状分布,这是由于离异共晶现象造成的[8]。但添加一定量的Si后,由于Si在烧结过程中形成了铝硅共晶相而抑制了Al-Sn离异共晶,使得Sn相变得更加细小均匀分布(图2(b)和(c))),显然这种形态将有利于合金力学和摩擦学性能的提高,这也说明Si能够起到改善Al-Sn合金组织结构的作用。但是,当Si含量提高至3.5%时,合金中可观察到灰色条块状相,通过能谱分析为Al5FeSi相(见图2(d))。这种Al5FeSi是由于球磨过程中随着硬脆相Si含量的提高而加剧了Fe的污染造成的。由于Al5FeSi相是脆性相,因此,其对合金的综合性能不利。此外,如图2(c)中插图所示的能谱面扫描结果说明,合金中Si的分布还是比较均匀的。

图2 Al-12%Sn-x%Si(MA)合金在600 ℃烧结1 h后的SEM像

Fig. 2 SEM images of Al-12%Sn-x%Si (MA) alloy sintered at 600 ℃ for 1 h

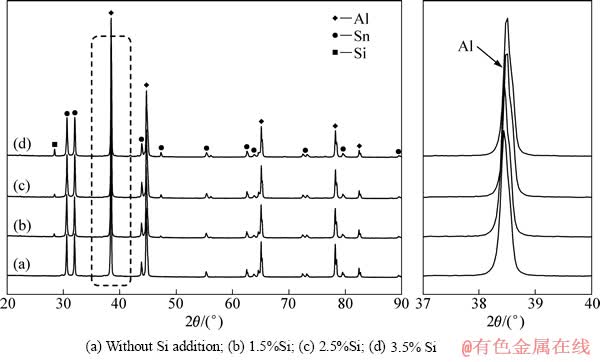

图3 Al-12%Sn-x%Si(MA)合金在600 ℃烧结1 h后的XRD谱

Fig. 3 XRD patterns of Al-12%Sn-x%Si (MA) alloy sintered at 600℃ for 1 h

图3所示为添加不同含量Si的Al-12%Sn(MA)合金在600 ℃烧结1 h后的XRD谱。由图3可见,添加不同量Si后,合金的衍射谱均只由Al、Sn和Si三相的衍射峰组成,但仔细观察发现Al的衍射峰位置随Si量的增加向高角稍漂移,这是由于有少量Si固溶到Al中,导致Al的点阵常数减小。图中并没有发现Al5FeSi相,这可能是由于该相的数量较少,在X线衍射中检测不到。

2.3 Si添加量对MA Al-12%Sn合金力学性能的影响

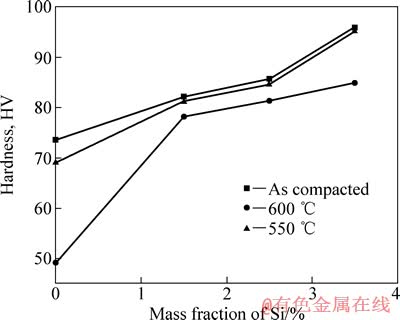

图4 Al-12%Sn-x%Si(MA)合金在不同温度烧结1 h后Si添加量与显微硬度的关系

Fig. 4 Relationship between of Si addition and microhardness of Al-12%Sn-x%Si (MA) alloy after compacting and sintering at different temperatures for 1 h

图4所示为不同温度烧结的合金的Si添加量与显微硬度的关系。由图4可见,随着Si添加量的增加,合金的显微硬度升高。这主要是因为Si作为一种硬质点,其均匀分布造成了弥散强化作用。此外,少量的Si固溶到Al基体中起到固溶强化作用。这两方面的共同作用导致了合金的硬度升高。由图4还可知,随着烧结温度的升高,合金的显微硬度逐渐下降。这是因为Al基体中的晶粒长大导致的细晶强化和Si相长大导致的弥散强化作用的减弱所致。

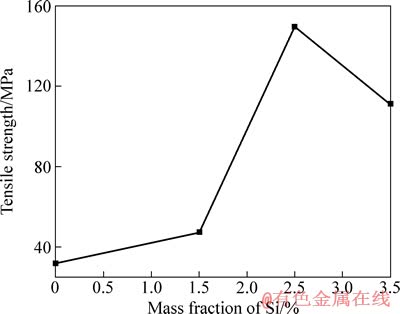

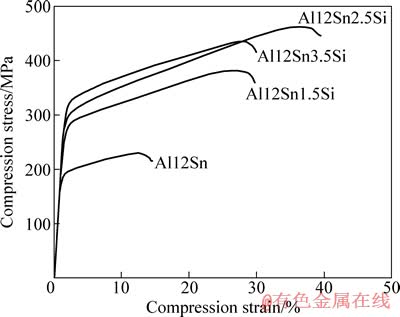

图5所示为添加不同Si添加量的合金在600℃烧结1h后的拉伸强度。由图5可以看到,随着Si添加量的增加,合金拉伸强度先增后减。拉伸强度的增大是因为Si相改善铝锡合金烧结性能的缘故,并且从合金在600 ℃烧结1 h后的压缩曲线(见图6)中也可以看到,添加Si后材料的塑性也明显改善,这也表明Si改善铝锡合金的烧结性能,增强了颗粒之间的冶金结合。但当Si添加量提高至3.5%时,由于形成了条块状Al5FeSi杂质相,而该相质硬脆,在Al基体中造成应力集中,拉伸或压缩时容易开裂[18-19],导致强度和塑性下降。由图1可以看到,Si添加量为2.5%的合金的拉伸强度和塑性提高幅度最大,因此,Si的最佳添加量应是2.5%。

图5 Al-12%Sn-x%Si(MA)合金在600 ℃烧结1 h后Si添加量与拉伸强度的关系

Fig. 5 Relationship between Si addition and tensile strength of Al-12%Sn-x%Si (MA) alloy sintered at 600 ℃ for 1 h

图6 Al-12%Sn-x%Si(MA)合金在600 ℃烧结1 h后压缩曲线

Fig. 6 Compression curves of Al-12%Sn-x%Si (MA) alloy sintered at 600 ℃ for 1 h

2.4 Si添加量对Al-12%Sn(MA)合金摩擦学性能的影响

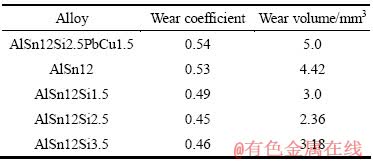

将不同成分烧结样品在100 N载荷下进行摩擦磨损试验,同时将AlSn12Si2.5PbCu1.5工业轴瓦作为对比样品,表1所列为所得到的摩擦因数和磨损体积数据。由表1可以看出,在Al-12%Sn(MA)合金中加入Si后,可明显提高合金的减摩性。这是因为在Al-12%Sn-x%Si(MA)合金中,Sn相变得更加细小、弥散地分布于Al基体上,故在合金的磨损表面容易形成连续的富锡氧化层[20],从而降低合金的摩擦因数。由表1还可见,Al-12%Sn-2.5%Si(MA)合金的磨损体积最小,这是因为该合金具有较高的硬度和强度以及良好的塑性配合。根据Archard公式[21],材料的耐磨性随着硬度的增加而提高。因此,Si相的添加能有效提高Al-12%Sn(MA)合金的耐磨性。此外,合金粉体之间的结合强度较高,使合金具有较大的承载能力,其磨损表面的氧化层在高载荷作用下不容易破裂和剥 落[10]。而且,对于脆性较高的纳米晶或超细晶合金,其塑性也是影响材料磨损性能的一个关键因素[22]。因此,在磨损过程中,对于Si添加量为1.5%和3.5%的Al-12%Sn(MA)合金而言,其摩擦表面因脆性断裂导致磨损量相对于Si添加量为2.5%的合金有所增加,故在硬度、强度和塑性的共同作用下Al-12%Sn-2.5%Si (MA)合金具有优异的耐磨性。从表1中还可见,添加Si的Al-12%Sn(MA)合金的耐磨性和减摩性均优于工业轴瓦AlSn12Si2.5PbCu1.5,因此,通过机械合金化方法制备的Al-12%Sn-x%Si合金,相对于传统铸造方法,具有优异的摩擦学性能。

表 1 Al-12%Sn-x%Si(MA)合金与工业轴瓦的摩擦学性能

Table 1 Tribological properties of Al-12%Sn-x%Si (MA) alloys and industrial bearing

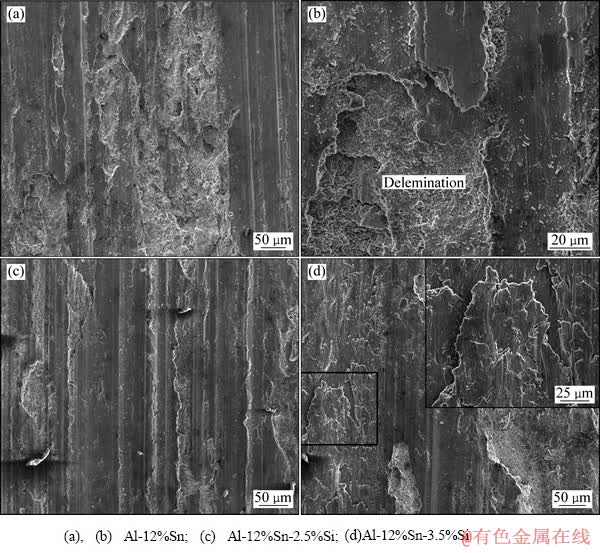

为了进一步研究其摩擦磨损机理,对磨损试样表面进行了SEM观察,其结果如图7所示。由图7可见, Al-12%Sn-2.5%Si(MA)样品的磨损表面明显比Al-12%Sn(MA)和Al-12%Sn-3.5%Si(MA)样品的磨损表面更加光滑且完整,从而有效地提高合金的耐磨性。能谱分析表明,磨损表面含有大量的氧元素,说明合金在空气中进行滑动磨损时由于摩擦生热而发生氧化。这种含有氧化物的光滑摩擦层具有很好的润滑作用,有利于提高合金的耐磨性。由于Si的添加有利于改善粉体颗粒之间的结合强度,从而有效增强了合金的承载能力,提高了氧化层的抗破裂能力,使得覆盖在磨损表面的氧化层更为连续完整分布。对于未添加Si的Al-12%Sn(MA)合金而言,由于缺乏铝硅共晶相的形成,颗粒之间的冶金结合效果差,造成了合金的承载能力不强,其磨损表面所形成的氧化层在高载荷下很容易形成裂纹,发生了剧烈的剥落磨损(图7(b))。对于Al-12%Sn-3.5%Si(MA)合金,如图7(d)所示,虽然具有较高的结合强度,但是合金的塑性较差,氧化层在高载荷的作用容易形成脆性断裂,发生局部破坏。此外,从合金的磨损过程中产生的磨屑的形貌也可以说明Si能够提高颗粒之间的结合强度,从而提高合金的耐磨性能。

图7 Al-12%Sn-x%Si(MA)合金磨损表面的SEM像

Fig. 7 SEM images of worn surface of Al-12%Sn-x%Si (MA) alloy

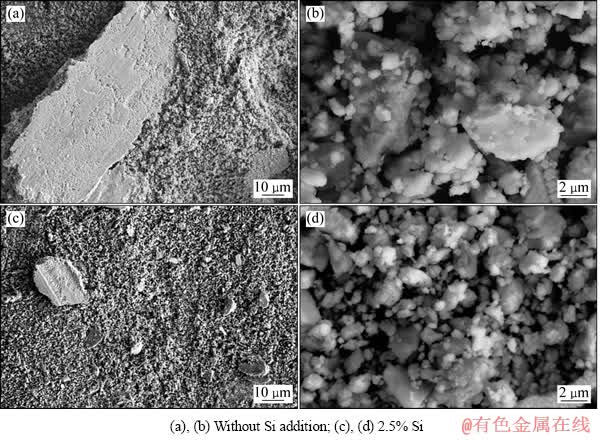

图8 未添加和添加2.5%Si的Al-12%Sn(MA)合金磨屑的SEM像

Fig. 8 SEM images of wear debris of Al-12%Sn (MA) alloy

图8所示为未添加和添加2.5%Si的MA Al-12%Sn合金在100 N的载荷下磨损1 h的磨屑形貌。从图8中可以明显看出,未添加Si的MA Al-12%Sn合金在磨损过程中产生两种不同尺度的磨屑:其中一种尺度的磨屑为松散、细小的近圆形颗粒状磨屑(约6 μm),如图8(b)所示;另一种尺度的磨屑为从摩擦面上的氧化摩擦层直接剥落的“大片”状磨屑(约120 μm),如图8(a)所示。对于添加2.5%Si的MA Al-12%Sn合金而言,片状磨屑的尺寸(约20 μm)比未添加Si的合金的“片状”磨屑尺寸明显减小,如图8(c)所示。同时,其圆形细小的颗粒状磨屑尺寸也明显减小,如图8(d)所示。未添加Si的Al-12%Sn(MA)合金的磨屑粗大是由于合金的强度较差造成的。而添加Si的Al-12%Sn(MA)合金的磨屑的尺寸较小,说明添加Si组元有效地提高Al-12%Sn(MA)合金颗粒之间的结合强度。

3 结论

1) 添加Si能够显著改善合金的组织,使Al-12%Sn(MA)合金中Sn相变得更加细小均匀分布;同时,Si能够改善Al-12%Sn(MA)合金的烧结活性,随着Si含量的增加,合金烧结致密度明显提高。

2) 随着Al-12%Sn-x%Si(MA)合金中Si含量的增加,合金的硬度、强度和塑性都有大幅度提升,并且Si含量为2.5%时,合金表现出最优的强度和塑性。

3) 添加Si后,Al-12%Sn-x%Si(MA)合金的摩擦磨损性能有较大提高,实验表明Si含量为2.5%时,合金具有最佳的减摩性和耐磨性。

REFERENCES

[1] LEPPER K, JAMES M, CHASHECHKINA J, RIGNRY D A. Sliding behavior of selected aluminum alloys[J]. Wear, 1997, 203/204: 46-56.

[2] KIM W T, ZHANG D L, CANTOR B. Microstructure of rapidly solidified aluminum-based immiscible alloys[J]. Materials Science and Engineering, 1991, 134: 1133-1138.

[3] PATHAK J, MOHAN S. Tribological behaviour of conventional and equivalent Al-Pb alloys under lubrication[J]. Bulletin of Materials Science, 2003, 26(3): 315-320.

[4] BANGERT H, EISENMENGER-SITTNER C, BERGAUER A. Deposition and structural properties of two-component metal coatings for tribological applications[J]. Surface and Coatings Technology, 1996, 80(1/2): 162-170.

[5] SERCOMBE TB, SCHAFFER GB. Sintering of a non-conventional aluminum powder alloy[J]. Advances in Powder Metallurgy and Particulate Materials, 1997(1): 10-21.

[6] NOSKOVA N I, VILDANOVA N F, FILIPPOV Y I, CHURBARV R V, PERRETURINA I A, KORSHUNOV L G, KORZNIKOV A V. Preparation deformation and failure of functional Al-Sn and Al-Sn-Pb nanocrystalline alloys[J]. The Physics of Metals and Metallography, 2006, 102(6): 646-651.

[7] 曾美琴, 戴乐阳, 王 涛, 王 辉, 李元元, 朱 敏. 与钢背轧制复合的纳米复合Al-Pb-Cu合金的组织及摩擦性能[J]. 中国有色金属学报, 2005, 15(1): 55-60.

ZENG Mei-qin, DAI Le-yang, WANG Tao, WANG Hui, LI Yuan-yuan, ZHU Min. Microstructure and wear properties of nanocomposite Al-Pb-Cu alloy cold-rolled onto steel matrix[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 55-60.

[8] LIU X, ZENG M Q, MA Y, ZHU M. Wear behavior of Al-Sn alloys with different distribution of Sn dispersoids manipulated by mechanical alloying and sintering[J]. Wear, 2008, 265(11/12): 1857-1863.

[9] 刘 辛, 曾美琴, 马 迎, 朱 敏. 机械合金化结合冷压烧结工艺制备Al-20%Sn合金[J]. 机械工程材料, 2009, 33(6): 55-58.

LIU Xin, ZENG Mei-qin, MA Ying, ZHU Min. Preparing Al-20%Sn alloy by mechanical alloying combining cold compacting and sintering[J]. Materials for Mechanical Engineering, 2009, 33(6): 55-58.

[10] 赖曲芳, 曾美琴, 鲁忠臣. 机械合金化制备Al-12%Sn合金的显微组织与耐磨性能[J]. 机械工程材料, 2010, 34(4): 65-68.

LAI Qu-fang, ZENG Mei-qin, LU Zhong-chen. Microstructure and wear resistance of Al-12%Sn alloy prepared by mechanical alloying[J]. Materials for Mechanical Engineering, 2010, 34(4): 65-68.

[11] LUMLEY R N, SERCOMBE T B, SCHAFFER G M. Surface oxide and the role of magnesium during sintering of aluminum[J]. Metallurgical and Materials Transactions A, 1999, 30(2): 457-463.

[12] YUAN Ge-cheng, ZHANG Xin-ming, LOU Yan-xiong, LI Zou-jian. Tribological characteristics of new series of Al-Sn-Si alloys[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(4): 774-780.

[13] FUENTES J J, RODRIGUEZ J A, HERRERA E J. Processing of mechanically alloyed aluminum powder: A metallographic study[J]. Materials Characterization, 2010, 61(4): 386-395.

[14] LU Zhong-chen, ZENG Mei-qin, GAO Yuan, ZHU Min. Minimizing tribolayer damage by strength-ductility matching in dualscale structured Al-Sn alloys: A mechanism for improving wear performance[J]. Wear, 304(1/2): 162-172.

[15] RODRIGUEZ J A, GALLARDO J M, HERRERA E J. An alternative route to the consolidation of mechanically alloyed aluminum powder[J]. Materials Transactions, 1995, 36(2): 312-316.

[16] GARCIA-CORDOVILA C, LOUIS E, NARCISO J. Pressure infiltration of packed ceramic particulates by liquid metals[J]. Acta Materialia, 1999, 47(18): 4461-4479.

[17] LANGFORD J I. A rapid method for analysing the breadths of diffraction and spectral lines using the Voigt function[J]. Journal of Applied Crystallography, 1978, 11: 10-14.

[18] KHALIFA W, SAMUEL F H, GRUZLESKI J E. Iron intermetallic phases in the Al corner of the Al-Si-Fe system[J]. Metallurgical and Materials Transactions A, 2003, 34(13): 807-825.

[19] ANANTHA NARAYANAN L, SAMUEL F H, GRUZLESKI J E. Crystallization behavior of iron-containing intermetallic compounds in 319 aluminum alloy[J]. Metallurgical and Materials Transactions A, 1994, 25(8): 1761-1773.

[20] LIU X, ZENG M Q, MA Y, ZHU M. Wear behavior of Al-Sn alloys with different distribution of Sn dispersoids manipulated by mechanical alloying and sintering[J]. Wear, 2008, 265(11/12): 1857-1863.

[21] ARCHARD J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953, 24(8): 981-988.

[22] ZHOU L, LIU G, HAN Z, LU K. Grain size effect on wear resistance of a nanostructured AISI52100 Steel[J]. Scripta Materialia, 2008, 58(6): 445-448.

(编辑 李艳红)

基金项目:广东省高新区发展引导专项计划项目(2010A011300046);清洁能源材料广东普通高校重点实验室(华南理工大学KLB11003)

收稿日期:2013-03-14;修订日期:2013-10-15

通信作者:朱 敏,教授;电话:020-87113924;E-mail:memzhu@scut.edu.cn