DOI: 10.11817/j.issn.1672-7207.2020.01.012

工艺参数对楔横轧42CrMo/Q235层合轴复合界面显微硬度的影响

张孝1, 2,彭文飞1, 2,束学道1, 2,吴志军1, 2

(1. 宁波大学 机械工程与力学学院,浙江 宁波,315211;

2. 宁波大学 浙江省零件轧制成形技术研究重点实验室,浙江 宁波,315211)

摘要:采用楔横轧方法成形42CrMo/Q235层合轴,对42CrMo/Q235层合轴复合界面显微硬度进行测试,研究成形角α、展宽角β、断面收缩率Ψ、轧制温度t、基材直径d等工艺参数对界面显微硬度的影响规律。研究结果表明:轧制温度、断面收缩率对界面显微硬度影响较大,基材直径、展宽角、成形角对界面显微硬度影响较小;随着轧制温度的升高,界面相同位置处显微硬度下降;随着断面收缩率的增大,界面相同位置处显微硬度增大;随着基材直径的增加,界面相同位置处显微硬度略微增加,但增加的幅度不大;随着成形角、展宽角的增加,界面相同位置处显微硬度略微增加,但增加的幅度不大。研究结果可为合理确定楔横轧42CrMo/Q235层合轴工艺参数和提高界面结合质量提供参考。

关键词:楔横轧;层合轴;工艺参数;显微硬度

中图分类号:TG335.19 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)01-0094-09

Effect of rolling parameters on microhardness of cross-wedge rolling of 42CrMo/Q235 laminated shaft composite interface

ZHNG Xiao1, 2, PENG Wenfei1, 2, SHU Xuedao1, 2, WU Zhijun1, 2

(1. College of Mechanical Engineering and Mechanics, Ningbo University, Ningbo 315211, China;

2. Zhejiang Provincial Key Lab of Part Rolling Technology, Ningbo University, Ningbo 315211, China)

Abstract: The 42CrMo/Q235 laminated shaft was formed by cross wedge rolling, and the microhardness of 42CrMo/Q235 laminated shaft composite interface was tested. The effects of forming angle α, broadening angle β, area reduction Ψ, rolling temperature t and substrate diameter d on the interfacial microhardness were studied. The results show that the rolling temperature and section shrinkage have a great influence on the interfacial microhardness, while the substrate diameter, broadening angle and forming angle have a little influence on the interfacial microhardness. With the increase of rolling temperature, the microhardness of the same position decreases. The microhardness of the same location increases with the increase of the area reduction. With the increase of substrate diameter, the microhardness of the same position increases slightly, but the extent of increase is not large. With the increase of forming angle and broadening angle, the microhardness at the same position increases slightly, but the increase is not significant. The results can be used as a reference for determining the process parameters of 42CrMo/Q235 cross wedge rolling and improving the interface bonding quality.

Key words: cross wedge rolling; laminated shaft; process parameters; microhardness

轴类件在高温、重载等苛刻服役条件作用下易出现过量变形、断裂、表面损伤等问题[1],传统的解决方法是开发性能优异的稀有金属、合金等新材料[2-3],但面临着新材料开发周期长、生产制造成本高等问题。复合材料层合轴是选择耐高温、耐磨损的优质钢作为覆层材料,选择韧性好、成本低的普碳钢作为基层材料。采用楔横轧的生产工艺在高温高压力的作用下实现基层材料和覆层材料界面的结合,生产出成本低,能够在高温、重载使役条件下的复合材料层合轴。层合材料界面结合过程中,界面在高温高压作用下的复合机理与界面附近硬度等性能的变化机理较为复杂。目前,对于双金属层合板的爆炸复合和轧制复合的复合机理研究较多。在爆炸复合领域,ZU等[4]研究了钛/钢爆炸复合板界面结合机理与力学行为,结果表明在金属板之间形成了波状界面组织,剧烈塑性变形使得钢基体发生明显的塑性流动;ZHANG等[5]通过有限元分析研究钛/钢复合板的爆炸焊接,发现模拟结果与实验结果一致,揭示了钛/钢复合板爆炸复合界面产生折叠缺陷的原因;刘荣等[6]通过调整炸药密度和配比,采用内爆法制备了小直径铝/不锈钢复合管,研究结果表明当结合界面为小波纹时结合强度最高;王芝玲等[7]采用爆炸复合法制备了Q345R/304爆炸复合板,并对爆炸复合板结合区的显微组织、结构及性能进行了研究。在轧制复合领域,焦少阳等[8]分析了双金属热轧复合过程中不同工艺条件对结合质量的影响;POZUELO等[9]研究了热轧界面对超高碳钢多层板力学性能的影响;NAMBU等[10]研究了界面结合强度对多层钢复合材料拉伸性能的影响,结果表明,随着界面结合强度的增加,拉伸延展性显著提高;MANESH等[11]利用上限法研究了层状材料的塑性变形行为,建立了对称夹层板冷轧的数学模型,并通过实验进行了验证。在层合材料硬度方面,张罡等[12-13]研究了304/Q245R爆炸复合板结合界面的硬度,揭示了界面变形区的硬化机理;VAIRAMANI等[14]研究了304奥氏体不锈钢和铜合金异种接头的界面处的最小硬度;陈志辉等[15]研究了在预置层中添加体积分数为16.7%钨铁粉对复合层的界面组织和基体硬度的影响,结果表明复合层基体中弥散分布的Fe3W3C相提高了复合层的基体硬度;姜岳峰[16]利用纳米显微硬度分析了TA2/316L爆炸焊接结合区内各层次的硬化机理。上述学者的研究成果为揭示层合材料界面结合机理和界面力学性能变化奠定了基础,但他们的研究多是基于等截面的复合板、复合棒等,对于变截面的层合材料的零部件成形研究还相对较少。WU等[17]提出采用楔横轧成形42CrMo/Q235层合轴的工艺,研究了轧制温度对层合轴界面微观组织、Cr元素的扩散和拉伸断口形貌等的影响,为改善层合轴界面处的结合质量提供了参考依据。层合材料结合界面力学性能是衡量复合材料质量的重要指标,是影响使用性能的一个重要因素。常用剪切强度、拉伸强度、冲击韧性和界面附近硬度等性能指标来衡量。层合材料在界面结合的过程中可能会产生某些缺陷,如局部产生融化、形成脆性相等,这些缺陷会导致层合材料界面硬化程度加重,而界面硬化严重则会导致层合材料的分层、脆断[18] 。因此,界面硬度反映了层合材料在复合过程中的界面硬化程度,对优化工艺参数、提高界面结合质量有重要的作用。42CrMo/Q235复合材料层合轴在楔横轧制过程中,其界面显微硬度会受到多种工艺参数的影响,显微硬度又是衡量界面结合质量的重要指标之一。故本文作者在实验的基础上,研究成形角α、展宽角β、断面收缩率Ψ、轧制温度t、基材直径d等工艺参数对界面显微硬度的影响规律,为轧制工艺参数的优化,判断楔横轧复合轴类零件的界面是否结合良好及解释宏观力学性能提供实验依据。

1 实验

1.1 楔横轧层合轴轧制原理

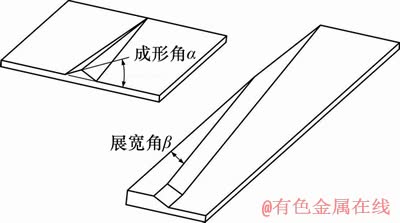

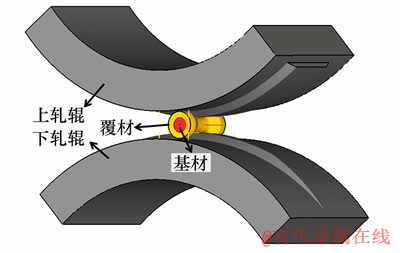

楔横轧原理是通过2个带楔形模具的轧辊同向转动,带动圆形坯料反方向旋转,在轧制力作用下,坯料同时发生径向压缩和轴向延伸的塑性变形,在模具孔型的作用下,最终获得所需轧件[19],其模具几何图如图1所示。楔横轧层合轴的轧制原理如图2所示,在高温高轧制力的作用下,基层材料和覆层材料发生径向压缩和轴向延伸的塑性变形,二者在界面接触区域通过金属原子的扩散形成结合界面,得到层合轴产品。

图1 楔横轧模具几何图

Fig. 1 Geometry of cross wedge rolling die

图2 楔横层合轴轧制原理

Fig. 2 Principle of cross wedge rolling of laminated shaft

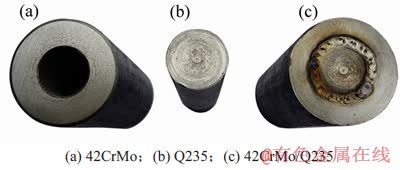

1.2 坯料制备与轧制实验

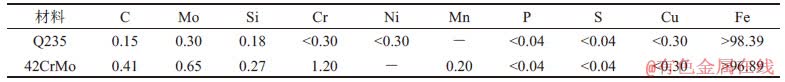

层合轴基层材料为低碳钢Q235,覆层材料为合金结构钢42CrMo,化学成分如表1所示。覆材42CrMo轧前外径为40 mm,基材Q235轧前直径随实验需求而改变。将覆材42CrMo和基材Q235打磨、清洗干净,去除表面的氧化膜,采用小过盈的配合方式,最大过盈量为0.05 mm,在复合坯料两侧端面采用电弧焊焊接,如图3所示。

表1 实验材料的化学成分(质量分数)

Table 1 Chemical composition of experimental materials %

将组装后的复合坯料在加热炉中分别加热到实验所需温度,采用H630楔横轧机(宁波大学浙江省零件轧制成形技术研究重点实验室)对其进行轧制(图4(a)),获得如图4(b)所示的复合轴轧件。对获得的轧件从正中心位置沿径向线切割,得到对称的2个半剖开轧件,选取其中之一轧件,通过金相试样研磨机对其表面进行打磨(图4(c)),通过光学显微镜观察打磨后的轧件界面是否结合。

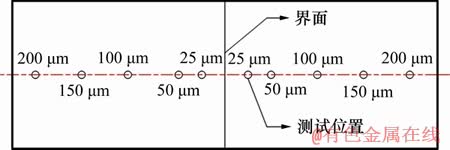

1.3 复合界面显微硬度测试

将图4(c)处获得的试样镶嵌后抛光,使用HV-1000型数显显微硬度计对试样进行显微硬度测试。从42CrMo/Q235复合界面处开始,分别向Q235侧和42CrMo侧进行显微硬度测定,测试位置如图5所示,加载载荷为0.49 N,加载时间为15 s。

2 结果与分析

显微硬度在一定程度上反映材料的抗磨能力、屈服强度和加工硬化性质等,通过分析界面附近显微硬度的变化,可反映出层合轴结合界面因元素的扩散而产生的过渡区性能。测量复合界面附近的显微硬度,整理不同工艺参数的显微硬度测试结果,得到工艺参数对界面显微硬度的影响规律,对优化工艺参数、提高界面结合质量有重要作用。

图3 覆材和基材组装

Fig. 3 Assembly of clad and core material

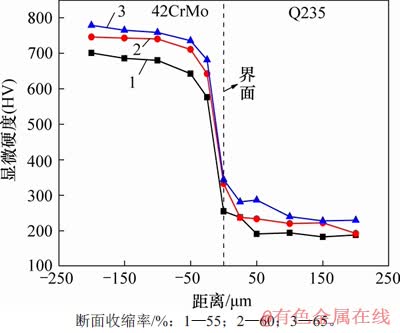

2.1 轧制温度对界面显微硬度的影响

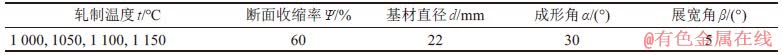

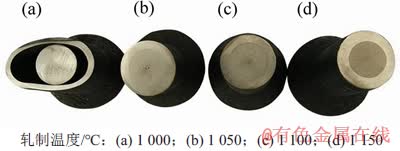

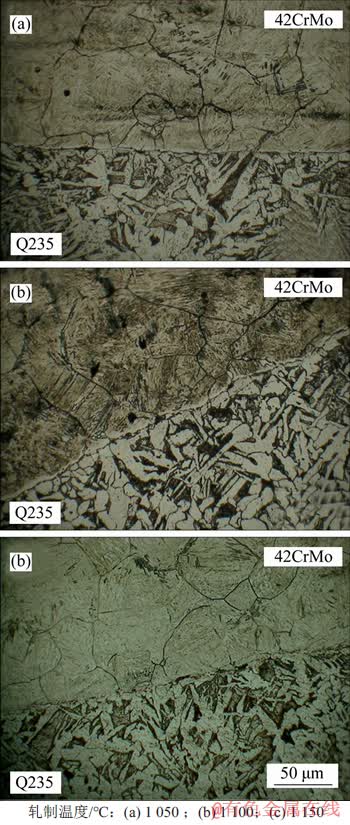

实验参数如表2所示,将轧制实验得到的轧件沿轴向对称中心切开,得到不同轧制温度下轧件横截面图,如图6所示。当轧制温度为1 000 ℃时,界面分离,对不同温度轧制成形后轧件的界面显微硬度进行测试,整理轧制温度变化时界面显微硬度测试结果,得到轧制温度对界面显微硬度的影响规律,如图7所示。

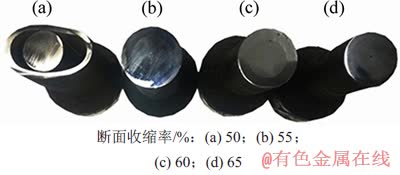

表2 不同轧制温度时的实验安排

Table 2 Experiment arrangements of different rolling temperatures

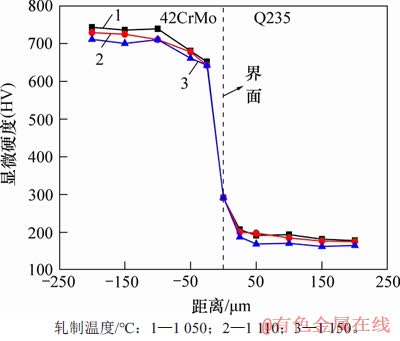

从图7可以看出:基材Q235侧显微硬度(HV)约为200,且距界面越远显微硬度越低,覆材42CrMo侧显微硬度(HV)约为700,距界面越远显微硬度越高,界面结合处的显微硬度(HV)约为290,其硬度介于42CrMo和Q235的硬度之间,呈现出较为明显的过渡特征。在不同温度条件下,距离界面相同距离处的显微硬度不同,在1 050 ℃条件下轧制的试样显微硬度最大,1 100 ℃时次之,1 150 ℃时最小。图8所示为不同轧制温度下界面微观组织。由图8可知:随轧制温度的升高,有利于界面处金属的回复和动态再结晶,促使界面处的晶粒增大,动态再结晶的软化作用使界面处的显微硬度降低。Q235侧界面附近显微硬度大于Q235基体硬度,42CrMo侧界面附近显微硬度明显小于42CrMo基体硬度,这是因为钢中Cr元素是强碳合金元素,主要以碳化物的形式存在于基体中,起到固溶体的作用,对界面附近硬度的影响较大;在楔横轧制过程中,2种金属界面的氧化膜不断破碎暴露出新鲜的金属,在高温高压力作用下形成较为稳定的热扩散,同时变形后的余热使2种金属间的原子扩散更加充分,使得42CrMo中的Cr元素不断通过界面扩散至Q235侧,导致复合界面附近硬度发生变化。

图4 轧制实验与取样图

Fig. 4 Rolling experiment and sampling

图5 显微硬度测试位置示意图

Fig. 5 Schematic diagram of microhardness test

图6 不同轧制温度下的轧件横截面图

Fig.6 Cross section of rolled pieces at different rolling temperatures

图7 不同轧制温度下界面附近显微硬度变化

Fig. 7 Distribution of interface microhardness at different rolling temperatures

图8 不同轧制温度下界面微观组织

Fig. 8 Interface microstructure at different rolling temperatures

2.2 断面收缩率对界面显微硬度的影响

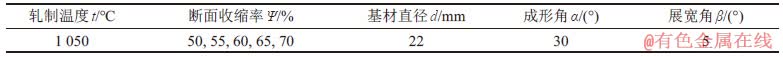

轧制实验参数如表3所示,轧制实验得到的轧件如图9所示。当断面收缩率为50%时,轧件出现椭圆化现象,界面未结合;当断面收缩率为70%时,轧件出现缩颈断裂,界面未结合。故对断面收缩率为55%,60%和65%的轧件进行显微硬度测试,整理断面收缩率变化时界面显微硬度测试结果,得到断面收缩率对界面显微硬度的影响规律,如图10所示。

表3 不同断面收缩率时的实验安排

Table 3 Experiment arrangements of different area reductions

图9 不同断面收缩率下的轧件横截面图

Fig. 9 Cross section of rolled pieces in different area reductions

图10 不同断面收缩率下界面附近显微硬度变化

Fig. 10 Distribution of interface microhardness in different area reductions

从图10可知:界面显微硬度呈梯度变化,基材Q235侧显微硬度(HV)约为240,覆材42CrMo侧显微硬度(HV)约为750,界面结合处的显微硬度(HV)在255~344之间,界面结合处的显微硬度大于基体Q235的显微硬度,而小于42CrMo的显微硬度。断面收缩率不同,距离界面相同距离处的显微硬度不同,断面收缩率为65%时显微硬度最大,60%时次之,55%时的显微硬度最小,即随着断面收缩率的增加,变形程度增大,显微硬度也随之增加。这是因为在轧制的过程中42CrMo中的Cr元素不断扩散至Q235一侧,而Cr元素是一种强碳合金元素,对材料的硬度影响较大。此外,随着断面收缩率的增加,径向力增加,加速界面处氧化膜的破损,使界面处的氧化物分布更加弥散,有利于提高界面显微硬度,而且,径向力增加迫使界面处晶粒变形与破损增加,界面晶粒度减小,界面显微硬度增加。综上所述,在距界面相同距离位置处显微硬度随断面收缩率增加而增大。

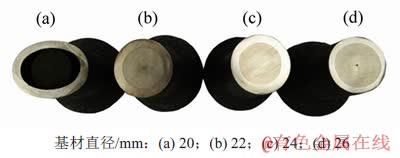

2.3 基材直径对界面显微硬度的影响

实验参数如表4所示,实验得到的轧件如图11所示。基材直径为20 mm时轧件出现椭圆化现象,界面分离,故对基材直径为22,24和26 mm的轧件进行显微硬度测试,整理基材直径变化时界面显微硬度测试结果,得到基材直径对界面显微硬度的影响规律,如图12所示。

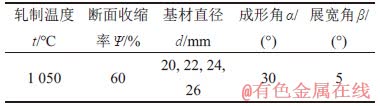

表4 不同基材直径时的实验参数

Table 4 Experimental parameters of different diameters of core material

图11 不同基材直径下的轧件横截面图

Fig. 11 Cross section of rolled pieces in different diameters of core material

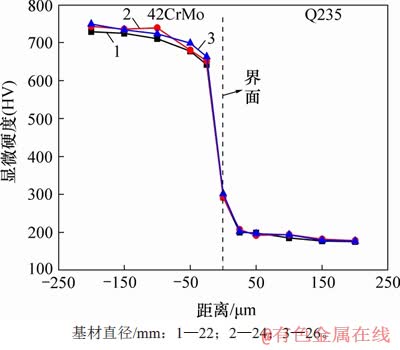

图12 不同基材直径下界面附近显微硬度变化

Fig. 12 Distribution of interface microhardness in different diameters of core material

从图12可以看出:界面显微硬度呈梯度变化,基材Q235侧显微硬度(HV)约为200,覆材42CrMo侧显微硬度(HV)约为700,界面结合处显微硬度(HV)约为292,Q235侧靠近界面处显微硬度大于Q235基体显微硬度,42CrMo侧靠近界面处显微硬度小于42CrMo基体显微硬度,随轧前基材直径的增加,距界面相同距离位置处显微硬度稍有增加,但增加的幅度不大。原因在于,基材直径增加不大,使得界面结合应力变化不大,Cr元素扩散深度增加不大,所以随着基材直径的增加,界面处显微硬度稍有增加,但增加的幅度不大。

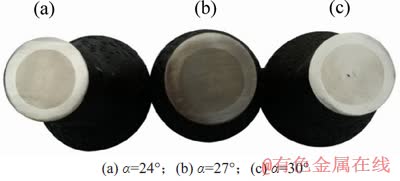

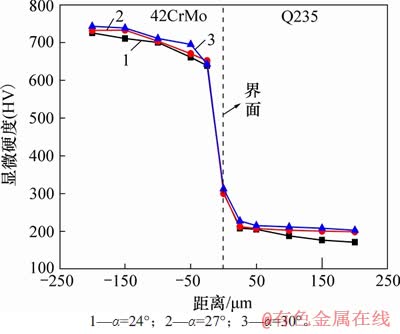

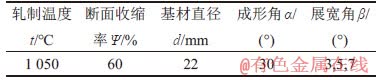

2.4 成形角对界面显微硬度的影响

实验参数如表5所示,实验得到的轧件如图13所示,对不同成形角轧制成形后的界面显微硬度进行测试,整理成形角变化时界面显微硬度测试值,得到成形角对界面显微硬度的影响规律,如图14所示。

表5 不同成形角时的实验参数

Table 5 Experimental parameters of different forming angles

图13 不同成形角下的轧件轧横截面图

Fig. 13 Cross section of rolled pieces in different forming angles

图14 不同成形角下界面附近显微硬度变化

Fig. 14 Distribution of interface microhardness in different forming angles

从图14可知:界面显微硬度呈梯度变化,基材Q235侧显微硬度(HV)约为200,界面结合处显微硬度(HV)约为300,覆材42CrMo侧显微硬度(HV)约为700,Q235侧靠近界面处显微硬度大于Q235基体显微硬度,42CrMo侧靠近界面处显微硬度小于42CrMo基体显微硬度,随着成形角的增加,距界面相同距离位置处显微硬度稍有增加,但增加的幅度不大。原因在于,42CrMo中的Cr元素在轧制过程中不断向Q235一侧扩散,复合界面附近的Cr元素呈梯度分度,导致复合界面附近的显微硬度也呈梯度变化,但随着成形角的增加,轧制力与轧制变形的增加幅度不大,对阻碍Cr元素扩散的氧化膜的破裂程度影响较弱,使得Cr元素的扩散深度增加不明显,因此距界面相同距离位置处显微硬度稍有增加,但总体对界面处显微硬度影响不大。

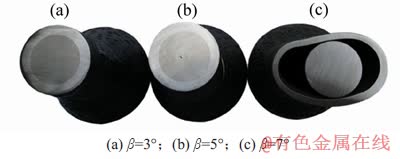

2.5 展宽角对界面显微硬度的影响

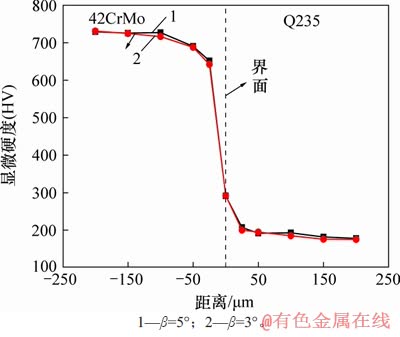

轧制实验参数如表6所示,轧制实验得到的轧件如图15所示,当展宽角为7°时,层合轴轧扁失效,界面未结合,故对展宽角为3°和5°的轧件界面显微硬度进行测试,整理展宽角变化时界面显微硬度测试结果,得到展宽角对界面显微硬度的影响规律,如图16所示。

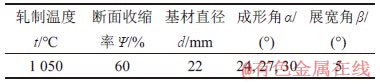

表6 不同展宽角时的实验参数

Table 6 Experimental parameters of different spreading angles

图15 不同展宽角下的轧件轧横截面图

Fig. 15 Cross section of rolled pieces in different spreading angles

图16 不同展宽角下界面附近显微硬度变化

Fig. 16 Distribution of interface microhardness in different spreading angles

从图16可知:界面显微硬度呈梯度变化,基材Q235侧显微硬度(HV)约为200,界面结合处显微硬度(HV)约为290,覆材42CrMo侧显微硬度(HV)约为700,Q235侧靠近界面处显微硬度大于Q235基体显微硬度,42CrMo侧靠近界面处显微硬度小于42CrMo基体显微硬度,随展宽角的增加,距界面相同距离位置处显微硬度变化不大,只是略微增加。原因是展宽角的增加,轧制力与轧制变形的增加幅度不大,对阻碍Cr元素扩散的氧化膜的破裂程度影响较弱,对Cr元素的扩散未产生较大影响,因此,展宽角对界面显微硬度影响不大。

3 结论

1) 层合轴复合界面显微硬度表现出明显的过渡特征,基材Q235侧显微硬度(HV)约为200,覆材42CrMo侧显微硬度(HV)约为700,界面结合处显微硬度(HV)约为300,其显微硬度介于基材与覆材硬度之间,说明层合轴实现了冶金结合。

2) 轧制温度升高有利于晶粒动态再结晶的发生与长大,使得距界面相同距离位置处的显微硬度随着轧制温度的升高而降低。断面收缩率增加,变形程度增大,使界面处氧化膜与晶粒破损增加,氧化物更加弥散分布于界面,界面晶粒度减小,有利于界面显微硬度提高,使得距界面相同距离位置处的显微硬度值随断面收缩率的增加而增大。成形角、展宽角和基材直径对复合界面Cr元素扩散的影响不大,所以,随着基材直径的增加,距界面相同距离位置处的显微硬度变化幅度不大。

3) 为实现层合轴界面的强结合,应该主要通过工艺参数轧制温度与断面收缩率进行调控。

参考文献:

[1] ROJO I, PSARRA A , PACHIDIS V, et al. Evaluation of the energy dissipated as friction/heat between turbines following shaft failure[C]//Proceedings of the ASME Turbo Expo 2010: Power for Land, Sea, and Air. Glasgow, UK, 2010: 1345-1352.

[2] 骆锐, 李强, 孙忠刚, 等. 轻金属前沿制造技术的研究进展[J]. 轻金属, 2011(4): 3-6.

LUO Rui, LI Qiang, SUN Zhonggang, et al. Research on front edge manufacturing technology of light metals[J]. Light Metals, 2011(4): 3-6.

[3] 黄江华, 刘晋平, 王宝雨, 等. 4Cr9Si2马氏体钢气门楔横轧工艺研究[J]. 中南大学学报(自然科学版), 2013, 44(7): 2744-2750.

HUANG Jianghua, LIU Jinping, WANG Baoyu, et al. Process research on 4Cr9Si2 martensite steel valve in CWR[J]. Journal of Central South University(Science and Technology), 2013, 44(7): 2744-2750.

[4] ZU Guoyin, SUN Xi, ZHANG Jinghua. Interfacial bonding mechanism and mechanical performance of Ti/steel bimetallic clad sheet produced by explosive welding and annealing[J]. Rare Metal Materials and Engineering, 2017, 46(4): 906-911.

[5] ZHANG Zhiying, PENG Lei, WANG Jimei, et al. Study on defects of large-sized Ti/steel composite materials in explosive welding[J]. Procedia Engineering, 2011, 16: 14-17.

[6] 刘荣, 汪洋, 李平仓, 等. 爆炸焊接小直径铝/不锈钢复合管的研究[J]. 稀有金属材料与工程, 2008, 37(S4): 645-648.

LIU Rong, WANG Yang, LI Pingcang, et al. Research of producing minor diameter Al/stainless steel clad tube by explosive welding[J]. Rare Metal Materials and Engineering, 2008, 37(S4): 645-648.

[7] 王芝玲, 刘威, 蒋佳强, 等. Q345R/304爆炸复合板的组织及力学性能研究[J]. 热加工工艺, 2015, 44(23): 243-245.

WANG Zhiling, LIU Wei, JIANG Jiaqiang, et al. Study on microstructure and mechanical properties of Q345R/304 explosive composite plate[J]. Hot Working Technology, 2015, 44(23): 243-245.

[8] 焦少阳, 董建新, 张麦仓, 等. 双金属热轧复合的界面结合影响因素及结合机理[J]. 材料导报, 2009, 23(1): 59-62.

JIAO Shaoyang, DONG Jianxin, ZHANG Maicang, et al. Influencing factors and bonding mechanism of hot rolling bonded bimetals[J]. Materials Review, 2009, 23(1): 59-62.

[9] POZUELO M, CARRENO F, CARSI M, et al. Influence of interfaces on the mechanical properties of ultrahigh carbon steel multilayer laminates[J]. International Journal of Materials Research, 2007, 98(1): 47-52.

[10] NAMBU S, MICHIUCHI M, INOUE J, et al. Effect of interfacial bonding strength on tensile ductility of multilayered steel composites[J]. Composites Science and Technology, 2009, 69(11/12): 1936-1941..

[11] MANESH H D, TAHERI A K. Theoretical and experimental investigation of cold rolling of tri-layer strip[J]. Journal of Materials Processing Technology, 2005, 166(2): 163-172..

[12] 张罡, 林东升, 姜岳峰. 304/Q245R爆炸复合板结合界面的退火组织和硬度[J]. 焊接学报, 2015, 36(9): 95-98, 118.

ZHANG Gang, LIN Dongsheng, JIANG Yuefeng. Annealing microstructure and hardness in bonded interface of 304 steel/Q245R steel composite plates by explosive welding[J]. Transactions of the China Welding Institution, 2015, 36(9): 95-98, 118.

[13] 张罡, 吕德超, 王启钧, 等. 304/Q245R爆炸复合板覆板侧结合界面的组织和硬度[J]. 焊接学报, 2017, 38(7): 9-12, 129.

ZHANG Gang, LU Dechao, WANG Qijun, et al. Microstructure and nano-hardness of bond interfacial zone of 304/Q245R explosive welding composite plate[J]. Transactions of the China Welding Institution, 2017, 38(7): 9-12, 129.

[14] VAIRAMANI G, KUMAR T S, MALARVIZHI S, et al. Application of response surface methodology to maximize tensile strength and minimize interface hardness of friction welded dissimilar joints of austenitic stainless steel and copper alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2250-2259..

[15] 陈志辉, 李祖来, 蒋业华, 等. 添加钨铁粉对WC/钢基表面复合材料界面及硬度的影响[J]. 材料热处理学报, 2011, 32(12): 38-42.

CHEN Zhihui, LI Zulai, JIANG Yehua, et al. Influence of addition of tungsten-iron powder on interface and hardness of WC/steel composite coatings[J]. Transactions of Materials and Heat Treatment, 2011, 32(12): 38-42.

[16] 姜岳峰. TA2/316L爆炸焊接结合区硬化机理研究[D]. 沈阳:沈阳理工大学材料科学与工程学院, 2015: 46-53.

JIANG Yuefeng. Investigation on hardening mechanism in the TA2/316L explosive welding bonding[D]. Shenyang: Shenyang University of Science and Technology. College of Materials Science and Engineering, 2015: 46-53.

[17] WU Z J, PENG W F, SHU X D. Influence of rolling temperature on interface properties of the cross wedge rolling of 42CrMo/Q235 laminated shaft[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(1/2/3/4): 517-526.

[18] 王耀华, 尤峻, 史长根. 爆炸焊接轧制复合板的结合界面研究[J]. 解放军理工大学学报(自然科学版), 2002, 3(6): 43-45.

WANG Yaohua, YOU Jun, SHI Changgen. Study of bonding interface of explosive welding and rolling cladding plate[J]. Journal of PLA University of Science and Technology(Natural Science), 2002, 3(6): 43-45.

[19] 束学道, VALERY Y, SHCHUKIN G, 等. 楔横轧理论与成形技术[M]. 北京: 北京科技出版社. 2014: 3-4.

SHU Xuedao, VALERY Y, SHCHUKIN G, et al. Theory and forming technology of cross wedge rolling[M]. Beijing: Beijing Science and Technology Press, 2014: 3-4.

(编辑 杨幼平)

收稿日期: 2019 -02 -18; 修回日期: 2019 -05 -05

基金项目(Foundation item):国家自然科学基金资助项目(51405248);浙江省自然科学基金资助项目(LY18E050006);山东省重点研发计划项目(2016ZDJQ0604);宁波市自然科学基金资助项目(2017A610088) (Project(51405248) supported by the National Natural Science Foundation of China;Project(LY18E050006) supported by the Natural Science Foundation of Zhejiang Province;Project(2016ZDJQ0604) supported by Key Research and Development Program of Shandong Province;Project(2017A610088) supported by the Natural Science Foundation of Ningbo City)

通信作者:彭文飞,博士,副教授,从事连续局部加载塑性成形技术、碳纤维增强树脂基复合材料成型技术研究;E-mail:pengwenfei@nbu.edu.cn