DOI: 10.11817/j.issn.1672-7207.2019.06.014

轧制参数对楔横轧变截面等内径空心轴晶粒粒径的影响

余璇1, 2,彭文飞1, 2,虞春杰1, 2,束学道1, 2

(1. 宁波大学 机械工程与力学学院,浙江 宁波,315211;

2. 宁波大学 浙江省零件轧制成形技术研究重点实验室,浙江 宁波,315211)

摘要:为了得到楔横轧变截面等内径空心轴的微观组织演变规律,借助刚塑性有限元软件DEFORM-3D,建立楔横轧热-力-微观组织耦合的有限元模型,对轧制过程的微观组织演变过程进行数值模拟,研究原始相对壁厚、成形角和展宽角对轧件平均晶粒粒径的影响规律。研究结果表明:轧件平均晶粒粒径随坯料原始相对壁厚Q的减小而减小,随着成形角α的减小而减小,随着展宽角β的增大先减小后增大。综合楔横轧空心轴内孔椭圆度和平均晶粒粒径的影响,原始相对壁厚Q=0.625、成形角α=40°、展宽角β=3°为最优的轧制参数,建立的有限元模型具有可靠性。

关键词:变截面等内经空心轴;楔横轧;数值模拟;轧制参数;晶粒粒径

中图分类号:TG335.19 文献标志码:文献标识码:A 文章编号:1672-7207(2019)06-1364-06

Effect of rolling parameters on grain size of hollow shaftwith variable cross section and equal diameter in cross wedge rolling

YU Xuan1, 2, PENG Wenfei1, 2, YU Chunjie1, 2, SHU Xuedao1, 2

(1. College of Mechanical Engineering and Mechanics, Ningbo University, Ningbo 315211, China;

2. Zhejiang Provincial Key Laboratory of Part Rolling Technology, Ningbo University, Ningbo 315211, China)

Abstract: In order to obtain the microstructure evolution regularities of the hollow shaft with variable cross section and equal diameter, a finite element model of thermo-mechanical-microscopic coupling of cross wedge rolling was established by means of rigid-plastic finite element software DEFORM-3D. The microstructure evolution of rolling process was simulated, and then the effects of the original relative wall thickness, forming angle and spreading angle on the average grain size of rolled piece were studied. The results show that the average grain size of the rolled piece decreases with the decrease of the blank original relative wall thickness (Q), decreases with the reduction of the forming angle(α), decreases first and then increases with the enlargement of the spreading angle(β). Under the influence of the ellipticity of the inner hole and the average grain size of the hollow axis of the cross wedge rolling, originally relative wall thickness Q=0.625, forming angle α=40°and spreading angle β=3° are the optimal rolling parameters. The finite element model is reliable.

Key words: hollow shaft with variable cross section and equal diameter; cross wedge rolling(CWR); numerical simulation; rolling parameters; grain size

随着汽车工业对环保和节能的高度重视,汽车轻量化成为必然,在满足强度的前提下,用空心轴代替实心轴是实现轻量化的重要途径。当同种材料承受相同的扭矩时,空心轴外径仅比实心轴外径大5%,但质量可以减少30%左右[1]。汽车中存在不少变截面空心轴类件,如连接汽车后轮和后桥的汽车半轴套管,在使用过程中,这些零件承受较大的扭矩和复杂的服役应力工况,对力学性能要求苛刻,其成形质量决定了汽车行驶的安全性。因此,需要选择合适的成形方法、合理的参数来保证其力学性能。楔横轧工艺以其高效、节材、产品综合力学性能良好等优势在成形变截面轴类件上得到了较广泛的应用,是生产轴类零件的最佳工艺方法之一[2]。现阶段,关于楔横轧空心轴的研究较多,例如,PATER等[3-4]研究了空心轴的楔横轧成形方法;PENG等[5]研究了多楔楔横轧空心长轴类零件工艺;张康生等[6-9]将仿真和实验相结合,对空心轴的壁厚规律、椭圆度等进行了较系统的研究;郑书华等[10]研究了工艺参数对多楔楔横轧空心车轴的壁厚均匀性的影响。这些文献主要是对内孔椭圆及壁厚进行了研究,缺乏对轧制空心轴类件的微观组织的研究。HUO等[11]通过模型预测楔横轧空心轴的微观组织演变,并通过实验验证了模型的准确性;俞澎辉等[12]研究了工艺参数对空心轴晶粒尺寸的影响规律,但是研究主要是基于等截面空心轴,对于楔横轧工艺中加工困难的变截面等内径空心轴的微观组织研究较少。在此,本文作者针对楔横轧工艺中成形难度较大的变截面空心轴微观组织进行了研究,通过建立热-力-微观组织耦合的有限元模型,研究了原始相对壁厚、成形角、展宽角对楔横轧变截面等内径空心轴晶粒粒径的影响规律,探究了不同轧制参数下平均晶粒粒径变化的原因,并通过实验验证了模型的可靠性和准确性。

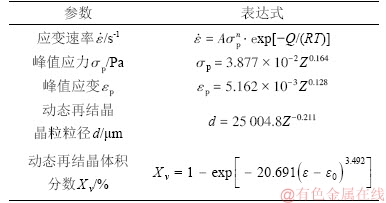

表1 40Cr的微观组织模型

Table 1 Microstructural model of 40Cr

1 有限元模型的建立和参数的选择

1.1 40Cr合金结构钢本构方程及再结晶本构方程

选用的实验材料为40Cr合金结构钢,本构方程和微观组织预测可以参考文献[13-15],模型参数见表1,其中: ,R为理想气体常数,J/(mol

,R为理想气体常数,J/(mol K);T为变形温度,K。经回归分析后可得应变速率

K);T为变形温度,K。经回归分析后可得应变速率 。

。

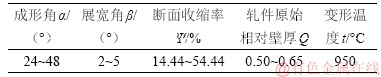

1.2 基本轧制参数

模具直径Φ为630 mm,坯料外半径R0为20 mm,内半径r根据原始相对壁厚变化,坯料长度l为40 mm,轧件的展宽量L为40 mm,其他轧制参数如表2所示。其中,原始相对壁厚Q=(R0-r)/R0;断面收缩率Ψ=(R -R

-R )/R

)/R ;其中,R1为轧后外半径,mm。

;其中,R1为轧后外半径,mm。

表2 轧制参数

Table 2 Rolling parameters

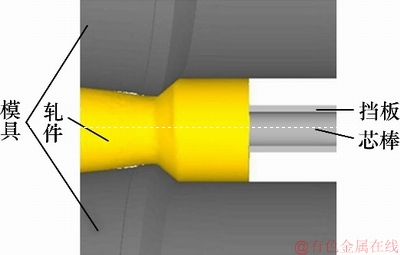

1.3 有限元模型

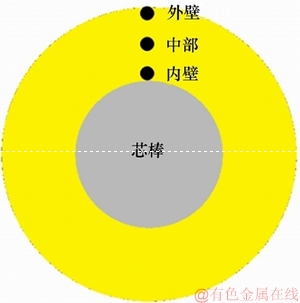

基于DEFORM-3D有限元软件,将表1的微观组织演变数学模型二次开发嵌入软件,建立楔横轧变截面等内径空心轴的热-力-微观组织耦合的有限元模型,模型包括上下模具、轧件、芯棒和导板(如图1所示)。模型定义为:轧件轴向上具有对称性,取轧件1/2作为研究对象,在对称面上施加对称约束;楔横轧成形过程中塑性变形较大,忽略弹性变形的影响,轧件定义为塑性体,模具、导板和芯棒定义为刚性体;轧件采用四面体单元网格划分,设置体积补偿;模具和轧件之间的摩擦因数设为常数;轧件和模具之间的传热系数设置为10 kW/(K m2) [16-19]。

m2) [16-19]。

图1 有限元模型

Fig. 1 Finite element model

2 轧制参数对平均晶粒粒径的影响

对楔横轧变截面等内径空心轴平均晶粒粒径影响较大的轧制参数有原始相对壁厚Q、成形角α、展宽角β和变形温度t,其中,晶粒粒径随着变形温度t升高而增大是普遍规律,同时,前期研究表明,变形温度在950 °C时空心轴的内孔椭圆度较好[20]。因此,综合形性控制的需要,选择950 °C为变形温度。

定义外壁、中部、内壁3个区域,外壁为轧件外部,内壁为轧件内孔壁,中部为两者中间区域,如图2所示。

图2 截面特征点

Fig. 2 Feature points of workpiece

2.1 原始相对壁厚对平均晶粒粒径的影响

当t=950 °C,α=40°,β=3°,轧件原始相对壁厚Q分别为0.700,0.625,0.550时,轧件平均晶粒粒径分布云图如图3所示。从图3可以看出:随着轧件原始相对壁厚的不断减小,轧件外壁平均晶粒粒径基本在15.8 μm以下,原因是轧件外壁和模具直接接触,变形剧烈,晶粒完全细化且细化程度基本相同,平均晶粒粒径都比较小。轧件中部和内壁的晶粒未细化区域逐渐变小,轧件内壁平均晶粒由Q为0.700时的60.0 μm左右逐渐下降到Q为0.550时的30.5 μm左右,这是因为原始相对壁厚越小,坯料越薄,变形越容易渗透到轧件内部,芯棒和模具对金属内部受力增大,使得轧件成形区域内部动态再结晶细化更加容易发生,使得轧件内部晶粒细化更加完全,平均晶粒粒径变小。

图3 原始相对壁厚对平均晶粒粒径的影响

Fig. 3 Influence of original relative wall thicknesson average grain size

图4 成形角对平均晶粒粒径的影响

Fig. 4 Influence of forming angle on average grain size

根据模拟结果,当原始相对壁厚为0.55时,晶粒细化程度最好,平均晶粒粒径在15.8~30.5 μm区间;当原始相对壁厚为0.625时,平均晶粒粒径大部分在15.8~30.5 μm,只有极少部分为30.5~45.3 μm,晶粒细化较好;当原始相对壁厚为0.700时,轧件中部和内壁大部分区域平均晶粒粒径为45.3~60.0 μm,平均晶粒粒径偏大,不适合选为轧制参数。由文献[20]可知,原始相对壁厚为0.6左右时内孔椭圆度最好。因此,综合椭圆度和平均晶粒粒径考虑,原始相对壁厚选0.625较合适。

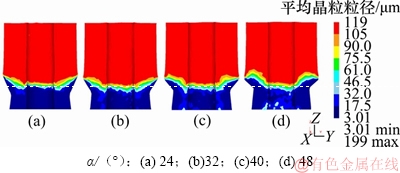

2.2 成形角对平均晶粒粒径的影响

当Q=0.625,t=950 °C,β=3°,成形角α分别为24°,32°,40°和48°时,轧件平均晶粒粒径分布云图如图4所示。从图4可以看出:虽然成形角不同,但轧件外壁平均晶粒粒径基本在17.5 μm以下。这是因为外壁变形剧烈,晶粒完全细化且细化程度基本相同,所以平均晶粒粒径都比较小。随成形角的增大,轧件中部和内壁晶粒未细化区域增大,平均晶粒粒径由α为24°时的17.5 μm左右逐渐增大到α为48°时的32.0~61.0 μm。这是因为成形角越大,轴向力越大,轧件上变形区的金属越容易沿轴向流动,在轴向表现为动态再结晶范围扩大;而径向力和切向力减小,导致轧件内部金属受力减小,平均晶粒粒径较大。

当α=24°时,轧件整体平均晶粒粒径基本在17.5 μm以下;当α=32°~40°时,轧件中部、内壁平均晶粒粒径增大,基本为17.5~32.0 μm,晶粒细化较好;当α=48°时,晶粒未细化区域较多,平均晶粒粒径为32.0~48.5 μm的较多,平均晶粒粒径偏大,不适合作为轧制参数的选择。由文献[20]可知,随成形角的增大,内孔椭圆度减小,因此,综合椭圆度的影响,选择最佳成形角为32°~40°。

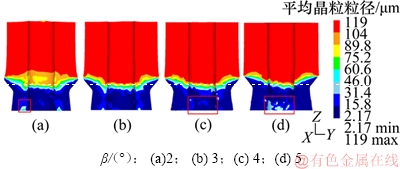

2.3 展宽角对平均晶粒粒径的影响

当Q=0.625,t=950 °C,α=40°,展宽角β分别为2°,3°,4°,5°时,轧件平均晶粒粒径云图如图5所示。从图5可以看出:不同展宽角下,轧件外部平均晶粒粒径基本在16.8 μm以下,平均晶粒粒径均匀,这是因为外壁变形较剧烈,晶粒完全细化,平均晶粒粒径小。随着展宽角的增大,轧件中部和内壁平均晶粒粒径先变小后变大,由β为2°时的46~60 μm(A区域)下降到β为4°的16.8 μm左右(B区域),随后增大到β为5°时的46 μm左右(C区域)。这是因为随着展宽角β增大,轧件沿径向变形的轴部接触面积增大,导致径向力和切向力增大,使得在径向上动态再结晶发生的更快更完全;同时,展宽角越小,模具长度越长,轧制时间延长,导致轧制过程后期轧件内部平均晶粒粒径有所增大。

对于展宽角的选择,需要综合考虑展宽角变化导致内孔椭圆度变化以及模具长度变化导致的晶粒平均粒径变化的影响,当β=3°~4°时,晶粒椭圆度较好,同时,轧件的平均晶粒粒径相对较小,因此,展宽角β选取3°~4°。

图5 展宽角对平均晶粒粒径的影响

Fig. 5 Influence of spreading angle on average grain size

3 楔横轧变截面等内径空心轴实验

3.1 空心轴轧制实验

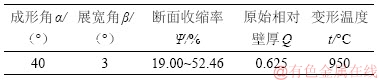

有限元模拟结果所得的最优参数如表3所示。为了验证有限元模型的准确性,选择最优参数,在浙江省零件轧制成形技术研究重点实验室的H630楔横轧机上进行轧制实验,所得部分轧件样品如图6所示。从图6可知:轧制后的空心轧件表面质量和内孔椭圆度均较好。

表3 实验轧制最优参数

Table 3 Optimal parameters of experiment of rolling

图6 轧制结束后空心轧件

Fig. 6 Hollow axle after rolling

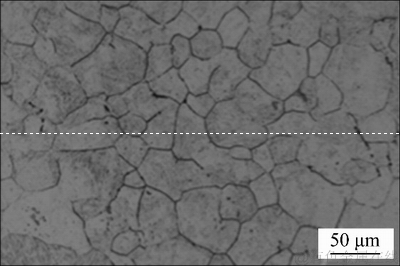

3.2 初始晶粒粒径的测定

原始40Cr棒料加热至950 °C后进行淬火,切块镶嵌成试样,打磨抛光后进行腐蚀,腐蚀液为沸腾饱和苦味酸,浸泡腐蚀30 s,试样取出后用酒精擦拭洗净表面。

用高倍显微镜观察金相组织,40Cr样品初始晶粒粒径如图7所示。采用Image-Pro-Plus软件对图7中的晶粒进行测量,得到其平均晶粒粒径d0约为108.3 μm,与软件设置值119 μm接近。

图7 40Cr样品初始晶粒粒径

Fig. 7 Initial grain of 40Cr sample

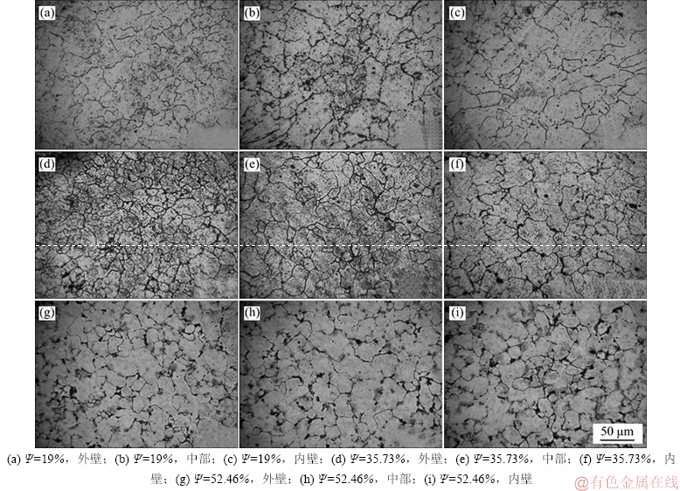

3.3 轧制后晶粒粒径的测定

对轧制后的轧件进行淬火,切割后腐蚀,同一轧件3个不同横截面(断面收缩率分别为19.00%,35.73%和52.46%)的金相组织如图8所示。

图8 40Cr样品轧制后晶粒粒径

Fig. 8 Grain sizes of 40Cr sample after rolling

经测量得到断面收缩率为19%的横截面的外壁、中部、内壁的平均晶粒粒径分别为21.17,38.53和56.38 μm。与相同轧制参数下的模拟云图(如图5(b)所示)进行对比可知:轧件中部和内壁的平均晶粒粒径基本在模拟仿真所得的区间内,轧件外部平均晶粒粒径略有偏差,最大相对误差约为26%,在可接受范围内,实验数据和仿真结果趋势基本相同,验证了有限元模拟结果的可靠性。

断面收缩率为35.73%的横截面的外壁、中部和内壁的平均晶粒粒径分别为17.26,30.68和34.74 μm;断面收缩率为52.46%的横截面的外壁、中部、内壁的平均晶粒粒径分别为19.30,20.71和21.34 μm。可见,随着断面收缩率的增加,平均晶粒粒径整体呈现减小的局势。与对应的模拟仿真结果(如图5(b)所示)进行对比可知:随着轴向上断面收缩率的增加,轧件中部和内壁区域未细化区域逐渐减小,中部和内壁的平均晶粒粒径也由46~60 μm逐渐减小到16.8~31.4 μm,实验结果与模拟结果趋势一致。产生这种现象的原因是:随着断面收缩率的增加,轧件变薄,轧制力渗透到内部容易,同时,芯棒和内壁的作用力变大,晶粒更容易细化,平均晶粒粒径减小。

4 结论

1) 建立楔横轧变截面等内径空心轴热-力-微观组织耦合数值模型,实现了对轧制过程晶粒粒径变化过程的模拟,通过轧制实验,验证了有限元模型的正确性。

2) 轧件晶粒粒径随着坯料原始相对壁厚Q和成形角α的减小而减小,随着展宽角β的增大先减小后增大。随着断面收缩率增大,轧件整体平均晶粒粒径减小。

3) 结合轧制参数对晶粒椭圆度的影响,变形温度为950 °C时,最佳轧制参数为:原始相对壁厚Q=0.625、成形角α=40°、展宽角β=3°。

参考文献:

[1] 杨程, 路星星, 孙跃, 等. 空心轴成形技术研究现状[J]. 锻压技术, 2018, 43(1): 1-8.

YANG Cheng, LU Xingxing, SUN Yue, et al. Research status on forming technology for hollow shaft[J]. Forging & Stamping Technology, 2018, 43(1): 1-8.

[2] 束学道, Valery Y S, 孙宝寿, 等. 楔横轧理论与成形技术[M].北京:科学出版社, 2014: 20-25.

SHU Xuedao, Valery Y S, SUN Baoshou, et al. Theory and forming technology of cross wedge rolling[M]. Beijing: Science Press, 2014: 20-25.

[3] PATER Z. Development of cross-wedge rolling theory and technology[J]. Steel Research International, 2010, 81(9): 25-32.

[4] BARTNICKI J, PATER Z. Numerical simulation of three-rolls cross-wedge rolling of hollowed shaft[J]. Journal of Materials Processing Technology, 2005, 164/165: 1154-1159.

[5] PENG W, ZHENG S, CHIU Y, et al. Multi-wedge cross wedge rolling process of 42CrMo4 large and long hollow shaft[J]. Rare Metal Materials & Engineering, 2016, 45(4): 836-842.

[6] 张康生, 王宝雨, 刘晋平, 等. 楔横轧空心件壁厚变化规律实验研究[J]. 锻压技术, 2000 (2): 34-36.

ZHANG Kangsheng, WANG Baoyu, LIU Jinping, et al. Research on wall thickness of hollow workpiece rolled by cross wedge rolling[J]. Forging & Stamping Technology, 2000(2): 34-36.

[7] YANG C, HU Z. Research on the ovality of hollow shafts in cross wedge rolling with mandrel[J]. International Journal of Advanced Manufacturing Technology, 2016, 83(1/2/3/4): 67-76.

[8] YANG Cuiping, MA Jiawei, HU Zhenghuan. Analysis and design of cross wedge rolling hollow axle sleeve with mandrel[J]. Journal of Materials Processing Technology, 2017, 239: 346-358.

[9] 江洋, 王宝雨, 胡正寰, 等. 工艺参数对楔横轧厚壁空心轴不圆度的影响[J]. 塑性工程学报, 2012, 19(1): 21-24, 29.

JIANG Yang, WANG Baoyu, HU Zhenghuan, et al. The effect of process parameter on non-circularity of thick-walled hollow axle during cross wedge rolling[J]. Journal of Plasticity Engineering, 2012, 19(1): 21-24, 29.

[10] 郑书华, 束学道, 孙宝寿, 等. 楔横轧多楔轧制高铁空心车轴壁厚均匀性[J]. 工程科学学报, 2015, 37(5): 648-654.

ZHENG Shuhua, SHU Xuedao, SUN Baoshou, et al. Wall thickness uniformity of railway hollow shafts by cross-wedge rolling[J]. Chinese Journal of Engineering, 2015,37(5): 648-654.

[11] HUO Y, LIN J, BAI Q, et al. Prediction of microstructure and ductile damage of a high-speed railway axle steel during cross wedge rolling[J]. Journal of Materials Processing Technology, 2017, 239: 359-369.

[12] 俞澎辉, 束学道, 彭文飞, 等. 工艺参数对多楔轧制空心车轴晶粒尺寸的影响规律[J]. 热加工工艺, 2014 (1): 96-99.

YU Penghui, SHU Xuedao, PENG Wenfei, et al. Influence of process parameters on grain size of hollow axle in multi-wedge cross wedge rolling[J]. Hot Working Technology, 2014 (1): 96-99.

[13] 杜凤山, 李学通, 王敏婷, 等. 40Cr钢奥氏体热变形及轴类件楔横轧微观组织预报[C]//2002年中国材料研讨会.北京, 2002: 640-647.

DU Fengshan, LI Xuetong, WANG Minting, et al. Hot deformation of austenite and microstructure prediction of cross wedge rolling of 40Cr steel[C]// China Material Symposium. Beijing, 2002: 640-647.

[14] 张芳, 黄华贵, 杜凤山, 等. 40Cr钢等温转变曲线与非等温冷却过程数值分析[J]. 材料热处理学报, 2009, 30(2): 187-191.

ZHANG Fang, HUANG Huagui, DU Fengshan, et al. Simulation on isothermal transformation curves and non-isothermal kinetics[J]. Transactions of Materials and Heat Treatment, 2009, 30(2): 187-191.

[15] 余新平, 董洪波. 40Cr钢奥氏体动态再结晶过程数值模拟[J]. 特种铸造及有色合金, 2015, 35(1): 26-29

YU Xingping, DONG Hongbo. Numerical simulation of austenite recrystallization process in 40Cr steel[J]. Special-cast and Non-ferrous Alloys, 2015, 35(1): 26-29.

[16] 向勇, 谭建平. 棒材热轧过程的三维温度场有限元分析[J]. 中南大学学报(自然科学版), 2008, 39(6): 1262-1266.

XIANG Yong, TAN Jianping. Three-dimensional elastic-plastic finite element analysis of bar hot rolling process[J]. Journal of Central South University(Science and Technology), 2008, 39(6): 1262-1266.

[17] 倪正顺, 帅词俊, 钟掘. 热挤压模具热力耦合三维数值分析[J]. 中南大学学报(自然科学版), 2004, 35(1): 86-90.

NI Zhengshun, SHUAI Cijun, ZHONG Jue. Three-dimensional coupled thermal-mechanical numerical analysis of hot extrusion dies[J]. Journal of Central South University(Science and Technology), 2004, 35(1): 86-90.

[18] YING F Q, PAN B S. Analysis on temperature distribution in cross wedge rolling process with finite element method[J]. Journal of Materials Processing Technology, 2007, 187/188: 392-396.

[19] 刘文科, 张康生, 孟令博, 等. 楔横轧变形小断面收缩率轴类件热力耦合数值模拟[J]. 中南大学学报(自然科学版), 2012, 43(1): 118-123.

LIU Wenke, ZHANG Kangsheng, MENG Lingbo, et al. Thermo-mechanical coupled numerical simulation of forming light area reduction shafts by cross wedge rolling[J]. Journal of Central South University(Science and Technology), 2012, 43(1): 118-123.

[20] 虞春杰, 彭文飞, 沈法, 等. 楔横轧变断面收缩率等内径空心轴的椭圆度分析[J]. 热加工工艺, 2015(3): 145-149.

YU Chunjie, PENG Wenfei, SHEN Fa, et al. Analysis on ovality of variable cross section reduction ratio of hollow shafts with equal inner diameter formed by cross wedge rolling[J]. Hot Working Technology, 2015(3): 145-149.

(编辑 赵俊)

收稿日期: 2018-07-06; 修回日期: 2018-09-10

基金项目(Foundation item):国家自然科学基金资助项目(51405248);浙江省自然科学基金资助项目(LY18E050006);山东省重点研发计划项目(2016ZDJQ0604);宁波市自然科学基金资助项目(2017A610088)(Project(51405248) supported by the National Natural Science Foundation of China; Project(LY18E050006) support by the Natural Science Foundation of Zhejiang Province; Project(2016ZDJQ0604) supported by Key Research and Development Programs in Shandong Province; Project(2017A610088) supported by the Natural Science Foundation of Ningbo City)

通信作者:彭文飞,博士,副教授,从事连续局部加载塑性成形技术、碳纤维增强树脂基复合材料成型技术研究;E-mail:pengwenfei@nbu.edu.cn