文章编号:1004-0609(2010)S1-s0713-04

钛合金焊接接头残余应力的消除方法

符 浩,刘希林,卢 海,张 浩,李 宁

(洛阳船舶材料研究所,洛阳 471039)

摘 要:对采用焊后退火、焊后振动时效处理、超声冲击、机械锤击4种去应力处理方法处理的钛合金对接接头与不采用去应力处理的对接接头进行残余应力测试和力学性能对比分析,得出不同的去应力方式对焊接接头残余应力和力学性能的影响规律,确定适合钛合金焊缝消应处理的最佳方法。

关键词: 钛合金;焊接接头;残余应力;消应方法

中图分类号:TG404 文献标志码:A

Relieving residual stress of titanium alloy welded joint

FU Hao, LIU Xi-lin, LU Hai, ZHANG Hao, LI Ning

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: The weld joints were treated by four methods of relieving stress, i.e., post annealing, aging treatment vibrantly after welding, ultrasonic impact layer by layer during welding, hammering layer by layer during welding, and they were compared with weld joints in titanium without relieving stress. Residual stress testing and mechanical property were analyzed. The results show that different relieving stress methods contribute to different regularities of residual stress and mechanical properties. The best option of relieving stress about titanium welding joints is established.

Key words: titanium; weld joint; residual stress; relieving stress

钛合金焊缝常用的应力消除方法有焊后退火、焊后振动时效处理、超声冲击、机械锤击4种应力消除方法,均在钛合金焊接过程中获得广泛应用[1-3]。人们对有关钛合金焊接接头残余应力测试和研究较多[4-6],但是鲜见针对几种消应方法的对比研究,在此,本文作者通过对比试验,研究不同消应处理方式处理后焊缝的残余应力分布,并对不同消应处理后焊接接头的组织和性能进行检验,结合不同处理方式的特点,确定适合钛合金焊缝消应处理的最佳方法。

1 残余应力测试

为了达到良好的对比效果,下料制备长×宽×高

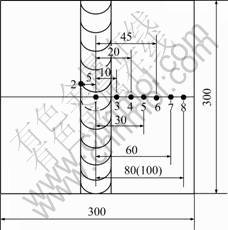

为300 mm×15 mm×12 mm的TA2试板5对,焊缝的长度方向和板材的轧制方向一致,采用的坡口形式如图1所示;5对试板采用的焊接工艺参数如表1所示,采用的消应处理方法如表2所示。

图1 焊接层道顺序

Fig.1 Welding orders

盲孔法是一种应用最广泛的残余应力测试技术,这种方法具有操作简单、成本低、通用的特点。所需

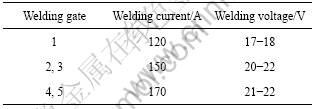

表1 焊接工艺参数

Table 1 Welding parameters

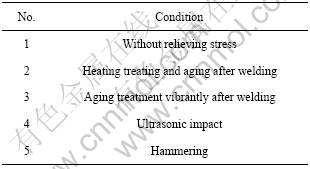

表2 应力消除方法及工艺

Table 2 Method and technics of relieving stress

设备可以放置于试验室也可以携带至场外进行测量,并适用于测量范围较宽的材料与零件[7],为此,本文作者采用盲孔法进行对比焊接接头的残余应力测试。

1.1 应力测试位置

采用盲孔法测量焊缝正面的残余应力,测量8个点,具体测量位置如图2所示。

图2 测量位置示意图

Fig.2 Positions of testing (Unit: mm)

1.2 测量结果及分析

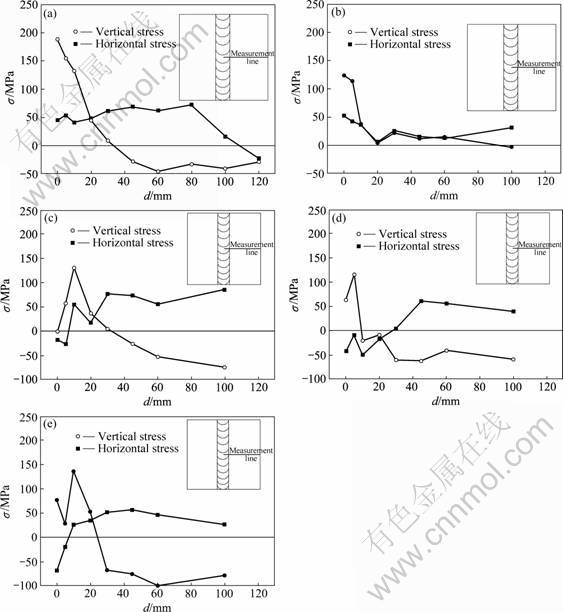

测量结果如图3所示,其中,σ为残余应力;d为距焊缝中心距离。

对比图3(a)和图3(b)可见:采用热处理时效消应,可大幅度降低焊缝的横向和纵向残余应力,但是,在距离焊缝10 mm内仍存在稍高的横向应力和纵向应力的峰值区域。

对比图3(a)和图3(c)可见:采用振动时效消应将距离焊缝中心10 mm附近变成了应力峰值区,距离焊缝中心10 mm以内区域的残余应力有所降低,甚至将距离焊缝中心5 mm以内区域的拉应力转化为了压应力,对于应力的消除有一定的效果,但是,熔合线附近成为新的应力峰值点。由此说明:采用振动时效消应可将焊接残余应力的峰值转移到热影响区附近(距离焊缝中心10 mm左右区域),从而将焊接应力的峰值转移到力学性能良好的母材上,这有利于提高焊缝质量。

对比图3(a)和图3(d)可知:采用超声冲击消应可以将距离焊缝中心20 mm之内的横向应力转化为压应力,同时也能在一定程度上降低纵向应力的峰值,这在很大程度上改善了近缝区残余应力的分布情况,可有效提高焊缝的质量。采用超声冲击方法,操作方便,可以随时随地进行,而且超声冲击探针尺寸小,可以对可达性差的焊缝进行消应处理[7]。

对比图3(a)和图3(e)可知:采用锤击消应在距离焊缝中心约5 mm范围内将横向应力转化为压应 力,所造成的压应力幅值较大(接近-100 MPa),纵向应力的峰值略降低,说明采用锤击消应在工艺上较难控制。

对比图3(a)~图3(e)可见:采用热处理消应,焊缝残余应力消除最多,去应力效果最好,但是,由于钛合金的热处理只能在真空条件下整体进行,适应范围窄;采用超声冲击消应可以使焊缝中心附近的横向残余应力转化为压应力,提高了焊缝的安全性,而且超声冲击装置前部狭小,现场操作方便,有利于进行各种形式焊缝的超声冲击消应;采用锤击消应,消应效果较冲击消应效果差,而且锤击消应参数不易控制,消应受人为因素影响较大;采用振动时效消应,仅将峰值残余应力由焊缝中心转移到熔合线附近,由于操作方便,可以作为钛合金焊缝辅助消应方法。

综上所述,采用超声冲击消应方法,操作方便,消应效果较好,是除热处理消应外,钛合金焊缝应力消除的首选方法。

图3 测量结果

Fig.3 Testing results: (a) Plate No.1; (b) Plate No.2; (c) Plate No.3; (d) Plate No.4; (e) Plate No.5

2 不同消应处理试板的组织性能检验

2.1 室温拉伸试验

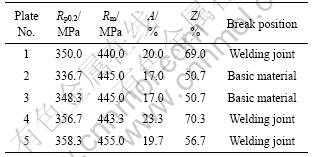

按照标准,要求每块试板取3个拉伸试样进行拉伸性能检验,试样的拉伸试验结果(均值)见表3。

由表3可以看出:采用不同消应处理方式对焊接接头的力学性能的影响差别不大,采用超声冲击消应处理的焊接接头(4号板)焊缝的伸长率为23.3%,较其他焊接接头的伸长率大,说明采用超声冲击,可以在一定程度上提高焊缝的伸长率。

表3 室温拉伸试验结果

Table 3 Mechanical properties of welding joints at room temperature

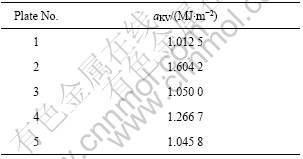

2.2 室温冲击试验

按照GB/T 2650—2008进行40 mm TA2焊接接头全厚度V型缺口冲击试验,冲击试验结果(均值)如表4所示。

表4 TA2焊接接头冲击试验结果

Table 4 Impacting test results of TA2 welding joint

从表4可以看出:采用焊后退火处理的试样具有最高的冲击值aKV=1.604 2 MJ/m2,采用超声冲击消应处理试样具有较高的冲击值aKV=1.266 7 MJ/m2,其他3个试样的冲击值差别不大。采用超声冲击消应时,产生塑性变形层,使金属晶粒细化,进而经过后期的焊道热处理,在一定程度上使焊缝的组织复杂化,从而增加了焊缝在冲击载荷作用下裂纹的扩展速率,提高了焊缝冲击韧性。

3 结论

1) 采用超声冲击消应方法,操作方便,消应效果较好,是除热处理消应外,钛合金焊缝应力消除的首选方法。

2) 振动时效消应方法可以将焊接残余应力均匀化,并将应力峰值转移至热影响区,因其操作方便,处理效率高,可以作为焊缝残余应力消除的辅助方法。

3) 采用超声冲击消应方法可以在一定程度上优化钛合金焊接接头的拉伸、冲击性能。

REFERENCES

[1] 王者昌. 关于焊接残余应力消除原理的探讨[J]. 焊接学报, 2000, 21(2): 55-58.

WANG Zhe-chang. The discuss of the theory of remove remains stress of weld[J]. Transactions of the China Welding Institution, 2000, 21(2): 55-58.

[2] 杨彦涛, 张永洋, 余 巍. 超声冲击处理钛合金焊接接头的性能研究[J]. 材料开发与应用, 2007, 22(1): 28-32.

YANG Yan-tao, ZHANG Yong-yang, YU Wei. Property of titanium alloy welded joints treated with ultrasonic peening[J]. The Development and Application of Material, 2007, 22(1): 28-32.

[3] 王东坡, 霍立兴, 张玉凤. 超声冲击法对钛合金焊接接头疲劳性能的改善[J]. 中国有色金属学报, 2003, 13(6): 1456-1460.

WANG Dong-po, HUO Li-xing, ZHANG Yu-feng. Improvement of fatigue properties of welded joints for titanium alloy by ultrasonic peening method[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1456-1460.

[4] JIANG Nan, ZHEN Liang, LIANG Li-hua. The experimental performance of residual stress in cold rotary extruding flat tubeplate head with welding seam[J]. Pressure Vessel, 2002, 19(2): 12-15.

[5] 王继周, 李晋霞, 石 路, 徐永昌. 冷轧管残余应力的测试和分析[J]. 稀有金属材料科学与工程, 1997, 26(5): 32-35.

WANG Ji-zhou, LI Jin-xia, SHI Lu, XU Yong-chang. Text and analysis on residual stress of cold worked tube[J]. Rare Metal Materials and Engineering, 1997, 26(5): 32-35.

[6] 闵 行, 赵 挺, 王能道. 异种金属焊接残余应力的分析和测试[J]. 机械强度, 1997, 19(2): 17-20.

MING Xing, ZHAO Ting, WANG Neng-dao. Analysis and experimental study of welding residual stresses of dissimilar metal welds[J]. Journal of Mechanical Strength, 1997, 19(2): 17-20.

[7] 唐幕尧. 焊接测试技术[M]. 北京: 机械工业出版社, 1988: 161-220.

TANG Mu-yao. Text technology of weld[M]. Beijing: China Machine Press, 1988: 161-220.

(编辑 陈灿华)

通信作者:符 浩;电话:0379-67256964;E-mail: XILIN.L@126.com