文章编号:1004-0609(2010)S1-0393-06

钛合金大厚板窄间隙焊接接头三维应力数值模拟计算

廖志谦,刘希林,周 川,张建欣

(中国船舶重工集团公司,洛阳 471039)

摘 要:基于热-力耦合的焊接热弹塑性有限元法,建立运动电弧作用下的二维体热源模型。采用“生死单元”技术实现焊缝的顺序生长来完成温度场的计算;选择平面应变模型,计算大厚度多道焊接的残余应力,最终得到钛合金厚板焊接过程温度场和应力场分布以及厚板焊接接头的三维应力的分布规律,并与钛合金厚板应力测试结果进行对比验证,两者很接近。该研究结果为钛合金厚板焊接接头残余应力的研究提供了参考。

关键词:钛合金;厚板;焊接接头;三维应力;热力耦合

中图分类号:TG404 文献标志码:A

Numerical simulation about three dimensional stress in titanium alloy heavy plate of narrow gap welded joint

LIAO Zhi-qian, LIU Xi-lin, ZHOU Chuan, ZHANG Jian-xin

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: Two dimension conical heat source model was established using two-dimension thermal-mechanical coupled simulations based on the hot-elastoplastic finite element method under moving arc. “Live-die unit” technology was adopted to simulate growth of welding line and finfish the calculation of temperature field. According to choosing the plane strain model, the residual stress of multipass welding on thick titanium alloy can be counted. The distribution of temperature field, the residual field and three-dimension stress of welding joint about thick plate all could be gotten. Compared with the testing results of thick titanium plate, it can be found that one is approaching another. This results provide reference to study residual stress of welding joint for thick titanium plate.

Key words: titanium alloy; heavy plate; weld joint; three dimensional stress; thermal-mechanical coupled

大厚板窄间隙焊接过程,因高度集中的瞬时热输入,在焊接过程中和焊后将产生相当大的残余应力和变形,而且焊接过程中产生的动态应力和焊后残余应力影响构件的变形,此外还影响焊接结构的可焊性和构件的脆性、断裂强度、疲劳强度、屈服强度、振动特性以及抗腐蚀性等工作性能,而且在一定程度上还影响结构的加工精度和尺寸稳定性。

关于研究厚板焊接残余应力大小目前国内外还没有很成熟的技术,但已有一些科研单位和个人投入到此项研究当中[1-7]且都取得了一定成果,但所得的结论还不能完全统一。有必要通过一定的方法进一步研究厚板焊接残余应力分布对于焊接残余应力的影响。采用直接测试的方法不但费时费力,还受到许多条件的限制,如能通过估算法得到比较准确的数据将更便于工程应用[8]。本文作者进行钛合金大厚板窄间隙焊接三维应力数值模拟,探索钛合金大厚板窄间隙焊接过程的温度场和应力场分布规律,为钛合金大厚板的工程应用提供理论依据。

1 焊接温度场和应力场有限元模型的建立

1.1 试验材料和焊接工艺

试验用母材为Ti75轧制厚板,板厚80 mm,其化学成分如表1所示。

将500 mm×200 mm×80 mm的Ti75钛合金板沿长度方向窄间隙对接焊接形成接头。由于窄间隙焊接过程为多层多道焊接,焊缝内部残余应力较大,容易出现焊接裂纹,所以在焊接过程中采用了消应处理措施,消应处理措施很难进行数值模拟,所以可能对后期残余应力实际测试结果造成影响。

表1 Ti75化学成分

Table 1 Chemical composition of Ti75 (mass fraction, %)

1.2 有限元模型

基于热-力耦合的焊接热弹塑性有限元法已广泛应用于各领域焊接应力变形产生机制、演化过程、分布状态预测等方面[9-11],本文作者采用此方法进行窄间隙焊接温度场和应力场模拟计算。由于大型焊接结构的计算模型庞大,计算效率低下,而且多道焊接过程数值模拟涉及在计算模型实现焊缝的生长过程,所以为减少焊接数值模拟计算时间和优化数值模拟结果,采用以下途径提高计算效率:1) 采用对称模型,只对一半焊接件建模计算;2) 简化材料属性,在应力应变计算中将材料的计算“截止”温度设置较低,以减少随温度变化的塑性对刚度矩阵的影响;3) 对于多道焊接情况,将多道分组,减少要计算的焊道数;4) 采用网格重划和子模型技术减少计算单元数;5) 三维模型简化为二维模型。

所建立的平面应变模型有限元网格如图1所示。

图1 有限元网格划分图

Fig.1 Graticule division map of finite-element method

由于焊接过程瞬时受热和快速冷却,为了准确反映焊缝处的温度和应力梯度,在焊缝处需要密化网格,远离焊缝的地方网格逐渐稀疏。焊缝区最小单元尺寸为0.6 mm×0.875 mm。

共焊接80 mm厚Ti75板共焊接45层,各层道的位置如图2所示。

图2 焊接层道分布示意图

Fig.2 Distribution map of welding gate

1.3 材料模型

设材料服从米塞斯屈服准则及双线性随动强化模型,且材料性能随温度变化。随动强化模型能够模拟反复塑性变形和包辛格效应,这符合多道焊接时材料被反复加热冷却的特点。同时假设填充金属和母材为相同材料。材料性能参数来自于试验以及相关参考文献,采用的材料热学和力学性能参数如表2所列。高温材料参数采用插值方法获得。焊缝和母材的性能区别只在于屈服强度不同。表2中,θ为温度;cp为比热容;λ为热导率;E为弹性模量;υ为泊松比;σb为材料屈服强度;ET为硬化模量;α为热膨胀系数。

1.4 焊缝生长的模拟

厚板多道焊接时,焊缝是熔敷金属熔化后逐道逐层生长起来的,这给数值模拟带来了更大的难度,准确模拟多道焊接要求数值模拟准确简化和实现焊缝金属的添加问题。大多数商业软件对于焊缝生长的模拟都采用生死单元技术,即文献[12]中的单元静止技术。生死单元方法要建立完整的包含未填充焊缝材料的模型。代表未生成焊缝的单元为“死单元”状态,代表当前焊道的单元在计算时要从“死单元”激活为“活单元”。要实现“单元死”的效果,程序并不是将“杀死”的单元从模型中删除,而是将其刚度矩阵乘以一个很小的因子。死单元的单元载荷将为0,从而不对载荷向量生效。同样,死单元的质量、阻尼和比热等也设为0。死单元的质量和能量不包括在模型求解结果中。单元的应变在“杀死”的同时也将设为0。本文作者采用生死单元技术实现多道焊接焊缝金属的生长。

表2 Ti75合金热物理参数

Table 2 Thermal parameters of Ti75 alloy

1.5 热源模型选择

温度场计算时由于热源是施加在二维模型上,因而要考虑选择的二维热源模型尽可能充分表达焊接热源的三维特征。

本研究采用均匀体热源加载,且电弧移动施加到表示当前焊道单元上的热量随时间变化。由于电弧的能量分布符合高斯分布,故考虑到移动效应的二维体热源可以写为

(1)

(1)

式中:U为电压,V;I为电流,A;η为电弧效率;v为热源移动速度,m/s;τ为电弧移至研究平面的时间,s,也称为延迟因子,其大小决定了热源中心的位置;c为电弧沿焊接方向的长度,m,可以假设为电弧半径; V为热源作用体积,m3,即代表当前焊道的所有单元所占体积;t为施加温度负载后的保持时间为加热周期或者为被加热节点在熔池中的保持时间。

1.6 计算过程

本项目数值模拟所采用的计算机平台为Dell Precision390工作站。先进行非线性瞬态热分析,计算焊接温度场,然后进行热力耦合的非线性热弹塑性计算。温度场计算时,采用“生死单元”技术实现焊缝的顺序生长,死单元表示为未熔敷的焊缝金属,其温度保持在室温。表示当前焊道的单元激活时,施加体热源负载,计算升温过程,升温时间到后就移除体热源,计算整个焊接件进行传导和散热的冷却过程。温度场计算完后,进行非线性结构计算,前面计算的温度场作为负载施加在结构单元的节点上,同样采用“生死单元”技术模拟焊缝的生长,并采用熔敷金属熔化和重熔的处理方法和“生死单元”激活时无应力应变状态处理。

2 有限元计算结果与分析

2.1 温度场计算结果

通过“生死单元技术”模拟多道焊接时焊缝的生长,将体热源函数计算的热生成率加载在相应地代表各道焊缝的单元上,进行非线性热分析。得到第5、45道加热终了时刻的温度场分布,如图3所示。

温度场计算结果的准确性通过焊缝单元处在熔点温度以上的单元体积和热影响区的宽度来判断。由图3看出,当到达加热终止时间时,代表各道熔敷金属单元都在熔点温度(1 600 ℃)以上,说明整个当前焊接焊道完全处在液态,且热影响区宽度都为距焊缝几个毫米,计算结果比较合理。

2.2 残余应力计算结果

将瞬态温度场计算结果作为结构计算的热负载,进行非线性弹塑性计算,得到焊接件冷却到室温后的残余应力分布,如图4所示。

从图4(a)可看出,计算的横向残余应力在焊缝区上下表层为200~300 MPa的拉伸应力,而在焊接件中部为-100~-200 MPa的压缩应力,焊缝中心位置从上表面到下表面的横向应力分布大致为拉应力-压应力-拉应力,且拉应力峰值出现在距上、下表面一定深度的位置。远离焊缝的区域,残余应力迅速减小。

图3 不同道次加热终了时刻的温度场

Fig.3 Temperature field at finishing temperature under different gates: (a) 5th gate; (b) 45th gate

图4 残应力分布图

Fig.4 Distribution of residual stress: (a) Residual stress along cross direction; (b) Residual stress along lengthwise direction; (c) Equivalent stress

由图4(b)可看出,计算的纵向残余应力在焊缝区呈现很大的拉应力,峰值拉伸纵向残余应力达到材料的屈服极限,且焊缝中心峰值拉伸纵向残余应力出现在距上、下表面一定深度区域,上、下表层的残余应力大于焊接件内部纵向残余应力,在焊接件内部热影响区位置出现较大的压应力分布区,压应力峰值达到-200 MPa。

由图4(c)可看出,计算的大部分焊缝区域等效应力达到了材料的屈服极限,远离焊缝区域其等效应力基本上为0值。

2.3 焊缝中心残余应力分布规律

焊缝中心残余应力计算结果如图5所示。

从图5(a)可以看出,横向残余应力的分布范围主要在-200 MPa~300 MPa,距上、下表面10 mm~20 mm的表层区域横向应力为拉应力,焊接件中部区域为压应力,且拉应力峰值出现在距上、下表面10 mm位置。

图5 焊缝中心位置沿厚度残余应力

Fig.5 Residual stress across centre of welding joint: (a) Residual stress along cross direction; (b) Residual stress along lengthwise direction

从图5(b)可以看出,纵向残余应力的分布范围主要在300~650 MPa,峰值出现在距离上、下表面10 mm的位置,焊缝厚度中心约20 mm为纵向残余应力较小的区域。

横向应力和纵向残余应力分布自焊缝中心到上、下表面呈减小→增大→减小的复杂对称变化趋势。

3 试验和计算结果比较

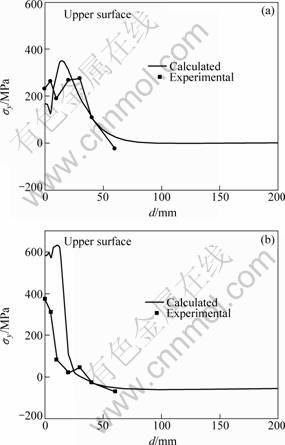

为验证数值模拟计算的结果,本文作者也采用盲孔法进行了80 mm Ti75焊接接头的表面残余应力测试,表面的计算和试验测得的残余应力分布的结果如如图6所示。

图6 表面残余应力分布

Fig.6 Residual stress distribution on surface: (a) Residual stress along cross direction; (b) Residual stress along lengthwise direction

从图6可以看出,计算和测量的表面横向应力在焊缝及热影响区为拉伸应力,在热影响区出现大约为300 MPa的峰值拉伸应力,随后随距焊缝距离的增加拉伸应力迅速减少为接近0。计算和测量的表面横向残余应力分布非常接近。

计算和测量的表面纵向残应力分布趋势符合较好,在焊缝和热影响区为较大拉伸应力,远离焊缝区域残余应力迅速降低,在距焊缝中心约30 mm位置纵向残余应力降为0,随后保持在-60 MPa的压应力。计算的焊缝区域纵向应力值大于试验测量的应力值,试验过程采用了消应处理措施,测量的纵向残余应力峰值比计算的纵向残余应力峰值低200~400 MPa,说明消应处理对高应力水平的纵向残余应力具有明显作用。

4 结论

1) 采用平面应变模型计算大厚度多道焊接的残余应力,采用“生死单元”方法实现多道焊接的焊缝生长,通过计算和试验测量结果比较表明,本研究提出的计算模型和计算方法能够比较准确高效地预测大厚度板多道焊接的残余应力。

2) 横向应力和纵向残余应力分布自焊缝中心到上下表面呈减小→增大→减小的复杂对称变化趋势,残余应力的峰值出现在距上、下表面10 mm位置,焊缝中部区域残余应力至相对较低。

3) 计算和测量的表面纵向残应力分布趋势符合较好。但计算的焊缝区域纵向应力值明显大于试验测量的应力值,测量的纵向残余应力峰值比计算值低200~400 MPa。试验过程采用了消应处理措施,说明所采用的消应处理措施对高应力水平的纵向残余应力具有明显的降低作用。

REFERENCES

[1] TAKAHASH E, SATOH K I K. A method of measuring triaxial residual stress in heavy section butt weldments[J]. Transactions of the Japan Welding Society, 1979, 10(1): 36-45.

[2] ROSENTHAL D, NORTON J T. A method of measuring triaxial residual stress in plates[J]. Weld J, 1945, 24(5): 295S-370S.

[3] UEDA Y, FUKUDA K, TANIGAWA M. New measuring method of three dimension residual stress based on theory of inherent strain[J]. Transaction of JWRI, 1979, 8(2): 89-96.

[4] IWATA M, OGAWA J. Advanced techniques of residual stress measurements part 1[J]. Welding Research Abroad Apr, 1997, 12(3): 5-10.

[5] 熊健民, 周金枝, 余天庆. 厚板焊接中残余应力的分布规律[J]. 湖北工学院学报, 1997, 12(3): 5-10.

XIONG Jian-min, ZHOU Jin-zhi, YU Tian-qing. The distribution law of welding residual stress in heavy plate[J]. Journal of Hubei Polytechnic University, 1997, 12(3): 5-10.

[6] 王宽福. 压力容器焊接结构工程分析[J]. 北京: 化学工业出版社, 1998: 20-50.

WANG Kuan-fu. The engineering analysis pressure vessel welding structure[J]. Beijing: Chemical Industry Press, 1998: 20-50.

[7] 姜翠香, 熊建民, 余天庆. 厚板焊接残余应力的测试[J]. 湖北工学院学报, 2000(1): 6-9.

JIANG Cui-xiang, XIONG Jian-min, YU Tian-qing. Research on the test of distribution law of welding residual stress in heavy plate[J]. Journal of Hubei Polytechnic University, 2000(1): 6-9.

[8] 杨 明. 厚板焊接残余应力的有限元计算[D]. 北京: 北京工业大学, 2003.

YANG Ming. Numerical simulation about residual stress in welded heavy plate[D]. Beijing: Beijing Industry University, 2003.

[9] LINDGREN L E. Finite element modeling and simulation of welding, Part 1: Increased complexity[J]. Journal of Thermal Stresses, 2001, 24(4): 141-192.

[10] LINDGREN L E. Finite element modeling and simulation of welding, Part 2: Improved material modeling[J]. Journal of Thermal Stresses, 2001, 24(4): 195-231.

[11] LINDGREN L E. Finite element modeling and simulation of welding, Part 3: Efficiency and integration[J]. Journal of Thermal Stresses, 2001, 24(4): 305-334.

[12] LARS-ERIK LINDGREN H R, MASTO O N. Simulation of multipass welding of a thick plate[J]. International Journal for Numerical Methods in Engineering, 1999, 44(9): 1301-1316.

(编辑 李向群)

通信作者:廖志谦,高级工程师;电话:0379-67256038;E-mail:XILIN.L@126.com