基于轮廓法测试钛合金 线性摩擦焊接的内部残余应力

来源期刊:中国有色金属学报(英文版)2014年第5期

论文作者:刘 川 董春林

文章页码:1387 - 1392

关键词:残余应力;线性摩擦焊;钛合金;轮廓法

Key words:residual stress; linear friction welding; titanium alloy; contour method

摘 要:采用轮廓法测试TC17钛合金线性摩擦焊接的内部应力。该方法是一种较新的能获得构件内部应力全貌的破坏性测试技术。首先将测试试件切割成两半,然后测试因应力释放而造成的切割面变形,最后将切割面的测试轮廓作为线弹性有限元的边界条件计算垂直切割面的内部残余应力。分析TC17线性摩擦焊接内部残余应力的分布特征。测试结果表明:TC17钛合金线性摩擦焊接头距焊缝中心12 mm区域的内部残余应力为拉伸应力,峰值拉伸应力出现在焊缝中心位置,达到360 MPa(约为TC17钛合金屈服强度的1/3);焊缝区域残余应力沿厚度分布不均匀,内部应力大于上下表层区域的应力。

Abstract: The internal residual stress within a TC17 titanium alloy joint welded by linear friction welding (LFW) was measured by the contour method, which is a relatively new and destructive technique to obtain a full map of internal residual stress. The specimen was first cut into two parts; the out-of-plane displacement contour formed by the release of the residual stress was then measured; finally, taking the measured contour of the cut plane as the boundary conditions, a linear elastic finite element analysis was carried out to calculate the corresponding distribution of residual stress normal to the cut plane. The internal stress distribution of the TC17 titanium alloy LFW joint was also analyzed. The results show that the tensile residual stress in the TC17 LFW weld is mainly present within a region about 12 mm from the weld centerline; the peak tensile residual stress occurs at the weld centerline and reaches 360 MPa (about one third of the yield strength of TC17 alloy); within the weld zone of the TC17 LFW weld, the through-thickness stress is not uniform, and the internal stress is larger than that near the top or bottom surface.

Trans. Nonferrous Met. Soc. China 24(2014) 1387-1392

Chuan LIU1, Chun-lin DONG2

1. Provincial Key Lab of Advanced Welding Technology, Jiangsu University of Science and Technology, Zhenjiang 212003, China;

2. China Friction Stir Welding Center, Beijing 100024, China

Received 25 June 2013; accepted 12 November 2013

Abstract: The internal residual stress within a TC17 titanium alloy joint welded by linear friction welding (LFW) was measured by the contour method, which is a relatively new and destructive technique to obtain a full map of internal residual stress. The specimen was first cut into two parts; the out-of-plane displacement contour formed by the release of the residual stress was then measured; finally, taking the measured contour of the cut plane as the boundary conditions, a linear elastic finite element analysis was carried out to calculate the corresponding distribution of residual stress normal to the cut plane. The internal stress distribution of the TC17 titanium alloy LFW joint was also analyzed. The results show that the tensile residual stress in the TC17 LFW weld is mainly present within a region about 12 mm from the weld centerline; the peak tensile residual stress occurs at the weld centerline and reaches 360 MPa (about one third of the yield strength of TC17 alloy); within the weld zone of the TC17 LFW weld, the through-thickness stress is not uniform, and the internal stress is larger than that near the top or bottom surface.

Key words: residual stress; linear friction welding; titanium alloy; contour method

1 Introduction

Titanium alloys are widely used in aerospace, power generation and chemical processing applications owing to their high specific strength and good corrosion resistance in many environments. Conventional fusion welding is less optimal when used with titanium alloys, as the material is highly reactive at elevated temperatures. The introduction of friction-based solid- state welding processes has provided an optimal welding method for titanium alloys [1,2]. These friction welding processes eliminate the necessity for a protective environment when welding, since the material does not reach fusion temperature. Among the friction welding processes, linear friction welding (LFW) is designed to join unaxisymmetry components through the relative motion of two components under compressive forces. In addition, the weld seam of LFW is very narrow, resulting in a fact that thermomechanically affected zone (TMAZ) is limited [3,4].

Although liquation does not occur during LFW, the extensive deformation and severe thermal excursion generate significant changes in microstructure and thereby, introduce mechanical property and residual stress variations across the weld. Residual stress produced by various manufacturing methods is a crucial factor when assessing the integrity of engineering components [5] and has been attracted attention all the time [6,7].

Experimental measurement is a direct method for measuring the distribution of welding residual stress. A wide range of residual stress measurement techniques are available for the characterization of residual stress in engineering components [8], but few are available to measure the whole stress distribution within the weld. The slitting method [9], hole-drilling method [10] and X-ray diffraction (XRD) method [11] can be used to determine the welding residual stress. However, these methods can only be used to determine the surface residual stress. The measurement of internal stress within thick welded components is difficult. Measuring the whole internal stress distribution within the very narrow weld zone produced by LFW is even more difficult. The deep hole drilling (DHD) technique [12] has been successfully applied to large and thick engineering structures, but it may be unavailable to measure the stress within narrow welds [13]. Neutron diffraction is a popular non-destructive technique that has been used to map multi-axial components of stress in engineering components [14], but its application is limited by the thickness of the sample, the component geometry, the sensitivity to microstructure and the need to take components to a neutron source.

The contour method is a relatively new technique for measuring residual stress in structures which offers some advantages compared with neutron diffraction and DHD techniques [14]. It provides a two-dimensional (2D) map of residual stress on a cut surface, and it is not limited by the microstructure or the thickness of the component.

The contour method has been applied to measuring internal residual stress introduced by various welding methods and various welding joints, such as friction stir welding of thick aluminum alloy plates [15], arc welding of a T-type joint [16], variable-polarity plasma-arc (VPPA) welding of aluminum alloy plates [17], and multi-pass welding of pipes [18]. In particular, it can also be available to obtain the full 2D map of stress field within the narrow welds produced by LFW [19] and electron beam welding [20].

In the present work, the 2D map of residual stress over the entire middle cross section of titanium alloy LFW joint is obtained using the contour method. The detailed measuring procedure is introduced and the stress distribution of the LFW joint is also analyzed.

2 Measuring principle and specimen

2.1 Measuring principle

When a specimen containing residual stress is cut into two parts, the residual stress acting normally to the cutting planes will release completely, arousing the deformation of the cut planes. Assuming that the residual stress relaxation is elastic when the specimen is cut and the material removal process does not introduce significant stress, if the deformed free surface created by cutting is forced back to its original flat shape, the resulted stress can give the original stress acting normal to the cutting plane based on the Bueckner’s supperposition principle [14].

In the contour method, the resulting relaxed surface contour was measured, then the elastic finite element (FE) method was used and the opposite of the measured contour is applied as boundary conditions to the cut face of the FE model, thus producing the original residual stress field that is present along the flat plane before the cutting [14].

The basic steps of a contour method measurement include cutting the part into two pieces, measuring the deformation of the cut surfaces, analyzing the measured deformation data and FE analysis to determine residual stress normal to the cutting plane.

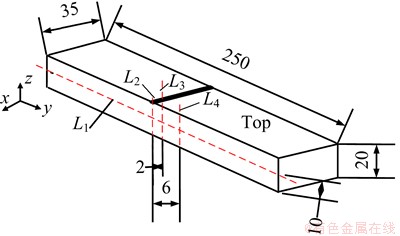

2.2 Specimen preparation

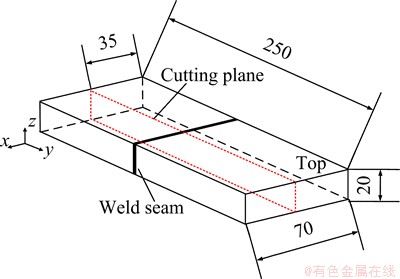

A linear friction weld was produced with two TC17 titanium alloy blocks in Beijing Aeronautical Manufacturing Technology Research Institute. One titanium alloy block was rubbed across the face of the second block, which is rigidly clamped, using a linear reversing motion. Based on a large number of experiments, the welding parameters were optimized to produce reproducible and high-quality LFW welds of TC17 titanium alloy. The final dimensions of the welded specimen were 250 mm in length, 70 mm in width and 20 mm in thickness, as shown in Fig. 1. After welding, the flash around the weld was milled away.

Fig. 1 Schematic diagram of TC17 LFW weld (unit: mm)

3 Measuring procedure

3.1 Specimen cutting

The cutting plane was of mid-thickness, perpendicular to the x-direction, as shown in Fig. 1. The specimen was clamped close to the cutting line on both sides, and cut with a SODICK AQ400LS wire electric discharge machining (EDM) machine with a 0.2 mm- diameter brass wire at the cutting speed of 6-9 mm/h. These parameters were chosen by the operators for better precision and a finer surface finish with low likelihood of wire failure, and also for minimizing any recast layer and cutting-induced stress [14].

3.2 Contour measurement

After the specimen was cut into two halves, the out-of-plane displacement contour was measured using a HEXAGON GLOBAL coordinate measuring machine (CMM).

Both halves of the cut specimen were measured with a point spacing of approximately 1 mm over the entire cutting surface. Subsequently, a region consisting of about 20 mm to either side of the weld center was measured with a point spacing of 0.2 mm to better capture the surface profile in the weld region. The irregular point spacing for contour measurement was also used by DEWALD et al [21] to measure the residual stress in Alloy 22 welds with or without laser peening.

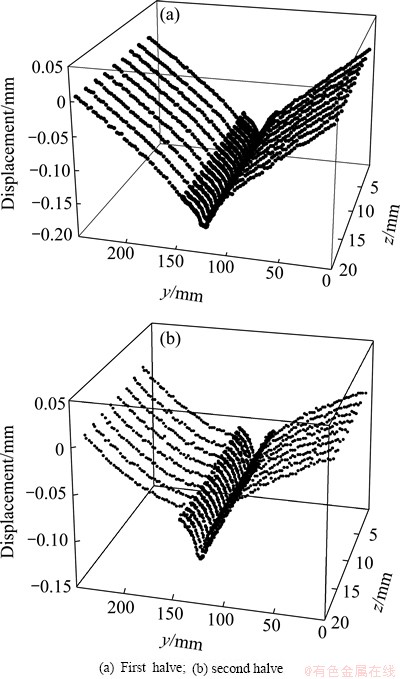

The measured out-of-plane displacements of the two halves are shown in Fig. 2. As seen in Fig. 2, the surfaces are low in the weld region with peak-to-valley surface heights of 115 μm and 175 μm on the two halves.

Fig. 2 Measured out-of-plane displacements

3.3 Surface data processing

The presence of noise and outliers in the measured raw displacements from the CMM is inevitable, that is why the profile and the peak-to-valley surface heights of the two halves are different, as shown in Fig. 2. This might also be due to cutting artefacts, surface roughness or errors in measurement [22]. The noise and outliers can lead to the dramatic errors in the final measured stress. Hence, it is necessary to process the raw displacements prior to their application as displacement boundary conditions in the FE model.

The most important steps of surface data processing are the alignment of measured data from both cutting faces, removing of noise and outliers, averaging of the two sets of measurements in order to remove shear stress effects and cutting imperfections, and finally fitting smoothly to the cleaned and averaged data [22].

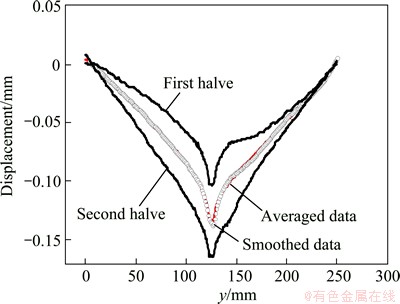

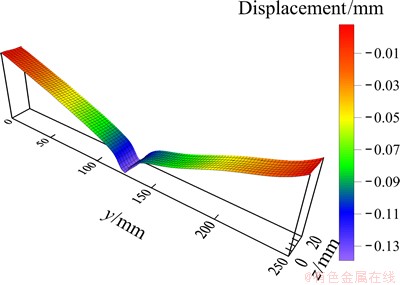

The surface fitting in the contour of cutting surfaces for LFW welds is quite difficult because most of the surface has a very low gradient compared with a high gradient present close to the weld line (Fig. 2). Fourier surface fit was used by PRIME [14] and DEWALD et al [21] for the residual stress measurement of arc welding with contour method; spline fitting algorithm was also used to smooth the measured deformation [22-24]. In the present study, the averaged surface contours were divided into two parts by the weld centerline, one part was fitted to a high-order Fourier surface, while the other smoothed with a high-order polynomial fit. Figure 3 shows the single-line profiles of measured displacements, averaged and smoothed results, and the line is located on the cutting plane and 10 mm below the welded plate surface. This figure clearly shows that the measured displacements on the two cutting surfaces are different and the fitted profile matches the measured surface profile very closely. The resulting smooth surface is shown in Fig. 4.

Fig. 3 Comparison of measured, averaged and smoothed displacements

Fig. 4 Smoothed surface after data processing

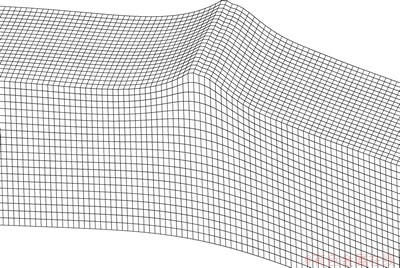

3.4 Finite element analysis

In the contour method, the original stress is finally inferred by applying the smoothed contour as a boundary condition to the previous flat cutting face. A one-half plate FE model is first built after which a linear elastic finite element analysis is then undertaken to calculate the corresponding distribution of residual stress normal to the cutting face. The material behavior is isotropic and linear elastic with an elastic modulus of 112 GPa and Poisson ratio of 0.34. Additional constraints are adopted to prevent rigid-body motions of the FE model. Figure 5 shows the finite element model of the weld zone with the opposite smooth contour applied as the boundary conditions to the cutting surface. In Fig. 5, the deformation is magnified by 200.

Fig. 5 Finite element model with opposite measured deformation on cutting surface

4 Results and discussion

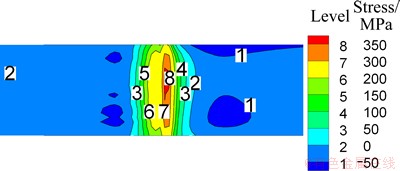

Figure 6 shows the 2D residual stress in the TC17 titanium alloy LFW weld measured by the contour method. The measured stress is normal to the cutting surface, which is the x-direction stress shown in Fig. 1. The estimated uncertainty for contour method is a ±32 MPa for the welding residual stress measurement using touch probe CMM to measure the deformation and spline fitting algorithm to fit the contour data [25].

Fig. 6 Measured longitudinal residual stress in cross-section of weld plate

As seen in Fig. 6, the weld zone is characterized by the tensile stress and the peak stress (about 360 MPa) is located at the weld center line. The peak stress is about one third of the yield strength of the TC17 titanium alloy at room temperature (about 1030 MPa). Out of the weld zone, the stress decreases very quickly to zero, which shows a very steep stress gradient within the LFW weld. In Refs. [19,26], the measured residual stress via diffraction method and contour method in the LFW of titanium alloys is also less than the yield strength of the materials at room temperature; in addition, the stress distribution trend in the present study is similar to that in these references. Moreover, the measured stress in the present study would be smaller than the actual as-welded stress because the removal of the flash may result in some stress release.

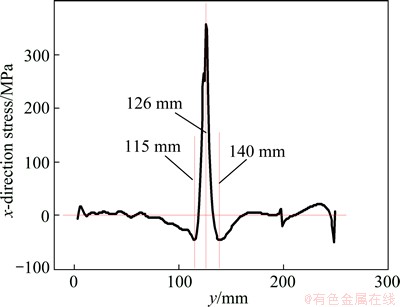

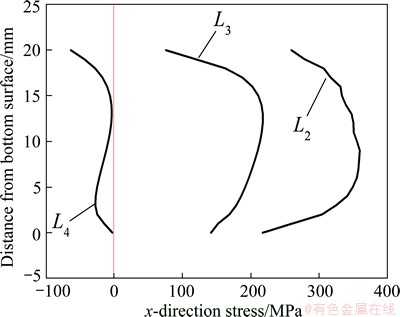

To clearly demonstrate the stress distribution in the TC17 alloy LFW joint, four lines on the cutting surface were selected to evaluate the measured stress (Fig. 7). The stresses along these lines are plotted in Figs. 8 and 9.

Fig. 7 Schematic diagram of stress evaluation lines (unit: mm)

Fig. 8 Stress distribution along line L1

Fig. 9 Stress distribution along lines L2, L3 and L4

As seen from Fig. 8, high tensile stress occurs at the weldline center, and decreases sharply to a small peak compressive stress (about 50 MPa) at distance of 11 mm (left side) and 14 mm (right side) from the weldline center, and then increases slowly to zero. From Fig. 8, it can be concluded that the steep stress gradient within the TC17 alloy LFW weld can be captured with the contour method.

It can be seen from Fig. 9 that the through-thickness stress is not uniform from top surface to bottom surface, and the stress near the top and bottom surfaces is smaller than the interior stress. In addition, the stress magnitude decreases sharply with increasing the distance from the weld centerline. At the location of 6 mm from the weld centerline, the stress is compressive through the entire thickness.

5 Conclusions

1) The contour method can produce a 2D map of residual stress over the entire cross-section of welded components. It can capture the steep stress gradient within the narrow LFW weld.

2) The peak tensile stress appears at the weld centerline of the TC17 LFW weld and reaches 360 MPa (about one third of the yield strength of TC17 alloy), and at locations of 11 mm to 14 mm far from the weld centerline, the tensile stress drops to a small peak of compressive stress (about 50 MPa).

3) Within the weld zone of the TC17 LFW weld, the through-thickness stress is not uniform; the interior stress is larger than that near the top or bottom surface.

References

[1] DALGAARD E, WANJARA P, GHOLIPOUR J, GHOLIPOUR J, CAO X, JONAS J J. Linear friction welding of a near-β titanium alloy [J]. Acta Materialia, 2012, 60(2): 770-780.

[2] WANJARA P, JAHAZI M. Linear friction welding of Ti-6Al-4V: Processing, microstructure, and mechanical-property inter- relationships [J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2149-2164.

[3] SHTRIKMANA M M. Linear friction welding [J]. Welding International, 2010, 24(7): 563-569.

[4] ROMERO J, ATTALLAH M M, PREUSS M, KARADGE M, BRAY S E. Effect of the forging pressure on the microstructure and residual stress development in Ti-6Al-4V linear friction welds [J]. Acta Materialia, 2009, 57(18): 5582-5592.

[5] DONG P, BRUST F W. Welding residual stresses and effects on fracture in pressure vessel and piping components: A millennium review and beyond [J]. Journal of Pressure Vessel Technology, 2000, 122(3): 329-338.

[6] JEYAKUMAR M, CHRISTOPHER T. Defect assessment of welded specimen considering weld induced residual stresses using SINTAP procedure and FEA [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1452-1458.

[7] YAN De-jun, LIU Xue-song, LI Jun, YANG Jian-guo, FANG Hong-yuan. Effect of strain hardening and strain softening on welding distortion and residual stress of A7N01-T4 aluminum alloy by simulation analysis [J]. Journal of Central South University of Technology, 2010, 17(4): 666-673.

[8] WITHERS P J, TURSKI M, EDWARDS L, BOUCHARD P J, BUTTLE D J. Recent advances in residual stress measurement [J]. International Journal of Pressure Vessels and Piping, 2008, 85(3): 118-127.

[9] DEPLUS K, SIMAR A, HAVER W V, MEESTER B D. Residual stresses in aluminium alloy friction stir welds [J]. The International Journal of Advanced Manufacturing Technology, 2011, 56(5-8): 493-504.

[10] XU Wei-feng, LIU Jin-he, ZHU Hong-qiang. Analysis of residual stresses in thick aluminum friction stir welded butt joints [J]. Materials & Design; 2011, 32(4): 2000-2005.

[11] HATAMLEHA O, DEWALD A. An investigation of the peening effects on the residual stresses in friction stir welded 2195 and 7075 aluminum alloy joints [J]. Journal of Materials Processing Technology, 2009, 209(10): 4822-4829.

[12] SMITH D J, BOUCHARD P J, GEORGE D. Measurement and prediction of residual stresses in thick-section welds [J]. The Journal of Strain Analysis for Engineering Design, 2000, 35(4): 287-305.

[13] LIU Chuan, WU Bing, ZHANG Jian-xun. Numerical investigation of residual stress in thick titanium alloy plate joined with electron beam welding [J]. Metallurgical and Materials Transactions B, 2010, 41(5): 1129-1138.

[14] PRIME M B. Cross-sectional mapping of residual stresses by measuring the surface contour after a cut [J]. Journal of Engineering Materials and Technology, 2001, 123(2): 162-168.

[15] PRIME M B,  T, BAUMANN J A, LEDERICH R J, BOWDEN D M, SEBRING R J. Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld [J]. Acta Materialia, 2006, 54(15): 4013-4021.

T, BAUMANN J A, LEDERICH R J, BOWDEN D M, SEBRING R J. Residual stress measurements in a thick, dissimilar aluminum alloy friction stir weld [J]. Acta Materialia, 2006, 54(15): 4013-4021.

[16] LIU Chuan, ZHUANG Dong. Internal welding residual stress measurement based on contour method [J]. Journal of Mechanical Engineering, 2012, 48(8): 54-59. (in Chinese)

[17] ZHANG Y, GANGULY S, EDWARDS L, FITZPATRICK M E. Cross-sectional mapping of residual stresses in a VPPA weld using the contour method [J]. Acta Materialia, 2004, 52(17): 5225-5232.

[18] HOSSEINZADEH F, BOUCHARD P J. Mapping multiple components of the residual stress tensor in a large P91 steel pipe girth weld using a single contour cut [J]. Experimental Mechanics, 2013, 53(2): 171-181.

[19] FRANKEL P, PREUSS M, STEUWER A, WITHERS P J, BRAY S. Comparison of residual stresses in Ti-6Al-4V and Ti-6Al-2Sn- 4Zr-2Mo linear friction welds [J]. Materials Science and Technology, 2009, 25(5): 640-650.

[20] BROWN D W, HOLDEN T M, CLAUSEN B, PRIME M B, SISNEROS T A, SWENSON H, VAJA J. Critical comparison of two independent measurements of residual stress in an electron-beam welded uranium cylinder: Neutron diffraction and the contour method [J]. Acta Materialia, 2011, 59(3): 864-873.

[21] DEWALD A T, RANKIN J E, HILL M R, LEE M J, CHEN H L. Assessment of tensile residual stress mitigation in Alloy 22 welds due to laser peening [J]. Journal of Engineering Materials and Technology, 2004, 126(4): 465-472.

[22] TRAORE Y, BOUCHARD P J , FRANCIS J, HOSSEINZADEH F. A novel cutting strategy for reducing plasticity induced errors in residual stress measurements made with the contour method [C]// Proceedings of the ASME 2011 Pressure Vessels & Piping Division Conference. New York, USA: American Society of Mechanical Engineers, 2011.

[23] HOSSEINZADEH F, TOPARLI M B, BOUCHARD P J. Slitting and contour method residual stress measurements in an edge welded beam [J]. Journal of Pressure Vessel Technology, 2012, 134(1): 1-6.

[24] TURSKI M, EDWARDS L. Residual stress measurement of a 316L stainless steel bead-on-plate specimen utilising the contour method [J]. International Journal of Pressure Vessels and Piping, 2009, 86(1): 126-131.

[25] PRIME M B, SEBRING R J, EDWARD J M, HUGHES D J, WEBSTER P J. Laser Surface-contouring and spline data-smoothing for residual -stress measurement [J]. Experimental Mechanics, 2004, 44(2): 176-184.

[26] GREGORY J. Residual stress measurements using the contour method [D]. Manchester: University of Manchester, 2008.

刘 川1,董春林2

1. 江苏科技大学 先进焊接技术省级重点实验室,镇江 212003;

2. 中国搅拌摩擦焊中心,北京 100024

摘 要:采用轮廓法测试TC17钛合金线性摩擦焊接的内部应力。该方法是一种较新的能获得构件内部应力全貌的破坏性测试技术。首先将测试试件切割成两半,然后测试因应力释放而造成的切割面变形,最后将切割面的测试轮廓作为线弹性有限元的边界条件计算垂直切割面的内部残余应力。分析TC17线性摩擦焊接内部残余应力的分布特征。测试结果表明:TC17钛合金线性摩擦焊接头距焊缝中心12 mm区域的内部残余应力为拉伸应力,峰值拉伸应力出现在焊缝中心位置,达到360 MPa(约为TC17钛合金屈服强度的1/3);焊缝区域残余应力沿厚度分布不均匀,内部应力大于上下表层区域的应力。

关键词:残余应力;线性摩擦焊;钛合金;轮廓法

(Edited by Xiang-qun LI)

Foundation item: Project (35061107) supported by the Doctoral Initiation Project of Jiangsu University of Science and Technology, China

Corresponding author: Chuan LIU; Tel: +86-511-84401184; E-mail: chuanliu2003@126.com

DOI: 10.1016/S1003-6326(14)63203-9