文章编号:1004-0609(2010)S1-s0886-04

钛合金等离子焊后焊接接头超声消应工艺

郭小辉,柳 军,徐希军,贾晓飞

(洛阳船舶材料研究所,洛阳 471039)

摘 要:针对大型钛制容器的中厚板焊接,研究12 mm厚钛板等离子焊接工艺,分析焊接参数对焊缝成形的影响,确定合适的焊接工艺规范,对焊缝进行超声冲击消应处理,并对比超声消应前后焊缝残余应力的变化。结果表明:钛合金中厚板采用等离子焊接,焊后进行超声消应处理,可有效改善焊缝的残余应力。

关键词:钛合金;等离子焊;超声冲击;残余应力

中图分类号:TF 804.3 文献标志码:A

Ultrasonic peening technical of titanium-alloy welded joint with

plasma arc welding

GUO Xiao-hui, LIU Jun, HE Gang, XU Xi-jun, JIA Xiao-fei

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: Aiming at the medium plate welding of the big specification vessel, the plasma arc welding technics of TA2 plate with 12 mm thickness were studied and the welding parameter effect of the joint shaping regularity was analyzed. The appropriate welding technical specifications were confirmed, the welded plate was treated by ultrasonic peening, the change of the welding residual stress was compared. The results show that the medium plate with plasma arc welding, after the welding joint was treated by ultrasonic peening, the welding residual stress can be improved.

Key words: titanium-alloy; plasma arc welding; ultrasonic treatment; welding residual stress

TA2具有良好的焊接性,并且接头具有比较理想的强度和塑韧性,再加上其本身良好的耐蚀性和成型性能,在储罐和塔器等主要用于腐蚀介质或者低温环境的压力容器中得到广泛的应用[1]。此类容器有大量的大规格中厚壁板,其纵缝和环缝的焊接量都相当大,为了更进一步提高生产效率和降低操作人员的劳动强度,采用PAW+ GMAW的焊接方法进行TA2中厚板的焊接。等离子弧焊(PAW)作为一种高效、优质的焊接技术,在国外已广泛应用于各种钛合金的研究和生产[2]。

钛合金焊接结构件在承受重载荷及恶劣的工况条件下,设计上对钛合金焊接接头的性能要求越来越高,除了提高材料的焊接性和改进焊接工艺外,焊后有效的工艺处理对焊接接头综合性能的提高具有重要作用。多年来发展的各种改善焊接接头性能的处理工艺中,超声冲击法具有效果显著、结构轻巧、噪音小、效率高、成本低、节能等诸多优势,因而成为一种理想的焊后改善焊接接头性能的工艺措施。

1 等离子焊接工艺试验

1.1 试验条件

1.1.1 焊接设备

法国SAF公司的NERTAMATIC300+SP6全自动等离子焊接系统。

1.1.2 试验材料

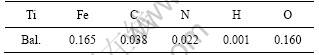

TA2板,厚度为12 mm,板材实测化学成分和力学性能见表1和2。

表1 TA2板化学成分

Table 1 Chemical element of TA2 plates (mass fraction, %)

表2 TA2板力学性能

Table 2 Mechanical properties of TA2 plates

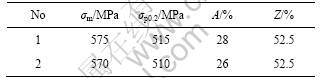

1.1.3 试样制备

采用150 mm×500 mm标准试板,Ⅰ型坡口对接焊(见图1)。

图1 坡口形式

Fig.1 Type of welding groove

1.2 工艺参数的确定

1.2.1 焊接电流

焊接电流增加时,热输入增加,等离子流力增大,表面张力梯度减小;焊接电流减少时,热输入减小,等离子流力减少,表面张力梯度增大。因此,随着焊接电流的增加,液态金属向焊件表面的流动趋势增大,焊缝背面熔宽和余高显著增大,正面熔宽增大,余高减小。试验表明,对于12 mm的TA2钛合金板材,电流在200~280 A范围内可实现良好的焊缝成形。

1.2.2 焊接电压

焊接电压增大,由焊件正、背面指向小孔的射流压力梯度增大,熔池表面张力梯度增大,因此,熔池上部熔化的液态金属向焊件背面流动的趋势减小,向正面流动的趋势增大,焊缝正面熔宽和余高增大,背面的熔宽和余高减小。试验表明,对于12 mm的TA2钛合金板材,电压在25~35 V范围内可实现良好的焊缝成形。

1.2.3 焊接速度对焊缝成形的影响

当焊接速度增加时,等离子流对熔池上部表面的压力增大,对下部的表面压力减小,由焊件正、背面指向小孔的射流压力梯度增大,重力对熔池上部液态金属流动的作用增强,对熔池下部液态金属流动的作用减弱,表面张力梯度增大。因此,焊接速度增加时,熔池液态金属向焊件正面的流动速度增大,向焊件背面的流动速度减小,因而焊缝正面余高增大,正面熔宽、背面熔宽和余高减小,但焊接速度过大,则出现未焊透。当焊接速度减小时,情形则相反。试验表明,对于12 mm厚的TA2钛合金板材,焊接速度在10~25 cm/min范围内可实现良好的焊缝成形。

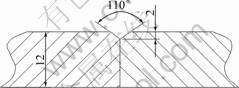

通过对焊接电流、焊接电压、焊接速度及离子气流量对焊缝成形的影响研究。完成了12 mm的TA2钛合金焊缝等离子焊接的基本工艺参数的优化设计,优化后的主要焊接工艺参数见表3。

1.3 焊缝外观和内部质量检验

按照上述规范及工艺参数完成的试板,焊缝表面颜色呈银白色,按照JB/T 4730—2005对焊缝先后进行PT 和RT无损检测,均达到Ⅰ级合格指标。

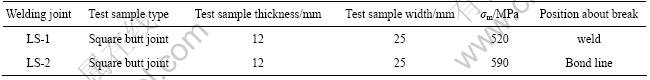

1.4 接头性能测试

按照GB/T 4745—2002钛制压力容器有关焊接工艺评定和焊缝检验的要求,进行焊接接头弯曲性能和拉伸性能的测试,其结果见表4。由表4中数据可以看出,等离子焊接头拉伸性能良好,抗拉强度与母材的相当,接头焊接系数按母材实测值计算分别为0.90和1.03,接头抗拉强度不低于母材抗拉强度下限值的90%;冷弯试验一组,正弯和背弯各两个38 mm×10 mm标准试样,弯径100 mm、弯角180°,正弯、背弯被拉伸面均无裂纹,完全达到钛制容器标准的合格要求。说明TA2等离子焊接头具有很好的工艺和力学性能。

表3 焊接参数

Table 3 Welding parameter

表4 焊缝接头拉伸性能

Table 4 Mechanical properties of welding joint

2 超声冲击处理工艺

由于容器设备体积大,其本身焊缝数量就很多,再加上因钛材板幅的限制,使得筒节的个数和拼接焊缝数量又明显增加,此外,钛材焊接过程中导热性较差,焊接区拘束度大,种种因素将导致焊缝的焊接残余应力和整个塔体结构内应力增大,必须进行焊后消应处理,以提高接头疲劳强度和疲劳寿命。

在多年来发展的各种改善焊接接头性能的处理工艺中,超声冲击法是一种理想的焊后改善焊接接头性能的工艺措施。对于12 mm厚的TA2对接焊缝的超声消应方法有必要进一步研究。

2.1 试验材料和试件的制备

为了能够准确比较得出超声冲击处理消除应力的效果,采用比较法即选择同材质、同规格的两组试板,在同样的焊接参数下,一组不采用,一组采用超声冲击处理,编号分别为HHP-21和HHP-22,焊接接头型式都采用平板对接型式。

2.2 超声冲击处理工艺

超声冲击处理的操作方法是将超声冲击枪对准试件接头焊趾部位,且基本垂直于焊缝。冲击头的冲击针阵列沿焊缝方向排列。略施加一定的压力,使其基本在冲击枪的自身质量条件下进行冲击处理。超声冲击处理工艺参数见表5。

表5 超声冲击处理工艺参数

Table 5 Ultrasonic treatment process parameters

2.3 测试方法及设备

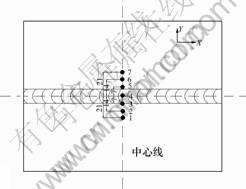

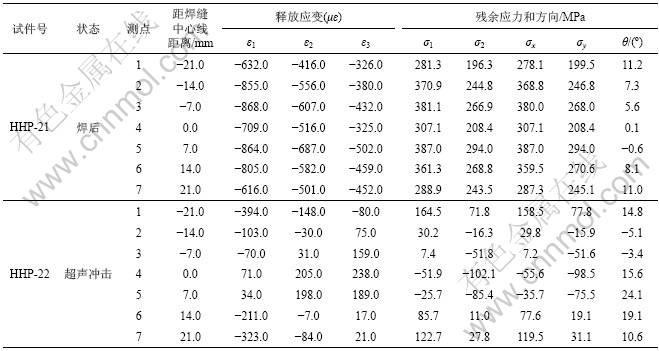

采用钻孔残余应力测试方法,即首先在被测材料表面粘贴应变花,然后在应变花中心钻孔,钻孔直径1.5 mm,深2 mm,根据钻孔后测量的释放应变就可以计算出残余应力。测试设备采用ZDL-Ⅱ型残余应力钻孔装置、YC-Ⅲ型应力仪和残余应力专用应变花。为了得到最典型的测量结果,测点布置在垂直于焊缝中心线上焊缝中心附近,其各点间距离分布见图2。上述2个试板HHP-21 和HHP-22的残余应力测量结果见表6。

图2 试板测量点示意图

Fig.2 Schematic diagram map of measure point of plate

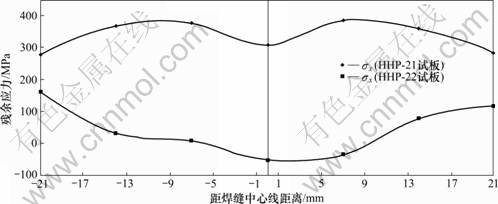

2.4 结果分析

图3所示为超声冲击工艺残余应力消除效果的对比。由图3可以看出,HHP-21试板在焊缝熔合线附近残余应力最大,其平行于焊缝的残余应力σx达到387.0 MPa,焊缝中心的残余应力小于熔合线附近的残余应力,相应值为307.1 MPa,残余应力分布符合一般的焊接残余应力分布规律。

HHP-22试板经过超声冲击工艺处理后,残余应力下降明显,如图3所示,其焊缝中心平行于焊缝的残余应力σx下降为压应力-55.6 MPa,达到了超声冲击处理理论上的效果,使焊缝区焊接残余应力整体降低和均匀化分布。图3中在远离焊缝处,残余应力下降不大,主要是由于超声冲击时没有冲击到的原因,因此实际应用时一定要注意,超声冲击处理应该冲击在残余应力比较大的区域。

表6 钛焊接试板垂直于焊缝中心线残余应力测量结果

Table 6 Test results of test piece of welding residual stress

图3 超声冲击工艺残余应力消除效果的对比

Fig3 Comparisons of welding residual stress of test piece of welded joints with ultrasonic treatment joints

3 结论

1) 试板在通过等离子焊接后,焊接头拉伸性能良好,与母材性能相当,接头性能满足焊接系数不小于0.9的指标要求。无裂纹,低倍组织照片中未发现裂纹、孔穴、固体夹杂、未熔合和未焊透等形状缺陷,说明等离子焊接接头具有很好的工艺性能。

2) 焊后的超声消应处理也符合预期的目标,试板在经过超声冲击工艺处理后,焊缝区焊接残余应力整体降低,由拉应力变为压应力,残余应力下降达到100%,效果十分明显。

REFERENCES

[1] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工艺出版社, 2005: 287-305.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Ti alloy and its application[M]. Beijing: Chemical Industry Press, 2005” 287-305.

[2] 廖志谦, 王忠平. 钛合金厚板等离子焊接[J]. 材料开发与应用, 2005, 20(4): 27-28, 37.

LIAO Zhi-qian, WANG Zhong-ping. Plasma welding of titanium alloy thick-plate[J]. Development and Application of Materials, 2005, 20(4): 27-28, 37.

(编辑 陈爱华)

通信作者:郭小辉;电话:13698867090;E-mail: terrygxh@yahoo.com.cn