DOI: 10.11817/j.issn.1672-7207.2019.05.009

玻纤增强聚丙烯与尼龙66模内混合加工成型实验研究

符亮1,蒋炳炎1, 2,吴旺青1, 2,闵丽萍1

(1. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

2. 中南大学 新型特种纤维及其复合材料湖南省重点实验室,湖南 长沙,410083)

摘要:为了解决纤维增强热塑性复合材料加工成型零件复杂程度与力学性能匹配的问题,提高不同热塑性基体纤维增强复合材料制件的力学强度,运用模内混合加工成型技术制备连续玻纤增强聚丙烯(PP)预制件与短玻纤增强尼龙66(PA66)平板实验件,采用单因素实验法研究熔体温度、预制件加热温度、模具温度和保压压力对实验件弯曲强度的影响规律。研究结果表明:界面温度和保压压力的提高有利于提高加工成型制件弯曲强度,其中预制件加热温度和熔体温度对制件弯曲强度影响最大,分别提高2.6倍和1.6倍,且呈线性增大关系;微观形貌显示混合界面出现PP与PA66树脂间融合共混区;模内混合加工成型工艺参数的优化提高了制件的力学性能,扩宽了轻量化材料的组合应用。

关键词:模内混合加工成型;热塑性基体;弯曲强度;微观形貌

中图分类号:TH145.4 文献标志码:A 文章编号:1672-7207(2019)05-1075-07

Experimental research on in-mold hybrid molding of glass fiber reinforced polypropylene and nylon66

FU Liang1, JIANG Bingyan1, 2, WU Wangqing1, 2, MIN Liping1

(1. State Key Laboratory of High Performance Complex Manufacturing, Central South University, Changsha 410083, China;

2. Hunan Key Laboratory of Advanced Fibers and Composites, Central South University, Changsha 410083, China)

Abstract: To address the matching issue between complexity and mechanical properties of fiber reinforced thermoplastics part, improve the mechanical strength of fiber reinforced composite part with different thermoplastic matrixes, the flat test sample of pre-formed part with continuous fiber reinforced polypropylene(PP) and short fiber reinforced nylon66(PA66) were prepared by in-mold hybrid molding technology. The effects of melt temperature, heating temperature of pre-formed part, mold temperature and holding pressure on the bending strength were studied by single-factor experiment. The results show that the bending strength increases with the increase of interface temperature and holding pressure. The heating temperature of pre-formed part and melt temperature have the greatest impact on bending strength, and the bending strength increases by 2.6 and 1.6 times, respectively, showing a linear growth relationship.The fusion blending zone appears between hybrid interface of PP and PA66 resin.The mechanical strength is improved by optimization of in-mold hybrid molding process parameters and the combined use of lightweight materials is expanded.

Key words: in-mold hybrid molding; thermoplastic matrix; bending strength; microscopic morphology

纤维增强热塑性复合材料具有质量小、比强度高、热膨胀系数低、可回收和尺寸稳定性强等性能,广泛应用于汽车轻量化领域[1-2]。由于汽车零部件种类多,如何加工成型高性能复杂结构零部件成为研究重点[3-4]。连续增强增强热塑性材料(continuous fiber reinforced thermoplastic, CFRT)采用热压加工成型,机械性能好但加工成型零件结构简单,长、短纤维增强热塑性材料(long/short fiber reinforced thermoplastic, L/SFT)采用注塑加工成型工艺加工成型,零件结构不受限制,但机械性能较差。模内混合加工成型技术结合了热压加工成型和注塑加工成型的优势,可加工成型CFRT与L/SFT混合制件,成为汽车轻量化生产制造发展的方向[5-7]。在模内混合加工成型过程中,CFRT与L/SFT间形成黏结界面,温度提高降低了树脂的黏度,促进了表面分子的运动;较大的压力对树脂产生剪切作用,保证了分子的扩散,从而保证制件具有较好的力学性能[8-10]。FIOROTTO等[11]在热压加工成型的热塑性U型槽内注塑格栅加强肋结构,发现加强肋对整体力学性能有明显改善作用,熔体温度能增加界面接触时间,形成分子扩散与缠结,制件的力学性能受注塑熔体中纤维取向与界面黏结力共同影响。FREDRICKSON等[12]提出共聚物界面的形成是由官能化的聚合物链质量传递控制,实验证明了2种聚合物界面聚合物链的扩散与时间、温度、剪切流等实验条件有关。TANAKA等[13-14]通过优化CFRT加热温度和模具温度,分别制备了界面强度较高的CFRT- PP/SFT-PP和CFRT-PA6/PA6制件。ERIC等[15]研究了连续玻纤增强PA6与质量分数为30%的短玻纤PA6混合加工成型平板制件,确定了预制件温度、熔体温度和模具温度对加工成型制件弯曲性能的影响,得出分子的扩散发生在结晶温度以上。何芳芳等[16]研究了注射压力和注射速率对短纤维增强PP的流动特性和纤维取向的影响,为模内混合加工成型短纤维增强热塑性材料注塑加工成型打下了良好的基础。为了进一步提高轻量化零件机械强度,降低制造成本,扩展模内混合加工成型轻量化材料应用,本文作者以平板实验件为研究对象,选择玻璃纤维增强聚丙烯热压加工成型作为预制件,采用短玻纤增强PA66注塑加强构件,研究模内混合加工成型中注塑熔体温度、CFRT预制件加热温度、模具温度和保压压力对CFRT/SFT平板实验件弯曲强度的影响,最后通过微观形貌检测界面间玻璃纤维与树脂的变化。

1 实验

1.1 实验原理与方法

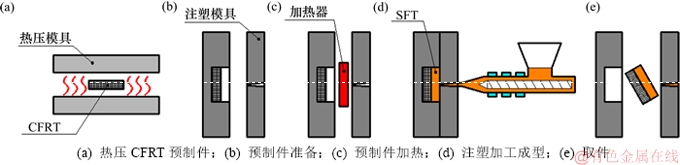

图1所示为模内混合加工成型原理示意图。将CFRT铺层预热后放置模具中热压加工成型预制件,裁剪后放置在注塑模具型腔中,经CFRT预制件加热并注塑L/SFT材料后完成整体制件加工成型。与传统嵌件注塑加工成型中嵌件只占少部分比例不同,模内混合加工成型中预制件所占比例可根据实际需要调整,同时,为保证CFRT预制件与SFT注塑件的混合加工成型质量,将CFRT预制件在注塑加工成型前完成模压加工成型,为注塑加工成型提供了质量优良的CFRT预制件。

1.2 实验材料与实验要求

1.2.1 实验材料

CFRT预制件采用连续玻纤增强聚丙烯(PP)复合材料混纤纱,牌号为CompofilTM-PP-60-P-980-1400;热塑性聚丙烯纤维与增强玻璃纤维按照质量比为4:6,两者直径相同,混合编制成正交纤维织物布,单位面积质量为980 g/m2;混编PP材料(中国巨石公司生产)结晶温度为165 ℃,;短玻纤增强尼龙66(PA66)(美国杜邦(DuPont)公司生产),牌号为Zytel 70G30LNC010,熔点为262 ℃,短玻纤质量分数为30%,密度为1.37 g/cm3,缺口冲击强度为13 kJ/m2。

70G30LNC010,熔点为262 ℃,短玻纤质量分数为30%,密度为1.37 g/cm3,缺口冲击强度为13 kJ/m2。

图1 模内混合加工成型过程示意图

Fig. 1 Schematic diagram of in-mold hybrid molding

1.2.2 实验件要求

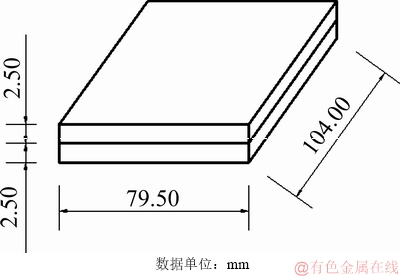

依据纤维增强复合材料弯曲强度实验测试标准ISO 14125:1998,为保证制作具有良好的纤维取向和加工成型质量,将其设计成长×宽×高设计为79.5 mm×104.00 mm×5.00 mm的立方体,其中,连续纤维增强聚丙烯预制件和短玻纤增强PA66注塑层长×宽×高均为79.50 mm×104.00 mm×2.50 mm,如图2所示。

图2 实验件几何模型

Fig. 2 Geometric model of test part

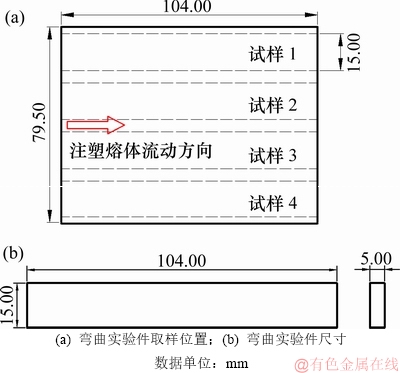

试样长度L取104 mm,试样宽度b取15 mm,试样厚度h取5 mm,弯曲实验时的跨度取75 mm。为了使弯曲强度测试结果更加准确,对同一参数下的制件取4根试样件进行实验。图3所示为弯曲试样件取样位置和尺寸示意图,沿着注塑熔体流动方向上的取样可保证PA66中短纤维取向最好[16],保证了注塑加工成型后制件的力学性能。

图3 实验件取样位置和尺寸要求示意图

Fig. 3 Schematic diagram of sample position and requirement size

1.3 CFRT预制件制备

根据测试标准要求,自主设计与制造抽真空 CFRT预制件热压加工成型模具,采用连续玻纤增强 聚丙烯(PP)复合材料混纤纱裁剪成长×宽为210 mm×240 mm的矩形,铺设4层,厚度约为8 mm,加热至195 ℃,在5 s之内将加热后的纤维布放置模具中热压加工成型。以17 mm/s的加载速度并抽真空以降低预制件孔隙率,加工成型完成后进行退火处理,其中退火温度为160 ℃,退火时长为30 min,最后将其裁剪成长×宽×高79.50 mm×104.00 mm×2.50 mm的立方体。优化的预制件热压工艺参数如下[17]:预制件温度为195 ℃,模具温度为100 ℃,保压时间为60 s,真空度为0.95×105 Pa。在此工艺参数下,得到低孔隙率和力学性能最优的CFRT预制件[17]。

1.4 模内混合加工成型实验件制备

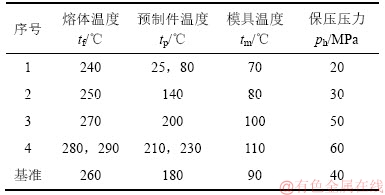

采用单因素法,依次研究熔体温度tf、CFRT预制件加热温度tp、模具温度tm和保压压力ph对加工成型实验件弯曲性能的影响,其工艺参数如表1所示。将裁剪好的CFRT预制件放置在自主设计制造的注塑模具中,采用自动控制的红外陶瓷加热器加热CFRT预制件至指定温度,然后合模注塑。注塑加工成型前,注塑料在80 ℃的干燥箱中干燥2~4 h,在实验中采用的注塑机安装了RADK-TECH RT4WRZ电液比例阀,使最大注射压力为171.1 MPa,最高的注射速率为130 g/s,保证了注塑加工成型实验件良好的加工成型质量。

表1 混合注塑加工成型工艺参数

Table 1 Process parameters of hybrid injection molding

1.5 制件弯曲强度测试

采用万能实验机进行三点弯曲法测量,加载压头直径和支架直径分别为10 mm和3 mm,选用的加载速度为2.5 mm/min。为减小实验环境对实验结果带来的误差,整个测试过程在恒温恒湿箱中进行,其中温度控制在(23±2)℃,相对湿度控制在50%±5%,弯曲强度计算式为

×

× (1)

(1)

式中: 为弯曲强度,MPa;P为破坏载荷,N;l为跨距,mm;h为试样厚度,mm;b为试样宽度,mm。

为弯曲强度,MPa;P为破坏载荷,N;l为跨距,mm;h为试样厚度,mm;b为试样宽度,mm。

2 结果与讨论

2.1 模内混合加工成型工艺参数对制件弯曲强度的影响

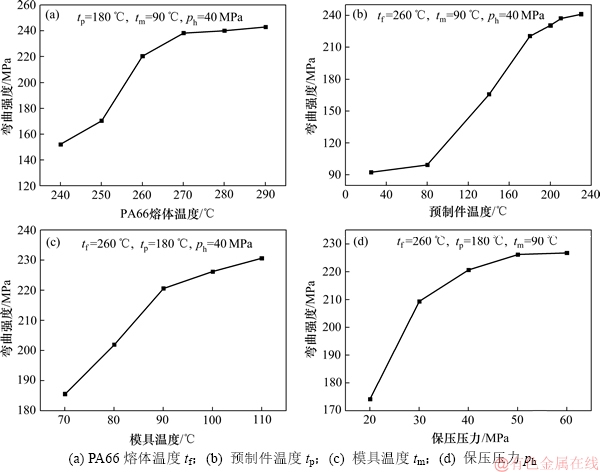

图4所示为实验件三点弯曲测试结果,其中受压面为注塑层。从图4可见:随着各参数增大,实验件弯曲强度呈线性增大,其中,图4(b)中预制件温度提高使其弯曲强度从92.58 MPa升高到241.34 MPa,提高了2.6倍,图4(a)中熔体温度tf提高使其弯曲强度从152.13 MPa升高到243.17 MPa,提高了1.6倍,这表明预制件温度和注塑PA66熔体温度对制件弯曲强度影响最大,这与温度提高连接界面中PP和PA66的分子势能有关,促进了两者分子间相互扩散[11-12];同时,尼龙属于大分子链聚合物,链间的缠结点多,加之其熔体黏度对温度极敏感,提高加工成型温度有利于改善其流动性能;但过高的温度会导致造成预制件树脂基体的高温降解,当熔体温度超过270 ℃时,实验件弯曲强度提高缓慢,若进一步提高温度,会导致制件弯曲强度迅速降低。弯曲实验结果显示最佳的界面温度应控制在材料的熔融温度以上,实验结果显示最优的熔体温度为270 ℃,最优预制件加热温度为210 ℃。

模具温度和保压压力的对实验件的力学性能影响较小,但模具温度影响注塑熔体和预制件界面间温度的保持时间并增加固化前的交融时间,还可影响PP和PA66的结晶度和冷却速率的变化,过高的模具温度将导致纤维取向程度降低;适当的保压压力则促进聚合物分子间相互扩散,增加熔体的切应力和剪切速率,提高取向程度和制件密度[9-10]。实验结果显示最优的模具温度为110 ℃,最优保压压力为50 MPa。

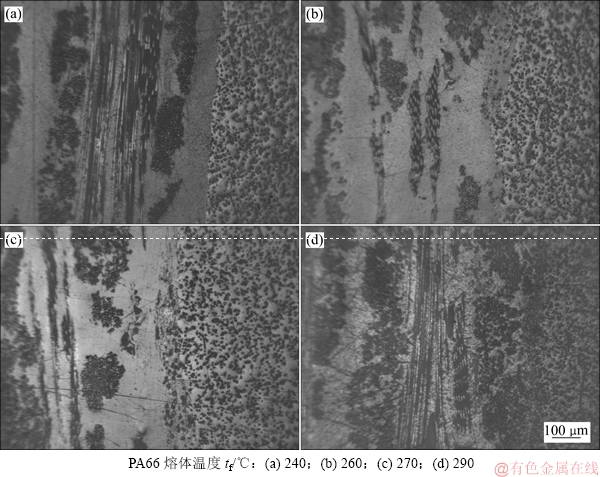

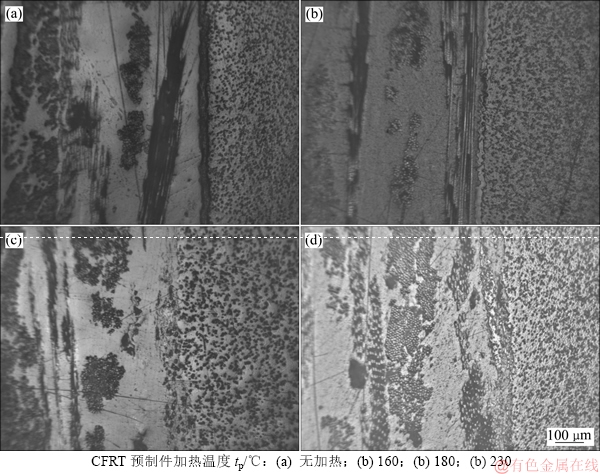

图5和图6所示为不同熔体温度和预制件加热温度下加工成型制件的微观形貌,显示了不同参数下PP与PA66连接界面的变化,证实了实验件弯曲性能提高的原因。图5中PA66熔体达到熔点温度(262 ℃)前后,注塑熔体与预制件界面间的分界线逐渐消失并融合在一起,形成了牢固可靠的连接;进一步提高熔体温度,高温下注塑熔体的热量进一步传递至预制件层,改变PP树脂的熔融状态,促进注塑层和预制件层间的温度传递,实验件弯曲强度进一步增大。图6中预制件PP树脂在低温下与PA66存在明显的分界面,当预制件加热温度超过PP熔点温度时,PP与PA66相互融合;当加热温度超过230 ℃时,连接界面基本消失,增强短玻纤和树脂间形成扩散,形成了相互交融区,宏观上表现为制件的弯曲强度最大。

图4 注塑工艺参数对实验件弯曲强度的影响

Fig. 4 Effect of injection molding process parameters on bending strength of specimens

图5 PA66熔体温度对连接界面微观形貌的影响

Fig. 5 Effect of PA66 melt temperature on microscopic morphology of interface

图6 CFRT加热温度对连接界面微观形貌的影响

Fig. 6 Effect of CFRT heating temperature on microscopic morphology of interface

2.2 制件受力断裂形式对比分析

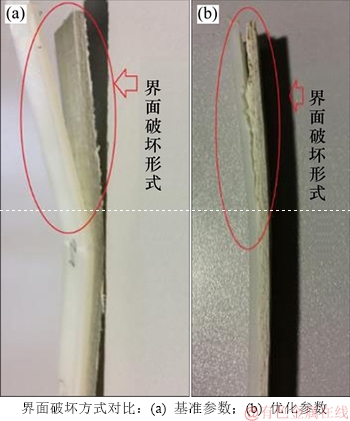

根据单因素实验法中熔体温度、预制件温度、模具温度和保压压力对实验件弯曲强度和制件微观形貌分析结果,确定了优化的工艺参数组合:熔体温度为270 ℃,预制件温度为210 ℃,模具温度为110 ℃,保压压力为50 MPa。图7所示为优化工艺参数与基准工艺参数制备的实验件断裂方式对比。从图7可见:经工艺参数优化后,黏接面不会发生整体分离,界面的连接强度较高,未出现整体断裂情况,说明优化工艺参数后可使连续玻纤增强PP与短玻纤增强PA66界面具有较好的性能。

图7 基准参数与优化参数下实验件界面破坏形式对比

Fig. 7 Comparison of interfacial failure of specimens under benchmark and optimization parameters

2.3 承载面对模内混合制件弯曲强度的影响

在不同的预制件温度下,不同承载面对制件弯曲性能的影响见图8。从图8可见:在2种受压方式下,承受弯曲强度均随温度增加呈线性增加,CFRT预制件加热至80 ℃前,弯曲强度均较低且相差不大,表明界面连接质量较差,界面结合力低产生界面崩开现象;超过140 ℃后,注塑层受压的弯曲强度高于预制件层受压的弯曲强度,最大相差75.7 MPa。注塑层受压时,载荷从注塑层传递到CFRT层,制件弯曲强度受注塑层性能和界面结合性能的共同影响,且CFRT的力学性能优于L/SFT[5]性能,导致注塑层受压后弯曲强度高于预制件层受压的弯曲强度。

图8 承载面不同对实验件弯曲性能的影响

Fig. 8 Effect of different load surface on the bending strength of specimens

3 结论

1) 随着熔体温度、预制件温度、模具温度和保压压力升高,连续玻纤增强聚丙烯与短玻纤增强尼龙66制件弯曲强度呈线性提高,界面连接区域出现融合共混,实现了不同热塑性基体纤维增强材料混合加工成型。

2) 工艺参数中,连续玻纤增强聚丙烯的加热温度对混合加工成型弯曲性能影响最大,参数优化后混合加工成型制件弯曲强度提高了2.6倍,界面破坏后连接面未出现整体断裂,工艺参数的优化提高了CFRT/SFT制件的力学性能。

3) 在模内混合实验中,温度保证了聚合物熔融态,保压压力促进聚合物间相互扩散,形成有效的互熔区,但工艺参数的优化仅使弯曲强度最大达243 MPa。研究结果可为后续进一步研究不同热塑性基体纤维增强材料的混合加工成型机理和制件力学性能提供工艺参考。

参考文献:

[1] 王福吉, 朱浩杰, 宿友亮, 等. 基于层合叠加理论的CFRP 多向层合板铣削力建模[J]. 中南大学学报(自然科学版), 2017, 48(9): 2352-2362.

WANG Fuji, ZHU Haojie, SU Youliang, et al. Modeling about milling force for

[1] 王福吉, 朱浩杰, 宿友亮, 等. 基于层合叠加理论的CFRP 多向层合板铣削力建模[J]. 中南大学学报(自然科学版), 2017, 48(9): 2352-2362.

WANG Fuji, ZHU Haojie, SU Youliang, et al. Modeling about milling force for multidirectional CFRP based on theory of superposition[J]. Journal of Central South University(Science and Technology), 2017, 48(9): 2352-2362.

[2] JUNG K H, KIM D H, KIM H J, et al. Finite element analysis of a low-velocity impact test for glass fiber-reinforced polypropylene composites considering mixed-mode interlaminar fracture toughness[J]. Composite Structures, 2017, 160(1): 446- 456.

[3] KLAUS F, ABDULHAKIM A A. Manufacturing aspects of advanced polymer composites for automotive applications[J]. Applied Composite Materials, 2013, 20(2): 07-128.

[4] KIM D H, KIM H G, KIM H S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle[J]. Composite Structures, 2015, 131(1): 742-752.

[5] TANAKA K, FUJITA Y, KATAYAMA T. Press and injection hybrid molding of glass fiber reinforced thermoplastics[J]. WIT Transactions on Engineering Sciences, 2015, 90(7): 225-232.

[6] GRUJICIC M, SELLAPPAN V, OMAR M A, et al. An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components[J]. Journal of Materials Processing Technology, 2008, 197(1/2/3): 363-373.

[7] KIM S Y, BAEK S J, YOUN J Y. New hybrid method for simultaneous improvement of tensile and impact properties of carbon fiber reinforced composites[J]. Carbon, 2011, 49(15): 5329-5338.

[8] PHILLIP J C, CHRISTOPHER W M. Polymer-polymer adhesion in melt-processed layered structures[J]. Journal of Plastic Film & Sheeting, 2000, 16(3): 213-222.

[9] MEISTER S, DRUMMER D. Influence of mold temperature on mold filling behavior and part properties in micro injection molding[J]. International Polymer Processing, 2013, 28(5): 550-557.

[10] DRUMMER D, GRUBER K, MEISTER S. Process optimization: Alternating temperature technology controls parts properties[J]. Kunststoffe International, 2011, 101(4): 25-27.

[11] FIOROTTO M, LUCCHETTA G. Experimental investigation of a new hybrid molding process to manufacture high-performance composites[J]. International Journal of Material Forming, 2013, 6(1): 179-185.

[12] FREDRICKSON G H. Diffusion-controlled reactions at polymer-polymer interfaces[J]. Physical Review Letters, 1996, 76(18): 3440-3443.

[13] TANAKA K, NOGUCHI R, KATAYAMA T. Effects of preheating temperature on the interfacial tensile strength for glass fiber reinforced polypropylene composites made by press and injection hybrid molding[J]. WIT Transactions on the Built Environment, 2016, 166: 287-296.

[14] TANAKA K, KONDO Y, KATAYAMA T. Effect of mold temperature on interfacial welded strength and outer shell laminate strength of CF/PA6 composites manufactured by press and injection hybrid molding molding[J]. WIT Transactions on the Built Environment, 2016, 166: 317-326.

[15] ERIC L, THIERRY R, PATRICIA K. Effect of the interdiffusion at the polymer/polymer interface on the flexural properties of over-moulded short glass fiber/glass fabric reinforced PA6 composites[J]. Key Engineering Materials, 2014, 611: 821-828.

[16] 何芳芳, 周洲, 蒋炳炎. 纤维增强塑料注射成型熔体流动性及纤维取向预测[J]. 复合材料学报, 2013, 30(S1): 128-133.

HE Fangfang, ZHOU Zhou, JIANG Bingyan. Prediction of melt flow and fiber orientation of fiber reinforced plastics injection molding[J]. Acta Materiae Compositae Sinica, 2013, 30(S1): 128-133.

[17] 周洲. CFRT预制件与短玻纤PP模内混合注塑工艺及其界面黏结[D]. 长沙: 中南大学机电工程学院, 2016: 44-56.

ZHOU Zhou. In-mold hybrid injection molding process and interface bonding of continuous glass fiber reinforced preformed part and short glass fiber reinforced PP[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2016: 44-56.

(编辑 陈灿华)

收稿日期:2018-07-10;修回日期:2018-09-11

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2012CB025905);湖南省科技计划项目(2015TP1007);中南大学中央高校基本科研业务费专项资金资助项目(2017zzts091) (Project(2012CB025905) supported by the National Basic Research Development Program (973 Program) of China; Project(2015TP1007) supported by the Science and Technology Plan of Hunan Province; Project(2017zzts091) supported by the Fundamental Research Funds for the Central Universities of Central South University)

通信作者:蒋炳炎,博士,教授,从事高分子材料精密注塑成型技术研究;E-mail:jby@csu.edu.cn