文章编号:1004-0609(2012)10-2855-07

新型铜/非晶复合板材的制备和弯曲性能

张 丽,杨湘杰,刘 勇

(南昌大学 江西省高性能精确成形重点实验室,南昌 330031)

摘 要:采用挤压成形工艺制备新型纯铜/Cu40Zr44Ag8Al8非晶复合板材。通过光学显微镜(OM)、X射线衍射 (XRD)、维氏硬度(HV)和扫描电子显微镜(SEM)研究复合板材芯部非晶尺寸与硬度的分布及复合板材的界面性能;并对比纯铜板材和复合板材的三点弯曲性能。结果表明:通过挤压成形工艺可以使复合板材获得良好的界面结合,界面元素梯度分布表明界面宽度约为2.15 μm。挤压开始阶段,复合板材由单一纯铜组成;随后芯部开始出现非晶,且在距离头部12 mm处非晶尺寸达到最大,其长度和宽度分别为2.785和1.481 mm;随着挤压的继续进行,芯部的非晶尺寸逐渐减小并趋于稳定,稳定阶段长度和宽度的平均尺寸分别为2.269和0.797 mm。X射线衍射和维氏硬度结果表明,芯部非晶在复合挤压过程中没有发生晶化现象。三点弯曲试验表明,复合板材的弯曲强度比纯铜的大,其弯曲断裂强度为377.4 MPa。

关键词:非晶合金;复合材料;热塑性成形;弯曲性能

中图分类号:TG306 文献标志码:A

Preparation and bending property of

novel copper/amorphous composite plate

ZHANG Li, YANG Xiang-jie, LIU Yong

(Key Laboratory of Near Net Forming of Jiangxi Province, Nanchang University, Nanchang 330031, China)

Abstract: The novel pure copper/Cu40Zr44Ag8Al8 amorphous composite plate was fabricated by the extrusion process. The core and interface of composite plate were characterized by optical microscopy (OM), X-ray diffractometry (XRD), microhardness (HV) and scanning electron microscopy (SEM). The bending properties of pure copper plate and composite plate were investigated by three point bending test. The results indicate that a good bonding interface of composite plate is obtained with an interface width of about 2.15 μm through EDS analysis. The composite plate is composed of single pure copper at the start of extrusion. Then, the core begins to appear amorphous, and reaches the maximum value at the distance of about 12 mm to head of plate. The length and width are 2.785 and 1.481 mm, respectively. The dimension of BMG core reduces gradually and then becomes stable. The average size of the length and width are 2.269 and 0.797 mm, respectively. The crystallization of amorphous in the core during extrusion does not occur through the analysis of XRD and microhardness. Three point bending test show that the composite plate exhibits a larger bending flexural strength (of about 377.4 MPa) than the pure copper.

Key words: amorphous alloy; composite; thermoplastic forming; bending property

基金项目:国家自然科学基金资助项目(51001058,50965015);国家科技支撑计划项目(2011BAE22B02);江西省铜钨新材料重点实验室开放基金资助项目(2010-WT-08);江西省国际合作项目(2010EHA02000);江西省自然科学基金资助项目(2010GQC0135)

收稿日期:2011-09-28;修订日期:2012-03-28

通信作者:杨湘杰,教授,博士;电话:0791-83969141; E-mail: yangxj@ncu.edu.cn

非晶态合金在结构上具有长程无序、短程有序和各向同性的特点,不存在晶态合金所特有的各种晶体缺陷。与相同或相似成分的晶态合金相比,非晶态合金往往具有优异的力学性能、化学性能和电磁性能等。

但是,大块非晶合金的室温塑性很低,伸长率几乎为零,这大大制约了大块非晶合金的应用[1-2]。最近,大块非晶合金的热塑性成形得到了广泛的研究[3-4]。当大块非晶合金被加热至过冷液相区间(Supercooled liquid region, SLR)会呈现急剧软化的流变行为[5-7]。大块非晶合金的热塑性成形正是利用了大块非晶合金在SLR的软化行为和热稳定性优点。目前,主要采用压缩成形和挤压成形两种工艺制备这类复合材料。RAGANI等[8-9]在SLR条件下,通过压缩成形工艺制备了BMG与轻质合金的层片状复合薄板。研究发现,压缩成形工艺容易在界面处产生氧化物,阻碍界面的结合,降低界面的结合强度。GRAVIER等[10-11]和LEE等[12-13]在SLR条件下,通过挤压成形工艺制备了BMG与轻质合金的复合棒材。结果表明,挤压成形工艺可以获得良好的界面结合,并且可以避免氧化物的产生。但在较高挤压温度与挤压速率条件下容易发生晶化。刘勇等[14]在SLR条件下,通过挤压成形工艺制备了纯铜与Cu40Zr44Ag8Al8大块非晶合金的复合棒材。研究挤压温度对复合材料成形的影响,结果发现,在703 K复合挤压时,芯部非晶呈圆棒状且尺寸分布均匀,同时可以获得良好的界面结合。本文作者在此研究基础上,采用挤压成形工艺进一步制备了纯铜与Cu40Zr44Ag8Al8 大块非晶合金的复合板材,利用OM、XRD、HV和SEM表征复合板材界面的显微结构特征,同时研究对比了纯铜与复合板材的三点弯曲性能。

1 实验

Cu40Zr44Ag8Al8大块非晶合金的制备及复合板材的制备工艺详见文献[14]。复合板材的模具尺寸是模具前腔直径为d 7mm,型腔为5 mm×1.5 mm的方 形,挤压比为5.1,挤压温度为703 K,挤压速率为 0.4 mm/min。为了使材料在挤压过程中受力均匀,对纯铜头部进行45°倒角处理。图1所示为挤压模具的结构示意图和实物图。采用OM、XRD和SEM对复合板材的显微结构、芯部非晶尺寸和硬度进行了详细分析。将该复合板材按ASTM D790—2标准等比例缩小制备非标弯曲试样,实际尺寸如下:两支撑点的跨距L为15 mm,试样宽度b为5 mm,试样厚度d为1.5 mm。弯曲试验机压头的移动速率为2 μm/s。在三点弯曲试验过程中进行应力卸载处理。为了获得弯曲过程的试样变化情况,采用高速数码相机摄像对整个弯曲试验进行了全程拍照跟踪,拍照时间步长为2 s。对弯曲后复合板材的芯部非晶进行结构观察和显微硬度测试。

图1 挤压模具结构示意图和实物图

Fig. 1 Schematic diagrams and real graphs of coextrusion die: (a) Cross section; (b) Longitudinal section; (c) Extrusion die; (d) Extrusion head

2 结果与分析

图2所示为在703 K复合挤压获得的铜/非晶复合板材的外观形貌和横截面形貌。由图2(a)可知,铜/非晶复合板材表面质量良好;由图2(b)可知,复合板材芯部非晶的横截面为椭圆形,且均匀分布在板材中间。

图2 铜/非晶复合板材的外观形貌和横截面形貌

Fig. 2 Appearance(a) and cross-section(b) of Cu/BMG composite plate

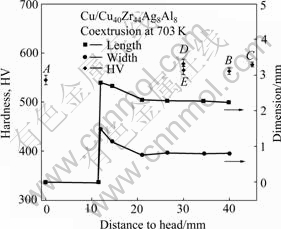

图3所示为复合板材芯部非晶沿挤压方向的尺寸分布及硬度值。由图3可知,在挤压开始至11.5mm长度,复合板材只由单一纯铜组成,随后芯部开始出现非晶,在距离头部12 mm处非晶尺寸达到最大值,其椭圆横截面的长度和宽度分别是2.785和1.481 mm;随着挤压的继续进行,芯部非晶尺寸逐渐减小并趋于稳定。通过OM测量,芯部非晶横截面长度和宽度的平均尺寸分别为2.269和0.797 mm。这说明复合板材的挤压过程经历了初始阶段的不稳定变形,而后达到稳定的变形阶段,芯部非晶和外层包覆铜材协调、均匀的变形,导致芯部非晶在复合板材中均匀分布。图3中A点所示为非晶铸态的硬度值(544 HV),B点所示为距离复合板材头部40 mm处的芯部非晶硬度值(563 HV),C点所示为复合板材底部未经挤压的芯部非晶硬度值(576 HV)。这说明芯部非晶经过挤压变形后,硬度的升高幅度有限,这与采用相同工艺制备的复合棒材芯部非晶的硬度变化规律相似[14]。对复合板材试样做XRD检测,没有发现新晶体相的产生,如图4所示。故芯部非晶硬度的改变不是由于非晶晶化所致,而是在复合挤压过程中,非晶经历了一定时间的时效作用,发生结构弛豫效应所致。铸态块体非晶合金含有大量的过剩自由体积,当块体非晶合金处于高温结构弛豫区,冻结的原子很快被热激活进行原子重排,与之对应的自由体积会迅速迁移和消失。随着弛豫程度的增加,非晶合金中自由体积逐渐减小,对应于合金硬度的增大。底部C点非晶经历了最长时间的时效,故其硬度的变化主要是由于结构弛豫所致。

图3 复合板芯部非晶尺寸和硬度分布

Fig. 3 Profiles of diameter and microhardness of core BMG (A is as-cast amorphous; B is 40 mm-distance to head; C is bottom; D is inner part; E is outside part)

根据模具的挤压比,挤压后的芯部非晶的理论截面积为1.385 mm2,对稳定阶段的复合板材芯部非晶进行测量可知,其实际截面积为1.435 mm2。对比分析理论值和实际值可知,芯部非晶发生了约3.6%的膨胀量。KAWAMURA等[15]研究发现,非晶直接挤压的膨胀量约为15%,而复合棒材芯部非晶的膨胀量约为8.6%[14]。这说明外层铜材的包覆有利于减小非晶挤压变形的膨胀量,同时,挤压变形模式对非晶膨胀量有一定的影响。

图4所示为Cu/Cu40Zr44Ag8Al8复合板材的XRD谱。由图4可知,该复合板材主要由纯铜的晶体衍射峰和非晶的馒头峰组成,没有发现其它晶体峰的存在。XRD结果表明,芯部非晶在挤压成形过程中没有发生晶化现象。

图4 Cu/Cu40Zr44Ag8Al8复合板材和纯铜的XRD谱

Fig. 4 XRD pattern of Cu/BMG composite(a) and pure Cu(b)

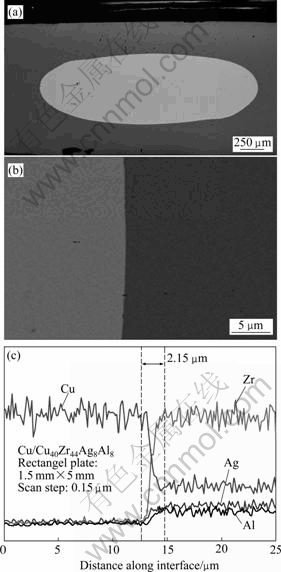

图5所示为铜/非晶复合板材界面的SEM像和界面剖面的元素分布图。由图5(a)和(b)可知,纯铜与非晶界面结合连续光滑且均匀,界面处没有产生氧化物。

图5 铜/非晶复合板材的界面SEM像和界面剖面的元素分布图

Fig. 5 SEM images of interface of Cu/BMG composite plate((a), (b)) and elements profile across interface of Cu/BMG composite plate(c)

为了分析纯铜和非晶的界面结合情况,利用EDX线扫描对界面进行了成分分布分析(扫描步长为0.15 μm),如图5(c)所示。由图5(c)可知,通过元素的分布情况可以确定铜和芯部非晶的界面宽度大约是2.15 μm。这归结于Cu40Zr44Ag8Al8非晶和纯铜含有大量相同的组元铜元素,所以在挤压成形过程中,两组元相同的铜原子可以加速界面的原子扩散,有利于获得良好的界面结合。

图6所示分别为初始弯曲的应变值为零和弯曲应变值为0.127时板材三点弯曲的宏观照片。应变值为0.127时,试样已发生了断裂。弯曲试验中的弯曲应力σf、弯曲应变εf和弹性模量EB可以通过下列公式计 算[16]:

(1)

(1)

(2)

(2)

(3)

(3)

式中:p是弯曲载荷(N);L是两支撑点之间的跨距(mm);b是试样宽度(mm);d是试样厚度(mm);m是挠度曲线初始直线部分的切线斜率(N/mm);D是变形扰度。表1所列为复合板材和纯铜的各参数值。

图6 非晶复合板材三点弯曲的宏观照片

Fig. 6 Photos of Cu/BMG composite plate under three points bending test under different flexural strains: (a) 0; (b) 0.127

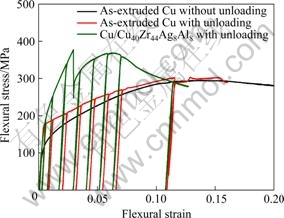

图7所示为纯铜和铜/非晶复合板材三点弯曲的应力—应变曲线。对于常温下的塑性弯曲,在外力作用下产生的总变形量由塑性变形和弹性变形两部分组成。当外力去除后,塑性变形会留存下来,而弹性变形则完全消失。同时弯曲变形区外侧因弹性恢复而缩短,内侧因弹性恢复而伸长,即回弹效应。由表1可知,卸载情况下,铜/非晶复合板材的弯曲强度比纯铜的高,而弯曲应变要比纯铜的小;复合板材的弯曲强度和弯曲应变分别是377.4 MPa和2.96%,纯铜的分别是302.7 MPa和15.2%。最终,复合板材在载荷力的作用下发生断裂,而纯铜板只是发生屈服。这说明复合板材的弯曲强度比纯铜的高,但断裂韧性不如纯铜的好。对于纯铜而言,卸载与不卸载两种情况对应的弯曲强度和弯曲应变也各不同。卸载下的弯曲强度比不卸载的略大,说明卸载可以提高材料的弯曲强度。

图7 纯铜和铜/非晶复合材料的弯曲应力—应变曲线

Fig. 7 Flexural stress—flexural strain curves of pure Cu and Cu/BMG

表1 纯铜和铜/非晶复合板材三点弯曲试验参数和力学性能

Table 1 Parameters size and mechanical properties of pure Cu plate and Cu/BMG composite plate under three points bending test

图8所示为铜/非晶复合板材弯曲断裂后的金相显微照片。由图8(a)可知,试样的裂纹源是从芯部非晶变形区的外侧开始,并向内侧扩展。由图8(b)和(d)可知,弯曲试样内侧没有发生断裂,且铜与非晶的结合界面保持良好。由图8(c)和(e)可知,弯曲试样在变形区外侧断裂,裂纹较明显。发生这种断裂的原因是弯曲变形过程中,芯部非晶外侧与内侧受到不同应力的作用,外侧受的是拉应力作用,而内侧受的是压应力作用。CHEN等[17]研究发现,压应力会诱导形成高密度剪切带,可以提高材料的塑性,不易发生断裂;而拉应力则相反,会加速裂纹的扩展。因而,该弯曲试样容易在受拉的外侧发生断裂。为了研究弯曲变形对芯部非晶性能的影响,进一步对弯曲断裂试样的芯部非晶进行维氏显微硬度测试。结果发现,内侧非晶的硬度(578 HV)比外侧非晶的硬度(565 HV)略大,如图3中D、E点所示。与弯曲前的芯部非晶硬度相比,内侧的硬度值略有提高,而外侧的硬度值变化较小。CHEN等[17]对Cu45Zr46.5Al7Ti1.5大块非晶合金弯曲前后硬度的研究还发现,压应力会诱导形成高密度剪切带,使材料变软,导致材料硬度降低;相反地,拉应力可以提高材料的硬度。然而,本研究结果则相反,受压的内侧硬度增大,而受拉的外侧硬度变化不大。这可能与材料的受力状态有关。由于芯部非晶在弯曲过程中受到外层铜的作用,使得材料的变形受力与纯非晶的弯曲不同,详细的原因有待于进一步分析。

图8 铜/非晶复合材料弯曲断裂后的金相显微组织

Fig. 8 Optical micrographs of Cu/BMG composite plate after fracture of bending test: (a) Appearance of sample after fracture; (b) Upper surface; (c) Interface in upper surface; (d) Lower surface; (e) Interface in lower surface

3 结论

1) 利用大块非晶合金在过冷液相区间热塑性成形好的特点,在挤压温度703 K和挤压速率0.4 mm/min条件下,通过挤压成形工艺制备铜/非晶复合板材。

2) 通过挤压成形工艺制备的复合板材质量较好,外层包覆铜材与芯部非晶的界面结合良好,芯部非晶沿挤压方向均匀分布,芯部非晶未发生晶化现象。

3) 新型铜/非晶复合板材的弯曲断裂强度要高于纯铜板材的,但其断裂韧性不如纯铜的好;复合板材倾向于在受拉应力的一侧发生弯曲断裂。

REFERENCES

[1] SPAEPEN F. A microscopic mechanism for steady state inhomogeneous flow in metallic glasses[J]. Acta Metallurgica, 1977, 25(2): 407-415.

[2] SCHUH C A, HUFNAGEL T C, RAMAMURTY U. Mechanical behavior of amorphous alloys[J]. Acta Materialia, 2007, 55(12): 4067-4109.

[3] SCHROERS J, PATON N. Amorphous metal alloys form like plastics[J]. Adv Mater Processing, 2006, 164(1): 61-63.

[4] SCHROERS J. Processing of bulk metallic glass[J]. Advanced Materials, 2009, 21: 1-32.

[5] 张志豪, 刘新华, 周 成, 谢建新. Zr基大块非晶合金的超塑性成形性能[J]. 中国有色金属学报, 2004, 14(7): 1073-1077.

ZHANG Zhi-hao, LIU Xin-hua, ZHOU Cheng, XIE Jian-xin. Super-plastic forming properties of Zr-based bulk amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1073-1077.

[6] HEILAMIER M. Deformation behavior of Zr-based metallic glasses[J]. Journal of Materials Processing Technology, 2001, 117(3): 374-380.

[7] 沈 军, 孙剑飞, 王 刚, 黄永江, 周彼德. 大块非晶合金过冷液相区的超塑性流变行为[J]. 材料导报, 2004, 18(7): 22-25.

SHEN Jun, SUN Jian-fei, WANG Gang, HUANG Yong-jiang, ZHOU Bi-de. Superplastic flow behavior of bulk metallic glasses in supercooled liquid region[J]. Materials Review, 2004, 18(7): 22-25.

[8] RAGANI J, VOLLAND A, GRAVIER S, BLANDIN J J, SUERY M. Metallic glass/light alloy (MEGA) multimaterials elaborated by co-pressing at high temperature[J]. Journal of Alloys and Compounds, 2010, 495(2): 323-326.

[9] RAGANI J, VOLLAND A, VALQUE S, LIU Y. Using thermoforming capacity of metallic glasses to produce multimaterials[J]. Journal of Alloys and Compounds, 2010, 504: 267-270.

[10] GRAVIER S, PUECH S, BLANDIN J J, SU?RY M. New metallic glass/alloy (MEGA) rods produced by co-extrusion[J]. Advanced Engineering Materials, 2006, 8(10): 948-953.

[11] GRAVIER S, BLANDIN J J, SU?RY M. Mechanical properties of a co-extruded metallic glass/alloy (MEGA) rod—Effect of the metallic glass volume fraction[J]. Materials Science and Engineering A, 2010, 527: 4197-4201.

[12] LEE K S, KANG S H, LEE Y S. Synthesis of Zr-based bulk metallic glass-crystalline aluminum alloy composite by co-extrusion[J]. Materials Letters, 2010, 64(2): 129-132.

[13] LEE K S, JUN H J, LEE Y S. Fabrication of bimetallic rods consist of a Zr-based bulk metallic glass and a crystalline copper by co-extrusion[J]. Intermetallics, 2010, 18(10): 1958-1963.

[14] 刘 勇, 张 丽, 郭洪民, 杨湘杰. 新型铜合金/非晶复合材料的挤压成形特性[J]. 中国有色金属学报,2011, 21(5): 1003-1008.

LIU Yong, ZHANG Li, GUO Hong-min, YANG Xiang-jie. Coextrusion forming characteristics of novel Cu alloy/bulk metallic glass composite[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1003-1008.

[15] KAWAMURA Y, SHIBATA T, INOUE A, MASUMOTO T. Workability of the supercooled liquid in the Zr65Al10Ni10Cu15 bulk metallic glass[J]. Acta Mater, 1997, 46(1): 253-263.

[16] ASTM Committee D-20. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials[R]. ASTM D790—99. 1999.

[17] CHEN L Y, GE Q, QU S, JIANG J Z. Stress-induced softening and hardening in a bulk metallic glass[J]. Scripta Materialia, 2008, 59: 1210-1213.

(编辑 龙怀中)