文章编号:1004-0609(2010)01-0112-06

Zr47Cu44Al9大块非晶合金的制备及其力学性能

张宝庆1, 2,曹国华3,郎庆斌2,张 志1,战再吉2,刘日平2,王文魁2

(1. 河南理工大学 材料科学与工程学院,焦作 454000;

2. 燕山大学 亚稳材料制备技术与科学国家重点实验室,秦皇岛 066004;

3. 河南理工大学 物理化学学院,焦作 454000)

摘 要:利用电弧炉制备一系列(Zr51.6Cu48.4)100?xAlx(x=6.0~10.0, 摩尔分数,%)大块非晶合金,利用示差扫描量热仪、X射线衍射仪和金相显微镜研究Al的含量对其非晶形成能力的影响。结果表明:当铝的含量为9.0%时,合金具有最优的非晶形成能力。适量铝的加入不仅能够抑制初生相CuZr的析出,而且还能有效地抑制其长大。临界冷却速率的经验公式计算结果显示该合金的临界冷却速率为10 K/s,室温压缩力学性能显示其断裂强度为1.9 GPa,且有0.5%的塑性变形,断裂方式为韧性剪切断裂。

关键词:大块非晶合金;非晶形成能力;临界冷却速率;力学性能

中图分类号:TG 139.8 文献标识码:A

Preparation and mechanical properties of

Zr47Cu44Al9 bulk metallic glass

ZHANG Bao-qing1, 2, CAO Guo-hua3, LANG Qing-bin2, ZHANG Zhi1, ZHAN Zai-ji2, LIU Ri-ping2, WANG Wen-kui2

(1. School of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

2. State Key Laboratory of Metastable Materials Science and Technology, Yanshan University,

Qinhuangdao 066004, China;

3. School of Physics and Chemistry, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: Bulk metallic glasses (BMG) (Zr51.6Cu48.4)100?xAlx(x=6?10, molar fraction, %) were prepared by copper mould casting. The effect of Al content on the glass-forming ability (GFA) of ZrCu based metallic glass alloys was investigated by differential scanning calorimetry, X-ray diffractometry, and optical microscopy. The results show that when the Al content is 9.0%, the alloy has the optimal GFA. Proper Al additions can suppress the precipitation and the growth of the primary CuZr phase. The critical cooling rate of the Zr47Cu44Al9 alloy is about 10 K/s. The compression strength is about 1.9 GPa and the elongation is about 0.5%. The surface morphology of fracture shows a clear vein pattern.

Key words: bulk amorphous alloy; glass forming ability; critical cooling rate; mechanical properties

ZrCu基非晶合金由于组元简单,不含有毒元素和贵金属元素,具有宽广的非晶形成成分区间和乐观的工业应用前景,受到很多科技工作者的重视。在二元ZrCu非晶合金的基础上,通过元素添加或替换的方法,ZrCuTi[1?3]、ZrCuGa[4]、ZrCuAl[5?7]等一批三元非晶合金被相继开发出来。其中,ZrCuAl非晶合金在ZrCu基非晶合金中的形成能力相对较强,其非晶形成能力对成分非常敏感,组元元素很小的变化就会显著影响到合金的非晶形成能力。近年来,国内外对ZrCuAl非晶合金的研究热情一直很高[8?11]。通过合理调节合金组元配比来提高合金的非晶形成能力及增强合金的力学性能是非晶研究领域的一个重要研究 方法。

本文作者通过研究Al元素的添加对ZrCu基合金非晶形成能力的影响,得到在所研究的成分区间内具有最佳非晶形成能力的合金成分Zr47Cu44Al9,分析此成分具有高的非晶形成能力的原因,预测此合金成分在理想状态下的临界冷却速率,并且研究了此成分合金的室温单轴压缩力学性能。

1 实验

将纯度大于99.9 % (摩尔分数) 的Zr、Cu和Al,按照(Zr51.6Cu48.4)100?xAlx(x=6.0~10.0,摩尔分数,%,以下同)的成分比例,在电弧炉里熔炼成合金锭,为保证成分均匀,每个样品反复熔炼4次,用1/100 000精度的天平精确称量熔炼前后的质量变化,其质量变化小于0.1%。然后将成分均匀的铸锭用电弧炉重熔并铸入到铜模中,得到长度为150 mm,直径为2~6 mm 的合金棒。利用STA449C差示扫描热分析(DSC)仪分析了样品的热物性参数。分析过程中采用氩气保护, 其加热速率为20 K/min。为防止制样过程中样品发生晶化,用装有金刚石锯片的慢速锯切割样品。利用D/max?2500/PC X射线衍射仪(XRD)对样品进行结构分析,采用Cu 靶,Kα辐射。金相样品的腐蚀剂为 40 mol/L HNO3+0.12 mol/L HF。在INSTRON?5569 试验机上进行了室温单轴压缩实验,压缩试样为直 径2 mm,高4 mm 的铸态标准圆柱,应变速率为 2×10?4 s?1。

2 结果与讨论

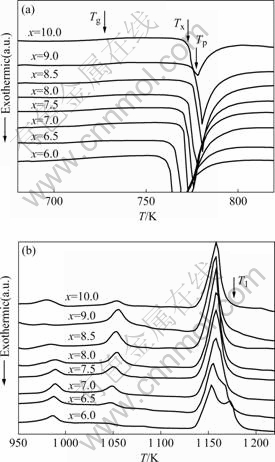

图1所示为直径为2 mm 的(Zr51.6Cu48.4)100?xAlx (x=6.0、6.5、7.0、7.5、8.0、8.5、9.0、10.0)系列样品的DSC曲线。表1所列为由DSC曲线所得到的合金热物性参数。从图1(a)可以看出,每个样品在晶化前都有明显的吸热峰,这证明样品在Tg点有明显的玻璃转变发生,紧接着玻璃转变的吸热峰,出现了一个很尖锐的放热晶化峰,这标志着样品从过冷液相区过渡到了稳定的晶化相。明显的玻璃转变和晶化反应进一步证明了这些合金样品的非晶结构。从图1(a)还可以看出,随着铝含量的增大,其特征温度值(Tg,Tx,Tp)都向高温端移动,当x=9.0时达到最大,当x=10.0时其特征温度值减小。

图1 加热速率为20 K/min时(Zr51.6Cu48.4)100?xAlx (x=6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 10.0)合金的DSC曲线

Fig.1 DSC curves of (Zr51.6Cu48.4)100?xAlx (x=6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 10.0) glassy alloys at heating rate of 20 K/min: (a) 650 K<T<850 K, (b) 950 K<T<1 250 K

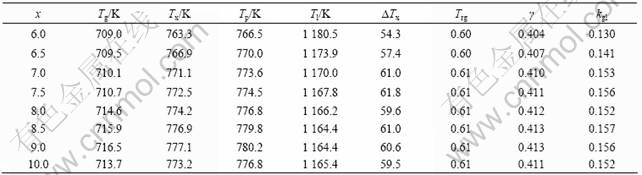

表1 非晶合金(Zr51.6Cu48.4)100?xAlx (x=6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 10.0)的热分析结果

Table 1 Thermal properties of (Zr51.6Cu48.4)100?xAlx (x=6.0, 6.5, 7.0, 7.5, 8.0, 8.5, 9.0, 10.0) bulk metallic glasses

图1(b)所示为(Zr51.6Cu48.4)100?xAlx (x=6.0、6.5、7.0、7.5、8.0、8.5、9.0、10.0)系列样品的熔化过程。从图1(b)可以看出,不同的铝的添加没有改变样品的熔化性质,在970~1 070 K的范围出现了两个小的吸热峰,这是由于在此温度范围内有两个不同的析出相存在。熔化是一个吸热过程,图1(b)中所对应的最后一个吸热峰结束的温度取为样品的液相线温度。从曲线上可以看出,其液相线温度随着铝含量的不同而改变,当x=9.0时其液相线温度最低,为1 064.4 K。一般玻璃形成能力强的体系其成分构成都在共晶点附近,拥有单一的熔化吸热峰[12]。由此可知,Al元素的添加降低了合金的液相线温度Tl,但对于所有添加Al 的合金样品其熔化行为并没有明显改变。

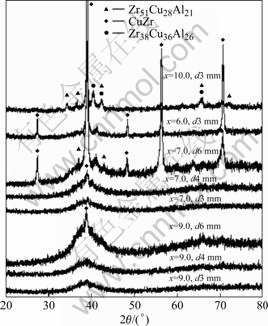

图2所示为不同直径(Zr51.6Cu48.4)100?xAlx (x=6.0,7.0,9.0,10.0)系列样品的XRD谱。由图2可见,对于直径为3 mm的样品,7.0<x<9.0时是全非晶态,而其它成分则有明显的晶化峰出现。在文献[6]中的报道中指出,当x=7.0时,纯非晶样品直径至少可以做到5 mm。但是在我们的试验条件下所得到的结果表明,此成分非晶合金的最大尺寸只能做到直径为3 mm。当直径为4 mm时,样品就会出现明显的晶化峰,这可能是由于所用合金原料纯度低、设备真空度差及冷却手段的差异所造成的。当x=9.0时,样品至少可以做到直径为4 mm,而在直径为6 mm的样品中,则出现有微弱的晶化峰。标定衍射峰可知,其晶化相为单一CuZr相,铝元素的添加明显地影响了样品地快

图2 (Zr51.6Cu48.4)100?xAlx (x=6.0, 7.0, 9.0, 10.0)合金的XRD谱

Fig.2 XRD patterns of (Zr51.6Cu48.4)100?xAlx (x=6.0, 7.0, 9.0, 10.0) alloys

速凝固过程,使得其CuZr相的析出和长大受到了抑制。但当加入的铝过量(x=10.0)后,非晶形成能力急剧降低,即使直径为3 mm的样品,晶化也很严重,主要析出相变为以CuZr相为主的多种晶相共存状态。

长期以来,人们期待用简单的参数来指导、预测、评判具有最好非晶形成能力的大块非晶合金成分,因此,很多的参数/判据被开发出来。但从根本上说,评判合金玻璃形成能力最直观的参数是临界冷却速率和最大样品直径或厚度。但是在实践中,这两个参数使用起来有困难,主要因为样品的临界冷却速率难以准确测量,而临界尺寸强烈地依赖于制备条件,所以人们在分析了具有不同非晶形成能力合金的热力学数据后,得出了一些玻璃形成能力判据。由于不同的研究者分析的合金体系侧重点不同,其热力学分析的角度也不一样,所以评判玻璃形成能力的判据也不尽相同。比较常用的参数有过冷液相区ΔTx(ΔTx=Tx?Tg) [13]、约化玻璃转变温度Trg(Trg=Tg/Tl )[14]、γ(γ=Tx/(Tg+Tl))[15]等。从表1可以看出,这些判据在数值上相差不大,说明这些判据对于该体系合金的非晶形成能力的表征不敏感。这一点在其他的研究中也有体现[16]。

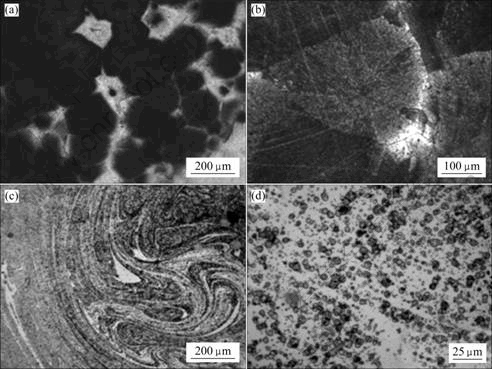

最初,人们研究合金的非晶形成能力时,往往只考虑了晶体相结晶过程中形核因素的影响(例如Turnbull 的Trg判据),如果合金凝固过程中晶体相不形核,液相合金最终会转变成非晶相,但是,合金凝固过程中晶体相的形成包括形核和长大两个方面。对于制备非晶来说,形核过程固然重要,但长大过程同样不能忽视。一些在XRD谱中具有完好非晶结构的非晶样品,在做显微组织观察时,仍然发现其中有晶体相的存在[17]。因此,控制晶核的进一步长大对于制备非晶合金或者是非晶/纳米晶复合材料也是非常重要的。对此,我们比较了缓冷情况下x=7.0和x=9.0时,直径为6 mm样品的显微组织。图3所示为x=7.0和x=9.0时,直径为6 mm样品中心部位的金相显微照片。

图3 直径为6 mm的合金样品的金相显微照片

Fig.3 Optical micrographs of ZrCuAl alloys with diameter of 6 mm: (a), (b) x=7.0; (c), (d) x=9.0

从3图可以看出,x=7.0时,已经明显晶粒长大;x=9.0时,晶粒形核很多,但是没有进一步长大(相对于x=7.0的样品来说)。这说明加入适量的铝不仅能抑制初生相CuZr相的析出,而且能有效地抑制其长大。同时,x=9.0时,即成分为Zr47Cu44Al9时,合金具有最优的非晶形成能力。

利用BARANDIARAN等[18]计算非晶态合金临界冷却速率的经验公式:

式中:b为材料常数,它与合金的成分和热分析过程有关;R为热分析过程中的冷却速率;Rc为临界冷却速率;Tl为非晶态合金加热熔化结束时的温度;Txc为不同冷却速率下合金冷却时的凝固开始温度。根据热分析(DSC)数据,通过计算和拟合,可以得到Zr47Cu44Al9合金的临界冷却速率约为10 K/s (拟合曲线未示出)。

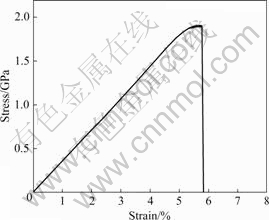

图4所示为Zr47Cu44Al9大块非晶合金的室温压缩曲线。从图4可以看出,试样在压缩过程中,在经历一定的弹性变形后出现0.5%左右的塑性变形,然后断裂,其抗压断裂强度为1.9 GPa。这两个指标比大多数的晶态金属材料的相应指标高出很多,因此,这些 非晶材料可以在很高的应力条件下承受较大的弹性形变,可以作为高强度、高弹性、高耐蚀性材料使用。

图4 Zr47Cu44Al9非晶合金的压缩应力─应变曲线

Fig.4 Compressive stress─strain curve of Zr47Cu44Al9 bulk metallic glasses

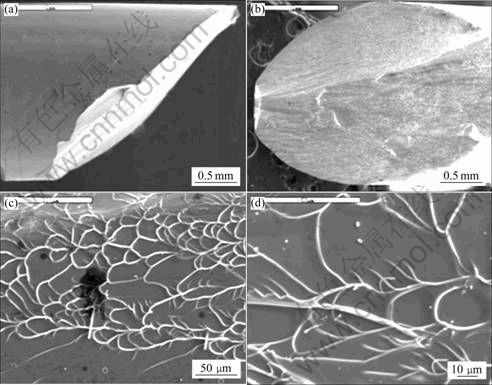

图5所示为非晶合金的断裂形貌。由图5可见,断口表面相对较平整,非晶合金的断面与压缩轴之间的角度约为43?。尽管试样的塑性很小,但仍能从断裂试样的侧表面观察到剪切带的存在。大量脉络状条纹及少量的液滴状物质的存在是非晶合金断裂表面的主要特征。脉络条纹是由于断裂表面局域软化剪切扩展而产生。脉络条纹的形成也可认为是非晶合金的韧性剪切断裂特征[19?20]。

图5 Zr47Cu44Al9大块非晶合金的断口形貌

Fig.5 Fracture morphologies of Zr47Cu44Al9 bulk metallic glasses: (a) Side view of fracture surface; (b) Panorama of fracture surface; (c) Vein patterns on franture surface; (d) Higher magnification image for vein patterns

3 结论

1) 通过合金成分优化的方法,利用传统铜模冷却铸造工艺,制备了一系列(Zr51.6Cu48.4)100?xAlx棒状试样,所得到的非晶合金具有良好非晶形成能力。尤其是Zr47Cu44Al9合金不仅具有最优的非晶形成能力,而且还具有较大的过冷液相区,即较好的热力学稳定性。添加适量的铝不仅能抑制初生相CuZr相的析出,而且能有效抑制初生相CuZr相的长大。

2) (Zr51.6Cu48.4)100?xAlx体系的非晶形成能力对成分的变化非常敏感,0.5%的铝的成分变化都会对其非晶形成能力和热稳定性产生明显的影响。

3) Zr47Cu44Al9非晶合金成分的临界冷却速率约为10 K/s。Zr47Cu44Al9非晶合金具有很高的压缩断裂强度,其断裂方式为韧性剪切断裂,室温压缩断裂强度为1.9 GPa。

REFERENCES

[1] INOUE A, ZHANG W, ZHANG T, KUROSAKA K. High-strength Cu-based bulk glassy alloys in Cu–Zr–Ti and Cu–Hf–Ti ternary systems[J]. Acta Materialia, 2001, 49: 2645?2652.

[2] FAN C, LI C, INOUE A. Effects of Nb addition on icosahedral quasicrystalline phase formation and glass-forming ability of Zr-Ni-Cu-Al metallic glasses[J]. Appl Phys Lett, 2001, 79(7): 1024?1026.

[3] 杨元政, 董振江, 仇在宏, 陈小祝, 谢致薇, 白晓军. 块体非晶合金Cu58Zr20Ti20Mo2的形成与力学性能[J]. 中国有色金属学报, 2007, 17(7): 1090?1095.

YANG Yuan-zheng, DONG Zheng-jiang, QIU Zai-hong, CHEN Xiao-zhu, XIE Zhi-wei, BAI Xiao-jun. Formation and mechanical properties of Cu58Zr20Ti20Mo2 bulk metallic glass[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1090?1095.

[4] ZHANG W, INOUE A. Cu-based bulk glass formation the Cu-Zr-Ga alloy system and their mechanical properties[J]. Mater Trans, 2004, 45(2): 532?535.

[5] INOUE A, ZHANG W, ZHANG T, KUROSAKA K. Cu-based bulk glassy alloys with high tensile strength of over 2 000 MPa[J]. Journal of Non-Crystalline Solids, 2002, 304(1/3): 200?209.

[6] WANG D, TAN H, LI Y. Multiple maxima of GFA in three adjacent eutectics in Zr-Cu-Al alloy system?A metallographic way to pinpoint the best glass forming alloys[J]. Acta Materialia, 2005, 53(10): 2969?2979.

[7] 余 鹏, 白海洋, 汤美波, 王万录, 汪卫华. 具有优良玻璃形成能力添加Al的CuZr基大块金属玻璃[J]. 物理学报, 2005, 54(7): 3284?3289.

YU Peng, BAI Hai-yang, TANG Mei-bo, WANG Wan-lu, WANG Wei-hua. CuZr-based bulk metallic glasse s with good glass-forming ability prepared by Al addition[J]. Acta Physica Sinica, 2005, 54(7): 3284?3289.

[8] LEE S W, HU M Y, FLUERY E, LEE J C. Crystallization- induced plasticity of Cu–Zr containing bulk amorphous alloys[J]. Acta Materialia, 2006, 54: 349?355.

[9] 孙玉峰, 郭 建, 王育人, 魏炳忱, 李维火. 一种新型Zr基块状非晶复合材料的显微组织与力学性能[J]. 科学通报, 2006, 51(1): 8?12.

SUN Yu-feng, GUO Jian, WANG Yu-ren, WEI Bing-chen, LI Wei-huo. Microstructure and mechanical properties of a new Zr-based bulk metallic glass composite[J]. Chinese Science Bulletin, 2006, 51(1): 8?12.

[10] ZHANG Bao-qing, JIA Yuan-zhi, WANG Suo-tao, LI Gong, SHAN Sheng-feng, ZHAN Zai-ji, LIU Ri-ping, WANG Wen-kui. Effect of silicon addition on the glass-forming of a Zr–Cu-based alloy[J]. Journal of Alloys and Compounds, 2009, 468: 187?190.

[11] 李春燕, 寇生中, 胡 勇, 丁雨田, 许广济. Cu基块状非晶晶化过程的微区变形及力学性能[J]. 中国有色金属学报, 2007, 17(10): 1586?1591.

LI Chun-yan, KOU Sheng-zhong, HU Yong, DING Yu-tian, XU Guang-ji. Deformation and mechanical properties of Cu-based bulk metallic glasses during crystallization[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(10): 1586?1591.

[12] WANG W H, LEWANDOWSKI J J, GREER A L. Understanding the glass-forming ability of Cu50Zr50 alloys in terms of a metastable eutectic[J]. J Mater Res, 2005, 20: 2307?2313.

[13] INOUE A, ZHANG T. Stabilization of supercooled liquid and bulk glassy alloys in ferrous and non-ferrous systems[J]. J Non-Crystalline Solids, 1999, 252: 552?559.

[14] TURNBULL D. Under what conditions can a glass Be formed[J]. Contemp Phys, 1969, 10(5): 473?488.

[15] LU Z P, LIU CT. A new glass-forming ability criterion for bulk metallic glasses[J]. Acta Materialia, 2002, 50: 3501?3512.

[16] JING Q, ZHANG Y, WANG D, LI Y. A study of the glass forming ability in ZrNiAl alloys[J]. Mater Sci Eng A , 2006, 441: 106?111.

[17] 景 勤. 多组元大块非晶合金研制及其空间搭载实验方案设计[D]. 秦皇岛: 燕山大学博士论文, 2004: 44.

JING Qin. Preparation of multi-component bulk amorphous alloys and design of payload experiments in space[D]. Qinhuangdao: Dissertation for the Doctoral Degree in Engineering of Yanshan University, 2004: 44.

[18] BARANDIARAN J M, COLMENRO J. Continuous cooling approximation for the formation of a glass[J]. J Non-Cryst Solids, 1981, 46(3): 277?287.

[19] 惠希东, 陈国良. 块体非晶合金[M]. 北京: 化工出版社, 2007: 65?73.

HUI Xi-dong, CHEN Guo-liang. Bulk metallic glass[M]. Beijing: Chemical Industry Press, 2007: 65?73.

[20] LEWANDOWSKI J, WANG W H, GREER A L. Intrinsic plasticity or brittleness of metallic glasses[J]. Philosophical Magazine Letters, 2005, 85(2): 77?87.

基金项目:国家自然科学基金资助项目(50731005/50821001/10702060)

收稿日期:2009-02-03;修订日期:2009-03-18

通信作者:张宝庆,博士;电话:15518504606;E-mail: bqzhang@hpu.edu.cn; bqzhang@ysu.edu.cn

(编辑 李向群)