文章编号:1004-0609(2011)05-1003-06

新型铜合金/非晶复合材料的挤压成形特性

刘 勇1, 张 丽1, 郭洪民2, 杨湘杰1

(1. 南昌大学 机电工程学院,南昌330031;2. 南昌大学 材料科学与工程学院,南昌330031)

摘 要:基于大块非晶在过冷液相区间具有较好的热塑性成形特点,选择铜基非晶Cu40Zr44Ag8Al8和铜合金,通过挤压成形工艺,制备出一种新型的铜合金/非晶复合材料;在703 K和挤压速度为0.4 mm/min下对该复合材料进行挤压,获得铜合金/非晶复合材料棒材。通过光学金相(OM)、X射线衍射(XRD)、示差扫描量热分析(DSC)和维氏硬度测试(HV)对挤压变形前、后芯部非晶进行形貌观察和结构分析。结果表明:芯部非晶在挤压前期呈不均匀分布,而后分布非常均匀;结合XRD、DSC和硬度的结果分析,在703 K下挤压后,芯部非晶没有发生晶化。

关键词:铜基非晶;热塑性成形;复合材料;晶化;过冷液相区间

中图分类号:TG306 文献标志码:A

Coextrusion forming characteristics of

novel Cu alloy/bulk metallic glass composite

LIU Yong1, ZHANG Li1, GUO Hong-min2, YANG Xiang-jie1

(1. School of Mechatronics Engineering, Nanchang University, Nanchang 330031, China;

2. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China)

Abstract: A novel Cu alloy/bulk metallic glass (BMG) composite was fabricated through the coextrusion process, based on the excellent thermoplastic forming characteristics of BMG in the supercooled liquid region (SLR). The Cu-based amorphous Cu40Zr44Ag8Al8 and pure Cu alloy were selected as components. The Cu alloy/BMG composite bar was easily fabricated at extrusion temperature of 703 K and extrusion speed of 0.4 mm/min. The morphology and structure of the core BMG before and after the coextrusion with Cu were characterized by optical microscopy (OM), X-ray diffractometry (XRD), differential scanning calorimetry(DSC) and microhardness(HV). The results indicate that the core BMG can reach the approximately uniform distribution of the dimension after suffering the shortly inhomogeneous distribution of the dimension in the initial stages of coextrusion. Combining the analysis of XRD, DSC and micro hardness (HV), it can be concluded that the crystallization of core BMG does not occur after the coextrusion with Cu at 703 K.

Key words: Cu-based bulk metallic glass; thermoplastic forming; composite; crystallization; supercooled liquid region

最近,大块非晶合金的热塑性成形得到了广泛的研究[1-4]。当大块非晶合金被加热至过冷液相区间(Supercooled liquid region, SLR)时,合金呈现急剧软化的流变行为[5-9]。大块非晶合金的热塑性成形正是充分利用了大块非晶合金在SLR的软化行为和热稳定性的优点,因此,大块非晶合金能获得良好的变形,同时能够避免非晶晶化的发生。受到此启发,RAGANI等[10]、GRAVIER等[11]和LEE等[12]提出合理利用大块非晶合金在SLR中热塑性成形好的特性,将大块非晶合金和传统合金在SLR中进行固态复合成形,制备新型的晶体/非晶复合材料。目前,可以采用压缩成形和挤压成形两种工艺制备这类复合材料。RAGANI等[10] 通过压缩成形工艺,在SLR条件下通过大块非晶合金和轻质合金(Al或者Mg合金)复合变形制备了层/片状薄板复合材料。研究结果表明,大块非晶合金和传统合金的共同热变形有助于两者的界面结合;但是,压缩工艺容易在界面处产生氧化物,阻碍界面的结合,因而界面强度较低。GRAVIER等[11]通过挤压成形工艺,在SLR条件下通过大块非晶合金和轻质合金(Al或者Mg合金)的复合变形,制备了棒状复合材料。结果表明,挤压工艺可以获得良好的块体非晶与晶体合金之间的界面结合,并且能够避免氧化物的产生。LEE等[12]也采用挤压成形工艺,选择Zr44Ti11Cu9.8Ni10.2Be25非晶合金和7075铝合金,在SLR条件下进行复合成形,制备出棒状复合材料。然而,在较高挤压温度(703 K)和挤压速率(0.1 mm/s)条件下,非晶发生了晶化,并在非晶与铝合金的界面处产生Be2Zr晶体相和裂纹。

本文作者以铜基大块非晶Cu40Zr44Ag8Al8作为芯部材料、以纯铜作为外部包覆材料,采用挤压变形工艺,制备新型铜合金/非晶复合材料。采用光学显微镜、X射线衍射、示差扫描量热分析和维氏硬度对挤压变形前后芯部非晶的形貌进行结构和观察分析,讨论新型铜合金/非晶复合材料的挤压成形工艺。材料组元设计如下:Cu40Zr44Ag8Al8大块非晶具有很强的非晶形成能力(Glass formation ability (GFA)>15 mm)、较好的热稳定性(过冷液相区间达98 K)和较高的强度(抗拉强度超过1.8 GPa)[13];同时,Cu40Zr44Ag8Al8合金的主要组元为铜元素,有利于在挤压变形过程中与铜合金形成原子间的界面结合,提高界面强度。

1 实验

Cu40Zr44Ag8Al8大块非晶的制备工艺如下:利用真空电弧炉熔化纯Cu、Zr、Ag和Al金属制备成纽扣试样;再将母合金粉碎, 在真空条件下,采用快速感应熔化吹铸成直径为3 mm的棒材。图1所示为挤压模具示意图和坯料尺寸,作为芯部材料Cu40Zr44Ag8Al8非晶的实际尺寸为d 3 mm×8.93 mm,作为外部包覆材料铜材的实际尺寸为外径d 6.98 mm×11.1 mm,内径d 3.3 mm×8.93 mm。同时,为了使挤压过程的受力均匀,对铜材头部进行45°倒角处理。挤压模具的前、后直径分别为d 7 mm和d 3 mm,挤压比为5.4,挤压温度为703和726 K,非晶和铜材的实际应变速率为0.01 s-1。为了获得挤压机压头相应的挤压速率,根据经典挤压变形公式[14]进行计算:

(1)

(1)

式中: 为应变速率;v为挤压进程速率;Di为挤入初始直径;Df挤出结束直径;φ为挤压圆锥模的角度;Re为挤压比。根据相应的挤压尺寸,得到挤压机压头的进程速率为0.4 mm/min。在外部包覆材料铜材表面喷涂一层石墨作为润滑剂,以降低材料与模具之间的摩擦力。挤压前试样在挤压温度下保温2 min,以保证挤压试样的温度分布均匀。

为应变速率;v为挤压进程速率;Di为挤入初始直径;Df挤出结束直径;φ为挤压圆锥模的角度;Re为挤压比。根据相应的挤压尺寸,得到挤压机压头的进程速率为0.4 mm/min。在外部包覆材料铜材表面喷涂一层石墨作为润滑剂,以降低材料与模具之间的摩擦力。挤压前试样在挤压温度下保温2 min,以保证挤压试样的温度分布均匀。

图1 挤压模具示意图及坯料尺寸

Fig.1 Schematic diagram of coextrusion apparatus (a) and dimension of as-prepared materials (b): 1—Extrusion die; 2—Copper; 3—Metallic glass; 4—Extrusion head; 5—Heating coil

为了表征非晶与铜之间的界面结构和获得尺寸分布,挤压后的铜合金/非晶复合材料用Well金刚丝线切割机沿着挤压方向切割成厚度约为1 mm的片状样品。采用光学显微镜(OM)测试芯部非晶的尺寸大小和分布;采用扫描电子显微镜(SEM)表征芯部非晶与铜材之间的界面结构;采用显微硬度仪、X射线衍射仪(XRD)、示差扫描量热分析(DSC,20 K/min)分别测试复合材料中芯部非晶挤压后的结构变化规律。

2 结果与分析

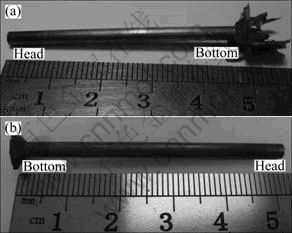

图2所示为在703和726 K挤压后获得的铜合金/非晶复合材料挤压圆棒的外观形貌。由图2可知,铜合金/非晶复合材料挤压圆棒表面质量良好,这说明在挤压过程中铜合金与非晶发生了较好的协调变形。如图2(a)所示,在703 K挤压时,棒材端部产生很多飞边;而在726 K挤压时,棒材端部产生的飞边较少。这说明挤压温度越低,需要的挤压成形力越大,产生飞边越容易,这与挤压实验结果一致。

图2 铜合金/非晶复合材料在不同温度下挤压后样品的外观形貌

Fig.2 Appearance of Cu/BMG composite with rod shape after coextrusion at different temperatures: (a)703 K; (b) 726 K

图3所示为铜合金/非晶复合材料在726 K挤压时芯部非晶的尺寸和显微硬度分布。由图3可知,挤压棒材芯部非晶尺寸呈抛物线分布规律,且形状不规则,通过OM分别测量了其最小尺寸和最大尺寸。在挤压初期至 6.8 mm长度的棒材由单一纯铜组成,随后,芯部开始出现非晶,其尺寸在距离头部7.5 mm处直径最大,最大直径为1.964 mm;随着挤压的继续进行,芯部非晶尺寸下降并逐渐达到一个相对稳定阶段,在距离头部21 mm处,芯部非晶的平均直径约为1.45 mm;随后,芯部非晶的尺寸减小,且呈不规则形状。

对芯部非晶的显微硬度进行测试,结果如图3所示,在726 K温度下挤压,芯部非晶的硬度急剧增大,同时非晶硬度的离散度也增加。这说明芯部非晶在挤压开始阶段已经发生了晶化,随着挤压的进一步进行,晶化程度增大,导致其硬度继续增加。芯部硬度的增大直接影响了非晶与铜材之间的协调变形,改变了铜材的流变行为,导致挤压棒材芯部非晶的尺寸增大。在挤压后期,由于芯部非晶体积分数的减小,残留铜材体积分数增多,使芯部非晶尺寸急剧减小。

图3 铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8在726 K挤压时芯部非晶的尺寸和显微硬度分布

Fig.3 Profiles of diameter and microhardness of core BMG in Cu/BMG composite Cu/Cu40Zr44Ag8Al8 after coextruded at 726 K

图4所示为铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8在703 K挤压时芯部非晶的尺寸和显微硬度分布。为了比较,图中还给出非晶铸态的显微硬度(见图4中A点)和复合材料底部芯部非晶未经挤压的显微硬度(见图4中B点)。由图4可知,在挤压初期至10 mm长度的棒材由单一铜材组成,随后芯部开始出现非晶,其直径约为2.5 mm。随着挤压的继续进行,非晶尺寸迅速减小并达到一个尺寸稳定阶段,其平均直径为1.397 mm。由此可知,芯部非晶在复合材料中呈均匀分布,这说明在挤压温度为703 K和挤压速率为0.4 mm/min的条件下,外层包覆铜材和芯部非晶可以相互协调、均匀地变形,制备得到铜合金/非晶复合材料。根据模具的挤压比,计算出芯部非晶挤出直径的理论值为1.286 mm。对尺寸稳定阶段的非晶直径进行测试,其实际值为1.397 mm。对比分析理论值与实际值可知,芯部非晶发生了约8.6%的膨胀量。KAWAMURA等[15]的研究表明,非晶在挤压成形时经历明显的材料膨胀效应(膨胀量约15%),即非晶的弹性回复效应。然而,非晶在热塑性成形温度区域极小的弹性变形显然不足以解释近15%的挤压膨胀量。CHIU等[3]则认为,当牛顿流体在低雷诺数条件下流动时,由于模具末端界面条件的突然变化会使挤压型材直径增加,这种尺寸的变化直接导致了挤压膨胀的产生。典型Zr44Ti11Cu10Ni10Be25合金的挤压膨胀量达到14%~17%[3]。在本研究中,非晶与铜的共同挤压产生的膨胀量(8.6%)明显低于非晶直接挤压的膨胀量,这表明外层铜材的存在有助于减弱非晶挤压变形中的膨胀效应。

图4 铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8在703 K挤压时芯部非晶的尺寸和显微硬度分布

Fig.4 Profiles of diameter and microhardness of core BMG in Cu/BMG composite Cu/Cu40Zr44Ag8Al8 after coextruded at 703 K

由图4可知,铸态非晶的显微硬度为544(HV),在挤压初期芯部非晶的硬度增加,随着挤压的继续进行,芯部非晶的显微硬度趋于稳定,在挤压棒材底部B点的非晶显微硬度为588(HV),即非晶在经历复合挤压后显微硬度略有增加。在挤压过程中,一方面,非晶在高温下经历了一定时间的时效,必然发生一定程度的结构驰豫,导致硬度变化;另一方面,非晶受到挤压压力和应力的双重作用,也有可能诱导非晶结构的转变而产生硬度变化。在底部B点非晶经历了最长时间的时效,其硬度的变化主要来自于结构驰豫的贡献。芯部和底部B点非晶的硬度差异不大,这说明复合挤压过程中的压力和应力并没有导致非晶硬度的额外变化,即芯部非晶的硬度变化主要来自于高温下的结构驰豫作用。

图5所示为703 K下复合挤压成形的铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8的XRD谱。由图5可知,该复合材料中有一些明显的晶体衍射峰和一个馒头峰。与纯Cu的衍射峰进行比较可知,这些晶体的衍射峰对应于纯铜的衍射峰。对非晶馒头峰进行放大,如图5(a)中插图所示,并没有发现其他晶体峰的存在。因此,XRD结果说明,该复合材料在703 K和0.4 mm/min条件下挤压没有发生晶化,这也印证了芯部非晶硬度的变化规律。

图5 在703 K挤压铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8的XRD谱

Fig.5 XRD pattern of Cu/BMG composite Cu/ Cu40Zr44Ag8Al8 after coextruded at 703 K (a) and standard of XRD pattern of pure Cu alloy (b)

图6所示为在703 K挤压铜合金/非晶复合材料Cu40Zr44Ag8Al8与铜合金界面的SEM像。由图6可知,非晶合金与铜合金界面的结合连续光滑,没有形成氧化夹杂物,界面结合很好。RAGANI等[10]通过压缩成形工艺制备了非晶和轻质合金的层片状薄板复合材料,然而,压缩工艺中在界面处容易产生氧化物,所产生的氧化物阻碍界面的结合,使界面强度降低。因此,挤压成形工艺能够更有效地防止在界面处形成氧化夹杂物,从而改善界面结合。另外,由于Cu40Zr44Ag8Al8大块非晶的主要合金元素为铜,在挤压成形过程中,两组元相同铜原子间的亲和力有利于加速界面间的原子扩散,获得良好的界面结合。

图6 在703 K挤压铜合金/非晶复合材料Cu/Cu40Zr44Ag8Al8界面的SEM像

Fig.6 SEM image of interface of Cu/BMG composite Cu/Cu40Zr44Ag8Al8 after coextruded at 703 K

图7所示为在703 K挤压铜合金/非晶复合材料Cu40Zr44Ag8Al8的DSC曲线,相关的特征参数见表1。由图7可知,铸态非晶合金的玻璃转化温度Tg、晶化开始温度Tx、过冷液相区间?T和晶化热焓?H分别为706 K、784 K、78 K和58.96 J/g。这些特征参数与文献[13]的结果有所不同,这说明制备工艺对非晶合金结构有一定的影响。在经历复合挤压之后,非晶合金相应的特征参数分别为714 K、789 K、75 K和47.38 J/g。这说明复合挤压导致非晶的玻璃转化温度和晶化开始温度得到一定的提高,而相应的过冷液相区间略有下降。同时,由于高温结构驰豫的原因,导致挤压后非晶的晶化焓降低。

图7 在703 K铜合金/非晶复合材料Cu40Zr44Ag8 Al8芯部非晶及其铸态的DSC曲线

Fig.7 DSC curves of core BMG of Cu/BMG composite Cu40Zr44Ag8 Al8 before and after coextruded at 703 K

表1 Cu40Zr44Ag8 Al8非晶铸态和变形态的DSC特征参数

Table 1 DSC characteristic parameters of Cu40Zr44Ag8Al8 under different conditions

3 结论

1) 利用非晶在过冷液相区间热塑性成形好的特点,通过挤压成形工艺制备新型的铜合金/非晶复合材料Cu40Zr44Ag8Al8棒材;研究挤压温度对复合材料成形的影响;对复合挤压后芯部非晶的尺寸和结构进行分析。

2) 在挤压速率一定的条件下,挤压温度对铜合金/非晶复合材料的复合变形影响很大。

3) 在726 K进行复合挤压时,芯部非晶呈不规则形状且尺寸分布不均匀,并发生晶化,导致硬度急剧增加。

4) 在703 K进行复合挤压时,芯部非晶呈圆棒状且尺寸分布均匀,铜与芯部非晶的界面结合良好,能够获得质量较好的铜合金/非晶复合材料棒材。在703 K挤压后的芯部非晶保持非晶结构,高温结构驰豫作用导致其晶化焓降低。

REFERENCES

[1] SCHROERS J, PATON N. Amorphous metal alloys form like plastics[J]. Adv Mater Processes, 2006, 164(1): 61-63.

[2] SCHROERS J. Processing of bulk metallic glass[J]. Advanced Materials, 2009, 21: 1-32.

[3] CHIU H M, KUMAR G, BLAWZDZIEWICZ J, SCHROERS J. Thermoplastic extrusion of bulk metallic glass[J]. Scripta Materialia, 2009, 61(1): 28-31.

[4] YU G S, LIN J G, LI W, WEN C E. Extrusion properties of a Zr-based bulk metallic glass[J]. Materials Letters, 2009, 63(15): 1317-1319.

[5] 张志豪, 周 成, 谢建新. Zr55Al10Ni5Cu30大块非晶合金的超塑性挤压成形性能[J]. 中国有色金属学报, 2005, 15(1): 33-37.

ZHANG Zhi-hao,ZHOU Cheng, XIE Jian-xin. Superplastic extrusion behaviors of Zr55Al10Ni5Cu30 bulk metallic glass[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 33-37.

[6] 张志豪, 刘新华, 周 成, 谢建新. Zr基大块非晶合金的超塑性成形性能[J]. 中国有色金属学报, 2004, 14(7): 1073-1077.

ZHANG Zhi-hao, LIU Xin-hua, ZHOU Cheng, XIE Jian-xin. Super-plastic forming properties of Zr-based bulk amorphous alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1073-1077.

[7] HEILAMIER M. Deformation behavior of Zr-based metallic glasses[J]. Journal of Materials Processing Technology, 2001, 117(3): 374-380.

[8] 沈 军, 孙剑飞, 王 刚, 黄永江, 周彼德. 大块非晶合金过冷液相区的超塑性流变行为[J]. 材料导报, 2004, 18(7): 22-25.

SHEN Jun, SUN Jian-fei, WANG Gang, HUANG Yong-jiang, ZHOU Bi-de. Superplastic flow behavior of bulk metallic glasses in supercooled liquid region[J]. Materials Review, 2004, 18(7): 22-25.

[9] 沈 军, 王 刚, 孙剑飞, 陈德民, 刑大伟, 周彼德. Zr基块体非晶合金在过冷液相区的超塑性流变行为[J]. 金属学报, 2004, 40(5): 518-522.

SHEN Jun, WANG Gang, SUN Jian-fei, CHEN De-min, XIN Da-wei, ZHOU Bi-de. Superplastic flow behavior of Zr base metallic glasses in supercooled liquid region[J]. Acta Metallurgica Sinica, 2004,40(5): 518-522.

[10] RAGANI J, VOLLAND A, GRAVIER S, BLANDIN J J, SUERY M. Metallic glass/light alloy (MEGA) multimaterials elaborated by co-pressing at high temperature[J]. Journal of Alloys and Compounds, 2010, 495(2): 323-326.

[11] GRAVIER S, PUECH S, BLANDIN J J, SU?RY M. New metallic glass/alloy (MeGA) rods produced by co-extrusion[J]. Advanced Engineering Materials, 2006, 8(10): 948-953.

[12] LEE K S, KANG S H, LEE Y S. Synthesis of Zr-based bulk metallic glass-crystalline aluminum alloy composite by co-extrusion[J]. Materials Letters, 2010, 64(2): 129-132.

[13] ZHANG W, ZHANG Q S, QIN C L, INOUE A. Synthesis and properties of Cu-Zr-Ag-Al glassy alloys with high glass-forming ability[J]. Materials Science and Engineering B, 2008, 148(1): 92-96.

[14] DIETER G E. Mechanical metallurgy[M]. London: McGraw-Hill, 1988: 33-37.

[15] KAWAMURA Y, SHIBATA T, INOUE A, MASUMOTO T. Workability of the supercooled liquid in the Zr65Al10Ni10Cu15 bulk metallic glass[J]. Acta Mater, 1997, 46(1): 253-263.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51001058, 51041002, 50965015);国家科技支撑计划项目(2011BAE22B02);江西省铜钨新材料重点实验室开放基金资助项目(2010-WT-08);江西省国际合作项目(2010EHA02000);江西省自然科学基金资助项目(2010GQC0135);江西省教育厅科学基金资助项目(GJJ11268);

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:刘 勇,讲师,博士;电话:0791-3969611;E-mail:liuyonggreg@yahoo.com.cn