DOI: 10.11817/j.issn.1672-7207.2018.07.008

模内混合注塑成型聚丙烯与预制件间界面黏结强度研究

卢一1,蒋炳炎1, 2,符亮2,吴旺青2

(1. 中南大学 新型特种纤维及其复合材料湖南省重点实验室,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:通过Moldflow软件仿真和成型实验,研究模内混合成型中连续纤维热塑性复合材料(CFRT)热压成型预制件与注塑成型聚丙烯间界面黏结强度。仿真研究预制件温度、熔体温度及保压压力对黏结界面温度场及压力场的影响规律,分析模内混合注塑成型界面黏结过程,指出CFRT预制件表面快速加热对界面黏结影响的重要性。研究结果表明:当预制件没有加热时,界面黏结强度随着熔体温度和保压压力的增加而显著提高,预制件达到熔点温度后,由于界面温度显著升高且足以满足界面分子扩散运动的能量需求,故熔体温度和保压压力的进一步提升对于界面黏结强度影响不大。

关键词:模内混合;界面黏结;CFRT;分子扩散

中图分类号:TQ320.63 文献标志码:A 文章编号:1672-7207(2018)07-1626-08

Interfacial bonding strength between polypropylene and perform on in-mold hybrid injection molding technology

LU Yi1, JIANG Bingyan1, 2, FU Liang2, WU Wangqing2

(1. Hunan Key Laboratory of Advanced Fibers and Composites, Central South University, Changsha 410083, China;

2. State Key Laboratory of High-Performance Complex Manufacturing, Central South University, Changsha 410083, China)

Abstract:Based on the simulation of Moldflow software and experiment, the interfacial bonding strength between the preform of continuous fiber reinforced thermoplastic(CFRT) composites and the plastic injection molding of polypropylene(PP) was studied during in-mold hybrid molding. The effect of preformed temperature, melt temperature and holding pressure on the temperature field and pressure field of bonding interface was researched by simulation, the interfacial bonding process of in-mold hybrid injection molding was analyzed, and the importance of rapid heating of CFRT surface for interfacial bonding was pointed out. The results show that without heating perform, the interfacial bonding strength is improved greatly with the increase of melt temperature and pressure. Due to the energy needs, the diffusion motion of interface molecules is satisfied by the significant increase of interface temperature after perform reaches the melting point, and the further improvement of melt temperature and holding pressure have little effect on the interfacial bonding strength..

Key words: in-mold hybrid; interfacial bonding; CFRT; molecular diffusion

模内混合注塑成型技术中塑料-塑料混合成型是在塑料-金属模内混合注塑成型[1]的基础上提出来,即采用连续纤维增强热塑性复合材料[2-3](continuous fiber reinforced thermoplastic, CFRT)预制件取代塑料-金属模内混合注塑成型技术中的金属制件,旨在进一步降低产品重量,提高产品性能。该工艺能克服塑料-金属模内混合注塑成型中塑料与金属相容性差及成型过程中产生应力集中或变形的缺陷[4]。预制件与注塑层界面黏结强度是决定制件整体性能的关键[5],模内混合成型制件性能不仅是由混合材料各自特性所决定,同时也取决于两者间的界面粘接特性[6]。在2种相容材料的模内混合成型中,黏结主要是2种聚合物材料大分子之间的缠结交联,界面黏结强度取决于2种材料接触的时间、表面的可润温度及分子链的扩散程度[7-8]。一种分子扩散理论指出黏结是高分子链相互缠结的结果。在分子扩散缠绕理论中同时强调黏结材料的相容性[9]。在一定的压力下,当2种相容的聚合物材料接触,增加2种相容聚合物接触界面的温度,能够提高接触界面聚合物表面分子的运动,使界面分子的扩散效果更为显著;另外,增加保压的时间,也有利于提高界面分子间的扩散作用[10]。由于热运动及外界压力作用,促使界面间的高聚物大分子在接触界面之间彼此流动、扩散以及相互缠绕[11]。随着温度下降,大分子开始结晶,得到一定的结晶度而达到理想的黏结强度[12]。因此,2种聚合物材料的相容性越好,则扩散性就越好,得到充分有效地缠绕,所表现出的宏观黏结性就越好[13]。本文作者采用Moldflow软件研究各工艺参数对黏结界面温度场及压力场的影响规律,指出CFRT预制件表面快速加热对界面黏结影响的重要性[14]。最后通过实验验证并阐述预制件温度、熔体温度及保压压力对界面黏结强度的影响和预制件与熔体界面愈合的过程,解释理论与仿真研究的可行性。

1 黏结界面温度及压力场数值模拟

1.1 模内混合成型界面粘接分析有限元建模

采用Solidworks软件对模内混合注塑成型CFRT预制件分别建立注塑层与预制件三维模型,并使用Hypermesh软件对该模型严格按照注塑流动的方向对称划分网格,采用热塑性重叠注塑模型进行模拟,并添加预制件层和注塑层的3D网格模型,定义预制件及注塑层的材料属性。有格有限元模拟的数学模型对熔体动力学进行计算,且分别采用Tucker-Folger和Jeffery模型计算纤维间相互作用及熔体对纤维的作用。网格划分如图1所示。

图1 模内混合注塑成型制件网格划分图

Fig. 1 Grid division of in-mold hybrid injection molding part

1.2 单因素仿真实验研究注塑工艺对界面黏结强度的影响

1.2.1 单因素仿真方案

由于界面分子扩散程度是由界面间温度、时间与压力共同作用的结果,在研究工艺参数对其影响的情况下,采用Moldflow软件对模内混合注塑成型黏结界面温度场及压力场进行仿真,选择“充填+保压”分析次序,速度/压力切换采用体积控制在97%,使用Basell Hostcom PF062-3的短玻纤增强PP作为熔体材料,玻纤的质量分数为30%,预制件材料为连续玻纤增强聚丙烯(PP)[15]。注塑工艺参数对黏结界面的温度、压力以及保持时间的影响中,熔体温度、预制件温度以及保压压力的影响较为突出,因此,采用单因素仿真分析分别对其进行单独讨论,注塑速率为24 cm3/s,保压时间为10 s,冷却时间为20 s。分别提取预制件表面节点N39793,N39776和N39759作为温度测量点,N39776为流动方向上中间位置节点,N39793与N39759分别为距中位置34 mm的近浇口端与远浇口端节点,提取注塑层表面中间点N2139作为压力测量点。

1.2.2 单因素实验仿真结果与分析

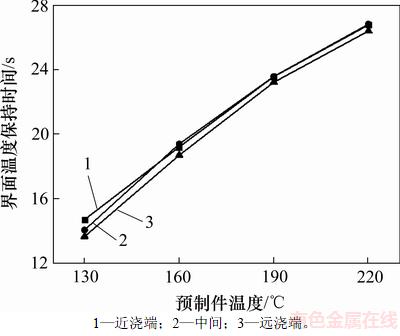

1) 预制件温度的影响。预制件温度对黏结界面流动方向上温度及保持时间的影响分别如图2和图3所示。从图2和图3可见:随着预制件温度的提高,黏结界面最高温度与超过结晶温度的保持时间都明显提高,当预制件温度为130 ℃时,近浇口端温度要明显高于中间点及远浇口端温度;注塑熔体在流过近浇端时,预制件温度过低,注塑熔体迅速冷却,导致流动方向上黏结界面的温度差异,这也将导致黏结强度从近浇端向远浇端逐渐变差,保持时间也呈现递减式分布;随着预制件温度接近PP熔点温度(165 ℃),流动方向上的温度差异得到明显改善。因此,快速加热CFRT预制件温度对黏结界面间的温度及超过结晶温度保持时间影响较显著。

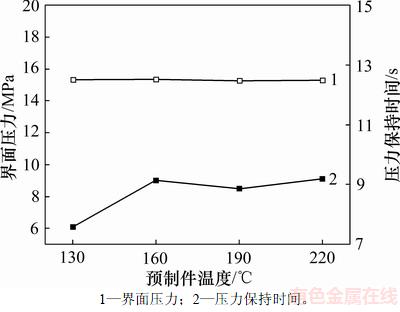

随着预制件温度的提高,黏结界面间的压力保持常量,但压力保持时间在温度达到熔点温度以后发生了突变,且保压压力和保压时间的增加都会提高界面的黏结强度,随后又保持不变,该现象与预制件材料达到熔点温度后发生相转变有关,如图4所示。

图2 预制件温度对黏结界面温度影响

Fig. 2 Effect of preform temperature on bonding interface temperature

图3 预制件温度对界面温度保持时间的影响

Fig. 3 Effect of preform temperature on holding time of bonding interface temperature

图4 预制件温度对界面压力及保持时间的影响

Fig. 4 Effect of preform temperature on bonding interface temperature and pressure holding time

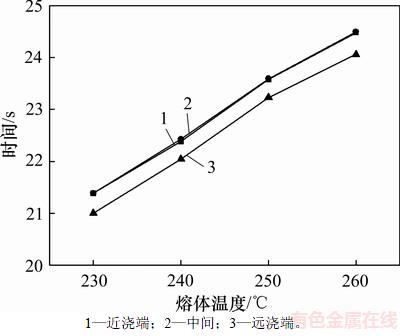

2) 熔体温度的影响。熔体温度对黏结界面温度影响仅次于预制件温度的影响如图5所示。从图5可见:随着熔体温度提高,黏结界面的温度也随之提高,在流动方向上温度一直呈阶梯式分布,但温度只相差1~3 ℃。黏结界面间超过结晶温度的保持时间与界面间最高温度变化趋势基本一致,且中间与近浇口端保持时间无差别,但远浇口端时间相差0.5 s左右,如图6所示。这也说明熔体温度的调节不能降低在流动方向上黏结界面温度的差异,随着流动距离的延长,这种现象表现得更加明显。

图5 熔体温度对界面间最高温度影响

Fig. 5 Effect of melt temperature on the maximum temperature of bonding interface

图6 熔体温度对黏结界面超结晶度温度保持时间的影响

Fig. 6 Effect of melt temperature on holding time beyond crystallinity

熔体温度对黏结界面压力及压力保持时间的影响如图7所示。从图7可见:当熔体温度达到240 ℃时,黏结界面间的压力突然由11.5 MPa增大到15 MPa;随着熔体温度继续升高到260 ℃,压力增加量低于1 MPa,而时间随着熔体温度的提高呈直线增加。这主要是因为压力的传递是由主流道冷却速度决定的,当熔体温度不够高时,主流道受较低模具温度的影响迅速凝固,压力损失增加,当熔体温度足够高时,保压压力在主流道凝固前得以施加,压力迅速增加。

图7 熔体温度对界面间最高压力及保持时间的影响

Fig. 7 Effect of melt temperature on the maximum pressure and holding time of bonding interface

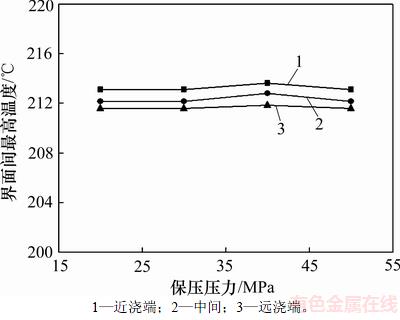

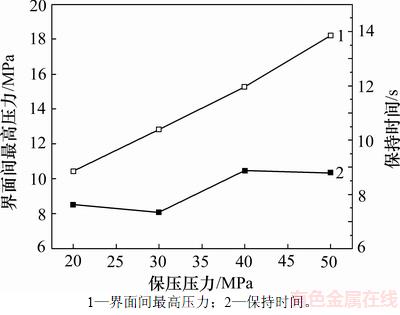

3) 保压压力的影响。保压压力对黏结界面最高温度保持时间及最高压力的影响分别如图8与图9所示。从图8和图9可见:随着保压压力增加,黏结界面间的最高温度及界面间温度保持时间几乎没有变化,说明保压压力对其几乎没有影响。但黏结界面间的压力与保持时间具有明显变化,如图10所示,这也是保压压力唯一影响黏结界面黏结强度的方式;随着保压压力的增大,界面间压力呈直线上升,而时间的变化呈现中间增大,两端保持的情况;保压压力在30 MPa前,压力持续时间变化不大;当保压压力增大到40 MPa后,压力持续时间由8 s提高到10 s,保压压力再增加压力持续时间不再改变。在选择工艺参数时,保压压力需大于40 MPa。

图8 保压压力对黏结界面最高温度的影响

Fig. 8 Effect of holding pressure on the maximum temperature of bonding interface

图9 保压压力对黏结界面超结晶度温度保持时间的影响

Fig. 9 Effect of holding pressure on holding time beyond crystallinity

图10 保压压力对黏结界面最高压力及保持时间的影响

Fig. 10 Effect of holding pressure on the maximum pressure and holding time

2 模内混合注塑成型界面黏结强度实验论证分析

通过Moldflow软件仿真研究,得出了模内混合注塑成型黏结界面愈合过程中预制件温度、熔体温度及保压压力对其影响的定性分析。参考其结果,选择合理的工艺参数,采用单因素实验方法研究模内混合注塑成型工艺参数(预制件温度、熔体温度、保压压力)对黏结界面强度影响规律,并通过观测和分析微观形貌中黏结界面愈合过程,与Moldflow仿真结果进行对比,为模内混合注塑成型提供参考依据并为后续实验奠定了基础。

2.1 预制件温度对黏结强度影响实验研究

仿真分析过程中CFRT预制件表面温度对于黏结界面温度的提高、聚合物熔体扩散时间的延长及最终对界面黏结强度的提高具有较大影响。图11所示为预制件表面加热温度与黏结强度的关系图。从图11可见:从室温至80 ℃,无明显影响;当达到熔点温度到165 ℃时,随着CFRT预制件表面温度的提高,黏结强度迅速提高。这是由于提高预制件表面温度后,增加了黏结界面冷却固化的时间,促进界面间分子扩散与界面愈合,力学强度得到极大提高。当预制件温度达到185 ℃左右时,黏结界面基本已完全愈合,但随着CFRT预制件表面温度的提高,强度还会进行一步提高。微观形貌如图12所示。从图12可见:注塑熔体中的短纤维已完成黏结界面中的穿越,形成牢固的黏结。但当温度达到225 ℃时,强度突然降低。这是由于当温度升高达到一定值时,CFRT预制件整体变得很软,表面一层纤维在高速熔体的剪切力下被冲散,与注塑熔体混在一起,从而降低最终力学性能[16]。图13所示为微观截面图,原来4层纤维织物被黏结层熔体冲散后只剩下3层。

从以上实验结果可知:CFRT预制件表面温度对于黏结界面强度的提高有明显的影响,其本质是预制件温度的提高延长了界面间分子的扩散时间,最终表现在界面的黏结效果得到改善。通过研究预制件温度对影响界面黏结效果的影响可以得出:通过调整预制件表面温度参数,可以改善并注塑工艺条件,从而降低工艺成本。

图11 CFRT预制件温度对层间剪切强度的影响

Fig. 11 Effect of preform temperature on shear strength between layers

图12 短纤维穿过黏结界面

Fig. 12 Short fibers pass through bonding interface

图13 CFRT截面图纤维分布情况

Fig. 13 Section diagram fiber distribution

2.2 熔体温度对黏结强度影响实验研究

Moldflow仿真结果表明熔体温度对黏结界面温度具有显著的影响,从而影响界面间聚合物熔体的扩散程度。通过对预制件温度对界面黏结情况的影响研究发现:在CFRT没有加热的条件下,当熔体温度为210 ℃时,CFRT预制件与注塑层黏结极为微弱,在外力很小作用下很容易剥离;随着熔体温度上升,层间剪切强度越来越大,当熔体温度达到250 ℃,强度最大可达18 MPa,如图14所示。

观测黏结界面微观形貌图可以看出:当熔体温度为210 ℃时,黏结界面还存大较大间隙且黏结强度较低,说明长纤维增强的预制件与短玻纤增强的熔体间界面黏结效果不理想,如图15(a)所示;当熔体温度进一步提高,黏结层层间剪切应力也进一步提高,形貌图显示黏结界面逐渐愈合,界面间隙减小,如图15(b)所示。随着熔体温度的进一步提高,层间剪切应力相应地基本成线性逐渐增加,从形貌图也可以直观地观测到黏结效果有明显的改善。当熔体温度升高至250 ℃时,层间剪切应力的增幅逐渐变缓,黏结界面愈合基本完成,虽然没有明显的间隙,但预制件层和熔体层间并没有形成相互穿越的效果,可以清楚地区分开来,如图15(c)所示。

图14 熔体温度对黏结界面层间剪切应力影响

Fig. 14 Effect of melt temperature on shear stress of bonding interface

图15 不同熔体温度下黏结界面形貌

Fig. 15 Bonding interface morphology at different melt temperature

当CFRT预制件采用红外加热器进行表面加热[17]、熔体温度为210 ℃时,界面粘接层的剪切应力由9 MPa左右大幅提高至20 MPa,可以推断在对预制件进行加热之后,其黏结强度得到极大提高,明显提高了其黏结强度;随着熔体温度进一步提高,层间剪切强度提高并不明显,说明熔体温度对界面黏结的影响很小,主要是由于提高预制件温度足够使界面间形成较好的黏结效果,所以,熔体温度对黏结界面愈合已经无明显影响,如图15(d)所示。

通过微观形貌的检测可以看出:在预制件没有加热的情况下,熔体温度提高可以改善界面黏结的效果,从而提高预制件与熔体间的黏结强度,且提升效果比较明显,但最终不能使预制件与注塑层间形成进一步融合;当预制件经过加热后,随着熔体温度提高,界面间的黏结效果也有所提升,虽然从层间剪切应力可以看出增长幅度只有3%左右,但最终的层间剪切应力相对于预制件没加热时有较大幅度提高,从形貌图观测到预制件与注塑熔体层已经完全融合,且黏结界面层已基本消失,再次证明加热预制件对界面黏结强度有较大的影响,同时也说明在界面黏结愈合基本完成之后,继续提高熔体温度,效果已经不明显。

2.3 保压压力对黏结强度的影响

根据Moldflow仿真实验可知:保压压力对CFRT预制件与注塑层界面间的温度无明显影响,但对于界面间黏结压力具有较大的影响作用;当界面间温度在结晶温度以上时,保压压力可以减少黏结界面间的距离,促进聚合熔体间的渗透和融合,从而增加黏结强度,如图16所示。当无红外加热时、保压压力小于30 MPa时,随着保压压力提高,层间剪切强度没有明显提高,当保压压力升高至40 MPa时,对黏结界面强度有了一定提高。在成型黏结时,保压压力克服型腔压力损失,作用在黏结界面上,促进了界面间熔体的扩散与缠结。而采用红外加热时,随着保压压力提高,黏结强度逐渐提高并趋于平缓,保压压力对黏结界面强度的提高比较有限。

图16 保压压力对层间剪切应力的影响

Fig. 16 Effect of holding pressure on shear stress between layers

3 结论

1) 采用Moldflow仿真软件研究各工艺参数对黏结界面温度场及压力场的影响规律,分析了PP聚合物间界面黏结强度是由界面间温度、时间与压力共同作用的结果,通过仿真研究表明工艺参数对界面间温度影响的主次顺序为预制件温度、熔体温度、保压压力,对超过结晶温度保持时间影响主次顺序为熔体温度、保压压力、预制件温度,对最高压力影响主次顺序为保压压力、熔体温度、预制件温度。

2) 在CFRT预制件表面没有加热至结晶温度以上时,各工艺参数对黏结强度影响较大,其中熔体温度影响最大。随着熔体温度上升,黏结界面逐渐愈合,但最终仍可观测到界面分界线存在。

3) 当CFRT预制件加热至熔点温度165 ℃以上时,界面黏结强度迅速提高,随着熔体温度继续升高,界面剪切应力增幅只有3%左右。熔体温度继续上升可使注塑熔体中的短纤维逐渐穿越粘接界面直至界面完全愈合,验证了仿真研究的可行性,表明CFRT预制件加热对黏结强度的影响至关重要。

参考文献:

[1] GRUJICIC M, SELLAPPAN V, OMAR M A, et al. An overview of the polymer-to-metal direct-adhesion hybrid technologies forload-bearing automotive components[J]. Journal of Materials Processing Technology, 2008, 197(1/2/3): 363-373.

[2] 左可雷, 关世伟. 复合材料在汽车轻量化设计中的应用[J]. 装备制造技术, 2015(5): 258-260.

ZUO Kelei, GUAN Shiwei. Application of composite materials in lightweight design of automobile[J]. Equipment Manufacturing Technology, 2015(5): 258-260.

[3] FIOROTTO M, LUCCHETTA G. Experimental investigation of a new hybrid molding process to manufacture high-performance composites[J]. International Journal of Material Forming, 2013, 6(1): 179-185.

[4] 杨卫民, 丁玉梅, 谢鹏程. 注射成型新技术[M]. 北京: 化学工业出版社, 2008: 392-421.

YANG Weimin, DING Yumei, XIE Pengcheng. New technology of injection molding[M]. Beijing: Chemical Industry Press, 2008: 392-421.

[5] JIANG Genjie, WU Hong, YAN Bowen, et al. Effect of a tie film on the enhanced interfacial adhesion between polyethylene and polyamide-6 in a sequential injection molding[J]. Society of Plastics Engineers Inc, 2010, 50(4): 719-729.

[6] 万明, 方立, 周天睿, 等. 聚丙烯自增强复合材料层压板的制备和性能研究[J]. 工程塑料应用, 2016, 44(2): 40-45.

WAN Ming, FANG Li, ZHOU Tianrui, et al. Study on Preparation and properties of polypropylene self reinforced composite laminates[J]. Engineering Plastics Application, 2016, 44(2): 40-45.

[7] DOMINICK V, ROSATO, DONALD V, et al, Injection molding handbook, chapter 15: specialized injection molding process[M]. New York: Kluwer Acdemic Publishers, 2000: 1197-1256.

[8] COLE P J, MACOSKO C W, COLE P J. Polymer-polymer adhesion in melt-processed layered structures[J]. Journal of Plastic Film & Sheeting, 2000, 16(3): 213-222.

[9] JUD K, KAUSCH H H, WILLIAMS J G. Fracture mechanics studies of crack healing and welding of polymers[J]. Journal of Materials Science, 1981, 16(1): 204-210.

[10] JIANG Genjie, ZHANG Fengshun, WU Hong, et al. Comparative studies on enhanced interfacial adhesion between PE and PA6 through two routes in a sequential injection molding process[J]. Polymer-Plastics Technology and Engineering, 2014, 53(1): 9-18.

[11] 冯余其, 罗怡, 孙屹博, 等. 热塑性聚合物热熔接过程界面扩散行为分子动力学模拟[J]. 焊接学报, 2011, 32(6): 41-44.

FENG Yuqi, LUO Yi, SUN Yibo, et al. Molecular dynamics simulation of interfacial diffusion in hot melt bonding process of thermoplastic polymer[J]. Welding Journal, 2011, 32(6): 41-44.

[12] YAN Bowen, WU Hong, JIANG Genjie, et al. Interfacial crystalline structures in injection over-molded polypropylene and bond strength.[J]. ACS Applied Materials & Interfaces, 2010, 2(11): 3023-3036.

[13] POMPE G, BR UER M, SCHWEIKLE D, et al. Influence of the temperature profile in the interface on the bond strength of polyamide–polyurethane two-component tensile bars[J]. Journal of Applied Polymer Science, 2006, 100(6): 4297-4305.

UER M, SCHWEIKLE D, et al. Influence of the temperature profile in the interface on the bond strength of polyamide–polyurethane two-component tensile bars[J]. Journal of Applied Polymer Science, 2006, 100(6): 4297-4305.

[14] JIANG Bingyan, ZHOU Zhou, LIU Yao. Research on bonding of PMMA microfluidic chip with precisely controlled bonding pressure[J]. Advanced Materials Research, 2011, 221(2): 8-14.

[15] LAFRANCHE E, RENAULT T, KRAWCZAK P. Effect of the inter diffusion at the polymer/polymer interface on the flexural properties of over-moulded short glass fibre/glass fabric reinforced PA6 composites[J]. Key Engineering Materials, 2014, 611/612: 821-828.

[16] 何芳芳, 周洲, 蒋炳炎. 纤维增强塑料注射成型熔体流动性及纤维取向预测[J]. 复合材料学报, 2013, 30(S1): 128-133.

HE Fangfang, ZHOU Zhou, JIANG Bingyan. Prediction of melt flow and fiber orientation of fiber reinforced plastics injection molding[J]. Acta Materiae Compositae Sinica, 2013, 30(S1): 128-133.

[17] ZHAO Guoqun, WANG Guilong, GUAN Yanjin, et al. Research and application of a new rapid heat cycle molding with electric heating and coolant cooling to improve the surface quality of large LCD TV panels[J]. Polymers for Advanced Technologies, 2011, 22(5): 476-487.

(编辑 杨幼平)

收稿日期:2017-07-06;修回日期:2017-09-17

基金项目(Foundation item):国家自然科学基金资助项目(51405519);湖南省科技计划项目(2015TP1007);中南大学中央高校基本科研业务费专项资金资助项目(2017zzts091) (Project(51405519) supported by the National Natural Science Foundation of China; Project(2015TP1007) supported by the Science and Technology Plan Project of Hunan Province; Project(2017zzts091) supported by the Fundamental Research Funds for the Central Universities of Central South University)

通信作者:蒋炳炎,博士,教授,从事高分子材料精密成型技术研究;E-mail: jby@csu.edu.cn