文章编号: 1004-0609(2005)02-0217-07

90W-7Ni-3Fe纳米晶粉末的瞬时液相强化烧结特征

范景莲, 汪登龙, 曹建虎

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要: 采用机械合金化(MA)制备了晶粒尺寸为8~18nm的90W-7Ni-3Fe纳米晶粉末(MA粉末)。 将粉末注射成形, 在1480~1500℃经3~5min瞬时液相烧结。 结果表明, 采用瞬时液相强化烧结可以得到W晶粒为3~8μm近全致密的细晶钨合金, 显微组织为细小的球形W晶粒均匀地连续分布在纤维状粘结相中, 烧结坯具有好的拉抻性能。 长时间的传统液相烧结使球状W晶粒迅速粗化, 而且密度和强度下降, 但延伸率反而增加。 在MA粉末中添加微量Y2O3后采用瞬时液相烧结, 可以使合金抗拉强度提高到1055MPa, 延伸率提高到16.5%。

关键词: 瞬时液相烧结; 90W-7Ni-3Fe纳米晶粉末; 机械合金化; 注射成形 中图分类号: TF123

文献标识码: A

Transient liquid enhanced sintering characteristics of nanostructured 90W-7Ni-3Fe powders

FAN Jing-lian, WANG Deng-long, CAO Jian-hu

(State key laboratory for Powder Metallurgy,

Central South University, Changsha 410083, China)

Abstract: Nanostructured 90W-7Ni-3Fe powders(MA powders) with tungsten crystalline size of 8-18nm were prepared by mechanical alloying (MA).The powders were mixed with an organic polymer binder, then injected and debinded. After that, the brown compact was consolidated via transient liquid phase sintering at 1480-1500℃ for 3-5min. The mechanical properties and microstructure of the sintered alloy were studied. At same time, the brown compact was consolidated via traditional liquid phase sintering at the same temperature for 120min for comparison. The results show that transient liquid phase sintering helps to obtain fully dense, fine spherical grained tungsten alloy with good tensile strength and elongation; the size of tungsten grains is 3-8μm; the alloy has typical liquid phase sintering microstructure, the fine spherical tungsten grains uniformly imbed in the continuous fiber binder phase; long time traditional liquid phase sintering coarsens the tungsten grain rapidly, and makes the density and tensile strength decrease except that elongation increases. Minor addition of Y2O3 in MA powders improves the tensile strength (1055MPa) and elongation (16.5%) of the tungsten alloy via transient liquid phase sintering.

Key words: transient liquid phase sintering; nanostructured W-Ni-Fe powder; mechanical alloy; injection molding

钨基合金是一种典型的经液相烧结而成的合金, 该合金被广泛地用作动能穿透器。 传统粉末冶金方法所制备的W基高比重合金的显微组织粗大, 钨晶粒一般在40~60μm[1], 合金强度延性等力学性能较低。 过去人们一般采用添加合金元素和形变强化方法提高合金性能, 如添加合金元素Co[2] 可有效地提高延性, 但对提高合金强度的作用不大。 添加合金元素Mo、 Re可提高合金的抗拉强度, 但是合金的延性下降[3-5]。 对烧结态钨合金强度采用形变强化的方法改变W晶粒的显微组织结构, 但是也只能在十分有限的强度上提高合金的拉伸强度, 并且以牺牲合金的延性为代价。 究其原因, 这些方法都不能明显改变(细化)钨合金的显微组织结构。 钨合金的显微组织结构对形变强化有较大的影响, 钨晶粒细化有利于提高钨合金的动态力学行为和穿甲自锐性[7]。 随着纳米材料新概念的出现, 细化钨合金的晶粒渐渐引起国内外学者的重视。 有资料报道, 将钨合金晶粒细化后再采用形变强化处理可以使合金的抗拉强度提高到1700MPa, 延伸率保持在15%。 采用纳米粉末作为原材料是细化钨合金显微结构尺寸的关键的第一步。 机械合金化(MA)是制备纳米粉末中的一种很重要的方法, 在国内外已有许多学者对MA制备W-Ni-Fe纳米粉末以及纳米粉末的烧结特征进行了大量的研究[8, 9]。 但是由于纳米粉末烧结活性非常大, 在烧结时会发生迅速的晶粒长大。 对W-Ni-Fe纳米粉末采用固相烧结可以得到晶粒较细的钨合金, 但由于W晶粒呈多角形, W晶粒互相接触, W颗粒连接度非常高, 因而虽然合金的强度高, 但合金的延性很差[10]。 在液相烧结时, W晶粒发生急剧粗化、 长大、 球化, 而且此时合金发生明显的鼓泡现象, 使密度和延性大大下降[11, 12]。 本文作者针对这些问题, 在制备90W-7Ni-3Fe纳米晶粉末(下文简称MA粉末)的MA过程中添加过程控制剂以降低粉末夹杂和团聚, 然后将MA粉末注射成形, 在高于第二相熔点以上温度分别进行瞬时液相烧结和传统长时间的液相烧结, 研究合金烧结体的力学性能与显微组织。 此外还研究了添加稀土氧化物对瞬时液相烧结钨合金的力学性能和显微组织的影响。

1 实验

采用还原钨粉、 羰基镍粉和羰基铁粉为原料, 粒度分别是2.91、 2.66和3.93μm。 将粉末按90W-7Ni-3Fe比例(质量分数)混合, 然后在QM-1行星式高能球磨机中进行机械合金化(MA)。 其球料比为5∶1, 转速为200r/min, 球磨过程中采用高纯Ar气作为保护气氛以防止氧化, 球磨时间分别为20和40h。 在制备部分MA粉末的球磨过程中加入低分子有机物作为过程控制剂(PCA)。 将MA粉末采用注射成形(MIM)的方法制成标准拉伸样, 然后脱除注射坯中的有机粘结剂。 注射成形所用的粘结剂和溶剂脱脂所用的溶剂与文献[13, 14]相同。 为了研究90W-7Ni-3Fe纳米晶粉末的烧结致密化、 瞬时液相烧结和传统长时间液相烧结对钨合金力学性能和显微组织的影响, 将90N-7Ni-3Fe纳米晶粉末在1250~1450℃进行固相烧结和在高于第二相熔点(1463℃)以上温度(1480~1500℃)分别进行3~5min的瞬时液相烧结和120min的传统液相烧结。 此外, 在MA过程中添加0.04%的Y2O3, 然后重复以上工艺, 研究Y2O3对瞬时液相烧结钨合金的力学性能和显微组织的影响。 采用XRD测定MA粉末的晶粒尺寸, 采用SEM扫描电镜观察了MA粉末的形貌和烧结坯金相组织和断口形貌。 采用Instron力学仪测定了材料的力学性能。

2 结果分析与讨论

2.1 粉末特性

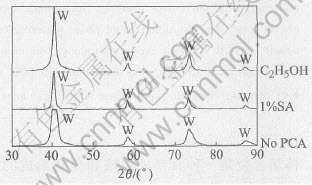

添加过程控制剂PCA与未加过程控制剂机械合金化40h后, 所得MA粉末的XRD衍射谱如图1所示。 从图中可以看出, 在球磨时间相同时, 未添加PCA的MA粉末的衍射峰宽化更为明显。 这说明其晶粒尺寸更小, 晶格畸变更大, 添加PCA对MA过程中的相变化具有阻碍或延缓的作用。 这是由于添加PCA后, 在研磨球、 球罐与粉末之间形成一层极薄的“液膜”[1]。 该“液膜”可以阻止粉末与磨球或球罐的接触, 影响到粉末与粉末之间的挤压冷焊效果, 降低了粉末间的扩散固溶速率, 因此对机械合金化有一定的延缓作用。

图1 球磨40h时MA粉末的XRD谱

Fig.1 XRD pattern of MA powders after grinding for 40h

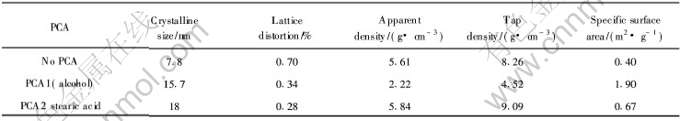

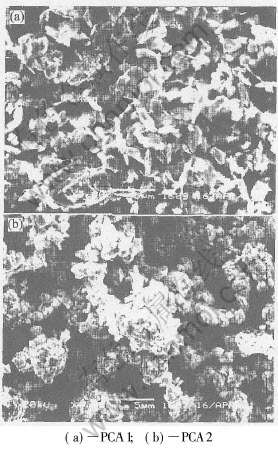

在未添加过程控制剂、 添加固体过程控制剂PCA2和液体过程控制剂PCA1这3种条件下, 球磨 40h时, MA粉末的密度、 比表面、 晶块尺寸和晶格畸变的变化如表1所示。 由表1可见, 添加过程控制剂对MA粉末的特性有很大影响。 添加过程控制剂延缓了MA过程中的晶粒细化过程。 添加过程控制剂后, MA粉末的晶粒尺寸较粗大, 晶格畸变较小, 液体过程控制剂的作用尤为明显。 表中结果还说明添加过程控制剂后松装密度下降, 比表面积增加, 这说明过程控制剂的加入可以避免粉末与粉末在高速高能撞击过程中的直接接触, 有效地减少粉末团聚。 添加液体过程控制剂可以大幅度降低粉末的密度和大幅度提高比表面积, 这说明液体过程控制剂在改善粉末的分散性方面取得了很好的效果。 球磨40h后MA粉末的SEM形貌如图2所示。 从图中可以看出, 添加固体PCA2的MA粉末呈等轴状, 颗粒大小极不均匀, 且团聚现象严重 (与未添加PCA的MA粉末类似)。 添加PCA1的MA粉末呈单一的薄片状, 团聚现象得到了明显的改善。

表1 球磨40h时MA粉末的性能

Table 1 Properties of MA powders after grinding for 40h

图2 添加过程控制剂球磨40h时MA粉末的SEM形貌

Fig.2 SEM morphologies of MA powders after

grinding for 40h with process control agents

2.2 注射成形与脱脂

将在3种条件下所制备的MA粉末与粘结剂混合制备喂料。 研究结果表明, 添加液体过程控制剂PCA1的MA粉末的粉末装载量只有35%~40%, 此时粘结剂含量过高, 液体过程控制剂使粉末比表面积过大、 密度过低而不适合注射成形, 其余两种粉末喂料中的粉末装载量为54%(体积分数), 混料温度为120~130℃, 混合时间为2h。 将喂料注射成形制备MIM标准拉伸样, 注射温度为120℃, 注射压力为80%, 加压时间为5s。 然后将注射坯进行溶剂脱脂或热脱脂两步脱脂工艺。 图3所示是溶剂温度为30~40℃条件下注射坯中的粘结剂脱脂量与脱脂时间的关系。 在溶剂脱脂2~4h时粘结剂的脱脂量的增加速率最快; 当脱脂4h时, 粘结剂可脱除62%。 当脱脂时间继续增加, 粘结剂的脱除量增加; 当脱脂时间为6h时, 粘结剂脱脂速率大大下降, 粘结剂脱脂量趋于稳定, 约为66%~70%。 为了提高脱脂效率, 溶剂脱脂4h后的脱脂坯再在300~500℃进行热脱脂, 其热脱脂工艺与传统模压成形钨合金的简单热脱脂工艺相似, 将溶剂脱脂坯中的剩余部分粘结剂全部脱除。

图3 粘结剂脱除量与溶剂脱脂时间的关系

Fig.3 Relationship between binder loss and

time during solvent debinding

2.3 瞬时液相烧结与传统液相烧结

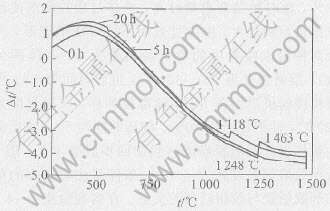

图4所示为90W-7Ni-3Fe纳米晶粉末在N2保护气氛下的DTA曲线[15]。 从图中可知, 第二相γ-(Ni, Fe, W)相熔点为1463℃, 因此在温度低于1463℃以下烧结时属于固相烧结。 反之, 当烧结温度高于此温度时, 属于液相烧结。 对于90W-7Ni-3Fe纳米晶粉末, 在1400~1450℃固相烧结时可达到近全致密, 合金具有较高的拉伸断裂强度。 但由于在固相烧结中液相的形成, W晶粒连接度高, 晶粒呈多角形, 因而合金的拉伸断裂层典型的脆性断裂, 合金的延伸率很低。 这不能充分发挥W-Ni-Fe合金延性大的特性。

图4 90W-7Ni-3Fe纳米晶粉末的DTA曲线

Fig.4 DTA curves of nanostructured 90W-7Ni-3Fe powders

为了提高钨合金的延性, 必须采用液相烧结使W晶粒呈球形。 为此, 我们对90W-7Ni-3Fe纳米晶粉末脱脂坯进行瞬时液相烧结和传统液相烧结。 研究结果表明, 对于添加了过程控制坯的烧结坯, 鼓泡现象大大减轻, 在较短的时间内, 可发生全致密化, 相对密度可接近100%; 对于未添加过程控制剂的MA粉末注射成形脱脂坯, 当烧结温度超过第二相熔点时, 即使采用短时间的瞬时液相烧结也容易发生鼓泡, 这说明添加过程控制剂能较好地控制了夹杂。

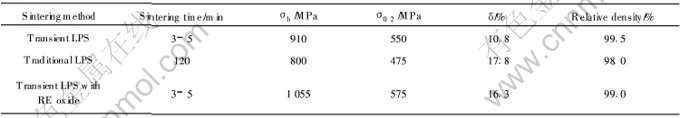

表2列出了PIM粉末脱脂胚经过瞬时液相烧结后合金的拉伸性能。 在本工艺条件下, 经过3~5min瞬时液相烧结, 合金具有很好的拉伸强度和延伸率, 延伸率为10.8%, 较好地克服了固相烧结时W晶粒连接度高和多角形W晶粒导致延伸率极低的缺点。 随保温时间的增加, 合金的拉伸强度下降, 延伸率大大增加。

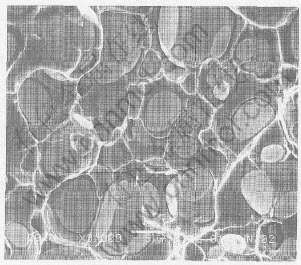

合金密度和性能的微小变化可以从显微组织的变化上得到反映。 在瞬时液相烧结时, 合金拉伸断口形貌表现为W晶粒的沿晶断裂和粘结相的延性撕裂, 出现粘结相撕裂的韧窝状。 如图5(a)所示。 在瞬时液相烧结时, 由于细晶的烧结活性大, W晶粒迅速发生球化, 合金的金相显微组织如图5(b)所示。 由图可见, 合金的显微组织由球形W晶粒和连续分布的粘结相组成, 此时W晶粒粒径一般为3~8μm, 因而合金仍保持与固相烧结时同样高的强度, 并具有较大的延性。

图5 瞬时液相烧结的显微组织

Fig.5 Tensile fracture microstructure(a) and optical microstructure(b) via transient liquid phase sintering for 3-5min

表2列出了90W-7Ni-3Fe纳米晶粉末在1480~1500℃经过120min长时间的液相烧结后的相对密度力学性能。 与瞬时液相烧结相比, 传统液相烧结后, 合金的相对密度和拉伸强度大大下降, 但延伸率仍有所提高。 相对密度下降是由于液相烧结产生的鼓泡和膨胀所致。 图6所示为液相烧结120min的合金显微组织。 从图中可以看出, 随保温时间增加, W晶粒迅速粗化, 且由于相析出与相反应[12], 产生柯肯达尔效应, 在晶界和晶内的孔隙大大增加。 晶粒粒度增大和孔隙增加是拉伸断裂强度下降的主要原因。 而且孔隙增加, 说明合金的相对密度降低, 这与致密度下降是一致的。 尽管如此, 其拉伸断口仍表现为粘结相延性撕裂程度增加, 因而在致密度较低的情况下, 合金的延伸率仍有所提高。 这可能是由于第二相粘结相在液相烧结温度下从含W量高的非稳定态γ′-(Ni, Fe, W)相向W含量较低的平衡态γ-(Ni, Fe, W)转变, 从而使粘结相呈现较好的延性撕裂。 对于传统钨合金, 当孔隙度大于1%时, 合金延伸率较差。 传统长时间液相烧结钨合金的W晶粒虽然与瞬时液相烧结钨合金的W晶粒相比大了许多, 但与传统钨合金相比, W晶粒仍然得到细化。 从图6可以看出, W晶粒一般为10~25μm, 因此长时间液相烧结后, 尽管有较大孔隙度而仍然具有大的延伸率, 这在某种程度上反映了细化晶粒的作用所在。

表2 在1480~1500℃采用瞬时液相烧结和传统液相烧结合金的相对密度和力学性能

Table 2 Relative density and mechanical properties of alloys via transient liquid phase sintering(LPS) and traditional liquid phase sintering(LPS)

图6 传统液相烧结120min的显微组织

Fig.6 Tensile fracture microstructure(a) and optical microstructure(b) via traditional liquid phase sintering for 120min

2.4 微量Y2O3对瞬时液相烧结钨合金显微组织与力学性能的影响

据资料报道[16-18], 稀土元素对高密度钨合金是一种很有用的元素, 它可以通过微合金化的方式细化钨晶粒, 降低合金中的O、 P等杂质在界面偏折, 提高合金力学性能, 尤其是稀土或稀土氧化物的添加可以大大改善钨合金在高应变剪切速率下的动态力学性能[16-18]。 由于在MA过程中即使采用了过程控制剂, 由于粉末的高活性, MA粉末的氧含量仍然较高。 为了进一步提高合金的性能, 本文作者研究了在MA过程中添加0.04%Y2O3对合金力学显微组织与性能的影响。

表2中列出了添加0.04%Y2O3的瞬时液相烧结钨合金的力学性能。 结果表明, 与未加Y2O3的钨合金相比, 添加Y2O3后合金的拉伸强度和延伸率大大增加, 它们分别为1055MPa和16.3%。 这说明添加Y2O3对起到了很好的晶界净化作用, 提高了界面结合强度。 图7所示为添加Y2O3的合金的拉伸断口形貌。 由图可见, 添加Y2O3后W晶粒略有细化, 晶粒大小变得更均匀, 拉伸断口上呈现明显的粘结相延性撕裂和W晶粒沿晶断裂。 与传统钨合金相比, W晶粒穿晶解理断裂较少, 这说明晶粒细化改变了钨合金的延性断裂方式。

图7 添加0.04%Y2O3的瞬时液相烧结钨合金的拉伸断口形貌

Fig.7 Tensile fracture microstructure of transient liquid phase sintered tungsten alloy with 0.04% Y2O3 addition

3 结论

1) 采用机械合金化的方法制备了晶粒尺寸为7.8~18.0nm的90W-7Ni-3Fe纳米晶粉末, 加入过程控制剂PCA后有效地减少了粉末的团聚和结块。 但以液体作为MA过程控制剂时, 将大幅度降低注射成形的粉末装载量, 这对注射成形不利。

2) 采用3~5min瞬时液相烧结可得到近全致密的细晶钨合金, 其显微组织由3~8μm的细小球形晶粒和连续分布的粘结相组成, 呈现典型的液相烧结特征, 烧结坯具有良好的拉伸性能和延伸性能。 采用120min的传统长时间液相烧结会使球状W晶粒迅速粗化, 孔隙率增加, 导致相对密度和拉伸强度下降, 但延伸率仍有增加。

3) 添加微量Y2O3可大幅度改善瞬时液相烧结钨合金的力学性能和显微组织。

REFERENCES

[1]Chaiat D, Gutmanas E Y, Gatman I. Effect of processing and alloying on microstructure and properties of tungsten heavy alloy[A]. Tungsten Refract Metal,1994, Proc Int Conf[C]. Princeton NJ: MPIF, 1995. 57-64.

[2]范景莲, 赵慕岳, 徐国富. 钼对钨基合金砧块性能的影响[J]. 粉末冶金技术, 1993, 11(2): 119-124.

FAN Jing-lian, ZHAO Mu-yue, XU Guo-fu, Influences of molybdenum on the properties of tungsten heavy alloy[J]. Powder Metallurgy Technology, 1993, 11(2): 119-124.

[3]German R M, Bose A, Kemp R B, et al. Additive effects on the microstructure and properties of tungsten heavy alloy composites[J]. Advances in Powder Metallurgy 1989, 1: 401-413.

[4]Kemp R B, German R M. Mechanical properties of molybdenum alloyed liquid phase sintered tungsten based composites[J]. Metall and Mater Trans A 1995, 25A: 2187-2189.

[5]Hogwood M C. The development of high strength and toughness fibrous microstructures in tungsten-nickel-iron alloys for kinetic energy penetrator application[A]. Tungsten Refract Metal, 1994, Proc Int Conf[C]. Princeton, NJ: MPIF, 1995. 37-45.

[6]Bentley A R. Microstructural aspects of highly deformed tungsten heavy alloys[J]. Tungsten Refract Metal, 1994, Proc Int Conf[C]. Princeton, NJ: MPIF, 1995. 145-155.

[7]Kim D K, Lee S, Ryu H J, et al. Correlation of microstructure with dynamic deformation behavior and penetration performance of tungsten heavy alloys fabricated by mechanical alloying[J]. Metall and Mater Trans A, 2000, 31A: 2475-2489.

[8]Soon S H, Ryu H J. Combination of mechanical alloying and two-stage sintering of a 93W-5.6Ni-1.4Fe tungsten heavy alloy[J]. Materials Science and Engineering A, 2003, 344: 253-260.

[9]FAN Jing-lian, HUANG Bai-yun, QU Xuan-hui. W-Ni-Fe nanostructured materials synthesized by high energy ball milling[J]. Trans Nonferrous Met Soc China, 2000, 10(1): 57-59.

[10]范景莲, 曲选辉, 李益民, 等. 高比重合金的固相烧结[J]. 中国有色金属学报, 1999, 9(2): 327-329.

FAN Jing-lian, QU Xuan-hui, LI Yi-min, et al. Solid state sintering of tungsten heavy alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(2): 327-329.

[11]范景莲, 黄伯云, 张传福, 等. 机械合金化纳米钨合金粉末在常压烧结下致密化与晶粒长大[J]. 中南工业大学学报, 2001, 32(4): 390-394.

FAN Jing-lian, HUANG Bai-yun, ZHANG Chuan-fu, et al. Densification and grain growth of the MA nano-crystalline tungsten alloy powder under constant pressure[J]. Journal of Central South University of Technology, 2001, 32(4): 390-394.

[12]Ryu H J, Hong S H, Back W H. Mechanical alloying process of 93W-5.6Ni-1.4Fe tungsten heavy alloy[J]. Journal of Materials Processing Technology, 1997, 63: 792-297.

[13]范景莲, 黄伯云, 曲选辉, 等. 注射成形钨合金用新型粘结剂的研究[J]. 粉末冶金技术, 2003, 21(3): 132-135.

FAN Jing-lian, HUANG Bai-yun, QU Xuan-hui, et al, Study on the new binder for injection molding tungsten heavy alloy[J]. Powder Metallurgy Technology, 2003, 21(3): 132-135.

[14]范景莲, 黄伯云, 曲选辉. 无变形高性能薄壁大散弹的制备方法[P]. CN011010657. 2002.

FAN Jing-lian, HUANG Bai-yun, QU Xuan-hui. Preparing Method of a Thin Wall Tungsten Ring Penetrator with High Properties and Without Distortion[P]. CN011010657. 2002.

[15]Fan J L, Huang B Y, Qu X H, et al. Thermal stability, grain growth and structure changes of mechanically alloyed W-Ni-Fe composite during annealing[J]. Inter J Refra Metal Hard Mater, 2001, 19: 73-77.

[16]Park S, Kim D K, Lee S, et al. Dynamic deformation behavior of an Oxide-dispersed tungsten heavy alloy fabricated by mechanical alloying[J]. Metal & Mater, Trans A, 2001, 32A(8): 2011-2020.

[17]Ryu H J, Hong S H. Fabrication and properties of mechanically alloyed oxide-dispersed tungsten heavy alloys[J]. Mater Sci & Eng A, 2003, A363, 179-184.

[18]冯庆芬, 丁华东, 方民宪. La, Ce对93W-Ni-Fe 合金动态拉伸性能的影响[J]. 兵器材料科学与工程, 2003, 26(3): 7-10.

FENG Qin-fen, DING Hua-dong, FANG Min-xian. Influences of La, Ce on the dynamic properties of 93W-Ni-Fe[J]. Ordnance Material Science and Engineering, 2003, 26(3): 7-10.

基金项目: 国家863国际合作基金资助项目; 国家863军工计划资助项目(2002AA305503); 湖南省纳米材料工程技术联合研究中心资助项目(01JZY2057)

收稿日期: 2004-07-15; 修订日期: 2004-11-30

作者简介: 范景莲(1967-), 女, 教授, 博士.

通讯作者: 范景莲, 教授; 电话: 0731-8836652, 8877651; 传真: 0731-8877651; E-mail: fjl@mail.csu.edu.cn

(编辑何学锋)