DOI:10.19476/j.ysxb.1004.0609.2019.11.03

Al-Cu-Mg-Si系铝合金的注射成形

杜智渊1,吴 茂1, 2, 3,邱婷婷1,曲选辉1, 2, 3

(1. 北京科技大学 新材料技术研究院, 北京 100083;

2. 北京科技大学 现代交通金属材料与加工技术北京实验室, 北京 100083;

3. 北京科技大学 先进粉末冶金材料与技术北京市重点实验室, 北京 100083)

摘 要:以纯Al粉为主要原料,添加Al-Mg、Al-Si合金粉和Cu、Sn元素粉,采用注射成形(MIM)工艺制备Al-Cu-Mg-Si系铝合金材料,研究了烧结过程中合金的微观组织演变及致密化机理,并与传统的压制-烧结粉末冶金(PM)工艺进行了对比。结果表明:PM和MIM铝合金的致密化过程均经历3个阶段,毛细管力主导的颗粒重排过程、溶解-再析出机制控制的晶界平直化过程以及晶粒长大引起的孔隙填充过程,但MIM铝合金的致密化过程明显滞后于PM铝合金;铝粉表面氧化膜破除后,氧元素主要存在于MgAl2O4、Al2SiO5以及无定形的Al-Si-Cu-O等化合物中,氧的存在形式与局部合金成分有关;添加少量合金元素Sn可降低合金液相的表面张力,显著促进烧结体致密度,但Sn含量较高时会对MIM铝合金力学性能产生不利影响。当Sn含量为0.5%(质量分数)时,MIM铝合金的致密度高于98%,固溶处理后抗拉强度可达到350 MPa。

关键词:铝合金;注射成形;液相烧结;微观组织演变;力学性能

文章编号:1004-0609(2019)-11-2471-10 中图分类号:TF124 文献标志码:A

铝合金具有密度低、比强度高、塑性好、导电性和导热性优良等优异性能,广泛应用于航空航天、电力电子、建筑等工业领域[1-5]。近年来,随着汽车轻量化、可穿戴电子产品的发展,对小型复杂形状铝合金零部件的需求日益增加[6-7]。相比机械加工、铸造等工艺,采用粉末冶金(PM)工艺可实现铝合金零部件的大批量、低成本以及近终形制备。目前,PM铝合金制品在汽车、办公设备、家电、照相器材和电子设备中获得了广泛应用,但是传统粉末冶金的压制成形工艺由于受模具的限制在制备复杂形状零件方面存在较大局限性,因此,限制了粉末冶金铝合金零部件更广泛地应用[8]。

金属粉末注射成形(MIM)是一种适合小型复杂形状零部件大批量生产的近净成形工艺。目前关于注射成形铝合金的研究较少,日本学者KATOU等[9]使用纯Al粉在650 ℃的真空环境烧结2 h,对比发现试样致密度和力学性能与Al粉粒径有关,Al粉粒径为3 μm时可获得致密度为96%,抗拉强度和伸长率分别为120 MPa和19%的合金材料。ACAR等[10]使用中粒径D50为7.35 μm的纯铝粉,在接近熔点的烧结温度下,所制备样品致密度为96%,微观组织中尚存在较多孔洞。LIU等[11]采用预合金粉AA6061(Al+0.95Mg+ 0.65Si+0.27Cu,质量分数,%)为原料,通过添加Sn元素以促进烧结,研究发现合金致密度随着Sn的增加而提高,最终在2%Sn(质量分数)时获得了致密度为97%的烧结坯,人工时效后抗拉强度为300 MPa。因此,目前采用合金粉末为原料的MIM铝合金可获得较高的致密度和力学性能,但其原料粉末成本较高,而采用纯Al粉为原料所制备的MIM铝合金致密度和力学性能普遍不高,主要原因是铝粉表面存在着致密的氧化膜,阻碍了烧结过程中粉末间原子的扩散和致密化过程,难以达到较高的致密度。

KONDOH等[12]和SCHAFFER等[13]研究表明,Mg元素可以与氧化膜反应生成尖晶石结构的化合物MgAl2O4,从而破除氧化膜。Cu和Si元素可以与Al形成共晶液相,填充孔隙实现致密化[14]。Sn等微量合金元素可降低合金液相的表面张力,改善体系的润湿性和促进液相的填充[15-18]。此外,烧结气氛对粉末冶金铝合金的致密化过程有重要影响,在N2气氛下烧结有利于获得较高的致密度,研究认为这主要是由于N2与Al发生反应形成AlN,消耗了孔隙内的N2,更有利于液相填隙的过程[17, 19-20]。

传统的PM工艺制备铝合金时,生坯中一般含有少量的润滑剂(低于2%),而MIM工艺中生坯含有30%~40%的粘结剂。脱除粘结剂后,注射成形坯体内部的孔隙率要远大于压制坯体,颗粒间接触少,原子扩散及烧结致密化更为困难。因此,深入研究MIM铝合金的致密化过程对生产高致密度、高性能的铝合金零部件具有重要的意义。

本文采用纯Al粉为主要原料,添加Cu、Si和Sn等合金元素,采用MIM工艺制备了铝合金材料,重点研究MIM铝合金氧化膜破除机制、微观组织演变和致密化机理,并与PM工艺进行对比。同时,研究了合金元素Sn对MIM铝合金微观组织、力学性能和失效模式的影响规律。

1 实验

本实验以Al(D50=26.65 μm)、Cu(D50=28.02 μm)、Sn(D50=2.65 μm)单质粉和Al-50Mg(D50=36.87 μm)、Al-12Si(D50=20.04 μm)中间合金粉为原料(各粉末形貌如图1所示),按质量比(下同)配制AlCuMgSi-xSn (其中,Mg 1.0%~2.0%,Si 0.5%~1.5%,Cu 3.5%~5.0%,x=0,0.2%,0.5%,1%,2%,质量分数)粉末,在混料机中混合均匀。MIM铝合金选用的粘结剂为蜡基粘结剂,配比为60%石蜡(PW)+35%聚丙烯(PP)+5%硬脂酸(SA)(质量分数),粉末装载量为62%(体积分数)。将粘结剂和混合粉依次放入混炼机,经过170 ℃混炼2 h后取出,冷却破碎后得到喂料。喂料在CJ80-E型注射机上注射得到生坯。将生坯置于正庚烷溶剂中40 ℃恒温溶剂脱脂10 h后取出烘干,得到MIM铝合金生坯。然后将生坯放置在管式炉中进行热脱脂-烧结,具体过程为:从室温以2 ℃/min升温至150 ℃,保温30 min;其次分别升温至250 ℃、350 ℃和460 ℃,均保温120 min,升温速率为0.5 ℃/min。最后以2 ℃/min升温至560 ℃和600 ℃,保温一定时间后炉冷或进行淬火。烧结过程采用高纯氮气为保护气氛,气流量1 L/min。

PM铝合金的成分和混料方式与MIM铝合金相同,利用HAD-400KN液压机将混合粉压制成直径30 mm×3 mm的生坯,所采用压力为200~300 MPa,保压时间5 min。本实验在粉末中并未添加润滑剂,而是在模具表面涂抹硬脂酸等以辅助脱模。PM铝合金烧结制度为:以2 ℃/min的速率从室温升至460 ℃、560 ℃和600 ℃,分别保温30 min、30 min和60 min,最后通过炉冷或淬火降至室温。

图1 原料粉的SEM像

Fig. 1 SEM images of raw material powders

采用LMS-30型激光粒度分析仪分析粉末的粒度和粒度分布,采用排水法测量合金烧结密度。按照GB/T 228.1—2010拉伸试验依据测定材料拉伸性能。本实验采用TEO1450型钨灯丝扫描电镜(SEM)观察粉末形貌和烧结样品的微观组织与断口形貌,采用日立JEOL-1230型透射电镜(TEM-SAED)观察样品中的物相。

2 结果与讨论

2.1 MIM与PM铝合金致密化过程对比研究

由铝合金二元相图可知,Mg、Cu和Si分别在 450、550和577 ℃左右与Al发生共晶反应,形成共晶液相。故本文选择稍高于各共晶液相形成温度,分别研究在460、560和600 ℃烧结时铝合金的微观组织演变。图2(a)所示为PM铝合金460 ℃保温30 min淬火的微观组织。可以看出,Al颗粒周围已产生少量白色液相,EDS显示液相中主要包含Al、Sn和Mg元素。此时,Al-Mg已通过共晶反应生成液相,而Mg在Al中的扩散系数为4.7×10-14 m2/s,因此,Mg原子可快速扩散到Al颗粒表面并与氧化膜反应,从而破除氧化膜[12-13]。同时,发现坯体中存在灰黑相间的网状组织(见图2(b)),EDS结果显示,晶内点状黑色相主要由Al-Mg-Si中3种元素组成,而晶界处连续的黑色相主要由Al-Mg-Si-O中4种元素组成,其中O含量约为20%(摩尔分数)。说明在460 ℃保温30 min的过程中,Mg元素也向Al-12Si颗粒的扩散,并形成含氧的化合物。由于Sn熔点只有231 ℃,表面张力较低,且其在Al中固溶度不足0.15%(质量分数),当Mg元素破除铝粉表面的氧化膜之后,熔化后的Sn铺展在部分Al颗粒之间的缝隙以降低表面能。但Sn形成的液相相对较少,所以图2(a)中部分Al颗粒已通过固相扩散烧结在一起。图2(c)所示为Al和Cu界面处的微观组织。在450 ℃时,Al、Cu之间互扩散系数分别为6.5× 10-19和1.1×10-14 m2/s[14]。因此,在此温度下,Al-Cu颗粒之间已发生扩散现象,并在颗粒边界形成Al-Cu互扩散区。

图3所示为PM和MIM两种工艺制备的铝合金在560 ℃分别保温0和30 min后淬火的微观组织。由图3(a)和(b)可以看出,刚升温至560 ℃时,PM合金中白色液相有所增加,并在毛细管力的作用下填充铝粉间的缝隙,晶界处仍存在一些图3(a)箭头所示的黑色相及较多的孔隙。图2(b)中晶内点状的黑色Al-Mg-Si相及原始的Cu颗粒已完全消失。在560 ℃保温30 min后,晶界黑色相消失,液相量明显增加,并大量填充铝粉间的缝隙,仅在三角晶界出留下一些小的孔洞。同时可以发现,PM铝合金中部分晶界出现明显的平直化特征,坯体中某些较大尺寸的孔隙已基本得到填充。

图2 PM铝合金460 ℃保温30 min淬火的微观组织

Fig. 2 Microstructures of quenched PM alloys after sintering at 460 ℃ for 30 min

研究表明,当温度升至550 ℃时,合金组织中Al与Cu首先发生互扩散形成Al2Cu,并发生共晶反应形成Al-Al2Cu液相,因此,原始的Cu颗粒逐渐消失。图4所示为图3(a)中晶界处黑色相的放大SEM像及能谱图。EDS显示,黑色相中包含Al、Mg、Si 3种元素,部分区域O含量较高,从组织特征和成分检测判断,黑色相是由图2(b)的灰黑相间的网格状组织演变而来。在560 ℃保温后,黑色相消失,可能是发生了Al+Mg2Si+Si→L的共晶反应,因此,原始的Al-Si颗粒也全部转变为液相[14]。所以,在本体系中,在550~ 560 ℃温度区间内会产生大量的液相,并快速填充铝合金中的缝隙。

图3(c)和(d)所示分别为MIM铝合金在560 ℃保温0 min和30 min淬火后的微观组织。可以看出,刚升温至560 ℃时,MIM铝合金组织结构仍较为松散,Al颗粒保持原始形貌,颗粒间接触少,只有极少数Al颗粒由液相连接,几乎没有固相烧结的现象。保温30 min后,组织中液相量明显增加,颗粒边界已经由液相大量填充。相比PM铝合金,晶界平直化不明显,组织中尚存在较多尺寸较大的孔洞。

图3 PM和MIM工艺制备的铝合金在560 ℃保温不同时间淬火的微观组织

Fig. 3 Microstructures of quenched PM and MIM alloys after being sintered at 560 ℃ for different time

图4 PM铝合金晶界区域的微观组织及能谱图

Fig. 4 Microstructure of grain boundary(a) and its EDS spectra of PM aluminum alloy((b1), (b2))

已有研究表明,铝合金的液相烧结致密化过程主要经历3个阶段:烧结前期为毛细管力主导的颗粒重排过程、烧结中期发生溶解-再析机制控制的晶界平直化过程以及烧结末期由晶粒长大引起的孔隙填充过程[17, 19, 21]。

在烧结初始阶段,对于MIM铝合金,在升温至560 ℃时颗粒间接触仍然较少,结构较为松散,Al-Cu、Al-Si等液相在Al颗粒表面发生润湿,并包裹部分铝颗粒表面,该润湿体系属于非反应性润湿,其润湿驱动力可由Young方程表示:

(1)

(1)

式中: 、

、 、

、 分别为液-气、固-气、液-固表面能;

分别为液-气、固-气、液-固表面能; 为t时刻的润湿角。此时润湿的动力学是通过液滴的润湿半径R(t)随时间t的变化规律进行表征,即dR(t)/dt,润湿半径与润湿时间呈指数关系R(t)n~t,n的取值范围为5~10[22]。而对于PM铝合金,铝粉会在压制压力作用下产生变形并紧密结合在一起,仅在颗粒边界存在极细的缝隙,或在三角晶界存在小孔隙,因此液相在润湿过程中的驱动力为毛细管力,其润湿动力学可由Washburn公式表示,即润湿距离x与时间t满足指数关系x2~t[23]。因此,MIM铝合金的润湿速率远低于PM铝合金中毛细管力驱动的润湿。当温度刚达到560 ℃时,PM铝合金已经在毛细管力的作用下,发生明显的颗粒重排过程;而MIM铝合金中,颗粒间搭接较少,液相对颗粒的重排作用不明显。

为t时刻的润湿角。此时润湿的动力学是通过液滴的润湿半径R(t)随时间t的变化规律进行表征,即dR(t)/dt,润湿半径与润湿时间呈指数关系R(t)n~t,n的取值范围为5~10[22]。而对于PM铝合金,铝粉会在压制压力作用下产生变形并紧密结合在一起,仅在颗粒边界存在极细的缝隙,或在三角晶界存在小孔隙,因此液相在润湿过程中的驱动力为毛细管力,其润湿动力学可由Washburn公式表示,即润湿距离x与时间t满足指数关系x2~t[23]。因此,MIM铝合金的润湿速率远低于PM铝合金中毛细管力驱动的润湿。当温度刚达到560 ℃时,PM铝合金已经在毛细管力的作用下,发生明显的颗粒重排过程;而MIM铝合金中,颗粒间搭接较少,液相对颗粒的重排作用不明显。

保温30 min后,控制颗粒重排过程的毛细作用逐渐减小,烧结过程进入溶解-再析出控制的晶界平直化阶段,这个阶段主要受烧结应力σ控制,其公式为

(2)

(2)

式中: 为毛细管力;

为毛细管力; 为液相的表面张力;

为液相的表面张力;  为孔隙半径;

为孔隙半径; 为孔隙内气体与烧结气氛的压力 差[17]。可以看出,由于成形工艺的差异,MIM合金中孔隙半径

为孔隙内气体与烧结气氛的压力 差[17]。可以看出,由于成形工艺的差异,MIM合金中孔隙半径 明显大于PM铝合金的孔隙半径

明显大于PM铝合金的孔隙半径 。同时,PM铝合金中,闭孔隙内气压小于烧结气氛压力,

。同时,PM铝合金中,闭孔隙内气压小于烧结气氛压力, 为负;而MIM合金中,由于存在较多的连通孔隙,孔隙气压与烧结气氛压力相近,

为负;而MIM合金中,由于存在较多的连通孔隙,孔隙气压与烧结气氛压力相近, 约为0。由式(2)可知,PM铝合金中的烧结应力σ明显高于MIM铝合金的。在烧结应力作用下,通过溶解-再析出过程,晶界发生平直化,颗粒间孔隙得到填充,组织逐渐致密,但MIM合金的致密化过程明显滞后于PM合金的,组织中晶界平直化现象不明显,尚存在较多大尺寸孔隙。

约为0。由式(2)可知,PM铝合金中的烧结应力σ明显高于MIM铝合金的。在烧结应力作用下,通过溶解-再析出过程,晶界发生平直化,颗粒间孔隙得到填充,组织逐渐致密,但MIM合金的致密化过程明显滞后于PM合金的,组织中晶界平直化现象不明显,尚存在较多大尺寸孔隙。

图5所示为PM铝合金和MIM铝合金升温至600 ℃保温60 min淬火的SEM像。可以看出,PM铝合金晶粒发生明显长大,液相主要位于原来大尺寸孔隙处,坯体已接近全致密。而MIM铝合金中仅有少数晶粒明显长大,液相已经填充大部分孔隙,还剩下一些较小的孔洞。本阶段处于烧结末期,铝合金的致密化过程主要由晶粒长大引导的孔隙填充控制。根据孔隙填充机制,随着烧结温度的升高和时间延长,晶粒逐渐长大,孔隙处液体的弯月面半径逐渐大于孔隙半径,造成孔隙内外压力失衡,使共晶液相不断流入孔隙中,从而填充残余孔隙[19]。此外,研究表明在560~600 ℃时,Al-Al2Cu共晶液相可以润湿氧化膜[24]。因此随着烧结温度升高,晶粒长大的同时,体系的润湿性得到进一步改善,更有利于残余孔隙的填充。此外,由图5(a)和(b)还可以看出,晶粒内部会存在白色球状相,这是由于部分合金元素扩散至晶内,并在淬火时的急冷条件下发生球化,生成复熔球。

由上述研究可以看出,对于MIM和PM铝合金,两者烧结致密化过程在两个方面是相同的。首先,物相转变过程相同,在烧结过程中二者物相的演变过程是一致的;其次,烧结致密化机制是相同的,两者均经历液相润湿后的颗粒重排、烧结应力作用下的溶解-再析出以及晶粒长大引起的孔隙填充3个过程。

图5 PM和MIM铝合金在600 ℃保温60 min淬火的微观组织

Fig. 5 Microstructures of quenched PM and MIM aluminum alloys after being sintered at 600 ℃ for 60 min

两者不同的地方在于,MIM铝合金的液相烧结过程明显滞后于PM铝合金的。这是由以下两个方面造成的。首先,在第一阶段,MIM铝合金生坯中大量的粘结剂脱除后,铝粉颗粒间距大,接触少,在液相生成的初期,MIM铝合金中液相润湿主要受表面张力控制,其润湿速率远低于PM铝合金中液相在毛细管力作用下的润湿。当MIM铝合金的致密度达到一定程度时,润湿驱动力逐渐由表面张力驱动转变为毛细管力驱动。其次,PM铝合金烧结应力大于MIM铝合金。由于PM和MIM铝合金生坯的致密度存在巨大差异,当MIM铝合金粘结剂脱除后,铝粉处于松散状态,颗粒间接触少,导致MIM和PM铝合金孔隙半径rp和内外压差△pgas的不同,根据式(2),PM铝合金比MIM铝合金具有更高的烧结应力σ,因此,PM铝合金比MIM铝合金更加致密,组织中晶界平直化特征更突出,且晶粒发生较为明显的长大。

2.2 氧化膜的破除机制研究

铝粉表面氧化膜的破除是实现PM铝合金致密烧结的前提。目前,一般认为Mg元素可以与铝粉表面的氧化膜反应生成MgAl2O4化合物,从而达到破除氧化膜,但YAN等[25]在Al-Mg-Si-Cu合金的晶界处发现了Al-Si-O化合物,推测Si也可能有破除氧化膜的作用。本文利用TEM-SAED技术,对MIM铝合金的不同晶界区域的物相进行分析研究。图6(a)所示为晶界处黑色相的TEM图及选区衍射光斑,发现其空间点群为Fd3m,点阵常数为a=b=c=0.8083 nm,确定为MgAl2O4化合物。图6(b)所示为其它晶界区域的TEM像,此处存在较多密集分布的黑色颗粒相,该相属于正交晶系,点阵常数为a=0.7553 nm,b=0.8273 nm,c=0.5660 nm,确定为Al2SiO5。同时,发现黑色颗粒相周围是无定形的Al-Si-Cu-O相。上述各相的能谱分析结果如表1所示。因此,在本研究的合金体系中,氧元素主要存在于MgAl2O4、Al2SiO5以及无定形的Al-Si-Cu-O 3种化合物中。可以看出,在不同区域,氧元素以不同的化合物形式存在,推测铝粉表面氧化膜的破除机制是由局部合金成分所决定的。

2.3 烧结制度及Sn含量对MIM铝合金微观组织和力学性能的影响

已有研究结果表明,烧结制度及微量合金元素(如Sn、Pb和Bi等)对PM铝合金的烧结致密化过程具有很大影响,但关于二者对MIM铝合金的影响研究很少。图7(a)所示为烧结温度(570~630 ℃)对不同Sn含量的AlCuMgSi合金致密度的影响,其中Sn含量分别为0、0.2%、0.5%、1%、2%(质量分数,下同)。由图7(a)可见,烧结温度低于600 ℃时,各成分合金的致密度均随着烧结温度的升高而提高,烧结温度在600~620 ℃内时,各成分合金烧结致密度不再发生明显变化。当烧结温度达到630 ℃时,致密度开始出现下降趋势,试样表面呈现熔融迹象。由图7(a)还可看出,合金中未添加Sn时,温度对致密度的影响较大,致密度最高约为95%;添加0.2%~0.5% Sn后,在烧结致密化初期(570~590 ℃)致密度迅速提升;当Sn含量高于0.5%时,Sn含量的增加和温度的提高对致密度的影响较小,烧结温度在600~620 ℃的区间内,含有Sn元素的铝合金的致密度达到98%以上。图7(b)所示为Sn含量0.5%的试样在600 ℃烧结时致密度随烧结时间的变化曲线。可以看出,随着保温时间的延长,坯体致密度逐渐从95%升至98%以上;当保温时间超过60 min后,合金致密度不再发生明显变化。

图6 AlCuMgSi合金晶界物相的TEM像及SAED谱

Fig. 6 TEM images and SAED patterns of grain boundary phases in AlCuMgSi alloy

表1 MIM工艺制备的AlCuMgSi合金中各晶界相成分

Table 1 Composition of grain boundary phases of AlCuMgSi alloy produced by MIM techniques

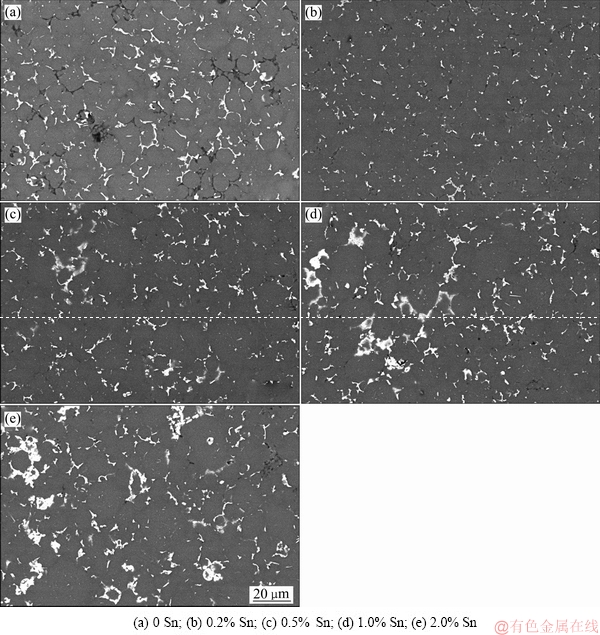

图8所示为采用MIM工艺制备的不同Sn含量的AlCuMgSi合金微观组织。对比发现,Sn含量对合金的微观组织有较大影响。未添加Sn元素时,组织中存在较多连续粗大的孔隙,液相填充不充分,组织结构松散。加入少量Sn(0.2%~0.5%)后,白色相均匀的分布在晶界,孔隙填充状况变好,组织明显致密,晶界只有极少量的微孔。进一步增加Sn元素至1%~2%时,组织较为致密,但随着Sn含量的增大,晶界处的白色相明显增加,偏聚现象严重,EDS显示这些偏聚处存在较多的Sn元素。

图7 烧结制度和Sn含量对AlCuMgSi合金致密度的影响

Fig. 7 Effect of sintering schedule and Sn content on relative density of AlCuMgSi alloys

图8 600 ℃烧结温度下不同Sn含量AlCuMgSi合金的烧结组织

Fig. 8 Microstructures of AlCuMgSi alloy with different Sn sintering at 600 ℃

研究表明,液态Sn和铝的表面张力分别为468 mN/m和914 mN/m,因此,Sn可以显著降低铝合金液相的表面张力,同时Sn熔化后也可增加体系的液相量。通过Thermo-Calc软件模拟计算可知,未添加Sn时,本体系合金中液相摩尔体积分数约为30%,添加0.2% Sn后液相摩尔体积分数约为31%。虽然添加少量Sn并没有明显提高体系的液相量,但坯体的致密度却明显提高。因此,添加少量Sn时,使坯体致密度显著增加的原因是Sn降低了Al-Cu和Al-Si等合金液相的表面张力,从而使液相迅速填充孔隙[15-18]。添加2.0% Sn后,液相摩尔体积分数虽高达38%,但对致密度没有明显的提升。由于Sn在Al中固溶度极低,因此过多的Sn会偏聚在晶界处。

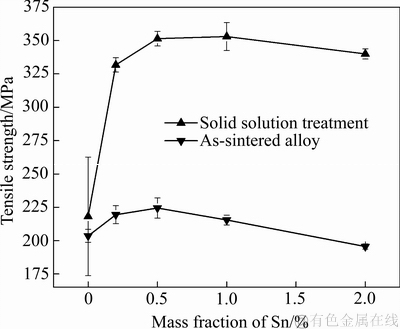

图9所示为合金在烧结态(600 ℃烧结60 min)和固溶处理后(505 ℃保温120 min后水淬)的拉抗拉强度随Sn含量的变化情况。固溶处理使Cu、Mg等合金元素溶于基体Al中形成过饱和固溶体,产生固溶强化。相比烧结态,固溶处理后合金的抗拉强度提高。由图9可以看出,在室温条件下,烧结态和固溶态合金的抗拉强度均随着Sn含量的增加呈现先增加后降低的趋势,当Sn含量为0.5%时,烧结态和固溶态合金抗拉强度均达到最高,分别为224 MPa和351 MPa。值得注意的是,相比其他成分的合金,未添加Sn时,固溶处理后合金的抗拉强度没有明显提升。

图9 Sn含量和固溶处理对AlCuMgSi合金抗拉强度影响

Fig. 9 Effect of Sn content and solid solution treatment on tensile strength of AlCuMgSi alloys

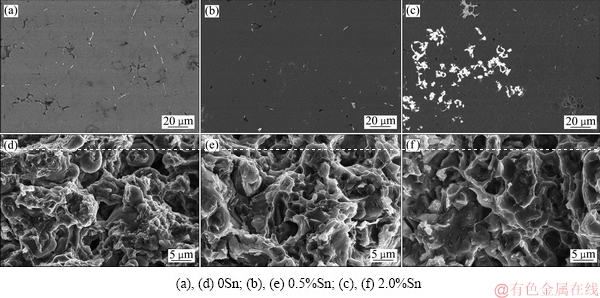

图10 不同Sn含量AlCuMgSi合金的固溶组织及固溶后的断口形貌

Fig. 10 Microstructures((a), (b), (c)) and fracture morphologies((d), (e), (f)) of AlCuMgSi alloy with different Sn contents after solid solution treatment

图10所示为不同Sn含量的合金固溶处理后的微观组织及断口形貌。其中图10(a)、(b)和(c)分别为Sn含量为0、0.5%和2%的合金固溶处理后的微观组织,图10(d)、(e)和(f)所示分别为3种成分对应的拉伸断口形貌。未添加Sn时(见图10(a)),合金的固溶组织中存在明显的孔隙,这是由于其原始的烧结态组织中孔隙填充不充分,经固溶处理后,晶界合金元素已基本扩散至基体,使孔隙更加明显。在其断口(见图10(d))中可以看出明显的孔洞及部分较为完整的晶粒,这是因为较多大孔隙的存在导致晶间结合力降低,固溶处理后,合金抗拉强度没有得到较大提升。当合金中添加0.5%Sn后(见图10(b)),由于烧结体致密度较高,因此固溶组织中只残留一些小的孔洞,其拉伸断口中出现了较多韧窝,说明晶界颗粒间结合力增强,抗拉强度提高。当Sn含量为2.0%时(见图10(c)),烧结体晶界处富集大量的Sn未能固溶在Al基体中,其断口中出现了较多的凹坑,EDS显示孔内往往包含较多的Sn元素(见图10(f))。这些凹坑是由于Al-Sn结合力较弱,在拉应力作用下将晶粒拔出所致。因此,图9中当Sn含量高于1.0%时,合金的抗拉强度降低。综上所述,Sn含量对MIM铝合金的致密度和力学性能有很大影响,当Sn含量较低时(<0.5%),可显著提高坯体的致密度和力学性能,但过高的Sn含量会导致铝合金力学性能降低。

3 结论

1) 合金元素对粉末冶金铝合金的致密化烧结具有重要作用,在Al-Cu-Mg-Si铝合金烧结过程中,Al-Mg首先形成共晶液相,Mg原子通过扩散与Al粉表面氧化膜反应,从而破除氧化膜,Cu和Si为主要的液相形成元素;微量合金元素Sn的添加可降低合金液相的表面张力,显著提高合金致密度。

2) PM和MIM铝合金的致密化过程均经历3个致密化阶段:烧结前期为毛细管力主导的颗粒重排过程,烧结中期发生溶解-再析机制控制的晶界平直化过程,以及烧结末期由晶粒长大引起的孔隙填充过程,但MIM铝合金的致密化过程明显滞后于PM铝合金的。

3) 铝粉表面的氧化膜破除后,氧元素主要存在于MgAl2O4、Al2SiO5以及无定形的Al-Si-Cu-O等化合物中,氧的存在形式与局部合金成分有关。

4) 合金元素Sn的含量对MIM铝合金的微观组织和性能具有重要影响。少量Sn的添加有效促进了合金的烧结致密化,当Sn含量低于0.5%时,合金致密度随着Sn的增加而提高,力学性能也随之提高;当Sn含量进一步增加时,致密度没有发生明显变化,但过量Sn的添加明显恶化了合金的力学性能。当Sn含量为0.5%时,合金致密度和抗拉强度均达到最高,烧结致密度高于98%,抗拉强度为224 MPa,固溶处理后抗拉强度可达到350 MPa。

REFERENCES

[1] SCHAFFER G B, SERCOMBE T B, LUMLEY R N. Liquid phase sintering of aluminium alloys[J]. Materials Chemistry and Physics, 2001, 67(1/3): 85-91.

[2] BISHOP D P, CAHOON J R, CHATURVEDI M C, KIPOUROS G J, CALEY W F. On enhancing the mechanical properties of aluminum P/M alloys[J]. Materials Science and Engineering A, 2000, 290(1/2): 16-24.

[3] BOLAND C D,HEXEMER JR R L,DONALDSON I W,BISHOP D P. Industrial processing of a novel Al-Cu-Mg powder metallurgy alloy[J]. Materials Science and Engineering A, 2013, 559(1): 902-908.

[4] LAVERNIA E J, AYERS J D, SRIVATSAN T S. Rapid solidification processing with specific application to aluminum alloys[J]. International Materials Reviews, 1991, 37(1): 1-44.

[5] IBRAHIM I A, MOHAMED F A, LAVERNIA E J. Particulate reinforced metal matrix composites-a review[J]. Journal of Materials Science, 1991, 26(5): 1137-1156.

[6] SRIVATSAN T S, IBRAHIM I A, MOHAMED F A, LAVERNIA E J. Processing techniques for particulate- reinforced metal aluminium matrix composites[J]. Journal of Materials Science, 1991, 26(22): 5965-5978.

[7] LLOYD D J. Particle reinforced aluminum and magnesium matrix composites[J]. International Materials Reviews, 1994, 39(1): 1-23.

[8] MA J D, QIN M L, ZHANG L, TIAN L S, LI R, CHEN P Q, QU X H. Effect of ball milling on the rheology and particle characteristics of Fe-50%Ni powder injection molding feedstock[J]. Journal of Alloys and Compounds, 2014, 590: 41-45

[9] KATOU K, MSTSUMOTO A. Appication of metal injection moulding of Al powder[J]. Journal of the Japan Society of Powder and Powder Metallurgy, 2016, 63(7): 468-471.

[10] ACAR L, GULSOY H O. Sintering parameters and mechanical properties of injection moulded aluminium powder[J]. Powder Metallurgy, 2011, 54(3): 427-431.

[11] LIU Z Y, SERCOMBE T B, SCHAFFER G B. Metal injection moulding of aluminium alloy 6061 with tin[J]. Powder Metallurgy, 2008, 51(1): 78-83.

[12] KONDOH K, KIMURA A, WATANABE R. Effect of Mg on sintering phenomenon of aluminium alloy powder particle[J]. Powder Metallurgy, 2001, 44(2): 161-164.

[13] LUMLEY R N, SERCOMBE T B, SCHAFFER G B. Surface oxide and the role of magnesium during the sintering of aluminum[J]. Metallurgical and Materials Transactions A, 1999, 30: 458-163.

[14] CROSSIN E, YAO J Y, SCHAFFER G B. Swelling during liquid phase sintering of Al-Mg-Si-Cu alloys[J]. Powder Metallurgy, 2013, 50(4): 354.

[15] SERCOMBE T B, SCHAFFER G B. The effect of trace elements on the sintering of Al-Cu alloys[J]. Acta Materialia, 1999, 47(2): 689-697.

[16] SERCOMBE T B, SCHAFFER G B. On the role of tin in the nitridation of aluminium powder[J]. Scripta Materialia, 2006, 55 (4): 323-326.

[17] SCHAFFER G B, YAO J Y, BONNER S J, CROSSIN E, PAS S J, HILL A J. The effect of tin and nitrogen on liquid phase sintering of Al-Cu-Mg-Si alloys[J]. Acta Materialia, 2008, 56(11): 2615-2624

[18] SERCOMBE T B, SCHAFFER G B. On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys[J]. Materials Science and Engineering A, 1999, 268(1/2): 32-39.

[19] SCHAFFER G B, HALL B J, BONER S J. The effect of the atmosphere and the role of pore filling on the sintering of aluminum[J]. Acta Materialia, 2006, 54: 131-138.

[20] SCHAFFER G B, HALL B J. The influence of the atmosphere on the sintering of aluminum[J]. Metallurgical & Materials Transactions A, 2002, 33(10): 3279.

[21] MARTIN J M, GOMEZ-ACEBO T, CASTRO F. Sintering behaviour and mechanical properties of Al-Cu-Mg-Si-Sn aluminum alloy[J]. Powder Metallurgy, 2002, 45(2): 173-180.

[22] WU M, CHANG L L, ZHANG L, HE X B, QU X H. Effects of roughness on the wettability of high temperature wetting system[J]. Surface and Coatings Technology, 2016, 287: 145.

[23] YANG D, KRASOWSKA M, PRIEST C, POPESCU M N, RALSTON J. Dynamics of capillary-driven flow in open microchannels[J]. The Journal of Physical Chemistry C, 2011, 115(38): 18761.

[24] KEHL W, FISCHMEISTER H F. Liquid phase sintering of Al-Cu compacts[J]. Powder Metallurgy, 1980, 23(3): 113.

[25] YAN M, YU P, SCHAFFER G B, MA Q. Secondary phases and interfaces in a nitrogen-atmosphere sintered Al alloy: Transmission electron microscopy evidence for the formation of AlN during liquid phase sintering[J]. Acta Materialia, 2010, 58(17): 5667-5674.

Metal injection molding of Al-Cu-Mg-Si alloy

DU Zhi-yuan1, WU Mao1, 2, 3, QIU Ting-ting1, QU Xuan-hui1, 2, 3

(1. Institute for Advance Materials and Technology, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Laboratory of Metallic Materials and Processing for Modern Transportation, University of Science and Technology Beijing, Beijing 100083, China;

3. Beijing Key Laboratory for Advanced Powder Metallurgy and Particulate Materials, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Al-Mg-Si-Cu alloy was prepared by metal injection molding (MIM) techniques using pure Al, Cu, Sn element powder and binary Al-Mg, Al-Si powder, the microstructure evolution and densification mechanism were studied compared with conventional press-and-sinter powder metallurgy techniques (PM). The results show that the sintering densification process of MIM and PM aluminum alloy can be mainly divided into three stages: the first stage is dominated by primary rearrangement, the second by solution-reprecipitation and the third by pore filling. The densification process of MIM aluminum alloy is apparently slower than that in PM aluminum alloy. The oxygen mainly exists in MgAl2O4, Al2SiO5 and Al-Si-Cu-O compounds after the oxide film was ruptured, suggesting that the mechanism of the oxide film disruption is related to the local alloy composition. The addition of small amount of Sn could significantly increase the sintering density by lower the surface tension of sintering liquid, but higher Sn content can adversely affect the mechanical properties of the MIM aluminum alloy. When the Sn content is 0.5% (mass fraction), the sintering density of the MIM aluminum alloy is higher than 98%, and the tensile strength reaches 350 MPa after the solid solution treatment.

Key words: aluminum alloy; metal injection molding; liquid phase sintering; microstructure evolution; mechanical properties

Foundation item: Project(51774036) supported by the National Natural Science Foundation of China; Project(2016Z-24) supported by the State Key Laboratory for Advanced Metal and Materials of University of Science and Technology Beijing, China

Received date: 2018-09-10; Accepted date: 2019-07-04

Corresponding author: WU Mao; Tel: +86-13810044463; E-mail: wumao@ustb.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51774036);新金属材料国家重点实验室自主课题(2016Z-24)

收稿日期:2018-09-10;修订日期:2019-07-04

通信作者:吴 茂,副教授,博士;电话;13810044463;E-mail:wumao@ustb.edu.cn