DOI: 10.11817/j.ysxb.1004.0609.2020-37519

铁基含油轴承材料表面硫化改性及摩擦学性能

张国涛1,尹延国2

(1. 安徽工业大学 机械工程学院,马鞍山 243002;

2. 合肥工业大学 机械工程学院,合肥 230009)

摘 要:为改善边界润滑工况下铁基含油轴承材料的摩擦学性能,采用低温液体渗硫技术在材料表面形成一层固体渗硫层,微观检测渗硫层形貌与成分,并在端面摩擦磨损试验机上进行摩擦学实验,分析其摩擦磨损性能与自润滑机理。结果表明:渗硫层中固体润滑剂的主要成分为FeS,硫化物沿着基体孔道由材料表面向内部扩散,渗硫层的厚度约为15 μm;与未硫化材料相比,硫化材料的摩擦因数明显降低,且硫化时间越长,轴承表面渗硫层的减摩性能越好;表面硫化改性后,利用轴承基体多孔含油与表面渗硫层的液固协同润滑作用,其综合摩擦磨损性能比单纯固体润滑或单纯油润滑的减摩性能都要好,边界润滑工况下的抗擦伤、抗咬合性能得到改善。

关键词:铁基轴承材料;粉末冶金;硫化;液固协同润滑

文章编号:1004-0609(2020)-02-0348-07 中图分类号:TG156.8;TH117.2 文献标志码:A

铁基含油轴承材料采用粉末冶金工艺制备,具有显著节材节能、含油自润滑特性,在汽车、仪表、农业工程、精密机械等领域获得广泛应用[1-3]。工作时材料基体孔隙中的油液不断析出至摩擦表面,使铁基含油轴承材料较多处于边界润滑状态。固体润滑技术是改善边界润滑性能的有效途径,在轴承材料表面改性中获得广泛应用[4-5]。在常见固体润滑剂中,FeS因具有低剪切强度、易滑移、表面疏松多孔、减摩性能优异等特点,广受研究人员的重视[6]。其中,王海斗等[7]采用低温离子渗硫技术、等离子喷涂法等不同制备工艺在45钢表面形成渗硫层,对比不同工艺对硫化层组织形貌和摩擦学性能的影响,并给出FeS涂层能够长效润滑的机制及物理模型[8],还探讨了FeS涂层及FeCrBSi/FeS复合涂层的摩擦学性能及在真空环境中应用的可能[9]。石万凯等[10]采用低温离子渗硫工艺在轴承钢(GCr15钢)表面制备FeS固体润滑层,有效提高了轴承钢材的减摩自润滑性能。然而,已有关于轴承表面硫化改性的研究多针对实体轴承材料,有关多孔含油轴承材料表面硫化改性的研究还较为少见,将表面减摩改性技术应用于含油轴承材料,充分发挥含油基体和表面减摩功能层的液固协同润滑作用,有望进一步提高边界润滑工况下的减摩性能,并丰富高性能含油轴承的摩擦学设计理论。

1 实验

1.1 渗硫处理

低温液体渗硫法属于化学热处理技术,具有设备简便、工件热变形小且不受尺寸所限等优点,所制备渗硫层能显著提高轴承材料在边界润滑工况下的摩擦学性能[11]。在课题组前期研究的基础上,以复层铁基含油轴承材料为研究对象,具体材料配方及制备工艺见文献[12],采用低温液体渗硫法对该复层铁基含油轴承材料表面硫化改性,首先进行预处理,并在室温条件下,将经预处理试件放在配制溶液中进行化学渗硫。具体工艺流程如下:表面加工—去油—打磨—超声波清洗—活化—渗硫—清洗—烘干。预处理包括化学除油、打磨除锈、稀盐酸对渗硫试件表面进行活化和清洗等过程。

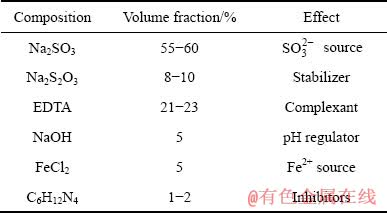

在轴承材料的化学镀过程中,由于Fe原子活性不高,通常难以获得致密均匀的硫化层[13],铁基含油轴承材料经过合金化处理,材料成分较45 号钢或低碳钢复杂,Fe原子活性不强的问题较突出。常见的解决方法如表面纳米化处理[14]将使材料表层孔隙率降低,不利于硫化后基体孔隙中储存的润滑油析出。表1中通过合理设计渗剂成分和含量较好解决了这一问题。渗硫处理可看成是一个微观腐蚀电池的过程。在活性的微阳极区,金属Fe失去电子而发生氧化溶解反应生产Fe2+,在活性的微阴极区,渗剂中的 分解生成S2-,随着金属表面附近的S2-和Fe2+不断的增多,发生成膜反应:

分解生成S2-,随着金属表面附近的S2-和Fe2+不断的增多,发生成膜反应:

Fe2++S2- =FeS (1)

生成的FeS沉积在铁基含油轴承材料表面形成具有一定厚度的渗层。

表1 硫化配方的主要成分

Table 1 Main ingredient of vulcanization

1.2 渗硫层表征

用JSM-6490LV型扫描电镜(SEM)观察摩擦实验前后硫化层微观结构,用X射线能谱仪(EDS) 进行硫化层成分分析;用D/MAX2500V型X射线衍射仪(X-ray Diffraction, XRD)对渗硫层的物相结构进行分析。

1.3 摩擦学性能测试

用端面摩擦磨损试验机评价渗硫铁基含油轴承材料的摩擦学性能。实验加载采用两种方式:定载实验和逐级加载实验。定载实验的初始载荷为980 N,10 min后增加490 N,运行20 min后试验结束。逐级加载试验的初始载荷为980 N,然后每隔10 min加载490 N,直至材料破坏。当摩擦因数突然变大或者试验机出现尖锐噪声时,手动停机,试验结束。摩擦实验转速均采用735 r/min。

2 结果和分析

2.1 渗硫层的组成和形貌

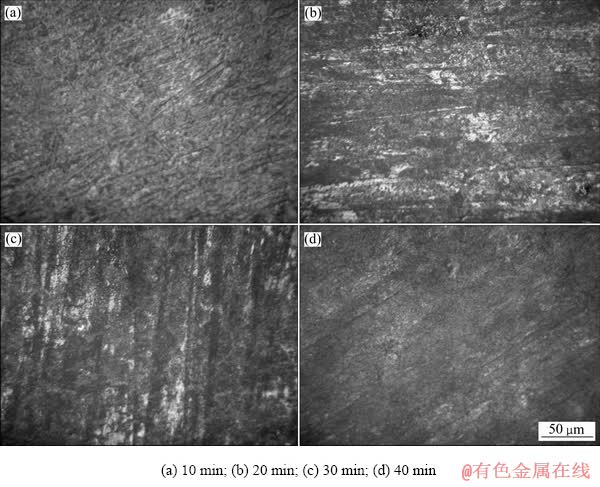

图1 不同渗硫时间铁基含油轴承材料的表面形貌

Fig. 1 Surface morphologies of samples with different sulfurizing time

图1所示为渗硫时间分别是10、20、30和40 min的铁基含油轴承材料表面形貌。硫化10 min后材料表

面覆盖有薄且均匀的层状物;硫化20、30 min后可以看出表面覆盖物逐渐变厚,局部依稀可见亮白色基体;硫化40 min后材料表面覆盖物变得均匀且致密,轴承基体材料被完全覆盖。由此可见,铁基含油轴承材料在10~40 min硫化时间内,随着硫化时间延长,渗硫层逐渐变厚且致密。

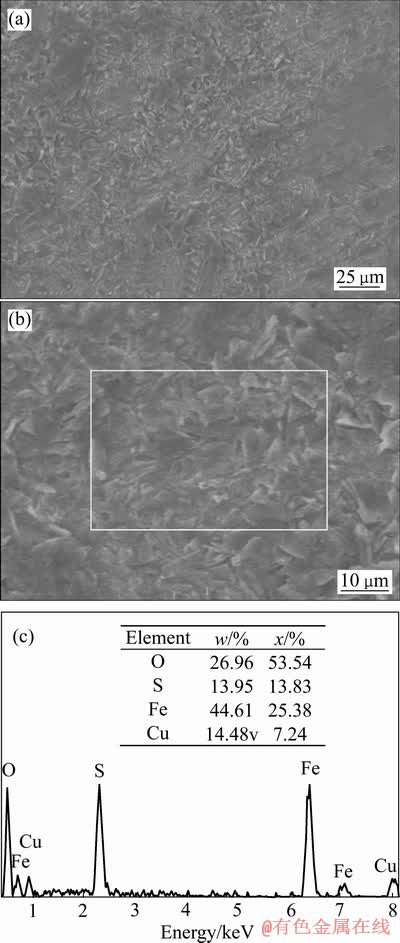

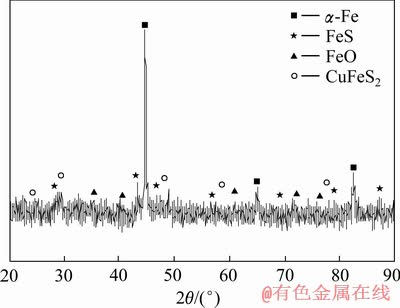

渗硫层表面形貌、成分及结构分析结果如图2、3所示,由SEM像可以看出,渗硫层表面呈片状堆垛,片与片间较疏松,摩擦实验过程中利于基体孔隙储油向摩擦界面析出。从EDS谱可以看出,渗硫层表面除有较多的Fe、S成分外,O元素含量也较高,经XRD分析可知,铁的硫化物主要为FeS,由于铁基含油轴承材料配方中含有一定量的Cu[12],在渗硫层成分中检测到有CuFeS2存在。铁的氧化物主要为FeO,FeO在渗硫层中作为杂质相存在,是渗硫层在烘干过程中发生氧化所致[15]。

图2 硫化层表面形貌及渗硫层组成

Fig. 2 Surface morphologies of sulfided layer((a), (b)) and its composition(c)

图3 渗硫层成分的XRD分析结果

Fig. 3 XRD analysis results of composition of sulphur layer

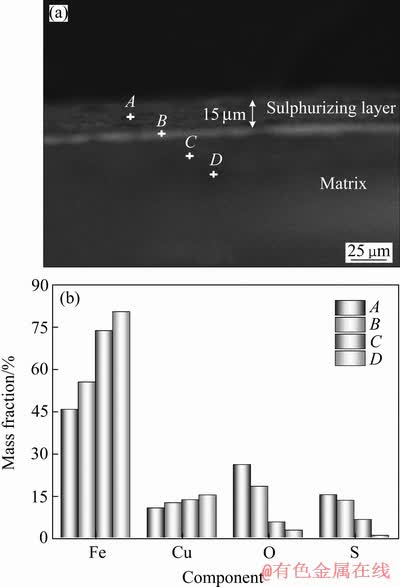

取渗硫层的纵向截面如图4(a)所示,在截面上从渗硫层到基体选取4个点A、B、C、D,分别对所选各点进行EDS能谱分析,以检测从渗硫层到基体各元素含量的变化,得到4点处各元素的含量如4(b)所示。

图4 渗硫层形貌及沿截面方向上不同位置处的元素分布

Fig. 4 Morphology of sulphur layer(a) and distribution of elements in different positions along cross section(b)

由图4(a)可见,渗硫层与基体有较为明显的分界线,渗硫层的厚度在15 μm左右。在图4(b)中,从各点处的元素分布可见,在渗硫层表面A处,S元素的含量相对较高,从A点到D点方向,S、O元素含量逐渐减少,Fe、Cu元素含量逐渐增加,到基体时,S元素含量接近为零。这是渗硫过程中S元素沿着多孔基体孔道扩散的结果。

2.2 摩擦学特性

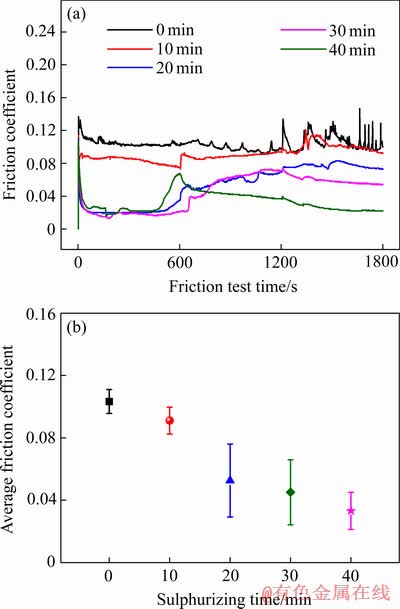

图5 变载工况下不同摩擦时间和渗硫时间材料的摩擦因数变化

Fig. 5 Friction coefficient of samples with different fraction test time(a) and sulphurizing time(b)

对不同渗硫时间的材料进行定载摩擦实验,探究渗硫时间对硫化层减摩性能的影响。摩擦磨损实验在油润滑工况下进行,摩擦因数的变化结果如图5所示。由图5可见,随着硫化时间延长,材料的摩擦因数降低。未硫化材料的摩擦因数在整个摩擦过程中维持在较高值(平均摩擦因数为0.105)且存在一定程度波动,特别是在20 min后,摩擦因数波动程度明显增加;在实验初期,硫化10 min的材料的摩擦因数低于未硫化材料的,20 min后两者的摩擦因数相当,区别在于硫化材料的摩擦因数波动程度较小;图5(b)所示的平均摩擦因数可见,与硫化10 min材料相比,硫化时间为20~40 min的材料摩擦因数有明显降低,且硫化时间越长,材料表面渗硫层的减摩性能越好;从硫化40 min材料的实验结果可以看出,在摩擦过程的前10 min摩擦因数较低(约为0.02),在10 min加载附近摩擦因数有明显上升现象,此后摩擦因数缓慢降低,直至25 min后稳定在0.02附近,摩擦因数的这种变化趋势符合一般减摩功能层在摩擦实验中的变化规律[15],此变化趋势的原因归结于固体润滑膜在跑合结束后由生成→破坏→再生成的循环作用。具体解释可参见文献[15],这里不再赘述。

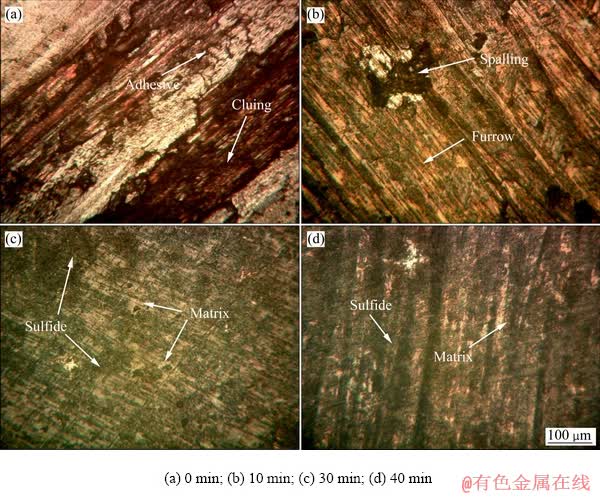

图6所示为不同渗硫时间材料的磨痕结果。由图6可见,未硫化材料表面破坏严重,磨痕中有明显胶合及粘着剥落存在,而渗硫材料的表面磨痕相对较轻,除渗硫10 min材料表面有较深犁沟和剥落坑存在之外,硫化30 min、40 min材料表面磨损轻微,且仍有部分硫化层未完全剥落,特别是硫化40 min材料表面仍有较厚的黑灰色硫化层存在。

2.3 润滑机制分析

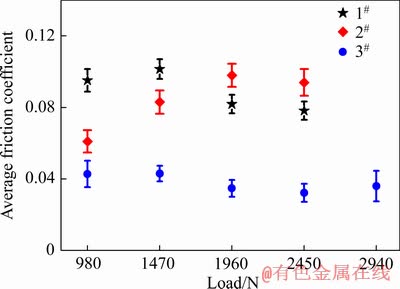

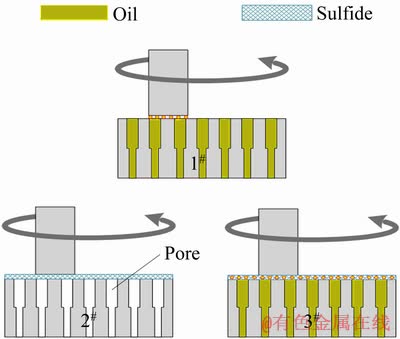

为分析硫化改性铁基含油轴承材料的润滑机理,对课题组前期制备的复层铁基含油轴承材料进行真空浸油、硫化改性两种工艺的任意搭配。只做真空浸油处理的轴承材料记为1#,只做表面硫化改性的轴承材料记为2#、3#材料同时采用真空浸油和硫化改性处理。对上述材料开展逐级加载实验,摩擦因数曲线如图7所示。

1#材料为未经硫化的复层铁基含油轴承材料,在逐级加载试验过程中,1#材料的摩擦因数呈先逐渐升高后降低趋势,当在1470 N的载荷工况下实验时,其摩擦因数较高。硫化处理后,2#材料依靠固体硫化层的减摩作用,当外载荷小于1470 N时,其摩擦因数比1#材料小,而当载荷处于1960~2450 N区间时,其摩擦因数高于1#材料。摩擦试验过程中2#表面的硫化层不断被磨去,摩擦因数不断升高,故当处于较高载荷作用时,表面硫化层磨损量严重,摩擦因数高于1#。3#材料硫化后依靠润滑油和固体润滑层的双重作用,摩擦因数明显降低,且承载能力显著提高,如1#、2#材料的极限载荷为2450 N,3#材料的极限载荷为 2940 N。综合来看,3#材料的液固协同润滑作用的效果比2#单纯固体润滑的减摩性能要好,也比1#材料单纯含油的减摩性能好。根据上述分析,可建立3种不同处理工艺的铁基含油轴承材料的摩擦模型如图8所示。

图6 不同渗硫时间材料的磨痕形貌

Fig. 6 Wear scar of samples at different sulphurizing time

图7 3种不同处理工艺下铁基含油轴承材料的摩擦因数

Fig. 7 Friction coefficients of three iron based bearing materials under different processes

图8 3种不同处理工艺下铁基含油轴承材料的润滑模型

Fig. 8 Lubrication models of three iron based bearing materials under different processes

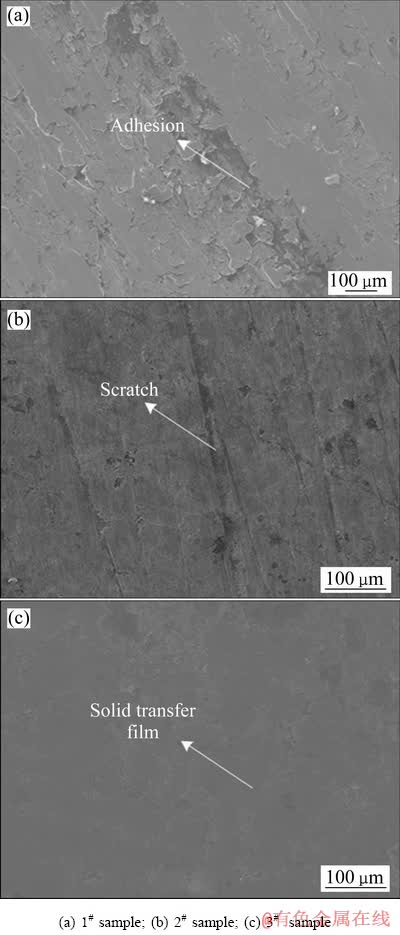

在图8中,1#材料摩擦表面上有若干油性分子组成的吸附膜提供边界润滑;2#材料摩擦表面由硫化物固体润滑介质提供润滑;由于硫化层具有疏松多孔结构,3#材料表面具有疏松多孔结构的含油固体润滑组织,摩擦实验时渗硫层能发挥固体润滑作用,同时,多孔渗硫层与多孔金属基体中含浸的油液能析出到摩擦界面,使摩擦副工作时能形成稳定的液-固协同润滑效应,摩擦学性能和承载能力较好。图9所示为3种材料的磨痕图。1#材料磨损较严重,磨痕中有较多黏着剥落坑存在,硫化改性后2#、3#材料表面无明显粘着剥落坑存在,其中2#材料表面有轻微擦伤、犁沟,3#材料在液固协同润滑作用下,抗粘着、抗擦伤性能显著提高,表面有连续的固体润滑转移膜生成,磨痕形貌较光滑。

综上可见,采用低温渗硫技术,在铁基含油轴承材料表面形成具有疏松多孔的含油减摩组织,摩擦实验时利于基体孔隙储存的大量油液向摩擦界面析出,使摩擦副工作时能形成稳定的液-固协同润滑效应,有效降低摩擦因数,提高承载能力和摩擦磨损性能。并且,渗硫后液固协同润滑作用的效果比单纯固体润滑或含油润滑的减摩性能都要好,进一步改善了铁基含油轴承材料的摩擦学性能,有效提高其在边界润滑工况下的抗擦伤、抗粘着性能。

图9 不同处理工艺下的铁基轴承材料磨痕

Fig. 9 Wear marks of three iron based bearing materials under different processes

3 结论

1) 渗硫层表面形貌呈片状疏松堆垛,硫化物中固体润滑剂的主要成分为FeS;在渗硫层表面,S元素的含量相对较高,沿渗硫层的纵向截面从材料表面向基体方向,S、O元素含量逐渐减少,Fe、Cu元素含量逐渐增加。

2) 在硫化时间0~40 min区间内,随着硫化时间延长,材料的摩擦因数和磨损程度降低。且硫化层摩擦因数的变化趋势的原因与一般减摩功能层相同,即润滑膜的生成→破坏→再生成的循环作用。

3) 对铁基含油轴承材料表面硫化改性,在材料表面形成具有一定储油能力的固体润滑层,同时利于基体孔隙储存的大量油液向摩擦界面析出,使摩擦副能形成稳定的液-固协同润滑效应,改善边界润滑工况下的抗擦伤、抗咬合性能。

REFERENCES

[1] 范 丽, 陈海龑, 刘珊珊, 董耀华, 董丽华, 尹衍升. 球形WC增强铁基复合等离子堆焊层的组织与摩擦学性能[J]. 摩擦学学报, 2018, 38(1): 17-27.

FAN Li, CHEN Hai-yi, LIU Shan-shan, DONG Yao-hua, DONG Li-hua, YIN Yan-sheng. Microstructure and tribological properties of Fe-based composite coatings reinforced by spherical WC[J]. Tribology, 2018, 38(1): 17-27.

[2] 钱旭东, 李 德, 许秉坤, 陆周, 叶旭初. Ti-Al和Ti-Al-Ce复合改性剂对高硼铁基耐磨合金组织和性能的影响[J]. 中国有色金属学报, 2017, 27(8): 1687-1692.

QIAN Xu-dong, LI De, XU Bing-kun, LU Zhou, YE Xu-chu. Effects of Ti-Al and Ti-Al-Ce additions on microstructures and properties of high boron iron-based wear-resistant alloys[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1687-1692.

[3] ZHANG G M, FENG K Q. Synthesis of iron-based friction material by in situ reactive sintering from vanadium-bearing titanomagnetite[J]. Advanced Manufacturing Processes, 2016, 31(2): 198-205.

[4] MIYAKE S, KOMIYA M, SHINDO T. Boundary lubrication properties of nanoperiod solid lubricant multilayer films composed of diamond-like carbon and gold layers[J]. Tribology Letters, 2012, 46(1): 1-9.

[5] OLIVEIRA M M D, HAMMES G, BINDER C, KLEIN A N, MELLO J D B. Solid lubrication in fluid film lubrication[J]. Lubrication Science, 2018, 30(3): 102-115.

[6] PENG Tao, YAN Qing-zhi, ZHANG Yan, SHI Xiao-jiao, BA Ming-yang. Low-cost solid FeS lubricant as a possible alternative to MoS2 for producing Fe-based friction materials[J]. International Journal of Minerals, Metallurgy and Materials, 2017, 24(1): 115-121.

[7] WANG Hai-dou, XU Bin-shi, LIU Jia-jun, ZHUANG Da-ming. The friction-reduction model of the iron sulfide film prepared by plasma source ion sulfuration[J]. Surface & Coatings Technology, 2007, 201(9/11): 5236-5239.

[8] WANG Hai-dou, XU Bin-shi, LIU Jia-jun, ZHUANG Da-ming. Characterization and tribological properties of plasma sprayed FeS solid lubrication coatings[J]. Materials Characterization, 2005, 55(1): 43-49.

[9] WANG Hai-dou, ZHUANG Da-ming, WANG Kun-lin, LIU Jia-jun. Study on tribological properties of ion sulfuration and thermal sprayed FeS solid lubrication layers[J]. Journal of Materials Engineering, 2003.

[10] 石万凯, 李 宁, 韩振华. 低温离子渗硫FeS涂层的摩擦学性能研究[J]. 重庆理工大学学报, 2015, 29(9): 48-52.

SHI Wan-kai, LI Ning, HAN Zhen-hua. Research on tribological properties of sulfide layer produced by ion sulphurization[J]. Journal of Chongqing University of Technology, 2015, 29(9): 48-52.

[11] 亓海全, 易成功, 孙延焕. W360热作模具钢渗硫的渗层组织及抗擦伤性能[J]. 表面技术, 2017, 46(9): 134-140.

QI Hai-quan, YI Cheng-gong, SUN Yan-huan. Effects of sulfurizing treatment on microstructure and scratch resistance of W360 hot work die steel[J]. Surface Technology, 2017, 46(9): 134-140.

[12] ZHANG G T, YIN Y G, XU M, LI C M. Tribological properties and mechanism of the bilayer iron based powder metallurgy materials[J]. Industrial Lubrication and Tribology, 2018, 70(9): 1642-1648.

[13] 朱立群, 刘慧丛, 李卫平, 陈贻炽. 粉末冶金零件中孔隙的涂镀前封闭处理技术进展[J]. 表面技术, 2017, 46(4): 1-6.

ZHU Li-qun, LIU Hui-cong, LI Wei-ping, CHEN Yi-chi. Research progress of pore sealing technology of powder metallurgy parts before plating[J]. Surface Technology, 2017, 46(4): 1-6.

[14] 沈 雁, 刘桂香, 王红星. 系泊缆用22MnCrNiMo钢表面纳米复合镀层的制备[J]. 表面技术, 2017, 46(10): 50-59.

SHEN Yan, LIU Gui-xiang, WANG Hong-xing. Preparation of composite coatings on 22MnCrNiMo steel for mooring rope[J]. Surface technology, 2017, 46(10): 50-59.

[15] 王 涛. 45钢低温液体渗硫技术及其渗硫层摩擦学性能研究[D]. 合肥: 合肥工业大学, 2015.

WANG Tao. Sulphurization of 45 steel at room temperature and tribological properties of sulfide layer[D]. Hefei: Hefei University of Technology, 2015.

Surface sulfurization modification and tribological properties of iron-based oil bearing materials

ZHANG Guo-tao1, YIN Yan-guo2

(1. School of Mechanical Engineering, Anhui University of Technology, Ma’anshan 243002, China;

2. School of Mechanical Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: To improve the tribological properties of iron-based oil materials under boundary lubrication, a solid sulfurization layer was formed on the materials surface by low-temperature liquid sulphurizing technology. The morphology and composition of the solid sulfurization layer were sutided. The tribological experiments were tested on the end-face friction and wear tester to reveal its self-lubricating mechanism. The results show that the main composition of the sulfide layer is FeS. The sulfide diffuses from the surface to the interior along the matrix pore, and the thickness of the sulfide layer is about 15 um. Compared with the unvulcanized sample, the friction coefficient of the vulcanized sample is obviously lower. And the longer the vulcanization time, the better the lubrication property. After surface modification, the comprehensive friction and wear performance is better than that of only solid or oil lubrication for the liquid-solid synergetic lubrication. And the anti-abrasion and anti-occlusal properties are improved under the boundary lubrication condition.

Key words: iron-based bearing material; powder metallurgy; surface sulphurizing; liquid-solid synergistic lubrication

Foundation item: Project(51575151) supported by the National Natural Science Foundation of China; Project (1908085QE195) supported by the Natural Science Foundation of Anhui Province, China

Received date: 2019-03-15; Accepted date: 2019-06-24

Corresponding author: ZHANG Guo-tao; Tel: +86-15375283582; E-mail: hfutt@sina.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51575151);安徽省自然科学基金资助项目(1908085QE195)

收稿日期:2019-03-15;修订日期:2019-06-24

通信作者:张国涛,讲师,博士;电话:15375283582;E-mail:hfutt@sina.com