文章编号:1004-0609(2015)10-2720-07

微细Fe2O3粉在Fe-2%Ni-1%Cu-0.6%C粉末冶金材料中的助烧结特性

滕 浩,李佑福,曾海卒,李志友,周科朝

(中南大学 粉末冶金研究院 粉末冶金国家重点实验室,长沙 410083)

摘 要:在Fe-2%Ni-1%Cu-0.6%C混合料中加入了少量微细Fe2O3粉末作为烧结助剂,研究Fe2O3粉末的添加量对混合料的压缩性、烧结合金的密度和强度以及氧和碳含量等的影响,研究微细Fe2O3粉末对合金的助烧结行为。结果表明:混合料中Fe2O3含量大于0.3%(质量分数)时,会导致成形生坯密度下降;当Fe2O3添加量为0.3%时,烧结合金的密度最高,经1120 ℃烧结0.5和1 h后,合金的抗弯强度比同等烧结条件下未添加Fe2O3样品的分别提高6.5%和4.2%。少量Fe2O3粉在材料烧结时对碳含量损失率的影响较小,然而可以降低烧结体中的氧含量。在压坯的烧结过程中,Fe2O3还原后于750 ℃左右开始加速基体颗粒间的连结,虽然在1050 ℃以上时微细粉的助烧结作用减弱,但烧结体中孔隙更趋于球化。

关键词:铁基粉末冶金;Fe-2%Ni-1%Cu-0.6%C;Fe2O3粉;烧结

中图分类号:TF124 文献标志码:A

Assist-sintering characteristics of ultrafine Fe2O3 powder in Fe-2%Ni-1%Cu-0.6%C powder metallurgy material

TENG Hao, LI You-fu, ZENG Hai-zu, LI Zhi-you, ZHOU Ke-chao

(State Key Laboratory of Powder Metallurgy, Research Institute of Powder Metallurgy,

Central South University, Changsha 410083, China)

Abstract: Fe-2%Ni-1%Cu-0.6%C powder premix was prepared with minor ultrafine Fe2O3 powder as a sintering aid. The effects of Fe2O3 addition on compressibility of the mixture, sintered density, strength of the alloy and its oxygen and carbon content were studied. The assist-sintering behavior of ultrafine Fe2O3 powder was also investigated. The results show that the green density decreases when the Fe2O3 content is above 0.3%, while the highest density of sintered alloy is obtained with 0.3% Fe2O3 addition. And the flexural strengths of the alloy sintered at 1120 ℃ for 0.5 h and 1 h increase by 6.5% and 4.2%, respectively, compared with that of sample without Fe2O3 powder addition. Minor ultrafine Fe2O3 powder has slight effect on the loss rate of C content of the sintered alloy, and yet the oxygen content is reduced. It is observed that the metallurgy bonding between matrix particles is accelerated from about 750 ℃ for the reduction of Fe2O3 particles. Though the assist-sintering function of ultrafine powder weakens when the temperature is above 1050 ℃, the pole shape in the sintered alloy is apt to spheroidize.

Key words: iron-based powder metallurgy; Fe-2%Ni-1%Cu-0.6%C; Fe2O3 powder; sintering

铁基粉末冶金可以高效地制造形状复杂、尺寸精度一致性好以及成本较低的零部件,广泛应用于汽车、机械、电器等领域[1-4]。随着市场的扩展,铁基粉末冶金制品逐渐向高性能方向发展,当前主要通过提高制品的成形密度实现,将来可能依靠改进烧结实现。

Fe-Ni-Cu-C是常用的低合金铁基粉末冶金材料,可制造具有一定硬度、耐磨性、冲击韧性并可进行热处理的结构零件。在成形与烧结密度稳定的前提下,元素的合金化是影响该合金的显观组织及其力学性能的一个重要方面。例如,镍与铜都有部分降低珠光体中碳浓度的作用,因而可以增加珠光体含量与减少铁素体含量[5-6]。镍的均匀化不充分会形成富镍区,使材料的强度、韧性以及淬透性得到改善[5]。如果原料中采用羰基镍粉,能在铁基烧结材料中形成分布更均匀的富镍相,提高制品的抗疲劳性能,但羰基镍粉的价格也较高。铜有形成瞬时液相促进烧结的作用,还能细化铁素体晶粒,提高合金的强度与硬度,然而铜含量过高也会导致烧结体的尺寸膨胀和塑性下降等[7]。因此,对合金元素粉末的选用一般要考虑材料的性价比。

除了合金元素带来的强化,铁颗粒间的冶金结合与孔隙圆化程度等显微组织特征也是影响合金力学性能的重要因素。对于Fe-Ni-Cu-C合金,要在常规的烧结条件下改善材料的烧结程度,应尽可能提高粉末的烧结活性。利用纳米铁粉、铜粉的高活性可以强化铁基材料的烧结性能[8-9],但微细金属粉末尤其是纳米粉存在易团聚、稳定性差和成本高等不足。因此,如果添加的微细粉为相应的金属氧化物,应具有较好的稳定性和分散性[10],且钨、钼等难熔金属的烧结也利用了氧化物还原后的高活性[11-12],但目前在铁基材料中利用氧化物还原活化烧结的研究报道较少,多数添加氧化铁(Fe2O3)粉末是应用在制备氧化物弥散强化铁基合金[13-14]。考虑到Fe-Ni-Cu-C材料中的金属元素均易被还原,本文作者探索添加少量微细Fe2O3粉末活化合金烧结的可行性,考察它的添加对混合料中压缩性、烧结体的氧与碳含量以及力学性能的影响,探讨压坯烧结过程中微细Fe2O3粉末还原后强化铁颗粒间冶金结合的行为与机理。

1 实验

1.1 试样制备

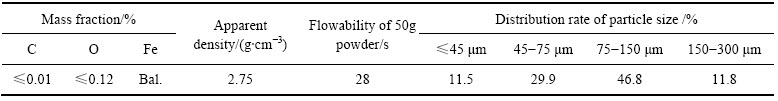

按化学组成Fe-2%Ni-1%Cu-0.6%C-xFe2O3(x分别取0、0.15%、0.3%、0.45%、0.6%,质量分数)对各粉末原料进行配料。其中铁粉为莱钢集团粉末冶金有限公司生产的100.29H水雾化铁粉,其化学成分、粒度组成和工艺性能如表1 所列。

其他原料为:粒径≤20 μm的镍粉、粒径≤50 μm的铜粉、胶体石墨、粒径≤300 nm的亚微米级Fe2O3粉末以及占混合粉总质量0.5%的硬脂酸锌。

将各原料装入混料筒中并密封混合3 h,然后将各混合料在室温下压制成形,压力为600 MPa。将压坯样品置于氢气氛烧结炉中,先慢速升温至400 ℃,保温0.5 h以脱除压坯中的有机成分。为考察Fe2O3活化烧结的效果,分别在1050、1090、1120 ℃烧结温度下烧结1 h以及1120 ℃下烧结0.5 h,然后推入水冷区冷却20 min出炉。为推断Fe2O3还原后的助烧结过程,将样品分别升温至600、750、900、1050和1120 ℃保温5 min后冷却出炉。

1.2 测试与表征

对混合料直接取样,将压制成形的生坯在液氮中打断,用Nova Nano SEM 230型场发射扫描电镜观察Fe2O3颗粒在混合料及压坯中的分布。测量压坯的质量和体积,计算得到压坯的密度。用排水法(阿基米德法)测量烧结合金的密度。用LECO公司生产的CS-600型碳硫测定仪与TCH-600型氮氧分析仪分别测定了烧结材料中碳和氧含量。根据国家标准GB 6525-86、GB/T 5319-2002分别制成压缩试样与抗弯试样,在Instron 3369型电子万能材料试验机上测试烧结合金的压溃强度与抗弯强度。采用Nova Nano SEM 230型场发射扫描电镜观察压溃试样的断口形貌。在LEICA 6532-01型金相显微镜上观察烧结合金的孔隙状态。

2 结果与分析

2.1 Fe2O3颗粒在混合料与压坯中的分布

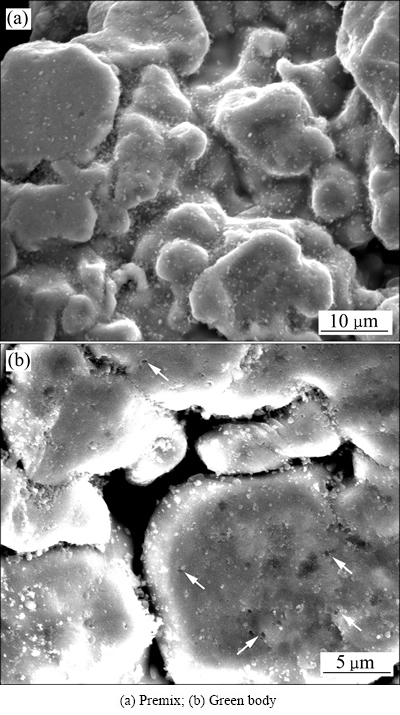

图1所示为微细Fe2O3粉末在Fe-2%Ni-1%Cu- 0.6%C-0.3%Fe2O3混合料以及生坯的SEM像。

表1 水雾化铁粉的化学成分及特性

Table 1 Chemical composition and properties of water atomization iron powder

图1 Fe-2%Ni-1%Cu-0.6%C-0.3%Fe2O3混合料及生坯的SEM像

Fig. 1 SEM images of Fe-2%Ni-1%Cu-0.6%C-0.3%Fe2O3

图1(a)所示为混合料的SEM像。由图1(a)可以看出,粗大灰色颗粒主要为基础铁粉,其表面均匀地分布着细小白色颗粒,这些颗粒的大小与Fe2O3原料的粒径相对应。图1(b)所示为压坯断口形貌。由图1(b)可以看到一部分细小的白色颗粒散布于铁粉间的缝隙处,一部分则分散在铁粉表面,而且铁粉表面还出现了一些与白色颗粒尺寸相当的凹坑(见图中箭头所指处)。由于石墨硬度较低而不可能被挤压嵌入铁粉中,这些凹坑应是夹在基础铁粉之间的较硬Fe2O3颗粒被挤压,压坯断裂后部分Fe2O3颗粒脱落而形成。由图1可见,微细Fe2O3粉末能较均匀的分布在铁基混合料及压坯中。如果这些Fe2O3颗粒在压坯烧结过程中被还原,生成的微细铁颗粒将会增加烧结颈的形成与生长点数量,尤其是处在基础铁粉间隙处的颗粒,在表面张力的作用下将加速缝隙的闭合与孔隙的圆化。

2.2 压坯与烧结体的密度

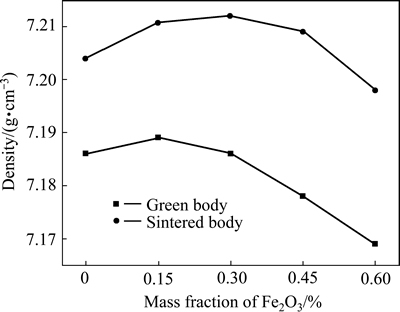

对添加了微细Fe2O3粉末的Fe-2%Ni-1%Cu- 0.6%C混合料进行了常规单轴压制成形,并在氢气氛下1120 ℃烧结1 h,考察了材料的生坯密度及烧结密度随Fe2O3粉末添加量的变化,结果如图2所示。

图2 Fe-2%Ni-1%Cu-0.6%C-xFe2O3材料的生坯及烧结密度

Fig. 2 Green body and sintered body density of Fe-2%Ni-1%Cu- 0.6%C-xFe2O3 material

由图2的曲线可以看出,在Fe2O3添加量不大于0.3%(质量分数)时,混合料的压制密度基本保持不变,而继续增大Fe2O3添加量时,压制密度下降相对明显。微细Fe2O3粉的添加会增大混合粉的总表面积,而且Fe2O3颗粒硬度较高,压制时会增大粉末间的摩擦力。但较少添加量时,微细Fe2O3粉在混合料内分布较均匀,由Fe2O3引起的粉末间的摩擦相对于润滑剂的作用可以忽略,部分Fe2O3颗粒可被挤入铁颗粒的间隙;而Fe2O3粉添加量,逐渐增多会对粉末压制产生的摩擦作用愈来愈明显,从而导致压坯密度降低。各样品的烧结密度随Fe2O3添加量增加的变化趋势为小范围内先升高后降低,且均高于相应的生坯密度。当Fe2O3添加量为0.3%时,烧结密度最大,且随着Fe2O3添加量增加,烧结体密度的提高幅度有增大的趋势,表明微细Fe2O3粉末在烧结过程中可起到一定的助烧结作用,提高了坯体的烧结收缩率。

2.3 烧结合金的O和C含量

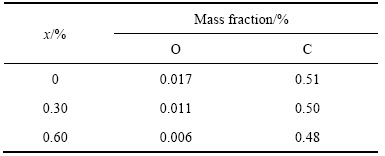

表2 烧结Fe-2%Ni-1%Cu-0.6%C-xFe2O3合金中的C和O含量

Table 2 C and O content of sintered Fe-2%Ni-1%Cu-0.6%C- xFe2O3 alloys

由于添加的Fe2O3可能会影响烧结材料的O和C含量,最终影响烧结材料的性能,因此,对不同Fe2O3添加量的样品在1120 ℃烧结1 h后进行O和C的含量测试,结果如表2所列。

由表2可知,未添加Fe2O3粉的压坯经过烧结后O含量反而高于添加了Fe2O3样品的,且烧结材料中O含量随Fe2O3添加量的增加而减少,可见添加的Fe2O3粉末完全可以在样品烧结过程中被还原。通常情况下,铁粉原料中含有微量的O(见表1),铁颗粒表面的氧化物可在700 ℃以上被还原,而颗粒内部的氧化物需在950~1100 ℃才能被还原[15]。对于不含微细Fe2O3粉的混合料,压制时铁基粉末发生重排、变形,颗粒间形成部分紧密接触面,这其中的氧化物较难与烧结氢气接触而被还原。随着烧结的进行,坯体内连通孔隙的减少更不利于残余氧的脱除。当添加少量的Fe2O3粉末时,由于这些微细的硬颗粒较均匀地粘附在基础铁粉表面,可导致压制时铁颗粒间接触不够紧密,尤其在Fe2O3微细粉的添加量增大致使压坯密度降低时,坯体内孔隙连通率应进一步增加,更有利于铁基颗粒表面与还原性气氛的接触。而对于这些微细的Fe2O3颗粒,由于具有较高的比表面积,其比基础铁粉表面的氧化物所需要的还原温度更低。王兴庆等[16]研究了平均粒径0.35 μm的Fe2O3粉在氢气氛下的还原,400 ℃下保温3 min的还原率达到91.4%。本研究采用的Fe2O3粉末粒径与之相当,在400 ℃脱脂保温阶段,分布在生坯孔隙内氢气容易渗透到部位的Fe2O3颗粒可以被还原,还原的过程为Fe2O3→Fe3O4→Fe [17];此温度下样品中的有机添加剂发生分解,部分产物可能参与碳热还原反应[18]。然而,少数处于封闭孔隙内或夹在基础铁颗粒接触面内的Fe2O3粉则可能未被还原。随着烧结温度的升高,700 ℃以上时C开始气化与扩散,坯体内部形成具有一定碳势的气氛,可进一步还原余下的微细Fe2O3颗粒以及基础铁粉表面的氧化物,其过程为Fe2O3→Fe3O4→FeO→Fe[17]。因此,少量微细Fe2O3粉的添加有助于降低烧结材料中的氧含量。

此外,烧结材料中的C含量随Fe2O3添加量增加略有减少,这是因为还原Fe2O3消耗了微量的C。然而,无论是添加了Fe2O3还是未添加Fe2O3粉末的烧结材料,它们的C含量都在0.5%左右,均低于名义上C含量,这应与混料和压制等过程中石墨粉的损失及烧结气氛的脱碳有关。

2.4 烧结合金的抗弯强度

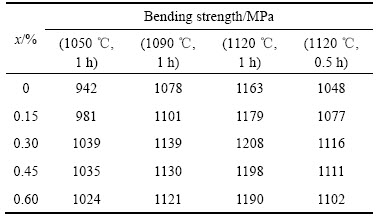

对不同Fe2O3添加量的压坯分别在1120、1090、1050 ℃烧结1 h,以及1120 ℃烧结0.5 h,然后测试烧结体的抗弯强度,其结果如表3所列。

表3 不同条件下烧结的Fe-2%Ni-1%Cu-0.6%C-xFe2O3合金的抗弯强度

Table 3 Bending strengths of Fe-2%Ni-1%Cu-0.6%C- xFe2O3 alloy sintered at different conditions

由表3可知,同样的Fe2O3添加量下,随烧结温度的升高或烧结时间的延长,所得到合金的抗弯强度也相应增加。在各烧结条件下,随着Fe2O3添加量增加,材料的抗弯强度都先上升后下降,且都在添加量为0.3%时达到最大值,这与烧结材料的密度变化趋势一致。同样在1120 ℃烧结时,与未添加Fe2O3粉末的样品相比,添加0.3%微细Fe2O3粉末的样品烧结0.5 h后抗弯强度提高约6.5%,而烧结1 h后,其抗弯强度提高的幅度下降为3.9%。烧结时间同为1 h,与未添加Fe2O3粉末的样品相比,添加0.3%微细Fe2O3粉末的样品在1090 ℃烧结后抗弯强度提高约5.7%,而在1050 ℃烧结时强度的提高幅度达到10.3%。结果表明,微细Fe2O3粉被还原后在相对较低的烧结温度或较短的烧结时间内活化烧结的作用更明显。随着烧结温度的增加或时间的延长,微细粉末活化烧结的作用减弱,这是由于颗粒的长大与合并使得活化烧结的驱动力下降,合金的强度提升更多归结于合金元素的均匀化与孔隙减小、圆化等结构改变。

2.5 Fe2O3颗粒的助烧结行为

2.5.1 材料烧结过程中的强度变化

为推断微细Fe2O3粉末在Fe-2%Ni-1%Cu-0.6%C材料中的助烧结过程,取Fe2O3添加量为0.3%与未添加Fe2O3的Fe-2%Ni-1%Cu-0.6%C压制样品进行对比烧结研究,图3所示为两组试样的压溃强度随烧结温度变化的曲线。

图3 Fe-2%Ni-1%Cu-0.6%C-xFe2O3材料的压溃强度随烧结温度的变化

Fig. 3 Change of rushing strength curves of Fe-2%Ni-1%Cu- 0.6%C-xFe2O3 material sintered with sintering temperatures

从图3可以看出,在600 ℃时烧结5 min,两种样品的压溃强度没有明显区别。从750℃开始,添加了Fe2O3的样品的压溃强度高于未添加Fe2O3样品的,而900 ℃时,两种样品的强度差距明显,表明在750~900 ℃间添加Fe2O3粉末样品的颗粒间连结力明显增强,这与此阶段Fe2O3粉末充分还原后形成烧结颈的数量和烧结颈的长大程度提升有关。当温度达到1050 ℃及以上时,两种材料的强度差值减小,这是因为此时烧结颈基本长大,坯体强度的提高主要依靠铁的自扩散与铁基体的合金化。

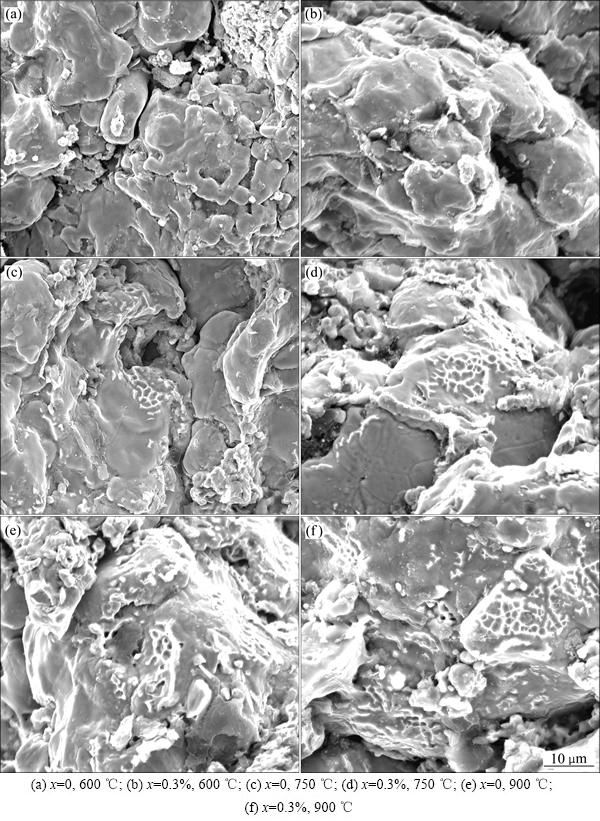

2.5.2 断口形貌

对上述600、750、900 ℃烧结5 min的样品断口形貌进行扫描电镜观察,其结果如图4所示。由图4(a)和(b)可以看出,在600 ℃烧结时,未添加Fe2O3与Fe2O3添加量为0.3%的样品断口基本为颗粒原始边界,未发现明显的冶金结合。当温度升至750 ℃时(见图4(c)和(d)),两种样品均出现了烧结颈断裂形成的韧性区,说明烧结已开始。此外,添加了微细Fe2O3粉末的样品中基础铁颗粒间的韧性区面积明显大于未添加Fe2O3粉末样品的韧性区,表明前者基础铁颗粒间的冶金结合程度更高,这是由于微细Fe2O3粉末已经被还原成新生微细Fe颗粒,其表面能更高,可形成更多数量的烧结颈,从而获得较大范围的烧结。当温度达到到900 ℃时,未添加Fe2O3的样品断口依然只有一些小范围的韧窝(见图4(e)),说明材料烧结程度较低。而添加了Fe2O3样品的断口韧窝数量明显较多,且尺寸较大,颗粒间的连接率明显高于未添加Fe2O3的样品(见图4(f)),这也与图3中材料压溃强度的变化规律一致。

图4 不同烧结温度下Fe-2%Ni-1%Cu-0.6%C-xFe2O3试样的压溃断口形貌

Fig. 4 Crushing fracture morphologies of Fe-2%Ni-1%Cu-0.6%C-xFe2O3 samples sintered at different temperatures for 5 min

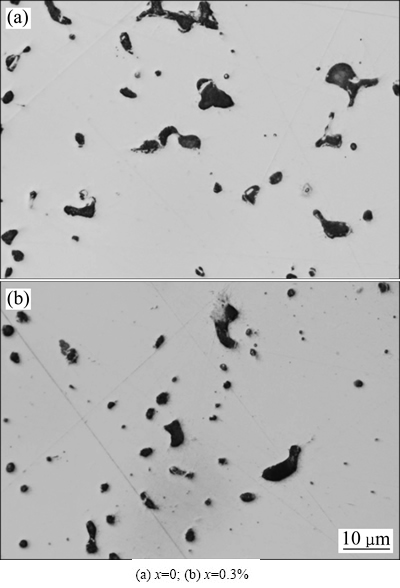

2.5.3 烧结材料的孔隙特征

图5 Fe-2%Ni-1%Cu-0.6%C-xFe2O3烧结合金的孔隙形貌

Fig. 5 Pore morphologies of Fe-2%Ni-1%Cu-0.6%C-xFe2O3 alloys sintered at 1120 ℃ for 1 h

观察1120 ℃烧结1 h后合金的孔隙形貌,结果如图5所示。由图5可以看出,未添加Fe2O3的烧结样品中孔隙形状不规则程度较大,部分粗大孔隙带有明显的尖角,而Fe2O3添加量为0.3%的烧结样品中孔隙趋于圆化,孔隙中尖角较少。这是因为微细Fe2O3粉末可分布在压坯中孔隙的尖角处(见图1(b)),烧结过程中随着Fe2O3颗粒被还原,在适当的温度下,高活性微细Fe粉中的原子在表面张力的驱动下将迅速迁移,使Fe颗粒间相互连结形成烧结颈并长大,填平尖角,进而球化孔隙,这也有利于烧结材料力学性能的提高。

3 结论

1) 添加含量大于0.3%的微细Fe2O3粉末会导致Fe-2%Ni-1%Cu-0.6%C混合料的压制密度下降,但当Fe2O3添加量为0.3%时,烧结合金的密度最高,合金在1120 ℃烧结0.5和1 h后,抗弯强度比同等烧结条件下未添加Fe2O3的样品的分别提高6.5%和4.2%。

2) 少量微细Fe2O3粉末的添加对Fe-2%Ni-1%Cu- 0.6%C烧结合金的碳含量损失率影响较小,然而可以降低合金中的氧含量,氧含量由未添加Fe2O3粉末时的0.017%减少到Fe2O3添加量为0.6%时的0.006%。

3) 微细Fe2O3粉经烧结还原后,在750 ℃左右开始加速基体颗粒间的连结,尽管1050 ℃以上时,微细粉的助烧结作用减弱,但添加微细Fe2O3粉末的烧结合金中孔隙更趋于球化,有利于材料力学性能的提高。

REFERENCES

[1] NARASIMHAN K S. Sintering of powder mixtures and the growth of ferrous powder metallurgy[J]. Materials Chemistry and Physics, 2001, 67: 56-65.

[2] 黄伯云, 易健宏. 现代粉末冶金材料和技术发展现状(一)[J]. 上海金属, 2007, 29(3): 1-7.

HUANG Bai-yun, YI Jian-hong. Current development of modern powder metallurgy materials and technologies (Ⅰ) [J]. Shanghai Metals, 2007, 29(3): 1-7.

[3] HANEJKO F. 粉末冶金齿轮材料进展[J]. 粉末冶金工业, 2010, 20(3): 40-46.

HANEJKO F. Advances in P/M gear materials[J]. Powder Metallurgy Industry, 2010, 20(3): 40-46.

[4] 王玮晔, NARASIMHAN K S, 余卫民. 北美地区粉末冶金发展报告[J]. 现代零部件, 2011(8): 30-32.

WANG Wei-ye, NARASIMHAN K S, YU Wei-min. Report on the development of powder metallurgy in North America[J]. Modern Components and Parts, 2011(8): 30-32.

[5] NARASIMHAN K S, SEMEL F J. 预混合粉材料烧结[J]. 粉末冶金工业, 2009, 19(5): 1-11.

NARASIMHAN K S, SEMEL F J. Sintering of powder premixes: A brief overview[J]. Powder Metallurgy Industry, 2009, 19(5): 1-11.

[6] 朱权利, 周建仁. 粉末冶金Fe-C-Cu-Cr-Mn的组织与性能研究[J]. 热加工工艺, 2014, 43(8): 87-90, 94.

ZHU Quan-li, ZHOU Jian-ren. Study on microstructure and properties of powder metallurgy Fe-C-Cu-Cr-Mn[J]. Hot Working Technology, 2014, 43(8): 87-90, 94.

[7] 张德金, 罗丰华, 高 翔, 王 翔, 雷龙林, 崔建民. Cu、C添加量对退火态Fe-1.75Ni-0.50Mo粉末烧结合金组织和力学性能的影响[J]. 粉末冶金技术, 2011, 29(2): 125-129.

ZHANG De-jin, LUO Feng-hua, GAO Xiang, WANG Xiang, LEI Long-lin, CUI Jian-min. The influence of C and Cu addition and annealing of prealloyed iron powders on the mechanical properties and microstructure of sintered Fe-1.75Ni-0.50Mo alloys[J]. Powder Metallurgy Technology, 2011, 29(2): 125-129.

[8] 张晓宇, 赵训茶, 季长涛, 王 淮, 鞠育平. 添加纳米粉体对铁基粉末烧结件组织与性能的影响[J]. 长春工业大学学报(自然科学版), 2008, 29(1): 41-43.

ZHANG Xiao-yu, ZHAO Xun-cha, JI Chang-tao, WANG Huai, JU Yu-ping. The influence of nano-level powder addition on the microstructure and performance of P/M ferrous-base materials[J]. Journal of Changchun University of Technology (Natural Science Edition), 2008, 29(1): 41-43.

[9] 王文浩, 尹海清, 曲选辉, KHAN D F. 纳米铜粉对高速压制铁基粉末冶金零件性能的影响[J]. 北京科技大学学报, 2013, 35(10): 1340-1345.

WANG Wen-hao, YIN Hai-qing, QU Xuan-hui, KHAN D F. Effect of copper nanoparticles on strengthening of iron base P/M parts by high velocity compaction[J]. Journal of University of Science and Technology Beijing, 2013, 35(10): 1340-1345.

[10] 崔洪梅, 刘 宏, 王继杨, 李 霞, 韩 峰. 纳米粉体的团聚与分散[J]. 机械工程材料, 2004, 28(8): 38-41.

CUI Hong-mei, LIU Hong, WANG Ji-yang, LI Xia, HAN Feng. Agglomeration and dispersion of nano-scale powders[J]. Materials for Mechanical Engineering, 2004, 28(8): 38-41.

[11] 牟科强. 氧化物共还原制取W-Cu和Mo-Cu复合材料的研究[J]. 粉末冶金工业, 2004, 14(5): 13-16.

MOU Ke-qiang. Study of W-Cu and Mo-Cu composites prepared from coreduced oxide powders[J]. Powder Metallurgy Industry, 2004, 14(5): 13-16.

[12] 罗铁刚, 蔡一湘, 曲选辉, 秦明礼. 粉末注射成形纯钨的活化烧结致密化研究[J]. 机械工程学报, 2013, 49(18): 63-68.

LUO Tie-gang, CAI Yi-xiang, QU Xuan-hui, QIN Ming-li. Research of active sintering densifying on powder injection of molding pure tungsten[J]. Journal of Mechanical Engineering, 2013, 49(18): 63-68.

[13] 刘东华, 刘 咏, 韩云娟, 刘祖铭. 铁基高温合金氧化物强化相的形成和演化[J]. 中国有色金属学报, 2010, 20(6): 1143-1148.

LIU Dong-hua, LIU Yong, HAN Yun-juan, LIU Zu-ming. Formation and evolution of oxide strengthening phase in iron-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1143-1148.

[14] OHTSUKA S, UKAI S, FUJIWARA M. Nano-mesoscopic structural control in 9CrODS ferritic/martensitic steels[J]. Journal of Nuclear Materials, 2006, 351(1/2/3): 241-246.

[15] DANNINGER H, KREMEL S, LEITNER G, JAENICKE- ROBLER K, YU Y. Degassing during sintering of Cr-Mo steels prepared from prealloyed powder[C]// Advances in Powder Metallurgy & Particulate Materials. Prinston: Metal Powder Industries Federation, 2002: 291-301.

[16] 王兴庆, 钟军华. 低温还原制取超细铁粉的研究[J]. 粉末冶金工业, 2007, 17(6): 14-18.

WANG Xing-qing, ZHONG Jun-hua. Research on preparation of superfine iron powder by reduction at low temperature[J]. Powder Metallurgy Industry, 2007, 17(6): 14-18.

[17] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1997: 18-19.

HUANG Pei-yun. The principle of powder metallurgy[M]. Beijing: Metallurgical Industry Press, 1997: 18-19.

[18] DANNINGER H, GIERL C. New alloying systems for ferrous powder metallurgy precision parts[J]. Science of Sintering, 2008, 40: 33-46.

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2013AA031102)

收稿日期:2014-12-15;修订日期:2015-08-07

通信作者:周科朝,教授,博士;电话:0731-88830464;E-mail: zhoukechao@csu.edu.cn