铜基粉末冶金摩擦材料的湿式摩擦性能

王秀飞1,黄启忠1,尹彩流2,谭瑞轩1,宁克焱3,吴才成3

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 广西民族大学 物理与电子工程学院,广西 南宁,530006;

3. 中国北方车辆研究所 车辆传动国家重点实验室,北京,100072)

摘 要:采用粉末冶金方法制备铜基湿式摩擦材料,利用金相技术分析材料表面的微观结构, 并用MM-1000摩擦试验机研究制动条件对动摩擦因数影响的变化规律。研究结果表明:添加短切炭纤维增强的材料能有效提高材料的能量许用负荷和摩擦因数;摩擦副的制动速度为1 500 r/min和2 500 r/min时,摩擦因数随制动压力的增加而减小;摩擦副的制动速度为3 500 r/min时,摩擦因数随制动压力的增大呈现先降低而后增大的趋势;当制动压力为1.0 MPa和1.5 MPa时,摩擦因数随制动速度的提高而缓慢减小;当制动压力为2.0 MPa和2.5 MPa时,摩擦因数随制动速度的增加呈现先减小而后急剧增大的趋势。

关键词:粉末冶金;湿式摩擦材料;铜基;短切炭纤维;摩擦性能

中图分类号:TF125.9 文献标识码:A 文章编号:1672-7207(2008)03-0517-05

Wet friction properties of copper-based material

via powder metallurgy

WANG Xiu-fei1, HUANG Qi-zhong1, YIN Cai-liu2, TAN Rui-xuan1, NING Ke-yan3, WU Cai-cheng3

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. College of Physics and Electronic Engineering, Guangxi University for Nationalities, Nanning 530006, China;

3. National Key Laboratory of Vehicle Transmission, China North Vehicle Research Institute, Beijing 100072, China)

Abstract: A kind of wet copper-based friction material was made through powder metallurgy process. The surface microstructure was analyzed through metallographic analysis. The effects of brake conditions on friction coefficients of the material were investigated with MM-1000 friction tester. The results show that chopped carbon fibers can efficiently enhance energy load permitting value and friction coefficient. When the brake velocities are 1 500 r/min and 2 500 r/min, respectively, the friction coefficients decrease with the increase of interface pressure. When keeping brake velocity is 3 500 r/min, the dynamic friction coefficient first decreases and then increases with the increase of the brake pressure. With the increase of brake velocity, the friction coefficients with interface pressure as 1.0 MPa and 1.5 MPa slowly decrease. When the brake pressures are 2.0 MPa and 2.5 MPa, respectively, the dynamic friction coefficient first decreases and then sharply increases with the increase of brake velocity.

Key words: powder metallurgy; wet friction material; copper-based; chopped carbon fiber; friction properties

随着工程机械工作载荷和轮转动速度的不断增大,制动器承受的热负荷越来越大,为了有效降低制动器的温升和减小磨损,开始采用湿式多盘式制动器。目前,这种多盘式湿式制动器已应用于国内外的大型装载机、挖掘机、矿用汽车等工程车辆上

[1-4]。

用于这些摩擦构件的摩擦材料主要有:纸基、石棉基、金属基、半金属基材料、粉末冶金材料等[5-8]。由于石棉基摩擦材料对人体和环境存在较大的危害,已逐渐被淘汰。而纸基摩擦材料热负荷较低,在高温下易因摩擦磨损而毁坏,导致性能恶化。粉末冶金摩擦材料具有较高的摩擦因数、高导热性、高耐磨性以及能承受较大的扭矩等优良性能而得到广泛应用。

在此,本文作者通过添加短切炭纤维以提高湿式摩擦材料的动摩擦因数,降低磨耗和提高材料的能量负荷能力以满足重载使用的要求,研究一种高性能的铜基粉末冶金摩擦材料并进行了变工况下的湿式摩擦性能试验。

1 实 验

1.1 原材料

电解铜粉:w(Cu)≥99.7%,粒径<74 mm;还原铁粉:w(Fe)≥98.0%,粒径<74 mm;电解钛粉:w(Ti)≥99.8%,粒径<50 mm;天然石英砂:不规则形状,w(SiO2)≥97%,粒径为150~246 mm;天然鳞片状石墨:w(C)≥97%,粒径为246~500 mm;MoS2:胶体粉剂,分析纯;短切炭纤维:T700炭纤维。

1.2 制备工艺

采用电解铜粉作为基体,添加还原铁粉、锡粉和钛粉共10%~16%(质量分数)作为基体强化组元,添加鳞片石墨和短切炭纤维作为润滑组元,其含量为8%~12%,加入5%~8%的SiO2作为摩擦组元,加入3% MoS2作为辅助组元,制备铜基粉末冶金摩擦材料。主要工艺过程为:按照配比称取各组元后将粉末混合料装入“V”型混料机内混合均匀,冷压成形,于H2保护条件下采用加压烧结制备铜基粉末冶金摩擦材料。烧结温度为(950±20) ℃,烧结压力为3.5 MPa,保温3 h后,随炉冷却至室温出炉。

1.3 性能测试

用光学显微镜观测摩擦材料的微观组织结构,在MM-1000型摩擦磨损试验机上进行湿式摩擦性能 试验。

摩擦试验试样采用内、外直径分别为65 mm和85 mm的圆环,厚度为13~15 mm,在表面上加工成等间隔的12个径向油槽,沿圆周向加工两道油槽并磨平,槽宽2.0 mm,槽深0.75 mm。偶件为65Mn钢,其硬度HRC为40~45,几何尺寸与材料试样圆环相同。摩擦试验所用润滑油为重型车辆专用4634传动油,油压小于1 MPa,流量为3~5 mL/(cm2·min)。

首先对摩擦副试验环进行磨合,当目视接触面积达到总面积的80%时进行摩擦试验。试验过程固定转动惯量为0.1 kg×m2,将惯性轮的速度分别设定为1 500,2 500和3 500 r/min,制动压力依次设定为0.5,1.0,1.5,2.0 和2.5 MPa。每个条件下测试5条制动曲线,取其平均值作为材料的动摩擦因数。

2 结果与讨论

2.1 材料的微观结构

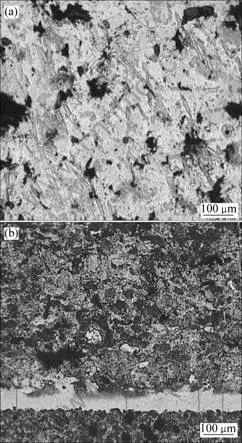

研究摩擦材料时,通过表面组织的变化情况可以了解摩擦副的表面温度、材料的耐热性等。图1所示为样品烧结后的微观组织形貌。

(a) 垂直压力方向;(b) 平行压力方向

图1 铜基材料的微观结构

Fig.1 Microstructures of copper-based material

图1(a)所示为材料在垂直压制压力方向上的金相显微组织照片。可见,添加的鳞片状石墨粉和短切炭纤维受压制压力的影响,其排布多平行于实际接触工作面,硬质点颗粒(摩擦相、摩擦组元)的分布较均匀、

平整并牢固镶嵌于基体中。这样的排布方式可以保证材料在摩擦时与对偶件表面接触良好。

图1(b)所示为样品在平行于试样摩擦方向上的金相显微组织照片。可见,鳞片石墨和摩擦组元较均匀地分布在基体中,从而保证了样品摩擦因数的平稳性和防止金属粘着及相对转移的发生。从图1(b)还可看出,铜基粉末冶金材料与钢背产生了冶金结合,故其结合性能良好。

Sn和Ti等各种成分均匀地分布在基体中。纯铜基材料的硬度较小,但基体铜经过Sn和Ti等合金元素强化后,基体材料的硬度显著增加[9]。尖角状的黑色颗粒是SiO2颗粒,加入Fe以颗粒形式均匀分布于Cu-Sn合金中,减少了材料内部应变区的扩展,使塑性变形趋势减小,提高基体的抗塑性流变能量,从而提高材料的强度和硬度。加入Ti粉一方面改善Cu与C的润湿性,解决了石墨和短切炭纤维与铜基体的结合问题,另一方面Ti与C反应生成TiC,使基体得到强化。同时,TiC的生成可以增大摩擦过程中的磨粒磨损,继而提高犁沟效应,以达到提高材料湿式摩擦因数的目的。

2.2 制动压力对铜基湿式摩擦材料动摩擦因数的 影响

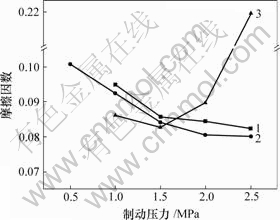

评价摩擦材料湿式摩擦性能的主要指标是动摩擦因数的大小和稳定性。铜基湿式摩擦材料摩擦因数随制动压力的变化关系如图2所示。可见,摩擦副的制动速度分别为1 500 r/min和2 500 r/min时,制动压力从0.5 MPa增大到2.5 MPa的变化过程中,摩擦因数的变化趋势一致,均随着制动压力的增加而减 小;当转速为1 500 r/min,制动压力从1.0 MPa增大到2.5 MPa时,摩擦因数从0.094 8减小至0.082 3,下降13.2%。当转动速度升高到2 500 r/min后,从压力0.5 MPa时的0.100 6减少到2.5 MPa时的0.081 4,下降16.4%;随制动压力的继续提高,摩擦因数的下降趋势减缓;在制动压力由1.5 MPa增加到2.5 MPa时,摩擦因数由0.084 1减小至0.081 4,下降比例仅为3.3%。摩擦因数的下降为非线性下降,随着压力的增大,摩擦因数下降的趋势变缓,并逐渐趋于平衡。

制动速度/(r?min-1): 1—1 500; 2—2 500; 3—3 500

图2 铜基湿式摩擦材料摩擦因数与制动压力的关系

Fig.2 Relationship between friction coefficient and

brake pressure for copper-based wet friction material

摩擦副的转动速度增加到3 500 r/min,当制动压力由1.0 MPa增加到2.0 MPa时,摩擦因数先降低而后增大,由0.086 2减小到0.082 6后又增大到0.089 7,当制动压力达到2.5 MPa时,摩擦因数剧增为0.219 3。

在制动速度一定、制动压力增大的情况下,制动开始时摩擦表面温度较低,润滑油黏度较高, 摩擦面油膜较厚。低压制动时摩擦表面的润滑油冷却效果好,摩擦表面温度低,油膜剪切力是摩擦力矩的主要成分, 由于低温润滑油剪切力大[10], 因而摩擦力矩较大,摩擦因数较高。

随着制动压力增加,制动时间缩短,摩擦表面温度在较短时间内升高, 润滑油黏度降低, 摩擦面润滑膜变薄, 油膜剪切力减小,由油膜剪切力产生的摩擦力矩减小。由于在摩擦副中使用的润滑油具有牛顿流体性质,其粘温特性可用Reynolds方程[11]表示为: (其中:η为T时黏度;η0为T0时黏度;β为常数)。随着制动压力升高, 动摩擦力矩呈现减小趋势,摩擦因数减小。

(其中:η为T时黏度;η0为T0时黏度;β为常数)。随着制动压力升高, 动摩擦力矩呈现减小趋势,摩擦因数减小。

当制动速度达到3 500 r/min时,此时材料在制动过程中的吸收能量增加。随着制动压力的增大,在制动的开始阶段,摩擦表面的温度迅速升高,当接触表面的接触温度超过润滑油的临界温度时,边界润滑膜发生破裂,摩擦副之间发生粘着磨损,摩擦因数急剧升高。

2.3 制动速度对铜基湿式摩擦材料摩擦因数的影响

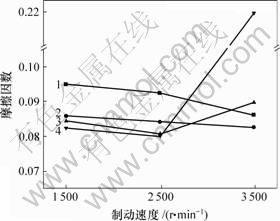

图3所示为铜基湿式摩擦材料的摩擦因数随制动速度的变化曲线。可见,当制动压力分别为1.0 MPa和1.5 MPa时,摩擦材料的摩擦因数随制动速度的提高而缓慢减小。随制动压力的继续增大,在制动压力分别为1.5 MPa和2.5 MPa时,制动速度由1 500 r/min增加到2 500 r/min时,摩擦因数随速度增大而减小。继续提高摩擦副速度,由2 500 r/min提高到3 500 r/min时,摩擦因数又呈现增大趋势。

制动压力/MPa: 1—1.0; 2—1.5; 3—2.0; 4—2.5

图3 铜基湿式摩擦材料摩擦因数随制动速度的变化关系

Fig.3 Relationship between friction coefficient and brake velocity for copper-based wet friction material

摩擦因数与制动速度之间的变化关系随制动压 力的不同而呈现相反的变化趋势。当制动压力较低时,摩擦因数随速度的升高而减小。当摩擦副的制动压力较高时,摩擦因数随制动速度的升高而增加。其原因是制动压力较低时,摩擦副之间的润滑油膜不足以被立即破坏,致使整个制动过程基本上都处于由流体润滑向混合摩擦状态过渡。

按照边界润滑理论[12],边界润滑的摩擦因数mBL为:

式(1)中右边的第1项和第2项分别为固体接触和液体接触产生的摩擦因数,第3项为犁沟效应产生的摩擦因数。在油膜存在的情况下,m p与前2项相比相对很小,可以忽略。摩擦因数主要来源于油膜的破坏程度。粗糙表面的平均膜厚与制动速度具有指数函数关系[12],即:

可见,膜厚随速度的增加而增加,所以,在制动速度增加的情况下摩擦因数减小。一方面,随着制动速度增加,在制动过程中摩擦副吸收的能量增加,导致摩擦副的表面温度升高,导致材料表面的温度升高,润滑油黏度减小,摩擦因数减小;另一方面,随着制动速度增加,润滑油在高速下的切应变率稀化,也将导致润滑油的黏度降低而呈现非牛顿性[12]。在高剪切力作用下,使分子排列规则化,从而减少相邻层之间的作用而降低表观黏度,导致摩擦因数降低。因此,材料的摩擦因数随速度的增加而减小。

当摩擦副的制动压力升高到一定程度时,摩擦副间油膜破坏。此时,随着制动速度的增大,一方面,导致制动初期摩擦表面温度快速升高,使润滑油的黏度减小,油膜的剪切强度降低,从而导致摩擦因数降低;另一方面,由于制动压力的增大,油膜被破坏,摩擦副直接接触的区域增大,导致摩擦因数的升高,同时,m p由于随制动压力的增大而增大,导致材料在制动压力较高的情况下,出现平均摩擦因数随速度变化的规律在高压力状态下与在低压力状态下呈现相反的趋势,即摩擦因数随速度的增大而升高。

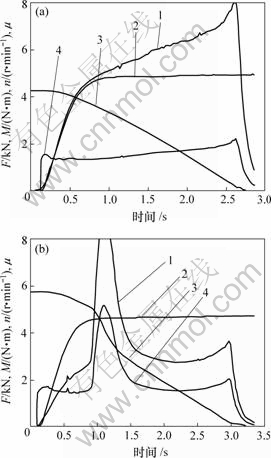

图4所示为铜基湿式摩擦材料在不同制动速度时的制动曲线。当制动速度n为3 500 r/min时,在制动压力p较小时,材料的摩擦因数μ呈下降趋势,当压力为2.0 MPa,摩擦因数开始增大。这是由于随着压力的增大,制动效率提高,在较短的时间内,摩擦表面的润滑油被挤出,铜基材料与对偶片间的粘着接触增大,动摩擦因数升高。当压力增大至2.5 MPa时,材料的摩擦因数骤然增大至0.219 3。这是由于摩擦副之间的润滑油在很短时间内被挤出,材料表面的温度骤然升高,造成材料与对偶件间的润滑油炭化,摩擦副在短时间内完成流体润滑摩擦—混合摩擦—粘着摩擦-混合摩擦的转变,导致材料的摩擦因数出现较大反常,如图4(b)所示。

1—M; 2—p; 3—n; 4—μ

(a) n=2 500 r/min, p=2.0 MPa, F=1 KN, M=2.5 N?m, μ=0.05; (b) n=3 500 r/min, p=2.0 MPa, F=1 KN, M=5.0 N?m, μ=0.05

图4 铜基湿式摩擦材料在不同制动速度时的制动曲线

Fig.4 Brake curves of copper-based wet friction material at different brake velocities

从图4(a)可以看出:材料在2 500 r/min制动时,随着制动过程的进行,摩擦因数稍增加。而图4(b)所示在3 500 r/min的制动速度下,摩擦力矩M在制动 1 s后出现了一个力矩的高峰值,随着制动过程的进行,摩擦力矩又逐渐降低至正常水平。这是因为在制动1 s后摩擦副表面出现了瞬时高温,宏观表现为制动时摩擦副接触处出现了“烟雾”,即导致摩擦副表面的润滑油出现了炭化现象,从而使摩擦副的2个表面出现了粘着摩擦,摩擦因数剧变。

在瞬时高温过后,由于润滑油的冷却和摩擦副材料热传导的双重作用,摩擦副表面温度逐渐降低,重新在摩擦副表面形成新的油膜,摩擦面由黏着摩擦向混合摩擦过渡,摩擦因数下降。此时,材料的能量负荷为8.731 4×104 J2?cm-4?s-1,远大于烧结金属摩擦材料规定中能量许用负荷值技术要求的8.5×103 J2?cm-4?s-1,表明该材料能在高能载的工况下使用。

3 结 论

a. 在铜基粉末冶金摩擦材料中添加短切炭纤维能有效提高材料的能量许用负荷和动摩擦系数,摩擦因数高且稳定。

b. 摩擦副的制动速度为1 500 r/min和2 500 r/min时,摩擦因数均随着制动压力的增加而减小。当摩擦副的制动速度增加到3 500 r/min,压力由1.0 MPa增加到2.5 MPa的过程中,摩擦因数先降低而后增大。

c. 当制动压力为1.0 MPa和1.5 MPa时,摩擦因数随制动速度的提高而缓慢减小。当制动压力达到 2.0 MPa和2.5 MPa,制动速度由1 500 r/min增加到 2 500 r/min时,摩擦因数减小;制动速度提高到3 500 r/min时,摩擦因数又呈现增大趋势。

参考文献:

[1] 李非雪, 张文明, 方 湄. 测量湿式多片制动器摩擦表面的温度分布[J]. 矿山机械, 2000(12): 56-58.

LI Fei-xue, ZHANG Wen-ming, FANG Mei. Measuring the friction temperature distribution in wet multi-disc brake[J]. Mining & Processing Equipment, 2000(12): 56-58.

[2] 付 华, 孙宝臣, 许泽凯. TB880E掘进机离合器摩擦片材料选择[J]. 石家庄铁道学院学报, 2002, 15(2): 16-18.

FU Hua, SUN Bao-cheng, XU Ze-kai. Selection of friction material for clutch disc in tunnel boring machine TB880E[J]. Journal of Shijiazhuang Railway Institute, 2002, 15(2): 16-18.

[3] Tjong S C, Lau K C. Tribological behavior of SiC particle-reinforced copper matrix composites[J]. Materials Letters, 2000, 43(5/6): 274-280.

[4] 王 晶, 姚志芳. 车用多盘湿式制动器[J]. 建筑机械, 2000(2): 35-37.

WANG Jing, YAO Zhi-fang. Multidisc wet brake[J]. Construction Machinery, 2000(2): 35-37.

[5] Malsumolo T, Ohume M, Kuse T. Research of a paper-based friction material and paper friction plate for application[J]. Drive System Technique, 1998(2): 16-23.

[6] Jullien A, Meurisse M H, Berthier Y. Determination of tribological history and wear through visualisation in lubricated contacts using a carbon-based composite[J]. Wear, 1996, 194(1/2): 116-125.

[7] 付业伟, 李贺军, 李克智. 纸基摩擦材料绿色制备工艺与摩擦磨损性能研究[J]. 摩擦学学报, 2004, 24(2): 172-176.

FU Ye-wei, LI He-jun, LI Ke-zhi. Study on the green preparation process and friction performance of paper-type friction materials[J]. Tribology, 2004, 24(2): 172-176.

[8] 熊 翔, 盛洪超, 姚萍屏. 铜基航空刹车材料的烧结温度和烧结压力[J]. 中南大学学报: 自然科学版, 2007, 38(2): 206-212.

XIONG Xiang, SHENG Hong-chao, YAO Ping-ping. Sintering pressures and temperatures of Cu-based aircraft brake materials[J]. Journal of Central South University: Science and Technology, 2007, 38(2): 206-212.

[9] Taga Y, Isogai A, Nakajima K. The role of alloying elements in the friction and wear of copper alloys[J]. Wear, 1977, 44(2): 377-391.

[10] Shima M, Suetake H, McColl I R. On the behavior of an oil lubrication fretting contact[J]. Wear, 1997, 210(1/2): 304-310.

[11] 温诗铸, 黄 平. 摩擦学原理[M]. 北京: 清华大学出版社, 2003.

WEN Shi-zhu, HUANG Ping. Principle of tribology[M]. Beijing: Tsinghua University Press, 2003.

[12] Kingsbury E. Parched elastic hydrodynamic lubrication film thickness measurement in the instrument ball bearing[J]. Tribol Trans, 1990, 33(1): 11-14.

收稿日期:2007-06-16;修回日期:2007-09-02

基金项目:国家重点基础研究发展计划资助项目(2006CB600901);车辆传动国家重点实验室基金资助项目(51457030105QT7106)

通信作者:黄启忠(1962-),男,湖南岳阳人,博士,教授,从事炭/炭复合材料、粉末冶金摩擦材料的研究;电话:0731-8836078;E-mail: qzhuang@mail.csu.edu.cn