文章编号:1004-0609(2011)08-1910-06

工艺参数对高速电镀锌层形貌和织构的影响

顾训雷,单玉桥,刘常升

(东北大学 材料各向异性设计与织构控制教育部重点实验室,沈阳 110819)

摘 要:应用模拟重力法高速电镀装置在无间隙原子钢(IF钢)基板上电镀锌,采用场发射扫描电镜(FESEM)和X射线衍射仪(XRD)研究电流密度和钢板运动速度对锌层微观形貌和织构的影响。结果表明:高速电镀锌层呈片晶状倾斜于基体表面紧密排列,随着电流密度(20~60 A/dm2)的增大,{10.3}和{10.4}等锥形织构系数降低,{00.2}基面织构系数显著增加,晶粒尺寸减小;当电流密度高于50 A/dm2时,伴有枝晶的出现;钢板运动速度(1~3 m/s)的增大提高镀层的致密度,同时降低{00.2}基面织构系数,对锥形织构的影响较小。

关键词:高速电镀锌;工艺参数;形貌;织构

中图分类号:TQ153.1 文献标志码:A

Effects of technological parameters on

morphology and texture of high speed galvanized coatings

GU Xun-lei, SHAN Yu-qiao, LIU Chang-sheng

(Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education,

Northeastern University, Shenyang 110004, China)

Abstract: The zinc was electrodeposited on the interstitial free (IF) steel plate by the simulation equipment of gravity method high speed galvanization. The influences of current density and velocity of steel plate on the morphology and texture of zinc coatings were investigated. The results show that the zinc platelets are tilted with respect to the substrate surface compactly. The increase of current density (20-60 A/dm2) results in the decrease of intensities of the {10.3} and {10.4} pyramidal texture and the increase of the intensity of the {00.2} basal texture. The application of high current density, 50 A/dm2 or higher, can lead to the existence of nodule. The increase of the steel plate velocity (1-3 m/s) results in the dense coating and the decrease of intensity of the {00.2} texture, but do not affect the intensity of the pyramidal texture obviously.

Key words: high speed galvanization; technological parameter; morphology; texture

镀锌层因具有壁垒和电偶的双重保护作用,广泛地应用于钢铁保护[1-2],随着社会需求的增加和产品竞争的增强,连续镀锌工业正从保证质量、提高产率、降低成本和满足环保等各个方面进行技术创新,其中重力法高速电镀锌技术因其具有较高的生产效率以及良好的厚度可控性应用日益广泛[3-4]。

WINAND[5]分析了电镀工艺中电流密度和阴极吸附层的协同作用机理,并根据形貌和取向的不同将镀层形貌分为4类:无取向型、织构取向型、基本取向型和独立取向型。WEYMEERSCH等[6]认为镀层形貌取决于镀液流速和电流密度的共同作用,而FILHO和LINS[7]认为,相比于镀液流速,电流密度对锌层形貌的影响更为显著。RAEISSI等[8]对电镀锌层织构的研究结果显示:镀层的{11.5}和{11.6}非纤维织构随着电流密度的增加而降低,{00.2}基面织构随着电流密度的增加而增强,而NAKANO等[9]认为高的阴极过电位可导致{00.2}、{10.3}取向指数的降低以及{10.1}、{10.0}取向指数的提高。PARK和SZPUNAR[10]将高电流密度下{00.1}织构成分的消失和{10.1}、{11.2}织构成分的增大归因于镀液的流体动力学。而部分学者认为,可用晶体的形核和长大机制解释锌层的形貌和织构的形成及变化[11-12]。镀锌过程中的氢氧化锌吸附层的抑制理论解释了形核和长大的问题,吸附层能够抑制三维形核的发生,同时提高二维形核的几率,该理论最早由HIGASHI等[13]提出,随后得到其他学者的肯定[8, 14-15]。

重力法电镀锌镀液自上而下流动,与钢板形成的相对高速运动提高了阴极极限电流密度,同时阴极析氢的发生增大了锌离子的传递系数,因此,电镀过程中常应用较高的电流密度[5],这就使得电流密度的控制和钢板运动速度的调节尤其重要。本研究工作目的是通过实验结果分析电流密度和钢板运动速度对镀层形貌和织构的影响并探讨影响机理。

1 实验

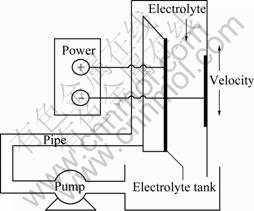

本研究电镀基板采用宝钢生产的冷轧IF钢,采用模拟重力法电镀锌装置(如图1),镀液通过水泵输送至装置顶端,在重力作用下自上而下流动,钛基氧化铱板作阳极,阴极板运动速度可调。镀液成分为Zn2+浓度为80~120 g/L的ZnSO4溶液,温度控制在40~60 ℃,pH调节为2~3。

采用JEOL JSM-7001F场发射扫描电镜观察镀层形貌;使用PANalytical公司生产的X’Pert PRO MPD型衍射仪测量镀层的衍射图谱并基于各相关晶面的衍射强度计算其织构系数[16]:

其中,

式中: 表示{hk.l}晶面的织构系数;

表示{hk.l}晶面的织构系数; 表示晶面的相对衍射强度;

表示晶面的相对衍射强度; 表示晶面的衍射强度值;

表示晶面的衍射强度值; 表示所有考虑的晶面的衍射强度之和。同理可计算得到无取向锌粉{hk.l}面的相对衍射强度

表示所有考虑的晶面的衍射强度之和。同理可计算得到无取向锌粉{hk.l}面的相对衍射强度 。

。

图1 重力法高速电镀锌模拟设备示意图

Fig.1 Schematic diagram of simulation equipment of gravity method high speed galvanization

2 结果与分析

2.1 工艺参数对锌层微观形貌的影响

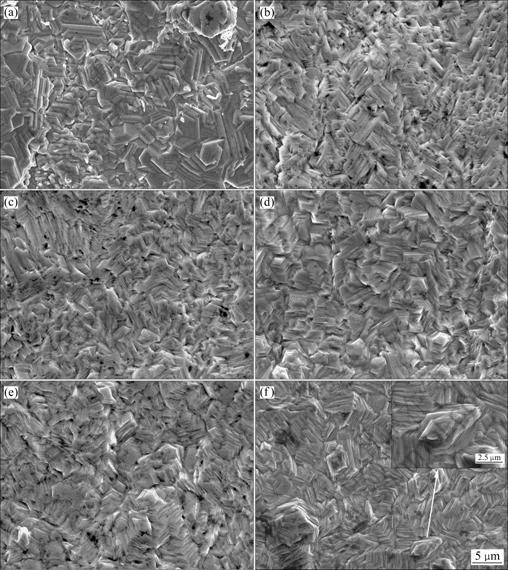

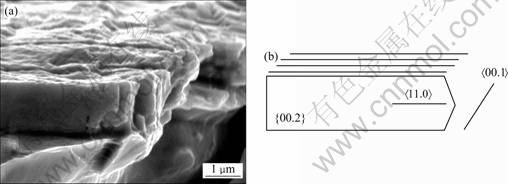

图2(a)所示为常规静态镀液电镀锌层微观形貌。晶粒多遵循螺旋生长,呈现层状平行于基板表面。由于重力法高速电镀锌的过程中,镀液自上而下流动,钢板在镀槽中高速运动,二者之间的相对运动增强镀液的强制对流作用,有利于液相传质和降低浓差极化,吸附离子得以有效补充,使得电镀过程中可以应用较高的电流密度。图2(b)~(f)所示为重力法电镀锌不同电流时的微观形貌。高速电镀锌层的微观形貌均以倾斜于基板表面的片状结晶为主,片晶间彼此平行,呈现团簇生长。在高速电镀过程中,由于高电流密度的应用,伴随有大量氢气的析出,而镀液相对基板的高速运动,可及时将氢气驱除,析氢过程中同时出现的大量氢氧化锌吸附在基板的表面,在抑制三维形核发生的同时,提高二维形核的几率[17],氢氧化锌的吸附也可促进晶核的团簇生长[18]。如图3所示,二维形核是在基体表面产生一个密排面{00.2}倾斜于基板表面的晶核,晶核沿某一晶面和晶向外延生长,形成一个倾斜于基板表面的片晶。

根据关联电化学过电位 与反应电流i的Butler-Volmer方程[19]

与反应电流i的Butler-Volmer方程[19]

(1)

(1)

式中:i0为交换电流; 为电子传递系数;n为反应转移电子数;F为法拉第常数;R为摩尔气体常数;T表示镀液温度。由于重力法高速电镀锌工艺中,镀液与阴极板相对的高速运动,交换离子得以快速补充,该式可简化为

为电子传递系数;n为反应转移电子数;F为法拉第常数;R为摩尔气体常数;T表示镀液温度。由于重力法高速电镀锌工艺中,镀液与阴极板相对的高速运动,交换离子得以快速补充,该式可简化为

(2)

(2)

式中:a和b为常数。

图2 不同电镀工艺和电流密度时锌层的微观形貌

Fig.2 Morphologies of zinc coatings at different electroplate technologies and current densities: (a) Conventional galvanized at 1 A/dm2; (b) Gravity method galvanized at 20 A/dm2; (c) Gravity method galvanized at 30 A/dm2; (d) Gravity method galvanized at 40 A/dm2; (e) Gravity method galvanized at 50 A/dm2; (f) Gravity method galvanized at 60 A/dm2

图3 电沉积初期锌层的低温断面形貌及片晶生长方向示意图

Fig.3 Cryogenic fracture of zinc coatings at initial deposit stage (a) and schematic diagram of growth direction of platelets (b)

由此可知,随着电流密度的增大,电化学过电位增加。当阴极电流密度低于30 A/dm2时,阴极极化作用较小,晶核形成速率较低,致使晶粒尺寸变大、镀层粗糙并伴有较多孔隙。随着电流密度的增大,电化学过电位增大,放电离子的增多增加了晶核的数目,镀层趋于致密,晶粒尺寸减小。VOLMER和WEBER[20]推导了成核速率方程

(3)

(3)

式中:J为形核速率;A和B为常数; 为过电位。

为过电位。

同时,相关文献也报道了形核几率Fn与电流密度的关系[21]

(4)

(4)

式中:ic表示阴极电流密度;R为摩尔气体常数;s 表示晶核表面能。

由式(3)和(4)可知,电流密度的增加提高了成核速率和成核几率,导致晶核数目的增加,使结晶趋于致密。

锌层的微观形貌取决于二维晶核的外延生长和单原子层的横向生长之间的竞争,横向生长过程可以在下一个结晶过程出现时停止[5]。当电流密度达到60 A/dm2,团簇状的结晶形貌较多,同时,过高的电流密度和相对较慢的液相传质使得阴极的局部区域放电金属离子贫乏,导致枝晶的出现(如图2(f)所示)。若干片晶相互接触时,在接触点产生螺旋位错群,吸附原子在相同的驻留时间内,更多的吸附原子沉积在扭结位置,同时,遵循螺旋位错生长,位错线每推进一周,晶体就向上生长了一个原子层,如此反复旋转生长,晶体沿位错线螺旋式长大[5]。

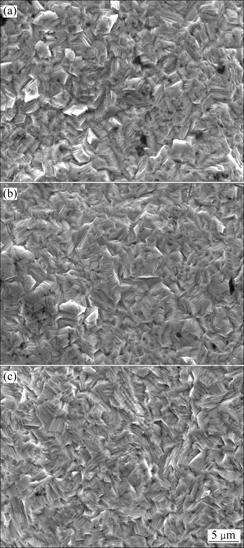

图4所示为电流密度为40 A/dm2时不同钢板运动速度下锌层的微观形貌。钢板与镀液相对的高速运动有利于金属离子的传递和浓差极化的降低,随着钢板运动速度的加快,结晶趋于致密。由极限电流密度Jdl的表达式[5]

(5)

(5)

式中:n为放电金属离子价态;F为法拉第常数;Dj为扩散系数;d 为扩散层的厚度;cj为金属离子在溶液本体中的浓度。

极限电流密度与扩散层厚度成反比,扩散层厚度可随着钢板与镀液相对运动速度的增大而降低,因此较高的钢板运动速度对应较高的极限电流密度[21]。如图4(c)所示,在较高的钢板运动速度下,镀层中因局部电流密度过高而出现的枝晶较少。此外,镀液与钢板间的高速相对运动有利于吸附氢气的驱除,当板速相对较慢时,残留的少量吸附氢影响了锌的沉积,从而导致钢板局部出现孔隙。

图4 不同钢板运动速度时锌层的微观形貌

Fig.4 Morphologies of zinc coatings at 40 A/dm2 and steel plate velocities of 1 m/s(a), 2 m/s(b) and 3 m/s(c)

2.2 工艺参数对锌层织构的影响

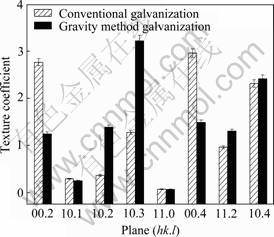

受到极限电流密度的限制,常规静态电镀锌仅能应用较低的电流密度,促进了低过电位条件下{00.2}织构形成[22]。图5所示为不同电镀技术时锌层各晶面的结构系数。由图5可看出,常规电镀锌层与重力法高速电镀锌层相比,前者显示出强烈的{00.2}基面织构。晶体表面能对镀层织构的形成具有重要作用,在电沉积的过程中,镀层织构趋向于具有最低表面能的状态,具有低表面能的晶粒趋向于增加自身表面积,而具有高表面能的晶粒趋向于减小其表面积,因此,随着电沉积的进行,晶粒多以密排面{00.2}平行于基板表面排列[17],吸附原子继而扩散到晶粒的边缘,片晶通过侧面生长模式得以长大[23]。对于高速电镀工艺,出现锥形织构的原因与高速电镀过程中氢氧化锌的大量吸附有关,基体表面的吸附层一定程度上影响了晶体表面能的各向异性[24],同时吸附层可作为“界面抑制剂”阻止吸附原子的聚集,并促进二维形核的发生和聚束生长,产生密排面{00.2}与基体表面呈一定夹角的片晶,片晶通过外延生长得以长大[18]。微观形貌测试中的一系列翘起的六方片晶,反映在XRD谱中,为锥形非纤维织构组分的存在。

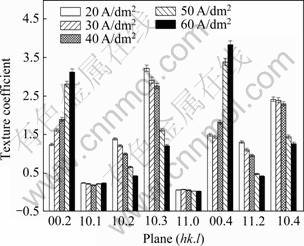

图6所示为电流密度不同时各晶面的织构系数图谱。锌层除显示{00.2}基面织构外,{10.3}、{10.4}、{11.2}和{10.2}等锥形织构也显示较强的织构系数。同时,随着电流密度的增加,{00.2}基面织构系数增大。尽管{00.2}基面与{10.3}等锥形面在织构系数上近似,但在微观形貌的测试中翘起状的片晶较多,原因是无取向锌粉的{00.2}面的相对衍射强度较低,导致其织构系数值较高。

图5 不同电镀技术时锌层各晶面的织构系数

Fig.5 Texture coefficients of crystal planes of zinc coatings with different electroplate technologies (conventional galvanization at 1 A/dm2 and gravity method galvanization at 20 A/dm2)

图6 不同电流密度时锌层各晶面的织构系数

Fig.6 Texture coefficients of crystal planes of zinc coatings at different current densities

基面织构的强度取决于过电位的高低,在相对较低的过电位下,通过二维形核和团簇生长实现片晶的外延生长,而基面织构来源于三维形核和取向生长,随着电流密度的增大,过电位的增大提高三维形核的几率,抑制了晶粒的外延生长,大量晶粒以片状平行于基板表面排列,{00.2}基面纤维织构得以加强[8]。当电流密度高于50 A/dm2时,基面织构系数增幅扩大,过高的电流密度导致枝晶部位的产生,枝晶部位以{00.2}密排面平行于基板表面为主。

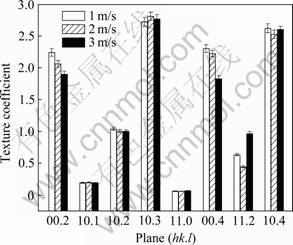

钢板速度的变化对应织构系数的图谱如图7所示。基面织构随着板速的增加有降低趋势,{10.3}和{10.4}等锥形织构系数变化不大。板速的增大有利于增强镀液的对流作用,提高极限电流密度,消除局部位置因为过高电流密度而发生枝晶的现象,枝晶位置的减少有利于{00.2}织构系数的降低,{00.4}作为{00.2}的二级衍射面与其具有相似的变化趋势。

图7 不同钢板速度时锌层各晶面的织构系数

Fig.7 Texture coefficients of crystal planes of zinc coatings at different steel plate velocities

3 结论

1) 常规静态电镀锌多以层状平行于基板排列,结晶取向以{00.2}基面织构为主;重力法高速电镀锌层以六方形片晶状倾斜于基体表面平行排列,结晶取向以锥形织构为主。

2) 随着电流密度的增大,镀层孔隙减少,结晶趋于致密,{10.3}和{10.4}等锥形织构系数降低,{00.2}基面织构系数增加,但过高的电流密度导致枝晶的出现。

3) 钢板运动速度对锥形织构的影响较小,但板速的提高降低{00.2}基面织构系数,同时有利于减少锌层孔隙和枝晶,提高镀层的致密度。

REFERENCES

[1] 章小鸽. 锌的腐蚀与电化学[M]. 仲海峰, 程东妹, 译. 北京: 冶金工业出版社, 2008: 22-26.

ZHANG Xiao-ge. Corrosion and electrochemistry of zinc[M]. ZHONG Hai-feng, CHENG Dong-mei, transl. Beijing: Metallurgical Industry Press, 2008: 22-26.

[2] BANDYOPADHYAY N, JHA G, SINGH A K, ROUT T K, RANI N. Corrosion behaviour of galvannealed steel sheet[J]. Surf Coat Technol, 2006, 200(14/15): 4312-4319.

[3] 顾训雷, 单玉桥, 刘常升, 于晓中. 在高速电镀锌钢板表面磁控溅射铝镁合金[J]. 材料研究学报, 2009, 23(5): 529-533.

GU Xun-lei, SHAN Yu-qiao, LIU Chang-sheng, YU Xiao-zhong. Research of magnetron sputtered Al-Mg alloy coatings on high-speed electro-galvanizing steel[J]. Chinese Journal of Materials Research, 2009, 23(5): 529-533.

[4] 朱晓东, 李 宁, 黎德育, 刘伟华, 李 伟. 高速电镀锌工艺对镀层粗糙度及微观形貌的影响[J]. 中国有色金属学报, 2005, 15(1): 145-151.

ZHU Xiao-dong, LI Ning, LI De-yu, LIU Wei-hua, LI Wei. Influence of technology of high-speed galvanization on roughness and micromorphology of coating[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 145-151.

[5] WINAND R. Electrocrystallization: fundamental considerations and application to high current density continuous steel sheet plating[J]. J Appl Electrochem, 1991, 21(5): 377-385.

[6] WEYMEERSCH A, WINAND R, RENARD L. Zinc electrodeposition at high current densities.Ⅰ. Electrochemical study[J]. Plating Surf Finish, 1981, 68(4): 56-59.

[7] FILHO J F S, LINS V F C. Crystallographic texture and morphology of an electrodeposited zinc layer[J]. Surf Coat Technol, 2006, 200(9): 2892-2899.

[8] RAEISSI K, SAATCHI A, GOLOZAR M A, SZPUNAR J A. Texture and surface morphology in zinc electrodeposits[J]. J Appl Electrochem, 2004, 34(12): 1249-1258.

[9] NAKANO H, ARAGA K, IWAI M, KAWAHUKU J. Effect of electrolysis conditions on the morphology and crystal orientation of zinc electrodeposit[J]. ISIJ Int, 1997, 83(12): 785-790.

[10] PARK H, SZPUNAR J A. The role of texture and morphology in optimizing the corrosion resistance of zinc-based electrogalvanized coatings[J]. Corros Sci, 1998, 40(4/5): 525-545.

[11] VASILAKOPOULOS D, BOUROUSHIAN M, SPYRELLIS N. Electrocrystallisation of zinc from acidic sulphate baths: A nucleation and crystal growth process[J]. Electrochim Acta, 2009, 54: 2509-2514.

[12] RAEISSI K, SAATCHI A, GOLOZAR M A. Effect of nucleation mode on the morphology and texture of electrodeposited zinc[J]. J Appl Electrochem, 2003, 33(7): 635-642.

[13] HIGASHI K, FUKUSHIMA H, URAKAWA T. Mechanism of the electrodeposition of zinc alloys containing a small amount of cobalt[J]. J Electrochem Soc, 1981, 128(10): 2081-2085.

[14] BALDWIN K R, SMITH C J E, ROBINSON M J. A study into the electrodeposition mechanisms of zinc-nickel alloys from an acid-sulphate bath[J]. Trans Inst Met Finish, 1994, 72(2): 79-88.

[15] TSURU T, KOBAYASHI S, AKIYAMA T, FUKUSHIMA H, GOGIA S K, KAMMEL R. Electrodeposition behaviour of zinc-iron group metal alloys from a methanol bath[J]. J Appl Electrochem, 1997, 27(2): 209-214.

[16] SERE P R, CULCASI J S, ELSNER C I, SARLI A R D. Relationship between texture and corrosion resistance in hot-dip galvanized steel sheets[J]. Surf Coat Technol, 1999, 122(2/3): 143-149.

[17] RAEISSI K, SAATCHI A, GOLOZAR M A, SZPUNAR J A. Effect of surface preparation on zinc electrodeposited texture[J]. Surf Coat Technol, 2005, 197(2/3): 229-237.

[18] RAEISSI K, SAATCHI A, GOLOZAR M A, TUFANI A, SZPUNAR J A. The effect of electrochemical adsorbates on texture and morphology development during zinc and zinc-cobalt electrodepositions[J]. Electrochim Acta, 2008, 53(14): 4674-4678.

[19] BUDEVSKI E, STAIKOV G, LORENZ W J. Electrocrystallization nucleation and growth phenomena[J]. Electrochim Acta, 2000, 45(15/16): 2559-2574.

[20] VOLMER M, WEBER A. Nucleation in super-saturated products[J]. J Phys Chem, 1927, 119: 277-301.

[21] LI D Y, SZPUNAR J A. Textural evolution in electrodeposits under the influence of adsorbed foreign species: PartⅠ Textural evolution in iron electrodeposits affected by hydrogen co-deposition[J]. J Mater Sci, 1997, 32(20): 5513-5523.

[22] PANGAROV A. Preferred orientations in electrodeposited metals[J]. J Electroanal Chem, 1965, 9(1): 70-85.

[23] KONDO K, MURAKAMI T, CERWINSKI F, SHINOHARA K. AFM study on morphology evolution of zinc electrodeposits[J]. ISIJ Int, 1997, 37(2): 140-145.

[24] LI D Y, SZPUNAR J A. A Monte Carlo simulation approach to the texture formation during electrodeposition—Ⅱ. Simulation and experiment[J]. Electrochim Acta, 1997, 42(1): 47-60.

(编辑 李艳红)

基金项目:国家高技术研究发展计划资助项目(2009AA03Z529);长江学者和创新团队发展计划资助项目(IRT0713)

收稿日期:2010-08-02;修订日期:2010-10-28

通信作者:刘常升,教授,博士;电话:024-83687365;E-mail: csliu@mail.neu.edu.cn