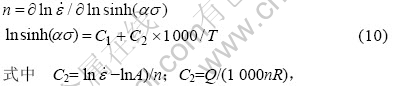

文章编号:1004-0609(2008)06-1012-08

Mg-9Y-3Zn-0.5Zr合金的热变形行为

李庆波1,叶 凡2,周海涛1,钟建伟1,赵仲恺1 ,王孟君1, 3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 北京航空航天大学 材料科学与工程学院, 北京100083;

3. 华中科技大学 材料科学与工程学院,武汉430074)

摘 要:用Gleeble-1500热/力模拟机研究Mg-9Y-3Zn-0.5Zr镁合金在应变速率为0.001~0.1 /s,变形温度为543~743 K下的热变形行为,分析实验合金在高温变形时的流变应力和应变速率及温度之间的关系,计算变形激活能和应力指数,并讨论热压缩过程中的组织变化。结果表明:在同一变形温度下,实验合金的真应力水平随应变速率的增加而增加,随温度的提高而降低且表现出明显的再结晶特征。当变形温度在643~693 K时,激活能变化不大;当温度大于693 K时,激活能随温度升高而增大。当温度达到693 K时,合金发生了完全再结晶。Mg-9Y-3Zn-0.5Zr合金在693 K挤压后的抗拉强度为340.0 MPa,伸长率为16.2%;该合金在时效后的抗拉强度为396.4 MPa,伸长率为6%, 时效抗拉强度明显上升。

关键词:镁合金;Y;动态再结晶;热变形

中图分类号:TG 146.22 文献标识码:

AHot deformation behavior of Mg-9Y-3Zn-0.5Zr alloy

LI Qing-bo1, YE Fan2, ZHOU Hai-tao1, ZHONG Jian-wei1, ZHAO Zhong-kai1, WANG Meng-Jun1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Beihang University, Beijing 100083, China;

3. School of Materials Science and Engineering, Huazhong University of Science and Technology,

Wuhan 430074, China)

Abstract: The thermal deformation behavior of Mg-9Y-3Zn-0.5Zr magnesium alloy at the strain rates of 0.001-0.1 /s and in a temperature range from 543 K to 743 K performed on Gleeble-1500 hot simulator was studied. The results show that the true stress increases with increasing the stain rate at the same temperature, and decreases with increasing the temperature at the same strain rate with a characteristic of dynamic recrystallization. The deformation activation energy increases when the deformation temperature is over 693 K, and it is stable in the range of 643-693 K. The alloy exhibits a complete recrystallization at 693 K, the extruded alloy has a tensile strength of 340.0 MPa and an elongation of 16.2%, and after aging, the tensile strength is 396.4 MPa, the elongation is 6%.

Key words: magnesium alloy; Y; dynamic crystallization; hot deformation

镁合金具有质轻、比强度高、刚性好等一系列优异的物理性能[1-2],能够在结构领域代替部分工程塑料和铝合金,因此具有广阔的发展前景。特别是现在对汽车节能和环保要求的重视,以及电子工业3C产品的大量出现,镁合金的应用开发更被重[3-5]。在现有的镁合金中只有镁铝锌系和镁锌锆系合金的抗拉强度较高,一般情况下,镁铝锌系的可达300 MPa,镁锌锆系的可达350 MPa,使用温度多在473 K以下[6]。当温度升高时,镁合金的抗拉强度和抗蠕变性能大幅度下降,使其难以作为关键零件(如发动机零件) 材料在汽车等工业中得到更广泛的应用[7]。Mg-Zn-Zr系合金普遍存在对显微疏松敏感、焊接性能差、热裂倾向严重等缺点,而稀土元素具有净化合金、改善组织、提高高温力学性能、增强耐腐蚀性、提高合金的抗氧化和抗蠕变性能等作用。因此,在Mg-Zn-Zr系合金的基础上添加少量稀土元素,可细化合金的晶粒,明显降低形成显微缩松的倾向,改善了铸态性能,形成的稀土相具有较高的热力学稳定性且合金的高温力学性能明显得到提高。前苏联最早研究发现w(Y)=10%的镁合金可以在533 K下使用,而w(Y)=9%、w(Zn)=1%的镁合金在具有高耐热性的同时,具有高的抗腐蚀稳定性,并开发出用Y代替有放射性的Th的新型耐热镁合金,其耐热温度达到543 K[7]。因此在镁合金中加入稀土开发新型Mg-Zn-Zr-RE四元合金是优化和改进ZK系合金化学成分的一个有效途径。

本文作者以Mg-Y-Zn-Zr(Mg-9%Y-3%Zn-0.5%Zr)合金为研究对象,通过热/力模拟和金相分析等手段,研究合金的热变形特性和挤压后的组织及性能,为后续工业化挤压提供理论依据。

1 实验

本实验合金为Mg-9Y-3Zn-0.5Zr(质量分数,%)。稀土元素Y以Mg-20%Y中间合金形式加入, Zr以Mg-30%Zr中间合金形式加入,Zn的熔点低,直接加入到合金熔液中。实验合金在井式坩埚电阻炉熔炼,熔炼温度保持在973 K左右。当充分熔化后加Mg-Zr和Mg-Y中间合金,精炼搅拌后,熔炼温度升至1 023 K,保温30 min,然后在金属模中浇注成直径55 mm 的圆柱锭。圆柱锭在765 K进行均匀化退火保温24 h后炉冷。利用金相显微镜观察对比合金铸态和均匀化退火态的显微组织。压缩试样尺寸为d10 mm×15 mm,其中两端开0.2 mm的凹槽填充含石墨的固体润滑剂以减少压缩时试样两端的摩擦力。压缩实验是在Gleeble-1500热模拟机上进行,设定的变形温度范围为543~743 K,应变速率为0.001~0.1 /s,压缩后立即水淬以保留高温变形组织。实验数据的采集由Gleeble-1500的计算机采集系统来完成。最后,将变形态、原始铸态和均匀化退火态试样制成金相试样, 所用浸蚀剂为:苦味酸5 g+醋酸5 g+蒸馏水10 mL+乙醇100 mL溶液。在NEOPHOT221金相显微镜下观察金相组织,并进行比较。

根据热/力模拟实验得出合适的挤压温度进行热挤压,挤压比为13,挤压后的棒材直径为14 mm,然后在INSTRON Model 8032电子万能实验机上对挤压态和时效态样品进行常温拉伸实验。

2 结果和分析

2.1 铸态显微组织分析

实验合金铸态显微组织如图1(a)所示。由图可见铸造组织呈现较粗大的枝晶状,晶粒尺寸为100 μm左右,主要由α-Mg相及晶界析出的化合物组成,晶界粗大,枝晶偏析现象严重。图1(b)所示为实验合金的均匀化后的显微组织 。由图可见,均匀化处理使其铸态组织中的枝晶偏析已明显消除,枝晶网胞及晶界上网状化合物相也大部分溶解,第二相细小弥散分布。原本沿晶界分布的连续第二相化合物经均匀化处理后变得不连续,它可能为稀土相,这种相在高温下热稳定性较好。

图1 实验合金的显微组织

Fig.1 Microstructures of experimental alloys: (a) As-cast; (b) Homogenized

图2所示为实验合金的XRD谱。由图2可见,实验合金的相组成物均为α-Mg、Mg3YZn6准晶相[7-8]。其中Mg3YZn6为一种具有二十面体的准晶相,具有五次对称轴。Mg3YZn6准晶相在凝固过程中主要以第二相的形式在α-Mg基体上析出。

图2 实验合金的XRD谱

Fig.2 XRD pattern of experimental alloy

2.2 变形条件对Mg-Y-Zn-Zr合金高温流变应力的 影响

图3所示为实验合金在不同应变速率条件下的真应力─应变曲线。由图可见,在不同温度下,试样的流变应力变化呈现以下3种不同形式。

1) 在变形温度较低时,即在643 K以下,随着变形量的增加,材料的应力不断升高,一直到发生破断时,应力仍持续升高。应变速率越大,应力升高越快,其最高值也越高,试样发生破断的时间越短,破断前的变形量也越小;当应变速率为10-3 /s试样没有发生破断,变形量也越大。

2) 随变形温度升高( 643 K时),当应变速率低于10-1 /s时,应变超过一定值后,应力随应变变化幅度变小,说明除加工硬化产生作用外,高温下动态回复和再结晶也产生软化作用。在应变速率提高到10-1 /s后,应力仍随应变量增大而增加,材料最终也发生了破断。

3) 随变形温度进一步升高,达到693 K时,应变速率为10-3 /s的真应力─真应变曲线大致可以分为4个阶段:第一阶段变形量较小时,随着应变的逐步增加,加工硬化速度减弱,但是在第一阶段总的趋势还是加工硬化超过动态软化,因此随着变形量的增加,变形应力还是不断增加;第二阶段当应变量超过一定值后,应力下降,表明材料在该温度下已经发生了动态再结晶,材料的变形应力很快下降;第三阶段,应变达到一定程度时,应力与应变呈现出稳态流变的特征,由于流变应力在此条件下维持一稳定值,加工硬化和动态再结晶软化达到平衡;第四阶段,当应变进行到 一定程度时,应力又继续上升。当温度达到743 K时,应变速率为10-2和10-3 /s的真应力—真应变曲线也具有上述特征。出现这种现象的原因一方面可能是由于变形程度已非常高,宽高比也很大,所需变形抗力急剧上升,加工硬化效应超过动态再结晶软化效应;另一方面,可能是由于高温变形下除了滑移和孪生,还开启了晶界滑动机制。变形初期的晶粒比变形后期的细小, 增加了可以滑动的晶界表面积,小晶粒晶界的滑动、移动和转动协调了变形, 使变形可以顺利进行,所以变形抗力较低。随着应变量的增加和时间的延长,晶粒逐渐长大,晶界滑动受到限制,塑性变形发生困难,最终导致变形抗力又缓慢升高。

图3 Mg-9Y-3Zn-0.5Zr合金不同温度下真应力─真应变曲线

Fig.3 True stress—strain curves of Mg-9Y-3Zn-0.5Zr alloy at different strain rates: (a)  =10-1 /s; (b)

=10-1 /s; (b)  =10-2 /s; (c)

=10-2 /s; (c)  =10-3 /s

=10-3 /s

2.3 Mg-9Y-3Zn-0.5Zr合金高温变形常数的求解

2.3.1 Mg-9Y-3Zn-0.5Zr合金应力指数的确定

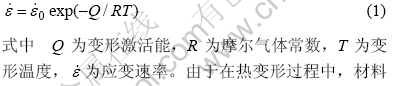

由上述实验结果可知,Mg-9Y-3Zn-0.5Zr合金的应力—应变速率—变形温度之间相互作用很明显,因此有必要明确合金塑性行为中各因素之间的相关性,从而掌握合金高温塑性变形行为。高温下金属和合金的热变形和高温蠕变一样,存在热激活过程,其特点之一就是应变速率受热激活过程控制,即遵从Arrhenius公式[3]:

由于在热变形过程中,材料的高温流变应力 取决于变形温度T和应变速率

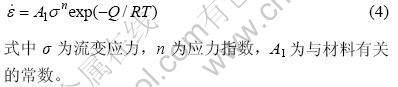

取决于变形温度T和应变速率 ,而对不同热加工数据研究表明,低应力水平下稳态流变应力

,而对不同热加工数据研究表明,低应力水平下稳态流变应力 和应变速率

和应变速率 之间的关系可用指数关系表示:

之间的关系可用指数关系表示:

而在高应力水平下稳态流变应力 和应变速率

和应变速率 之间的关系可用幂函数表示:

之间的关系可用幂函数表示:

FROST和ASHBY认为纯镁在573 K以上、流变应力在2~80 MPa内, 金属流变过程根据式(1)和式(2)可用幂函数模型来描述[10]:

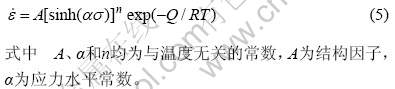

这些关系式描述了应变硬化和动态软化之间的动态平衡过程,它与动态蠕变对应的关系类似。又根据式(4),有学者提出可采用包括变形激活能Q和温度T在内的双曲线正弦形式修正Arrhenius关系来描述这种热激活稳态变形行为[11, 13] :

公式(5)在低应力水平下接近公式(2),而在高应力下接近公式(3),因而可应用于整个应力范围[12]。

及n1 之间满足如下关系[14] :

及n1 之间满足如下关系[14] :

为获得ln —ln[sinh(ασ)]关系曲线, 先计算

—ln[sinh(ασ)]关系曲线, 先计算 和n1值。

和n1值。

对式(2)和(3)两边分别取对数得

可以看出 n1 和β分别为ln —ln σ和ln

—ln σ和ln —

— 曲线的斜率。作ln

曲线的斜率。作ln —ln

—ln 和ln

和ln —

— 图,采用用最小二乘法进行线性回归处理,得ln

图,采用用最小二乘法进行线性回归处理,得ln —ln

—ln 和ln

和ln —

— 曲线,如图4所示。n1值取图4(a)中应力较低、即温度为693和743 K的2条直线斜率的平均值,得n1= 4.68,

曲线,如图4所示。n1值取图4(a)中应力较低、即温度为693和743 K的2条直线斜率的平均值,得n1= 4.68, 值取图4(b)中应力较高、即温度为643和693 K的2条直线的平均值,得

值取图4(b)中应力较高、即温度为643和693 K的2条直线的平均值,得 = 0.029,则

= 0.029,则 =

= /n1 = 0.006 2 mm2/N。

/n1 = 0.006 2 mm2/N。

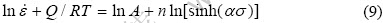

由式(5)可知:

图 4 应变速率与峰值应力的关系

Fig.4 Relationships between strain rate and maximum stress: (a) ln —ln

—ln ; (b) ln

; (b) ln —

— 通过

通过

通过ln 与

与 作图可求出材料常数n,n即为应力指数(见图5)。由式(9)可以看出n的值即为ln

作图可求出材料常数n,n即为应力指数(见图5)。由式(9)可以看出n的值即为ln -

- 图中各直线的斜率:

图中各直线的斜率:

图5 不同温度下的ln 与ln [sinh(

与ln [sinh(

)]的关系

)]的关系

Fig.5 Relationships between ln and ln [sinh(

and ln [sinh(

)] at different temperatures

)] at different temperatures

由上图可以求出Mg-9Y-3Zn-0.5Zr合金不同温度下的应力指数n见下表:

表1 不同温度下的Mg-9Y-3Zn-0.5Zr合金的应力指数

Table 1 Stress index of Mg-9Y-3Zn-0.5Zr alloy at different temperatures

2.3.2 Mg-9Y-3Zn-0.5Zr变形激活能的确定

由式(9)可知:

将实验数据代入式(10)中进行计算,即可绘制出ln[sinh(

)]—1 000/T关系,如图6如示。

)]—1 000/T关系,如图6如示。

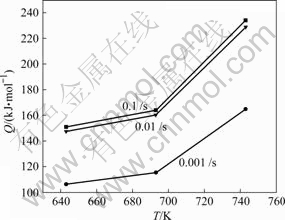

图6 不同应变速率下的1 000/T与ln [sinh(ασ)]的关系

Fig.6 Relationships between ln[sinh(ασ)] and 1000/T at different strain rates

式中 等号右边第一项代表ln[sinh(

)]—1 000/T的斜率,第二项即为应力指数,再用上述求得的应力指数值即可计算出Mg-9Y-3Zn-0.5Zr合金的变形激活能,如图7所示。

)]—1 000/T的斜率,第二项即为应力指数,再用上述求得的应力指数值即可计算出Mg-9Y-3Zn-0.5Zr合金的变形激活能,如图7所示。

图7 不同应变速率下合金变形激活能与温度的关系

Fig.7 Relationships between deformation activation energy and temperature at different strain rates

可见,合金的变形激活能曲线在应变速率为0.1和0.01 s-1的条件下几乎重合,这表明两个应变速率对变形机制的影响规律相同,即变形过程中的位错机制及其变化规律相同。合金的变形激活能在温度643~693 K温度内变化不大,而当温度大于693 K时产生了急剧的上升。这表明变形过程中有新的位错机制参与,棱柱面和锥面滑移系相继被激活,合金的塑性变形行为受交滑移控制,非基面滑移激活能增加。根据文献 [13, 15-16],密堆六方金属在T<0.7Tm变形时,变形激活能接近于自扩散激活能,说明变形行为受自扩散控制的;而在T>0.7Tm时则大于自扩散激活能,因此不再是自扩散控制,可能是由基面的螺型位错通过热激活脱离基面而在棱柱面上滑移的过程所控制。在温度大于或等于693 K时变形时,动态恢复和再结晶进行得比较充分,因而有利于合金变形。因此,在制定挤压工艺时,考虑到变形速率较大时,应选择较高温度挤压。

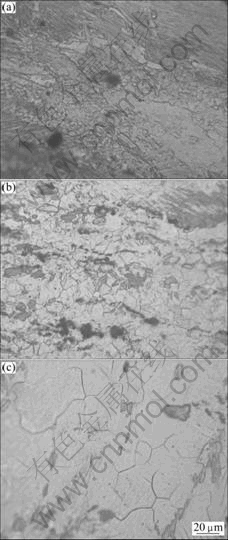

2.4 变形温度与变形速度对Mg-9Y-3Zn-0.5Zr合金组织的影响

变形温度是影响镁合金动态再结晶的主要因素之一。当温度升高时,位错的滑移、攀移、交滑移比低温时更容易,动态再结晶的形核率增加,同时晶界迁移能力增加,因此温度的升高可促进镁合金动态再结晶的发生[11]。图8所示为合金在不同温度下的金相组织。可见,在变形温度643 K下再结晶过程于处初始阶段,可以看到清晰的流线和大量未发生再结晶而被拉长的纤维组织,粗大的晶粒呈锯齿状,细晶粒正逐步蚕食粗晶粒;变形温度为693 K时,组织由细小的等轴晶粒组成,晶粒已经有一定程度的长大。当温度继续升高到743 K时,晶粒明显长大。可见,在693 K温度下,晶粒较为细小并且发生了完全动态再结晶。

图8 不同温度下Mg-9Y-3Zn-0.5Zr合金在ε=66.7%、 =10-3 /s时的金相组织

=10-3 /s时的金相组织

Fig.8 Microstructures of Mg-9Y-3Zn-0.5Zr alloys atε = 66.7%,  =10-3 /s and different temperatures: (a) 643 K; (b) 693 K; (c) 743 K

=10-3 /s and different temperatures: (a) 643 K; (b) 693 K; (c) 743 K

动态再结晶是一个速度控制的过程, 变形速度对新生晶粒的尺寸有很大的影响。应变速率增加时,变形过程中产生的位错来不及抵消,位错增多,再结晶形核增加,导致晶粒细化[17]。从图9(a)~(c)应变速率依次降低,因此晶粒的尺寸逐渐增大。由图9(a)可见由新生晶粒的尺寸特别细小,动态再结晶进行得不够完全。

根据霍尔-配奇公式可知,细化晶粒可以提高材料的强度和塑性等综合力学性能,动态再结晶的晶粒大小取决于热加工的流变能力 [18]。因此,要通过热加工来细化晶粒,必须在高流变应力下进行动态再结晶。根据变形温度与变形速度对Mg-9Y-3Zn-0.5Zr合金组织的影响,确定693 K为进行工业挤压变形的温度。

[18]。因此,要通过热加工来细化晶粒,必须在高流变应力下进行动态再结晶。根据变形温度与变形速度对Mg-9Y-3Zn-0.5Zr合金组织的影响,确定693 K为进行工业挤压变形的温度。

图9 Mg-9Y-3Zn-0.5Zr合金在 v =66.7%、T=743 K时的金相组织

v =66.7%、T=743 K时的金相组织

Fig.9 Microstructures of Mg-9Y-3Zn-0.5Zr alloys at  = 66.7% and T = 743 K: (a)

= 66.7% and T = 743 K: (a)  =10-1 s-1; (b)

=10-1 s-1; (b)  =10-2 s-1; (c)

=10-2 s-1; (c)  =10-3 s-1

=10-3 s-1

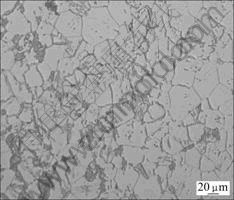

2.5 挤压态组织观察和力学性能

图10所示为Mg-9Y-3Zn-0.5Zr合金热挤压后的金相组织。由图可见,合金发生了完全动态再结晶,原始的粗晶组织基本被动态再结晶的细小晶粒取代,组织比较均匀。

图10 Mg-9Y-3Zn-0.5Zr合金在693 K时的热挤压组织

Fig.10 Microstructure of Mg-9Y-3Zn-0.5Zr alloy hot extruded at 693 K

对挤压态和时效态的Mg-9Y-3Zn-0.5Zr合金在常温下分别进行拉伸实验。挤压态合金的抗拉强度为340.0 MPa,伸长率为16.2%;时效态合金的抗拉强度为396.4 MPa,伸长率为6%。由此可见,时效后合金强度有很大的提高,其原因可能是析出了稀土第二相。由于Y的含量比较高且在镁基体中有着较大的固溶度,因而合金时效过程中沿棱面析出的第二相有着较强的强化作用。

3 结论

1) 在同一变形温度下,Mg-9Y-3Zn-0.5Zr合金的真应力水平随应变速率的增加而增加,说明材料是正应变速率敏感材料。

2) 在同一应变速率条件下,实验合金的真应力水平随温度的升高而下降,在较高温度下发生动态再结晶使其明显软化。

3) 当变形温度在643~693 K时,Mg-9Y-3Zn-0.5Zr合金的变形激活能变化不大;当温度大于693 K时,激活能随温度升高而增大。

4) 挤压态Mg-9Y-3Zn-0.5Zr合金抗拉强度为340.0 MPa,伸长率为16.2%,时效态合金的抗拉强度为396.4 MPa,伸长率为6%,塑性明显降低。

REFERENCES

[1] DECKER R F. The renaissance in magnesium[J]. Advanced Mater & Proc, 1998(9): 31-35.

[2] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及应用[M]. 北京: 机械工业出版社, 2002: 9.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory foundation and application of lightweight alloys based magnesium[M]. Beijing: China Machine Press, 2002: 9.

[3] 陈振华, 夏伟军, 严红革, 李落星, 程永奇, 郭 强, 陈 鼎. 变形镁合金[M]. 北京: 化学工业出版社, 2005. 2-4.

CHEN Zhen-hua, XIA Wei-jun, YAN Hong-ge, LI Luo-xing, CHENG Yong-qi, GUO Qiang, CHEN Ding. Deformed magnesium alloys[M]. Beijing: Chemical Industry Press, 2005: 2-4.

[4] TAO Chun-hu, ZHANG Shao-qing, LU Li-qi. Magnesium products design[J]. Journal of Rare Earth, 1991, 9(2): 125-129.

[5] TANG Ya-li, SHEN Ning-fu, YUAN Xin. Quasicrystalline phase in as-cast Mg-Zn-Y-Zr alloy[J]. Mater Sci Technol, 1994, 10(4): 304-309.

[6] 于文斌, 刘志义, 程南璞, 吴安如. 稀土变形镁合金的研究和开发[J]. 材料导报, 2006 , 20 (11): 65-72.

YU Wen-bin, LIU Zhi-yi, CHENG Nan-pu, WU An-ru. Study and development of RE deformed magnesium alloy[J]. Materials Review, 2006, 20(11): 65-72.

[7] 黎业生, 董定乾, 吴子平. 稀土镁合金的研究现状及应用前景[J]. 轻合金加工技术, 2006, 34(4): 1-6.

LI Ye-sheng, DONG Ding-qian, WU Zi-ping.Study current situation and application prospect of RE magnesium alloy[J]. Light Alloy Fabrication Technology, 2006, 34 (4): 1-6.

[8] KIM I J, BAE D H, KIM D H. Precipitates in a Mg-Zn-Y alloy reinforced by an icosahedral quasicrystalline phase[J]. Mater Sci Eng A, 2003, 359: 313-318.

[9] 麻彦龙, 潘复生, 左汝林. 高强度变形镁合金ZK60的研究现状[J]. 重庆大学学报, 2004, 27(9): 80-85.

MA Yan-long, PAN Fu-sheng, ZUO Ru-lin. Study current situation on the research of high-strength wrought magnesium alloy ZK60[J]. Journal of Chongqing University, 2004, 27(9): 80-85.

[10] 陈振华, 严红革, 陈吉华, 全亚杰, 王慧敏, 陈 鼎. 镁合金[M]. 北京: 化学工业出版社, 2004: 207.

CHEN Zhen-hua, YAN Hong-ge, CHEN Ji-hua, QUAN Ya-jie, WANG Hui-min, CHEN Ding. Magnesium alloys[M]. Beijing: Chemical Industry Press, 2004: 207.

[11] 夏长清, 武文花, 吴安如, 王银娜. Mg-Nd-Zn-Zr稀土镁合金的热变形行为[J]. 中国有色金属学报, 2004, 14(11): 1810-1816.

XIA Chang-qing, WU Wen-hua, WU An-ru, WANG Yin-na. Heat-compression deformation behavior of Mg-Nd-Zn-Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1810-1816.

[12] 余 琨, 黎文献, 王日初, 马正青, 赵 俊, 孟力平. Mg-5.6Zn-0.7Zr-0.8Nd合金高温塑性变形的热/力模拟研究[J]. 金属学报, 2003, 39(5): 492- 498.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing, ZHAO Jun, MENG Li-ping. Thermal dynamic simulate study of Mg-5.6Zn-0.7Zr-0.8Nd alloy high temperature plastic deformation[J]. Acta Metallurgica Sinica, 2003, 39(5): 492-498.

[13] POIRIER J P. 晶体的高温塑性变形[M]. 关德林, 译. 大连: 大连理工大学出版社, 1989: 25-30.

POIRIER J P. The plastic deformation of crystals at high temperature[M]. GUAN De-lin, trans. Dalian: Dalian University of Science and Technology Press, 1989: 25-30.

[14] DAVENPOT S B, SILK N J, SPARKS C N, SELLARS C M. Development of constitutive equations for modeling of hot rolling[J]. Mater Sci Techno, 2000, 16(5): 539-546.

[15] CROSSLAND I G, JONES R B. Dislocation creep in magnesium[J]. Met Sci J, 1972, 6: 162-168.

[16] MEHRER H, SEEGER A. Interpretation of self diffusionand vacancy properties in silver[J]. Phys Stat Sol, 1970, 39: 647-650.

[17] 张先宏, 崔振山, 阮雪榆. 镁合金塑性成形技术—AZ31B成形性能及流变应力[J]. 上海交通大学学报, 2003, 37(12): 1874-1877.

ZHANG Xian-hong, CUI Zhen-shan, RUAN Xue-yu. Magnesium alloy forming technology—AZ31B alloy formabilityand flow stress[J]. Journal of Shanghai Jiao Tong University, 2003, 37(12): 1874-1877.

[18] 郑子樵. 材料科学基础[M]. 长沙: 中南大学出版社, 2005: 385.

ZHENG Zi-qiao. Fundamental of material science[M]. Changsha: Central South University Press, 2005: 385.

收稿日期:2007-10-10;修订日期:2007-12-29

通讯作者:周海涛,教授,博士;电话:0731-2655250;E-mail: htzhou62@yahoo.com.cn

(编辑 何学锋)