文章编号:1004-0609(2013)07-1796-09

铸轧AZ31镁合金在高温拉伸中的动态再结晶行为

史国栋1,乔 军2,何 敏2,张庆丰2,张永彬2,陈 敏2

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 辽宁科技大学 材料科学与工程学院,鞍山 114051)

摘 要:在250~ 400 ℃温度范围内以恒温、恒应变速率(10-3 和10-2 s-1) 对铸轧AZ31 镁合金进行拉伸实验,在不同应变下研究温度和应变速率对动态再结晶的影响,探讨二相粒子对动态再结晶的影响,并分析动态再结晶机制。结果表明:当应变相同时,再结晶晶粒尺寸随温度升高而增大。中温区(200~300 ℃)动态再结晶的主导机制为连续动态再结晶,高温区(300 ℃以上)动态再结晶的主导机制为不连续动态再结晶。变形过程中破碎的Mg17Al12相粒子及钉扎在晶界处的(Al,Mn)相粒子可提高动态再结晶的形核率。在350 ℃下,当应变速率由10-3 s-1 升高到10-2 s-1 时,晶粒尺寸逐渐减小,且出现孪生再结晶。

关键词:AZ31 镁合金;铸轧;动态再结晶

中图法分类号 TG146.22 文献标志码:A

Dynamic recrystallization behaviors of twin-roll cast AZ31 magnesium alloy during high temperature tensile deformation

SHI Guo-dong1, QIAO Jun2, HE Min2, ZHANG Qing-feng2, ZHANG Yong-bin2, CHEN Min2

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, University of Science and Technology Liaoning, Anshan 114051, China)

Abstract: Tensile tests were conducted for a twin-roll cast AZ31 alloy under constant temperatures (250-400 ℃) and constant strain rates of 10-3 and 10-2 s-1, aimed to study the effects of temperature and strain rate on dynamic recrystallization at different strains, to explore the effects of the second phase particles on dynamic recrystallization, and to analyze the mechanisms of dynamic recrystallization. The results show that the grain size of the recrystallized grains increases with temperature under the same strain. The continuous dynamic recrystallization dominates at the intermediate temperature range (200-300 ℃), while the discontinuous dynamic recrystallization dominates at high temperatures (over 300 ℃) . The fractured Mg17Al12 particles and the (Al, Mn) phase particles pinning at grain boundary can improve the nucleation rate of dynamic recrystallization. When the strain rate increases from 10-3 s-1 to 10-2 s-1 at 350 ℃, the grain size gradually decreases, and the twin recrystallizaiton occurs.

Key words: AZ31 magnesium alloy; twin-roll cast; dynamic recrystallization

镁为密排六方晶体结构,室温下的c/a值为1.62,只有2个独立的基面滑移系,不满足5个独立滑移系的多晶体塑性变形协调性原则,因此,室温塑性较低。然而,镁及镁合金的塑性在高温下(>180 ℃)可显著提高,其主要原因是棱面和锥面滑移系被激活,利于位错滑移和位错蠕变。此外,高温下原子和空位的扩散能力增强,具有细小晶粒的镁合金可通过晶格扩散或晶界扩散所协调的晶界滑移机制获得超塑性[1-4]。目前,热冲压和气胀成型是利用细晶粒镁合金板材生产汽车部件的主要超塑性成形方法。

研究表明,镁的堆垛层错能较低,仅为78 mJ/m2,在变形过程中容易发生动态再结晶而使晶粒细化并获得超塑性[5]。因此,动态再结晶作为一种有效的晶粒细化机制,对控制镁合金变形组织、提高塑性变形能力以及改善力学性能具有重要意义[6-8]。GALIYEV等[9]发现ZK60镁合金在低温、中温、高温条件下动态再结晶的形核分别通过基面滑移与孪生、交滑移、位错攀移等方式进行,并指出动态再结晶形核机制受变形温度和塑性变形机制的影响。ION等[10]认为镁合金的晶界扩散速度较快,在亚晶上堆积的位错能够被晶界吸收,从而加速动态再结晶过程。因此,镁合金动态再结晶与变形温度、变形速度、变形程度以及原始晶粒组织密切相关。李树海等[11]发现,铸轧AZ31B镁板在温度为100 ℃、应变速率为10-3 s-1的条件下压缩变形时,合金中产生大量孪晶并且有动态再结晶晶粒,通过TEM表明AZ31B镁合金低温孪生动态再结晶存在孪晶-孪晶交截形核的动态再结晶机制。胡丽娟等[12]发现随着变形温度的升高,AZ31镁合金中动态再结晶晶粒逐渐增加,尺寸先增后减。肖凯[13]对AZ31镁合金进行了热压缩实验发现,随着Zener-Hollomon参数值的增加,动态再结晶作用增强并且再结晶晶粒尺寸随变形温度的降低而减少。虽然很多文章针对AZ31镁合金的动态再结晶进行了研 究[14-16],但实验方法多为轧制、挤压,而关于高温拉伸过程中的AZ31镁合金动态再结晶鲜有报道。

本文作者对铸轧AZ31镁合金进行不同温度、不同拉伸速度、和不同应变条件下高温拉伸实验,并重点讨论材料在高温拉伸中的动态再结晶行为,分析动态再结晶机制,并对变形条件和第二相粒子对动态再结晶的影响进行探讨。

1 实验

所研究的AZ31镁合金板材采用水平式铸轧生产,厚度为3 mm,化学成分如表1所列。利用线切割机沿最后一道轧制方向切取高温拉伸试样,其形状与几何尺寸如图1所示。

表1 铸轧AZ31镁合金的化学成分

Table 1 Chemical compositions of twin-roll cast AZ31 magnesium alloy (mass fraction, %)

图1 常温拉伸试样的几何尺寸及形状

Fig. 1 Specimen geometry for high-temperature mechanical test (Unit: mm)

将试样置于MTS810拉伸试验机所附的三段式电阻炉内,两端分别连接热电偶测量温度,确保试样温度和目标温度的差别在±2 ℃范围内。在恒温(250、300、350和400 ℃)和恒速(25.4×10-3 mm/s)条件下,将试样分别拉伸至应变为0.2、0.4和断裂后迅速取出进行水冷,以保留高温拉伸状态下的显微组织。此外,在350 ℃进行了拉伸速度为25.4×10-2 mm/s,应变分别为0.6和0.8的拉伸试验。试验条件如表2所列。

利用金相光学显微镜(JVC TK-350EG)观察铸轧AZ31的原始组织,和拉伸试样在不同变形条件下的均匀变形区及断口处的显微组织,并利用线截距法测量晶粒尺寸。所用的金相腐蚀液配比为:3 g苦味酸,20 mL乙酸,20 mL蒸馏水和50 mL酒精。利用透射电子显微镜(JEM-2100)观察位错和二相粒子的形态和分布。

表2 拉伸试验参数

Table 2 Tensile tests parameters

2 结果与分析

2.1 显微组织

图2所示为所研究的铸轧AZ31镁合金的原始显微组织,由尺寸不均匀的等轴晶粒组成,在部分晶粒内存在孪晶。原始组织的平均晶粒尺寸约为d ≈10.11 μm。

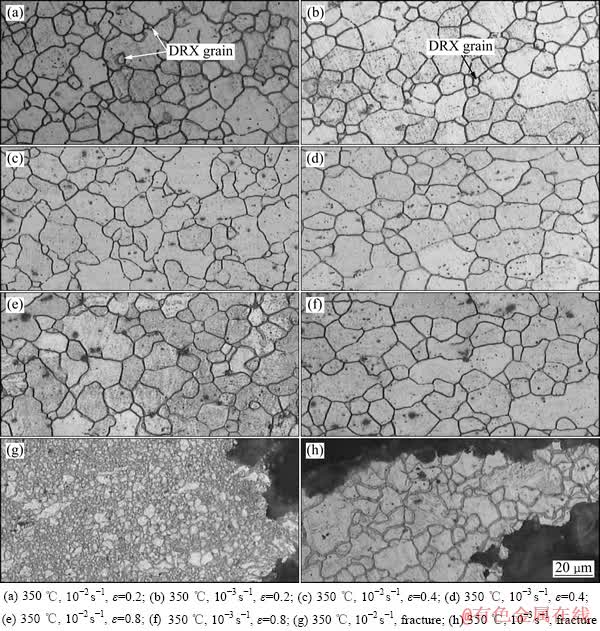

在350 ℃拉伸至不同应变时,材料在10-2 s-1(以下简称高速)和10-3 s-1(以下简称低速)应变速率条件下的显微组织分别如图3(a)和(b)所示,水平方向为拉伸方向。当应变为0.2时,在两种应变速率条件下孪晶基本消失,且出现了等轴的动态再结晶(DRX)晶粒。大部分再结晶晶粒在晶界交汇处形核,少量在晶内的孪晶或二相粒子处形核,如图3(a)中箭头所示。高速拉伸显微组织中的晶界曲率较大,而低速拉伸显微组织中的晶界较为平直,表明在低速下有更多的位错、原子及空位与晶界发生相互作用而使晶界能降低。当应变为0.4时(见图3(c)和(d)),低速拉伸显微组织以晶界较为平直的等轴晶粒为主,动态再结晶晶粒发生一定程度的长大,而在高速拉伸显微组织中依然存在不规则的原始晶粒,直至应变增至0.8时(见图3(e)和(f))才以等轴的再结晶晶粒为主。试样断口处的显微组织(见图3(g)和(h))均由大量细小的再结晶晶粒组成,在高速拉伸条件下的晶粒尤为细小,由大量尺寸为1~2 μm的细小晶粒组成,这是由于变形时间较短,断裂前通过再结晶、原子和空位扩散运动释放的能量有限,使试样在断裂前储存了较高的畸变能,发生再结晶时的形核率较高,导致晶粒显著细化。

图2 铸轧AZ31镁合金原始组织

Fig. 2 Optical micrographs of twin-roll cast AZ31 magnesium alloy

图3 铸轧AZ31镁合金在350 ℃拉伸至不同应变的显微组织(水平拉伸方向)

Fig. 3 Microstructures of twin-roll cast AZ31 magnesium alloy at 350 ℃and different strains (horizontal tensile direction)

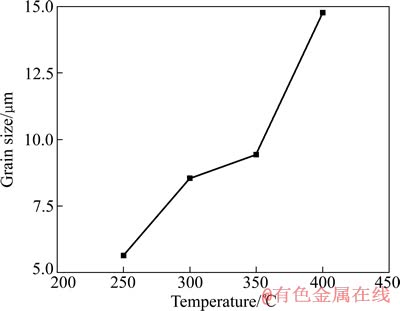

由图4可知,当应变相同时,高速拉伸条件下的平均晶粒尺寸较小。一般而言,Zener-Hollomon参数对动态再结晶晶粒尺寸有显著影响[17-20],

Zd m=A (1)

Z= exp[Q/(RT)] (2)

exp[Q/(RT)] (2)

式中:Z为Zener-Hollomon因子;d为动态再结晶晶粒尺寸;m为晶粒尺寸指数;A为常数; 为应变率;Q为形变激活能;R为摩尔气体常数;T为绝对温度。

为应变率;Q为形变激活能;R为摩尔气体常数;T为绝对温度。

因此当变形温度一定时,提高应变速率可以使Z值增加,从而使动态再结晶晶粒尺寸减小。BARNETT等[21]在研究中证实,在热变形过程中,AZ31镁合金的晶粒尺寸随着参数的增大而减小。同时LIU[22] 也指出,AZ31 合金在350 ℃变形时,应变速率从10-3 s-1 升高到10-2 s-1时,细小晶粒的体积分数随应变速率的增加而增加。

图4 铸造AZ31镁合金在350 ℃下拉伸至固定应变的晶粒尺寸图

Fig. 4 Grain size of twin-roll cast AZ31 magnesium alloy during tensile test at 350 ℃ and strain rate of 10-2 s-1 and 10-3 s-1

图5 应变速率为10-3 s-1、应变为0.2时不同试样的微观组织

Fig. 5 Microstructures of different samples at strain rate of 10-2 s-1, strain of 0.2 and different temperatures

如图5和6所示:在应变速率为10-3 s-1和应变为0.2的条件下,平均晶粒尺寸随温度升高而明显增大。在相同的应变和应变速率下,温度越高,则发生动态再结晶的临界畸变能越低,再结晶的速度越快。当变形温度较低时,由于镁合金塑性变形时滑移系少,孪晶和位错难以通过运动实现重组,所以动态再结晶不易发生。当温度升高,合金中原子热振荡及扩散速率增加,位错的滑移、攀移、交滑移及位错节点脱锚比低温时更容易,动态再结晶的形核率增加,因此,温度的升高可以促使镁合金的动态再结晶的发生,同时晶界迁移能力增强。由图4可知,在250和300 ℃时,动态再结晶基本完成,晶界曲率较大;在350和400 ℃时,晶粒长大较为明显,且晶界变得平直。由于在高温下动态再结晶更充分,同时晶界迁移能力和晶界扩散也随之增强,晶粒容易长大而形成图5(c)和(d)所示的粗大组织,不利于晶界滑移和超塑性。

图6 应变速率为10-3 s-1和应变为0.2的条件下不同温度的晶粒尺寸

Fig. 6 Grain size during tensile test at strain rate of 10-2 s-1, strain of 0.2 and different temperatures

2.2 二相粒子

二相粒子对动态再结晶过程主要有两个方面的影响:1) 细小的和接近分割的粒子将阻碍再结晶过程的形核和长大;2) 粗大的和不可变形的粒子将增加其周围再结晶的驱动力。然而,第二相粒子对动态再结晶的作用是阻碍还是促进依赖于粒子的相关参数,如尺寸大小、破片体积等。

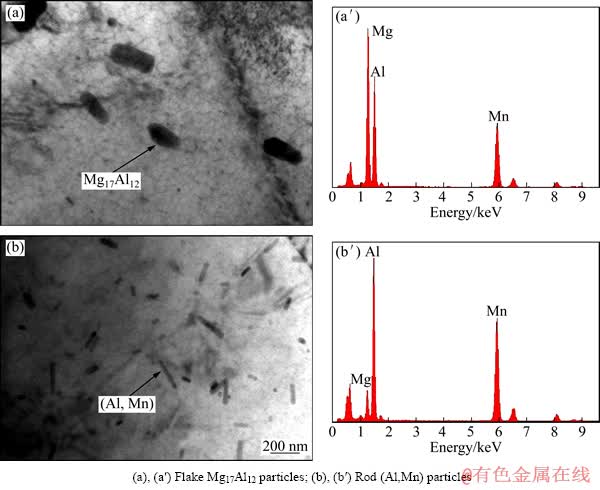

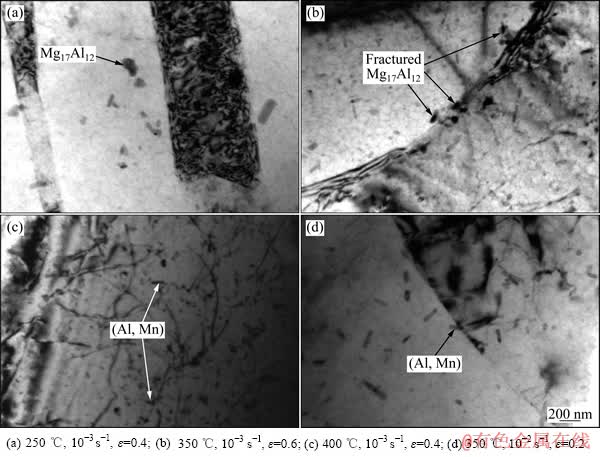

图7所示为铸轧AZ31在高温拉伸中的典型二相粒子的TEM像和能谱分析,粒子呈片状和杆状,根据能谱分析,分别为片状Mg17Al12粒子及杆状(Al,Mn)粒子。图8所示为拉伸过程中二相粒子的分布及演变。当温度为250 ℃时,Mg17Al12和(Al, Mn)粒子同时存在,片状的Mg17Al12分布在晶内,并未在晶界处发现,如图8(a) 所示;在350 ℃时,片状Mg17Al12相粒子开始破碎并出现在晶界处,这些钉扎在晶界处的Mg17Al12可以促进动态再结晶形核,如图8(b) 所示;当温度上升至400 ℃时,Mg17Al12相粒子基本消失,而(Al, Mn)相粒子仍然在基体中存在并且没有明显的形变,如图8(c)所示。

图7 二相粒子的TEM像和能谱分析

Fig. 7 TEM images and EDS analysis of second-phase particles

图8 拉伸过程中二相粒子的分布及演变

Fig. 8 Distribution and evolution of second-phase particles under different tensile test conditions

从图8中同时发现,杆状的(Al,Mn)相粒子分布在晶内及晶界处、未破碎的片状Mg17Al12相粒子主要分布在晶内,而破碎的Mg17Al12相粒子可以存在于晶界附近。由于晶界处局部应变往往高于晶粒内部,而且原始大角度晶界能够促进形核核心的发展,位于晶界的粒子更有利于动态再结晶形核。如图8(d)所示,钉扎在晶界处的杆状(Al,Mn)相粒子阻碍了晶界及位错的运动,塞积的位错形成位错胞,如果继续吸收位错便会增大取向差变成新的再结晶晶粒。在塑性变形过程中,晶界附近的二相粒子能有效地阻碍位错运动,并阻碍晶界或亚晶界迁移。变形时第二相粒子周围产生畸变,在畸变区域累积了位错并形成相对大的晶界取向差,使畸变区域成为再结晶的核心,从而提高再结晶形核率。

2.3 动态再结晶机制

镁及镁合金在不同条件下变形时,微观组织特征随变形条件的不同而发生变化。微观结构在变形时的发展一般可以分为低温区(473 K)、中温区(473~573 K)和高温区(573 K以上)[23],这里主要研究中温及高温区的动态再结晶。

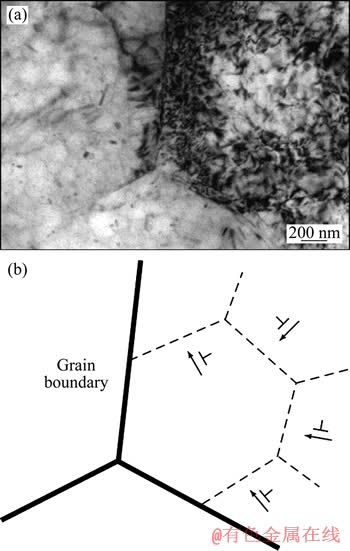

图9 拉伸过程中连续动态再结晶TEM像及示意图

Fig. 9 TEM image (a) and schematic diagram (b) of CDRX under tensile test conditions of 250 ℃, 10-3 s-1, ε=0.4

图9(a)所示为试样在中温区(473~573 K)进行拉伸变形时发生连续动态再结晶的TEM像。从图9(a)可看出,在晶界和三叉节点处产生了明显的位错堆积,这是由于拉伸过程中的应变硬化使得不同取向晶粒产生位错,位错在应力的作用下沿着基面或非基面滑移,当滑移到初始晶界时产生位错塞积。位错塞积达到一定程度时发生重排和合并形成位错胞结构和小角度晶界,这些结构进一步增大取向差就会发展成亚晶。亚晶界通过不断吸收晶格位错来增大取向差,进而转变为大角度晶界。大角度晶界随变形发生迁移,消除部分亚晶界和晶界,产生等轴的再结晶晶粒,这种现象与连续动态再结晶的形核机制相吻合,如图9(b)所示。

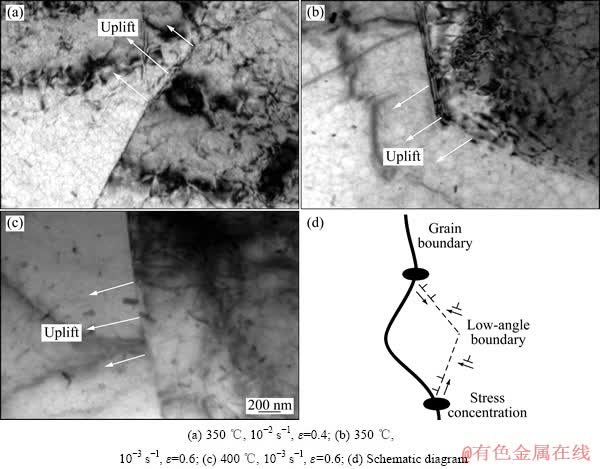

图10所示为试样在高温区(573 K以上)进行拉伸变形时发生非连续动态再结晶的TEM像。由图10(a)可见,晶界处的高位错密度区出现了晶界的局部迁移,产生了晶界局部凸起。高温下位错的滑移变得容易,位错滑移的局部化使原始晶界局部迁移,形成凸起,非平面的晶界滑移导致强烈的应变梯度。晶界位错源为了协调塑性变形向晶粒内部发射位错,这些位错与基面位错相互作用形成亚晶界,亚晶界切割晶粒的凸出部分。这些亚晶界随应变的进行不断吸收晶格位错从而提高取向差,最后发展成大角度晶界,这与不连续动态再结晶机制相吻合。不连续动态再结晶要求晶界具有较大的迁移活动能力,变形温度越高,晶界的迁移能力就越强,越容易发生不连续动态再结晶。这种现象也在温度为350和400 ℃,速率为10-3 s-1,应变为0.6的条件下存在,如图10(b)和(c)所示。

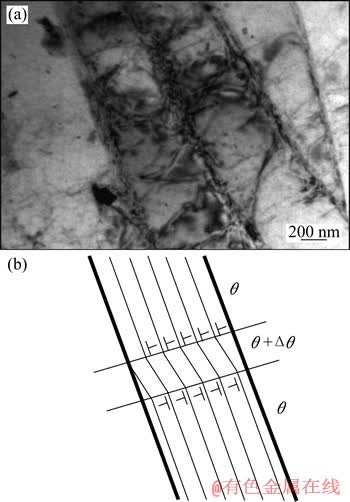

此外,在较高变形速率下,变形过程中产生的孪晶也可能成为再结晶形核核心。如图11所示,在350 ℃、10-2 s-1、应变为0.6时,由于变形速率较高,组织中出现孪晶,位错受到孪晶晶界的阻碍不断堆积并产生应力集中,在孪晶内通过位错的交互作用发生位错重排和合并,并产生位错胞,形成动态再结晶晶核。这种现象与孪晶动态再结晶机制相吻合。

综上所述,所研究的铸轧AZ31镁合金在应用的试验条件下发生了动态再结晶和晶粒长大,并且影响动态再结晶机制的主要变形条件是变形温度。变形温度决定AZ31镁合金在塑性变形时位错的运动方式及晶界迁移能力,从而影响动态再结晶机制。在250 ℃变形时,基面滑移和非基面滑移同时发生,伴随有交滑移[24],然而晶界迁移能力较弱,位错易在晶界处堆积重组形成位错墙,并通过吸收新的位错转化成大角度晶界,发生连续动态再结晶。在350和400 ℃变形时,变形激活能与晶格自扩散激活能相当,同时发生基面滑移、非基面滑移、交滑移和攀移,并且晶界迁移能力随温度升高而增强,在晶界高密度位错区发生局部晶界弓出形核,发生不连续动态再结晶。变形速率也影响动态再结晶机制,在较高应变速率下,为了协调塑性变形而产生孪晶,位错在孪晶晶界处堆积,进而诱发孪晶动态再结晶。

图10 拉伸过程中不连续动态再结晶TEM像及示意图

Fig. 10 TEM images ((a), (b), (c)) and schematic diagram (d) of CDRX during tensile test

图11 拉伸过程中孪晶动态再结晶TEM像及示意图

Fig. 11 TEM image (a) and schematic diagram (b) of TDRX under tensile test conditions of 350 ℃, 10-2 s-1, ε=0.6

3 结论

1) 铸轧AZ31镁合金高温拉伸中的动态再结晶与应变、应变速率和温度密切相关。在应变相同时,温度越高则再结晶晶粒越大,动态再结晶越完全。在350 ℃变形时,平均再结晶晶粒尺寸随变形速率的升高(10-3 s-1 升高到10-2 s-1)而减小。在350 ℃、10-2 s-1变形时,随着变形程度的增加,断裂前晶粒迅速减小,组织内存在大量的晶粒尺寸为1~2 μm的细小晶粒。

2) 在高温拉伸过程中,铸轧AZ31镁合金内存在片状Mg17Al12相粒子和杆状(Al,Mn)相粒子。Mg17Al12相粒子在变形时发生破碎,并在高温下溶入基体。(Al,Mn)相粒子在拉伸时不发生变形,在400 ℃时仍存在于基体中。变形过程中破碎的Mg17Al12相粒子及钉扎在晶界处的(Al,Mn)相粒子可促进动态再结晶形核。

3) 在拉伸温度为250 ℃时,晶界迁移能力较低,动态再结晶晶粒优先在晶界三叉节点处位错密度高的区域形核,通过亚晶界转变为高角度晶界而发生连续动态再结晶。在拉伸温度为350和400 ℃时,晶界迁移能力较强,可在局部晶界弓出处发生不连续动态再结晶。在较高变形温度和变形速率下(350 ℃,10-2 s-1),由于出现孪晶,位错在孪晶晶界堆积,可诱发孪晶动态再结晶。

REFERENCES

[1] MOHRI T, MABUCHI M, NAKAMURA M, NAKAMURA M, ASAHINA T, IWASAKI H, AIZAWA T, HIGASHI K. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Materials Science and Engineering A, 2000, 290(1/2): 139-144.

[2] MABUCHI M, AMEYAMA K, IWASAKI H, HIGASHI H. Low temperature superplasticity of AZ91 magnesium alloy with nonequilibrium grain boundaries[J]. Acta Materialia, 1999, 47(7): 2047-2057.

[3] KIM W J, CHUNG S W, CHUNG C S, KUM D. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures[J]. Acta Materialia, 2001, 49(16): 3337-3345.

[4] WATANABE H, MUKAI T. Superplasticity in a ZK60 magnesium alloy at low temperatures[J]. Scripta Materialia, 1999, 40(4): 477-484.

[5] 于彦东, 张凯峰, 蒋大鸣. 轧制镁合金超塑性和超塑胀形[J]. 中国有色金属学报, 2003, 13(1): 71-75.

YU Yan-dong, ZHANG Kai-feng, JIANG Da-ming. Superplasticity and superpastic bulging capability of rolled magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 71-75.

[6] 陈振华, 夏伟军, 严红革. 镁合金材料的塑性变形理论及其技术[J]. 化工进展, 2004, 23(2): 127-135.

CHEN Zhen-hua, XIA Wei-jun, YAN Hong-ge. Principles and technologies of plastic deformation for magnesium alloys[J]. Chemical Industry and Engineering Progress, 2004, 23(2): 127-135.

[7] 张 娅, 马春江, 卢 晨. 变形镁合金的塑性变形机制与动态再结晶[J]. 轻合金加工技术, 2003, 31(7): 35-41.

ZHANG Ya, MA Chun-jiang, LU Chen. Plastic strain mechanism and dynamic recrystallization of magnesium alloy[J]. Light Alloy Fabrication Technology, 2003, 31(7): 35-41.

[8] TAN J C, TAN M J. Superplasticity and grain boundary sliding characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Materials Science and Engineering A, 2003, 339(1/2): 81-89.

[9] GGLIYEV A, KAIBYHEV R, COTTSTEN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[10] ION S E, HUMPHREYS F J, WHITE H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium[J]. Acta Materialia, 1982, 30(10): 1909-1919.

[11] 李树海, 汪明朴, 张 真, 李 周, 唐 宁, 雷 前. AZ31B镁合金的低温压缩变形机制[J]. 中国有色金属学报, 2010, 20(7): 1254-1259

LI Shu-hai, WANG Ming-pu, ZHANG Zhen, LI Zhou, TANG Ning, LEI Qian. Compression mechanism of AZ31B Mg alloy at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1254-1259.

[12] 胡丽娟, 彭颖红, 唐伟琴, 李大永, 张少睿. AZ31镁合金薄板动态再结晶对其拉伸性能的影响[J]. 中国有色金属学报, 2008, 18(9): 1571-1576.

HU Li-Juan, PENG Ying-hong, TANG Wei-qin, LI Da-yong, ZHANG Shao-rui. Effect of dynamic recrystallization on tensile properties of AZ31 magnesium alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1571-1576.

[13] 肖凯. 铸态AZ31镁合金热压缩过程的再结晶行为[J]. 材料工程, 2012(2): 9-12.

XIAO Kai. Recrystallization of as-cast AZ31 magnesium alloy during high temperature compression[J]. Journal of Materials Engineering, 2012(2): 9-12.

[14] WANG Mao-yin, XIN Reng-long, WANG Bing-shu, LIU Qing. Effect of initial texture on dynamic recrystallization of AZ31 Mg ally during hot rolling[J]. Materials Science and Engineering A, 2011, 528(6): 2941-2951.

[15] YANG Xu-yue, JI Ze-sheng, MIURA H, SAKAI T. Dynamic recrystallization and texture development during hot deformation of magnesium alloy AZ31[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 55-60.

[16] DUDAMELL N V, ULACIA I, GALVEZ F, BOHLEN J, LETZIG D, HURTADO I, PEREZ-PRADO M T. Influence of texture on the recrystallization mechanisms in an AZ31 Mg sheet alloy at dynamic rates[J]. Materials Science and Engineering A, 2012, 532(15): 528-535.

[17] MAKOUDA I A, AHMED H, RODEL J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2009, 504(1/2): 40-48.

[18] BEER A G, BARNETT M R. Microstructure evolution in hot worked and annealed magnesium alloy AZ31[J]. Materials Science and Engineering A, 2008, 485(1/2): 318-324.

[19] FATEMI-VERZANEH S M, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy[J]. Materials Science and Engineering A, 2007, 456(1/2): 52-57.

[20] KAIBYSHEV R, GALIYEV A, SITDIKOV O. On the possibility of producing a nanocrystalline structure in magnesium and magnesium alloys[J]. Nanostructured Materials, 1995, 6(5/8): 621-624.

[21] BARNETT M R. Recrystallization during and following hot working of magnesium alloy AZ31[J]. Material Science Forum, 2003, 491: 503-508.

[22] LIU Y. Transient plasticity and microstructural evolution of a commercial AZ 31 magnesium alloy at elevated temperatures[D]. Detroit, Michigan: Wayne State University, 2003: 111-124.

[23] SIDIKOV O, KAIBYSBEV R. Dynamic recrystallization in pure magnesium[J]. Materials Transactions, 2001, 42(9): 1928-1937.

[24] 刘楚明, 刘子娟, 朱秀容, 周海涛. 镁及镁合金动态再结晶研究进展[J]. 中国有色金属学报, 2006, 16(1): 1-12.

LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong, ZHOU Hai-tao. Research and development progress of dynamic recrystallization in pure magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 1-12.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50801034);辽宁省高等学校杰出青年学者成长计划基金资助项目(LJQ2011026);辽宁省十百千高端人才引进工程基金资助项目(2012207)

收稿日期:2012-09-10;修订日期:2013-05-13

通信作者:乔 军,副教授,博士;电话:0412-5929532;E-mail:qiaojun@ustl.edu.cn