文章编号:1004-0609(2011)06-1205-09

ZK60镁合金热变形过程中的动态再结晶动力学

何运斌1, 2,潘清林1, 2,覃银江1, 2,刘晓艳1, 2,李文斌1, 2,Yu-lung CHIU3, J. J. J. CHEN3

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料与工程教育部重点实验室,长沙 410083;

3. Department of Chemical and Materials Engineering, University of Auckland, Auckland 1102, New Zealand)

摘 要:采用Gleeble-1500热模拟机对ZK60镁合金在温度为200~400 ℃、应变速率为0.001~10 s-1、最大变形量为60%的条件下进行恒应变速率高温压缩实验,研究高温变形过程中合金的动态再结晶行为;采用EM模型描述合金的动态回复曲线,以此为基础,得出ZK60合金热压缩过程中的动态再结晶动力学Avrami方程。利用有限元模拟合金热压缩过程中的动态再结晶。结果表明:ZK60合金热压缩过程中由于存在动态再结晶的软化作用,流变应力达到峰值后逐渐减小,并最终达到稳态;随着变形量的增加和变形温度的升高,动态再结晶体积分数增加,合金变形更加均匀;随着应变速率的增加,动态再结晶分数有所减小,且变形也更不均匀。

关键词:ZK60 镁合金;热变形;流变应力;动态再结晶;动力学

中图分类号:TG 146.2 文献标志码:A

Dynamic recrystallization kinetics of

ZK60 magnesium alloy during hot deformation

HE Yun-bin1, 2, PAN Qing-lin1, 2, QIN Yin-jiang1, 2, LIU Xiao-yan1, 2, LI Wen-bin1, 2, Yu-lung CHIU3, J. J. J. CHEN3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China;

3. Department of Chemical and Materials Engineering, University of Auckland, Auckland 1102, New Zealand)

Abstract: The kinetics of dynamic recrystallization of ZK60 magnesium alloy was investigated by compression tests at temperature of 200-400 ℃ and strain rate of 0.001-10 s-1. The flow stress curves considering only dynamic recovery was described by EM model. Based on EM model, the kinetics of dynamic recrystallization of ZK60 alloy was modeled by an Avrami-type equation. The finite element simulations were utilized to simulate the recrystallization process of ZK60 alloy during hot compression. The results show that, due to the effect of dynamic recovery, the flow stress increases to a peak value and subsequently decreases to steady state. Both the volume fraction of dynamic recrystallization and the deformation homogeneity increase with the increase of the plastic strain and deformation temperature, while decrease with the increase of strain rate.

Key words: ZK60 magnesium alloy; hot deformation; flow stress; dynamic recrystallization; kinetics

镁合金由于具有密度低、比强度高以及阻尼性能和电磁屏蔽性好等优点,在汽车行业以及电子产品中都具有广阔的应用前景。然而,由于镁具有密排六方结构,常温下的变形只限于基面滑移,因此,常温下其塑性较差。大部分镁合金产品主要是通过传统铸造和新型半固态成形方式获得,而变形镁合金则相对较少。与铸造镁合金相比,变形镁合金组织更加致密,综合力学性能更高,尺寸精度也较高。为了发挥镁合金的潜力,有必要对变形镁合金进行研究。

热模拟作为一种研究合金热变形行为的有效手段,近年来得到广泛的应用[1-9]。同时,大量流变模型也被用来描述合金的热变形过程。最早的包括Hollomon模型[10]、Voce模型[11]和KM模型[12]等。对于镁合金,GALIYEV等[13]指出,ZK60合金的流变方程符合蠕变方程。TAKUDA等[14]研究发现,对于AZ31和AZ91合金,合金的屈服强度与Zener-Hollomon参数的半对数成线性关系。然而,以上模型都没有考虑动态再结晶(DRX)对合金流变行为的软化作用。而对于镁合金而言,由于其层错能较低且独立滑移系较少,在热变形过程很容易发生动态再结晶而使合金的流变应力降低。LIU等[15]对镁合金热变形过程研究表明,镁合金的软化主要取决于动态再结晶。因此,为了准确描述镁合金的流变行为,必须对合金的动态再结晶过程有更深的认识。

本文作者主要研究ZK60镁合金热压缩过程中的流变行为,并对热变形过程中的动态再结晶行为进行了研究。利用Avrami方程对动态再结晶动力学进行了描述。并采用有限元对合金的动态再结晶过程进行了模拟,研究热加工各参数对动态再结晶过程的影响。

1 实验

实验材料为ZK60(Mg-5.78Zn-0.76Zr)镁合金半连续铸锭。合金铸锭经400 ℃、12 h均匀化处理后切割成d 10 mm×15 mm的热压缩试样。试样分别在200~400 ℃以及变形速率为0.001~10 s-1的条件下进行热压缩试验。压缩变形量为60%。压缩试验在Gleeble-1500热模拟机上完成。通过其自动控制系统在预设的温度和应变速率下进行恒温、恒应变速率压缩。试样压缩前的升温速度为10 ℃/s,在加热到预定变形温度之后保温3 min。为减小试样与压头之间的摩擦,在压缩试样两端分别加工一厚度为0.2 mm的凹槽,并填充润滑剂(75%石墨+20%机油+5%硝酸三甲苯脂)。试样压缩完后马上进行水淬以保留其变形 组织。

为了分析变形条件对动态再结晶体积分数分布的影响,同时验证本文作者所建立的动态再结晶动力学模型的有效性,采用Deform-3D有限元数值模拟软件对ZK60合金的动态再结晶行为进行了模拟。模拟过程中的试样边界条件如下:环境温度为20 ℃,试样与空气的对流系数为0.1 N·s-1·mm-1·℃-1,试样与模具的传热系数为5 N·s-1·mm-1·℃-1,试样与模具的摩擦因数为0.3。

2 结果与分析

2.1 动态回复型流变曲线的描述

金属热变形流变应力曲线如图1所示。当软化仅由动态回复引起时,由曲线σrecov表示,它可以通过动态再结晶发生以前的硬化行为导出。当应变量超过动态再结晶临界应变εc时,由于动态再结晶的发生使流变应力曲线偏离σrecov,即σdrx。且随着变形的进行,当加工硬化与动态再结晶软化达到平衡时,合金流变应力达到峰值σp,之后随着变形量的增加,流变应力逐渐减小,当变形进行到一定程度后,流变应力不再减小,即进入稳态流变阶段,此时的流变应力可用σss表示。

图1 动态回复与动态再结晶型流变应力曲线示意图

Fig.1 Typical stress—strain curves of dynamic recovery and dynamic recrystallization

根据EM理论[16],材料在变形过程中位错增殖速度可表示如下:

(1)

(1)

式中:ρ为位错密度;ε为应变;k1为加工硬化参数;k2为动态回复系数,表示由于动态回复而产生的软化。引入初始条件ε=0时,ρ=ρ0,求解式(1)可得:

(2)

(2)

采用经典的应力—位错密度关系 [12],其中,

[12],其中, 为材料常数,G为剪切模量,b为柏氏矢量。于是,屈服应力

为材料常数,G为剪切模量,b为柏氏矢量。于是,屈服应力 ,流变应力可表示为

,流变应力可表示为

(3)

(3)

当应变ε很大,即在稳态变形时,动态回复饱和应力 可通过式(4)求得,即

可通过式(4)求得,即

(4)

(4)

于是,在仅有加工硬化和动态回复作用的条件下,流变应力可表达如下:

(5)

(5)

为了求得动态回复系数k2,本文作者采用JONAS等[17]提出的方法。对式(5)微分后得

(6)

(6)

两边同乘以 ,得

,得

(7)

(7)

将式(5)改为

(8)

(8)

于是,由式(7)可得

(9)

(9)

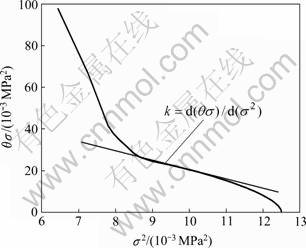

定义 为硬化速率,由式(9)可知,

为硬化速率,由式(9)可知, 与

与 之间呈线性关系,曲线

之间呈线性关系,曲线 的斜率为

的斜率为 。于是,k2的值可通过计算-2k而求得。图2为k的求解示意图。其中,斜率k由临界应变εc前的实验数据所确定。

。于是,k2的值可通过计算-2k而求得。图2为k的求解示意图。其中,斜率k由临界应变εc前的实验数据所确定。

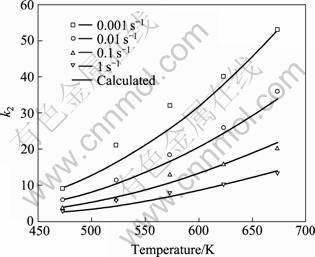

图3所示为应变速率与变形温度对ZK60合金动态回复系数k2的影响。从图3可以看出,k2随着应变速率的增加和变形温度的降低而减小,这也说明了k2是动态回复程度的量度。为了定量描述变形参数对k2的影响,LIN和CHEN[18]采用如

的经验关系式,其中,d0为初始晶粒尺寸(mm),Q为表观激活能(kJ×mol-1),A、n和m为常数;R为摩尔气体常数;T为温度。通过回归分析可得k2的表达式如下

的经验关系式,其中,d0为初始晶粒尺寸(mm),Q为表观激活能(kJ×mol-1),A、n和m为常数;R为摩尔气体常数;T为温度。通过回归分析可得k2的表达式如下

(10)

(10)

图2 θσ —σ2曲线及斜率k的求解示意图

Fig.2 θσ —σ2 plot for determining value of k

图3 应变速率与变形温度对k2的影响

Fig.3 Effect of deformation temperature and strain rate on value of k2

作为对比,图3中也显示出k2的计算值,结果表明用式(10)表示应变速率和变形温度对k2的影响是比较精确的。需要指出的是,为了研究初始晶粒尺寸d0对k2的影响,本文作者引用了YANG等[19]的实验结果。在YANG等的研究中,ZK60合金初始晶粒尺寸为50 μm,而本模拟中为100 μm。

2.2 动态再结晶动力学

本文作者采用经典的Avrami型方程来描述ZK60合金的动态再结晶动力学,其表达式为[18]

(11)

(11)

式中:X为动态再结晶体积分数;r和q为与材料化学成分和变形条件有关的参数;ε0.5为发生50%再结晶时对应的应变,其通常具有如下形式[19]:

(12)

(12)

式中:A1、m1和n1为材料常数;d0为初始晶粒尺寸,mm;Q1为再结晶激活能,kJ/mol;R为摩尔气体常数,8.314 J/(mol·K);T为绝度温度,K。

由图1可知,曲线σdrx偏离σrecov的程度,即?σ,代表了动态再结晶的软化程度,其最大值为σsat-σss。因此,动态再结晶体积分数又可用软化分数表示如下:

(13)

(13)

于是可以直接从流变应力曲线上确定不同应变量时的动态再结晶分数。

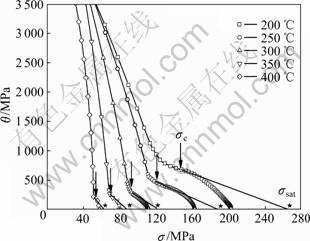

动态回复饱和应力σsat可通过将θ-σ曲线外推至θ=0处而获得。可见,σsat的大小也由εc前的加工硬化行为而确定。图4所示为ZK60合金在应变速率为0.1 s-1时不同温度下的θ—σ曲线。其中,动态再结晶临界应力σc和饱和应力σsat分别用箭头和星号标出。

图4 应变速率为0.1 s-1时不同温度下的θ—σ曲线

Fig.4 θ—σ plots at strain rate of 0.1 s-1 and different temperature

由于峰值应力σp在实验中最易准确测量,为了便于模拟计算,有必要将σ0、σsat和σss表示为σp的倍数。其中,σ0取屈服强度σ0.2,而σss直接从实验曲线取得。图5所示为ZK60合金σ0、σsat和σss与σp的关系,通过回归可得:σ0=0.36σp,σsat=1.20σp,σss=0.62σp。

根据实验数据和文献[20-21]可知,εc和ε0.5都是初始晶粒尺寸d0,变形温度T和应变速率 的函数,它们都可以用形如式(12)的方程加以描述,其回归分析结果如下:

的函数,它们都可以用形如式(12)的方程加以描述,其回归分析结果如下:

(14)

(14)

(15)

(15)

图5 σ0、σsat和σss与σp的关系

Fig.5 Relationships among σ0, σsat, σss and σp

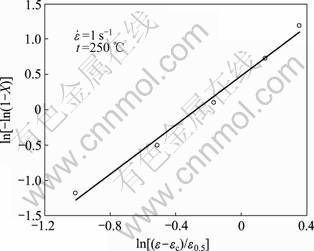

为了确定ZK60合金的动态再结晶动力学,以 和

和 为横纵坐标作图,则参数r和q可分别由拟合曲线的斜率和截距求得。图6所示为

为横纵坐标作图,则参数r和q可分别由拟合曲线的斜率和截距求得。图6所示为 =1 s-1和t=250 ℃时的r和q。通过对其它条件下的回归结果的分析可知,q与

=1 s-1和t=250 ℃时的r和q。通过对其它条件下的回归结果的分析可知,q与 和T关系不大,约为1.65,而r为

和T关系不大,约为1.65,而r为 和T的函数,可表示如下:

和T的函数,可表示如下:

(16)

(16)

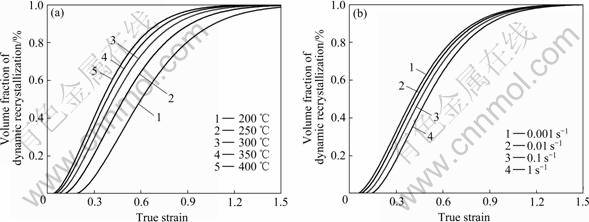

图7所示为不同温度和应变速率条件下ZK60合金的再结晶动力学曲线。由图7可见,动态再结晶体积分数随着温度的升高和应变速率的降低而增加。

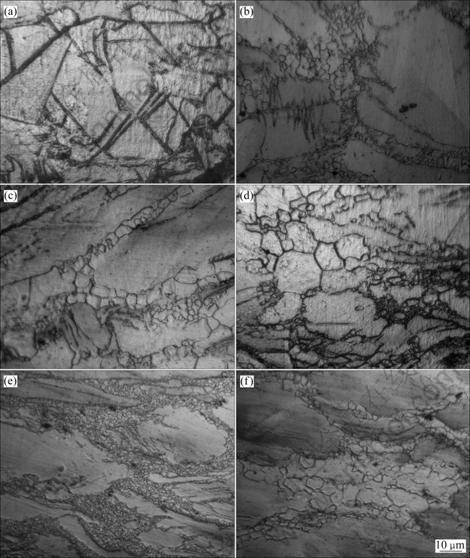

图8所示为不同变形条件下ZK60合金变形过程中的显微组织演变。图8(a)~(d)为变形温度250 ℃,应变速率0.001 s-1时,合金不同变形量下的显微组织。从图中可见,合金的原始晶粒为粗大的铸态晶粒,经变形后在晶粒内部存在大量的变形孪晶,动态再结晶晶粒在原始晶界和孪晶界上形核。当变形量继续增大时(见图8(b)),沿晶界分布的动态再结晶晶粒通过新晶粒晶界的迁移而长大,同时仍有新的细小的再结晶晶粒正在形成;进一步增加变形量,细小的再结晶晶粒进一步长大,动态再结晶晶粒的体积分数随着变形量的增大而增多(见图8(c))。当变形量达到0.9时,合金基本完全再结晶(见图8(d))。从图中还可以看出,当应变速率增加至0.01 s-1时,合金中的再结晶晶粒明显减小,而随着温度的升高,再结晶晶粒逐渐长大,这与上面动态再结晶的动力学结果相符。

图6 再结晶动力学方程中q和r的确定

Fig.6 Determination of values of q and r in kinetics equation

图7 ZK60合金的再结晶动力学曲线

Fig.7 Kinetics curves of ZK60 alloy during hot deformation: (a )  =0.01 s-1; (b) t=250 ℃

=0.01 s-1; (b) t=250 ℃

图8 ZK60合金在不同变形条件下压缩后的显微组织

Fig.8 Microstructures of ZK60 alloy during hot deformation under different conditions: (a) t=250 ℃,  =0.001 s-1, ε=0.2; (b) t=250 ℃,

=0.001 s-1, ε=0.2; (b) t=250 ℃, =0.001 s-1, ε=0.4; (c) t=250 ℃,

=0.001 s-1, ε=0.4; (c) t=250 ℃, =0.001 s-1, ε=0.6; (d) t=250 ℃,

=0.001 s-1, ε=0.6; (d) t=250 ℃, =0.001 s-1, ε=0.9; (e) t=250 ℃,

=0.001 s-1, ε=0.9; (e) t=250 ℃, =0.01 s-1, ε=0.9; (f) t=350 ℃,

=0.01 s-1, ε=0.9; (f) t=350 ℃, =0.01 s-1, ε=0.9

=0.01 s-1, ε=0.9

2.3 有限元模拟结果与分析

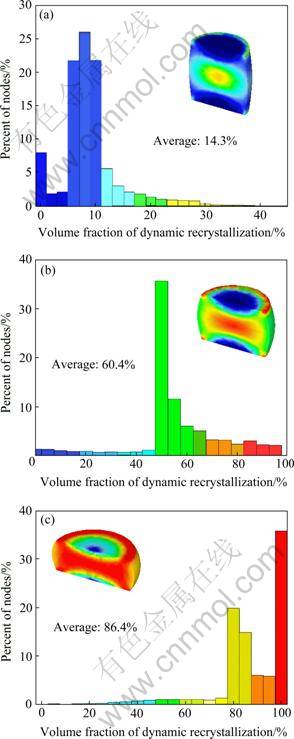

2.3.1 变形程度的影响

图9所示为ZK60合金在变形温度250 ℃、应变速率1 s-1、压下率分别为20%、40%和60%时动态再结晶体积分数分布情况。纵坐标表示具有某一动态再结晶体积分数的节点分数。由图可知,动态再结晶首先在试样心部的大变形区发生,然后向自由变形区(圆柱体四周)和粘着区(圆柱体上下表面)延伸;当变形程度较小时(见图9(a)),试样的动态再结晶体积分数很小,仅为14.3%,此时基体的大部分区域处于动态再结晶形核阶段,这也说明只有当变形量达到一定程度时动态再结晶才开始发生;随着应变量的继续增大(见图9(b)),动态再结晶体积分数迅速增加,但是当应变量再进一步增大时,再结晶体积分数增加的速度减缓,当变形量达到60%时,合金再结晶体积分数达到86.4%;此外,由图中动态再结晶体积分数分布的标准偏差(esd)可知,试样动态再结晶发生部位的不均匀性先增大后减小,说明随着变形量的增加,合金组织变得更均匀。

2.3.2 变形温度的影响

图10所示为ZK60合金在应变速率0.1 s-1时,不同温度(250, 300, 350和400 ℃)下压缩60%后动态再结晶体积分数分布情况。由图10可见,随着变形温度的增加,试样的平均动态再结晶体积分数增加;同样,试样的再结晶体积分数分布也不均匀,试样中心区域再结晶体积分数较大,这是因为试样的应变分布不均匀,在中心区域应变相对较大;从不同温度条件下的标准偏差变化可知,随着变形温度的升高,合金动态再结晶体积分数分布更加均匀。

图9 ZK60合金不同变形量下动态再结晶体积分数分布

Fig.9 Volume fraction of dynamic recrystallization at different strains: (a) 20%; (b) 40%; (c) 60%

2.3.3 应变速率的影响

图11所示为ZK60合金在变形温度300 ℃、不同应变速率(0.001、0.1和10 s-1)下压缩60%后动态再结晶体积分数分布情况。可见,随着应变速率的增加,试样的平均动态再结晶体积分数减小;试样的再结晶体积分数分布也不均匀,试样中心大变形区动态再结晶体积分数较大;从不同应变速率条件下的标准偏差变化可知,随着应变速率的增加,合金动态再结晶体积分数分布越来越不均匀。

图10 ZK60合金不同温度压缩时动态再结晶体积分数分布

Fig.10 Volume fraction of dynamic recrystallization of ZK60 alloy deformated at different temperatures: (a) 250 ℃; (b) 300 ℃; (c) 350 ℃; (d) 400 ℃

图11 ZK60合金不同应变速率压缩时动态再结晶体积分数分布

Fig.11 Volume fraction of dynamic recrystallization of ZK60 alloy deformated at different strain rates: (a) 0.001 s-1; (b) 0.1 s-1; (c) 10 s-1

3 结论

1) 由于ZK60合金热压缩过程中存在动态再结晶,合金流变应力出现明显的软化现象,流变应力达到峰值后逐渐减小,并最终达到稳态。

2) 采用EM模型描述了合金的动态回复曲线,并以此为基础,得出ZK60合金热压缩过程中的动态再结晶动力学Avrami方程。

3) 有限元模拟结果表明,随着变形量的增加和变形温度的升高,动态再结晶分数增加,合金变形更加均匀;随着应变速率的增加,动态再结晶分数有所减小,且变形也更不均匀。

REFERENCES

[1] 罗丰华, 尹志民, 左铁镛. CuZn(Cr,Zr)合金的热变形行为[J]. 中国有色金属学报, 2000, 10(1): 12-16.

LUO Feng-hua, YIN Zhi-min, ZUO Tie-yong. Hot deformation behavior of CuZn( Zr,Cr) alloys[J]. The Chinese Journal of Nonferrous Metals Society, 2000, 10(1): 12-16.

[2] ZHANG H, ZHANG H G,PENG D S. Hot deformation behavior of KFC copper alloy during compression at elevated temperatures[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(3): 562-566.

[3] 李慧中, 梁霄鹏, 张新明, 黄伯云, 张传福. 2519铝合金热变形组织演化[J]. 中国有色金属学报, 2008, 18(2): 226-230.

LI Hui-zhong, LIANG Xiao-peng, ZHANG Xin-ming, HUANG Bai-yun, ZHANG Chuan-fu. Microstructure evolution of 2519 aluminum alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals Society, 2008, 18(2): 226-230.

[4] KANG F W, ZHANG G Q, LI Z, SUN J F. Hot deformation of spray formed nickel-base superalloy using processing maps[J]. Transactions of Nonferrous Metals Society of China, 2008, 18 (3): 531-535.

[5] 李庆波, 叶 凡, 周海涛, 钟建伟, 赵仲恺, 王孟君. Mg-9Y-3Zn-0.5Zr合金的热变形行为[J]. 中国有色金属学报, 2008, 18(6): 1012-1019.

LI Qing-bo, YE Fan, ZHOU Hai-tao, ZHONG Jian-wei, ZHAO Zhong-kai, WANG Meng-Jun. Hot deformation behavior of Mg-9Y-3Zn-0.5Zr alloy[J]. The Chinese Journal of Nonferrous Metals Society, 2008, 18(6): 1012-1019.

[6] 李文斌, 潘清林, 梁文杰, 何运斌, 刘俊生, 李运春. 含Sc超高强Al-Zn-Cu-Mg-Sc-Zr合金的热压缩变形流变应力[J]. 中国有色金属学报, 2008, 18(5): 777-782.

LI Wen-bin, PAN Qing-lin, LIANG Wen-jie, HE Yun-bin, LIU Jun-sheng, LI Yun-chun. Flow stress of super-high strength Al-Zn-Cu-Mg-Sc-Zr alloy containing Sc under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals Society, 2008, 18(5): 777-782.

[7] YANG X Y, JI Z S, MIURA H, SAKAI T. Dynamic recrystallization and texture development during hot deformation of magnesium alloy AZ31[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 55-60.

[8] 王忠堂, 张士宏, 齐广霞, 王 芳, 李艳娟. AZ31镁合金热变形本构方程[J]. 中国有色金属学报, 2008, 18(11): 1977-1982.

WANG Zhong-tang, ZHANG Shi-hong, QI Guang-xia, WANG Fang, LI Yan-juan. Constitutive equation of thermal deformation for AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals Society, 2008, 18(11): 1977-1982.

[9] 刘晓艳, 潘清林, 何运斌, 李文斌, 梁文杰, 尹志民. Al-Cu-Mg-Ag合金热压缩变形的流变应力行为和显微组织[J]. 中国有色金属学报, 2009, 19(2): 201-207.

LIU Xiao-yan, PAN Qing-lin, HE Yun-bin, LI Wen-bin, LIANG Wen-jie, YIN Zhi-min. Flow stress behavior and microstructure of Al-Cu-Mg-Ag alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals Society, 2009, 19(2): 201-207.

[10] HOLLOMON J H. The mechanical equation of state[J]. Transaction of AIME, 1947, 171: 535-545.

[11] VOCE E. The relationship between stress and strain for homogeneous deformation[J]. Journal of Institute Metals, 1948, 74: 537-562.

[12] MECKING H, KOCKS U F. Kinetics of flow and strain- hardening[J]. Acta Metallurgica, 1981, 29(11): 1865-1875.

[13] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[14] TKUDA H, FUJIMOTO H, HATTA N. Modelling on flow stress of Mg-Al-Zn alloys at elevated temperatures[J]. Journal of Materials Processing Technology, 1998, 80/81: 513-516.

[15] LIU J, CUI Z, LI C. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B[J]. Computational Materials Science, 2008, 41(3): 375-382.

[16] ESTRIN Y, MECKING H. A unified phenomenological description of work hardening and creep based on one-parameter models[J]. Acta Metallurgica, 1984, 32(1): 57-70.

[17] JONAS J J, QUELENNEC X, JIANG L, MARTIN ?. The Avrami kinetics of dynamic recrystallization[J]. Acta Materialia, 2009, 57(9): 2748-2756.

[18] LIN Y C, CHEN M S. Numerical simulation and experimental verification of microstructure evolution in a three-dimensional hot upsetting process[J]. Journal of Materials Processing Technology, 2009, 209(9): 4578-4583.

[19] YANG Y S, KO D C, KIM B M. Application of the finite element method to predict microstructure evolution in the hot forging of steel[J]. Journal of Materials Processing Technology, 2000, 101(1/3): 85-94.

[20] LIAO S l, ZHANG L W, YUE C W, PEI J B, GAO H J. Hot deformation behaviors and flow stress model of GCr15 bearing steel[J]. Journal of Central South University of Technology, 2008, 15(5): 575-580.

[21] ZHANG L, YANG W, SUN Z. Modeling of microstructural evolution during dynamic recrystallization in coarse Nb microalloyed austenite[J]. Journal of University of Science and Technology Beijing: Mineral, Metallurgy, Material, 2007, 14(2): 130-135.

(编辑 龙怀中)

基金项目:新西兰奥克兰大学国际合作项目(9271/3609563)

收稿日期:2010-06-22;修订日期:2010-07-03

通信作者:潘清林,教授,博士;电话0731-88830933;E-mail: pql@mail.csu.edu.cn