文章编号:1004-0609(2011)10-2534-17

铝合金大型复杂薄壁壳体旋压研究进展

杨 合1, 2,詹 梅1, 2,李 甜1, 2,王巧玲1, 2

(1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 西北工业大学 材料科学与工程学院,西安 710072)

摘 要:大型复杂薄壁壳体是航空航天等高技术产业迅速发展的迫切需求,带横向内筋大型复杂薄壁壳体是其中的典型代表。然而,带横向内筋大型复杂薄壁壳体多道次复合旋压却是一个多因素耦合作用下的复杂塑性成形过程。作者采用数值模拟和实验相结合的方法,以铝合金带横向内筋大型复杂薄壁壳体为代表,建立大型复杂薄壁壳体复合旋压全过程仿真平台与模型,研究不同条件下大型复杂薄壁壳体复合旋压及其特征结构旋压过程中的不均匀塑性变形行为和成形缺陷的形成机理。揭示不同塑性变形行为对工件内筋质量的影响规律,获得对不同塑性变形行为有决定性影响的因素,确定合理的毛坯、工艺和旋轮参数的选择准则。研究结果对发展大型复杂薄壁壳体精确成形技术具有重要的理论意义和实际应用价值。

关键词:铝合金;大型复杂薄壁壳体;横向内筋;多道次复合旋压;全过程仿真优化

中图分类号:TG302 文献标志码:A

Advances in spinning of aluminum alloy large-sized complicated thin-walled shells

YANG He1, 2, ZHAN Mei1, 2, LI Tian1, 2, WANG Qiao-ling1, 2

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Large-sized complicated thin-walled aluminum alloy shells are the urgent needs of the development of aero-space high technology. Large-sized complicated thin-walled aluminum alloy shells with transverse inner ribs (LCTAASTIR) are one representative of those. But Multi-pass compound spinning of LCTAASTIR is one of the complicated plastic forming processes under the action of multi-parameters and their coupled effects. In this work, a modeling platform for the process was developed and some finite element models for the whole process were established. The characteristics of uneven deformation behaviors during the process and the forming mechanism of defects were investigated. The laws of different deformation behaviors on the quality of ribs were revealed, the decisive parameters on deformation behaviors were obtained, and the reasonable rules of blank, process and die parameters for the spinning process were determined. The achievements of this work are of significance to developing advanced theory and technology of precision plastic forming for LCTAASTIR.

Key words: aluminum alloy; large-sized complicated thin-walled shells; transverse inner ribs; multi-pass compound spinning; simulation and optimization for whole process

随着航空航天等高技术产业的迅速发展,先进飞机、航天器、火箭及导弹中迫切需要大量采用结构效益十分显著的大型整体复杂薄壁壳体,以减轻质量和提高整体性能,新一代飞机和航天器等更是如此。带内筋大型整体复杂薄壁壳体就是其中的典型代表。然而,这些构件大型整体化、薄壁轻量化、形状复杂化,性能要求苛刻,材料成形困难。由于问题的复杂性和现有整体成形技术的限制,目前我国对这些大型整体复杂薄壁壳体不得不采用旋压成形和机加工相结合,并主要靠机加工来保证成形精度和成形质量的工艺路线与制造技术[1]。这不仅使这些构件的可靠性差,而且制造周期长、材料利用率低。

目前,关于带内筋构件的研究,国内外学者将重点集中在包括齿轮在内的纵向内筋构件成形过程等方面的研究,如各种工艺参数下应力、应变变化规律以及内筋的成形质量,另外还包括对成形缺陷成形机理及预测等方面的研究[2-9]。另外,李亚辉等[10-12]及DAVIDSON等[13]开展了大型锥形件、筒形件以及复杂曲面薄壁异性件成形质量以及工艺参数等方面的研究。然而,对于带横向内筋大型复杂薄壁壳体方面的研究却鲜见报道,而此类构件在航空航天领域的应用日渐广泛,因此,有必要开展带横向内筋大型复杂薄壁壳体旋压方面的一系列研究。为了提高其工件成形质量和成形极限,多道次复合旋压已成为成形带横向内筋大型复杂薄壁壳体的一种首选成形方式[14-16]。然而,通过复合旋压成形,不仅要获得满足精度要求的轮廓外形,而且还要获得充填饱满的内筋,所以,和传统的普旋和强旋成形相比,带横向内筋大型复杂薄壁壳体复合旋压成形过程的影响因素更多,成形机理更加复杂。在多道次大型复杂薄壁壳体复合旋压的成形过程中,材料要经历复杂的多道次局部加载、卸载和不均匀变形,更易出现起皱、破裂、筋部充填不满、旋轮前方金属堆积等缺陷。因此,迫切需要开展大型复杂薄壁壳体多道次复合旋压精确成形全过程建模仿真、塑性变形行为和缺陷形成机理、毛坯与过程和模具优化研究,为该成形过程及其模具优化设计与控制提供依据。这对发展大型复杂薄壁壳体多道次复合旋压精确成形技术,提高大型复杂薄壁壳体的高质量、低成本、短周期制造技术水平和能力具有重大战略意义和十分迫切的现实意义。

1 研究思路与方法

由于大型复杂薄壁壳体复合旋压是一个多道次、多参数耦合的高度非线性复杂过程,因此,基于理论、经验和反复试验的方法难以满足对该过程数字化、高技术化发展的需求。而计算机建模仿真优化与理论分析及实验研究有机结合的方法,能虚拟成形现实,将大量反复试验在计算机上完成,可以比理论和实验做得更全面、更深刻、更细致,可以进行一些理论和实验暂时还做不到的研究,已成为研究与发展先进精确塑性成形技术,高质量、低成本、短周期、自主创新地实现塑性成形产品开发的强有力工具。

因此,本文报告的工作采取以计算机数值模拟仿真为主,并与实验研究相结合的方法,以铝合金带内筋大型复杂薄壁壳体为研究对象,先提取大型复杂薄壁壳体的典型特征,建立横向内筋特征结构旋压成形有限元仿真模型,并结合大型复杂薄壁壳体多道次复合旋压成形全过程仿真分析模型,开展大型复杂薄壁壳体多道次复合旋压毛坯、过程和模具优化以及旋压过程中不均匀变形、塑性变形行为与成形缺陷研究。

2 大型复杂薄壁壳体多道次复合旋压精确成形全过程的建模与仿真

大型复杂薄壁壳体多道次复合旋压精确成形全过程的建模仿真研究已成为宇航高新技术发展的迫切要求,然而面临复杂非线性导致的有限元计算的效率和精度难于平衡、网格易畸变、材料性能难于准确描述、多道次旋压建模繁锁易出错等难题。

2.1 有限元计算方法的选择

在大型复杂薄壁壳体多道次复合旋压成形过程中,考虑旋轮和坯料外表面、芯模和坯料内表面的复杂动态接触,并根据大型复杂薄壁壳体多道次复合旋压成形过程的特点及隐式、显式算法的特点及其适用范围,采用基于动态显式算法的ABAQUS/Explicit模块模拟计算大型复杂薄壁壳体多道次复合旋压成形与道次间退火,采用将ABAQUS/Explicit的旋压成形结果导入ABAQUS/Standard模块的方法,实现对回弹的建模分析[16]。

2.2 屈服准则的选择

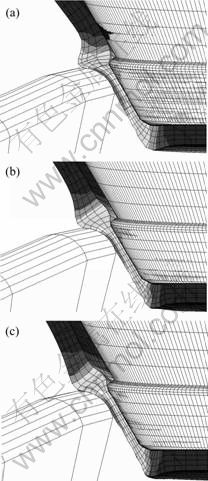

考虑到铝合金大型复杂薄壁壳体多道次复合旋压具有体积成形和板材成形的综合特征,板料的厚向异性特征对成形具有较大影响,因此,为了更准确地描述材料的各向异性,提高模型的计算精度,采用希尔1948各向异性屈服准则来考虑金属板料的厚向异性特征[17]。发现随着板料厚向异性指数r的变化,成形过程中塑性变形区的应力应变状态及金属流动特征具有很大的差别,如图1所示。

图1 不同厚向异性指数r下工件的变形行为

Fig.1 Deformation behaviors of workpieces with different r: (a) r=0.776; (b) r=1.276; (c) r=1.000

2.3 网格划分与网格自适应技术应用策略

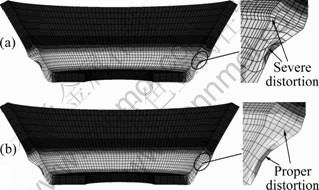

鉴于内筋成形区域是大型复杂薄壁壳体多道次旋压成形过程中需要关注的特征区域,有必要对该区域的网格进行充分细化,并采用网格自适应技术。为避免网格自适应技术对整个板料范围内网格都进行重新划分而使所关注的内筋区域的网格难以得到充分细化,并避免旋轮进给至两个网格密度的交界处可能引起的网格严重扭曲变形,提出了采用带缓冲区的分区域、分阶段网格自适应技术应用策略(见图2),由此避免了成形过程中的网格畸变[17]。

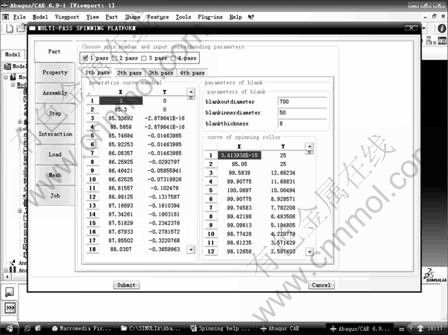

2.4 多道次复合旋压建模仿真平台的研发

采用python语言并基于ABAQUS用户图形界面(GUI)工具,研究解决了关键字注册、快速获取建模命令并改写为后台程序主函数、复杂芯模形状的生成以及网格的控制等关键技术,开发了多道次复合旋压建模仿真平台(图3所示为该平台建模的参数输入界面),可实现多道次复合旋压模型的快速建模分析[18]。

图2 采用带缓冲区的网格自适应技术与否的模拟结果对比

Fig.2 Comparison of mesh technologies with and without buffer zone: (a) Without buffer zone; (b) With buffer zone

图3 多道次旋压建模仿真平台建模参数输入界面

Fig.3 Parameters input interface for FEM simulation of multi-pass spinning module

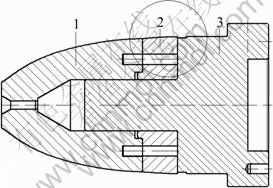

2.5 有限元模型的建立

根据大型复杂薄壁壳体的构件特征及多道次复合旋压的变形特征,基于该平台,建立了大型复杂薄壁壳体多道次复合旋压成形全过程的三维仿真模型(见图4~6),实现了对大型复杂薄壁壳体的多道次复合旋压、退火、回弹全过程以及材料复杂不均匀塑性变形行为的描述[16, 19-24]。在对成形过程系统的力学分析的基础上,提取大型复杂薄壁壳体多道次复合旋压的典型特征,建立了带横向内筋构件旋压成形仿真模 型[17, 25-28](见图7)。上述平台与模型的建立,为大型复杂薄壁壳体多道次复合旋压变形分析、模具设计、工艺参数选取、过程优化控制等提供了高效、可靠的分析工具。

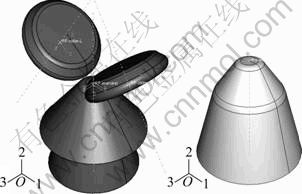

图4 第1道次模型

Fig.4 FE model for the first pass

图5 第2道次模型及芯模

Fig.5 FE model for the second pass and mandrel

2.6 失稳起皱的预测

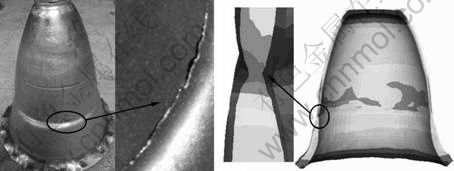

采用动态显式有限元数值模拟方法,实现了大型复杂薄壁壳体复合旋压过程中失稳起皱的仿真分析与预测。图8所示为大型复杂薄壁壳体旋压过程仿真分析和实验中出现的凸缘起皱缺陷[19-20, 22]。

图6 第3道次旋压模型及芯模

Fig.6 FE model for the third pass and mandrel

图7 带横向内筋特征结构旋压模型及芯模凹槽

Fig.7 FE model for spinning of parts with inner rib and groove of mandrel

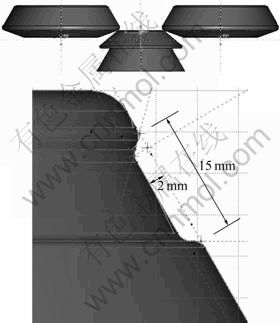

图8 旋压过程中的凸缘起皱

Fig.8 Flange wrinkling during spinning process

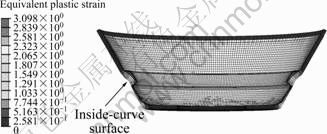

2.7 破裂的预测

考虑材料的损伤值与塑性应变之间的非线性关系,改进了Lemaitre韧性断裂准则[29-30]。基于有限元软件ABAQUS/Explicit的VUMAT平台,分别建立了耦合Lemaitre损伤模型和耦合改进的Lemaitre损伤模型的本构方程用户子程序[29-32],建立了预测大型复杂薄壁壳体多道次旋压破裂的模型。结果表明,改进的Lemaitre准则的预测精度高,如图9所示。采用改进的Lemaitre准则对大型复杂薄壁壳体多道次旋压的研究发现,该过程中易于出现非筋部过度减薄拉裂缺陷,如图10和11所示。获得了偏离率和芯模转速等工艺参数对破裂的影响规律,提出了通过控制芯模转速、旋轮进给比、偏离率,尤其是控制旋轮轨迹来控制破裂的方法[29-30]。

3 带横向内筋大型复杂薄壁壳体复合旋压的不均匀塑性变形行为与成形缺陷

对横向内筋大型复杂薄壁壳体复合旋压过程中的不均匀塑性变形行为与成形缺陷进行深入、系统的研究,已成为发展旋压精确成形技术、充分发挥旋压技术优势所迫切需要解决的重要基础问题,也是进行毛坯、工艺和模具优化的前提。

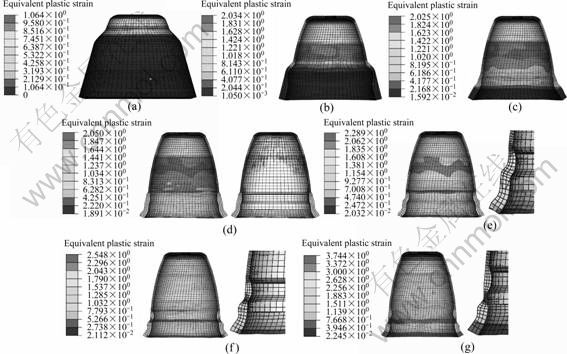

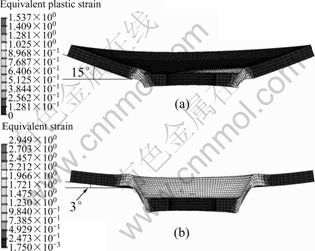

3.1 全过程不均匀塑性变形行为

模拟分析了不同毛坯形状、旋压道次、旋轮轨迹、间隙、旋轮进给比、芯模转速等条件下带横向内筋大型复杂薄壁壳体复合旋压成形过程,归纳获得了大型复杂薄壁壳体在多道次复合旋压过程中不同变形区及特征区域的不均匀变形特征[19-20, 23, 33-36]。图12所示为旋压成形带横向内筋复杂薄壁壳体过程中筋部上区、筋部特征区、筋部下区的不均匀变形特征[23, 33]。结果表明,在旋压成形筋部上区(见图12(a)~(d)),大变形集中于旋轮作用的环带区以及旋轮后方的已成形区,并且随着旋压过程的进行,大变形区不断扩大。进入筋部成形阶段后(见图12(e)),大变形区集中于工件筋部和与筋部上区交接处。直到筋部成形结束(见图12(f)),筋部与筋部上区和筋部下区的交接处都成为大变形区。在随后成形筋部下区的过程中(见图12(g)),大变形区始终位于筋部与筋部下区的交接处。

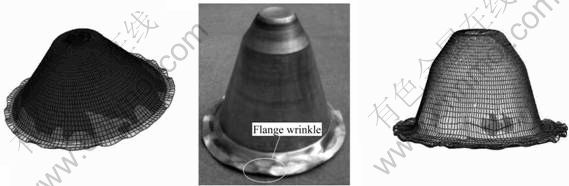

图9 采用改进前后的Lemaitre准则对锥形件旋压破裂的预测结果与实验结果的比较

Fig.9 Comparison among experimental results and predicted results of crack by using Lemaitre criterion and modified Lemaitre criterion for cone spinning: (a) Lemaitre criterion; (b) Modified Lemaitre criterion; (c) Experiment

图10 第1道次旋压过程中的非筋部破裂

Fig.10 Non-rib region crack during the first pass spinning

图11 第3道次旋压过程中的非筋部破裂

Fig.11 Non-rib region crack during the third pass spinning

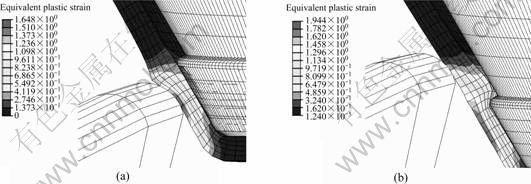

3.2 筋部特征结构不均匀塑性变形行为

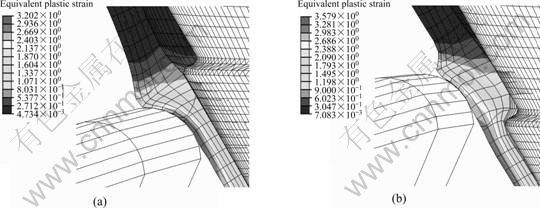

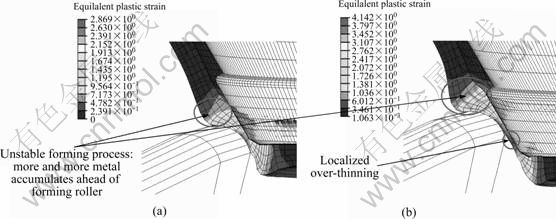

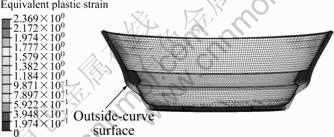

通过系统研究不同毛坯、工艺与模具参数条件 下,带横向内筋特征结构强旋成形过程中的不均匀变形,发现带横向内筋特征结构强旋成形过程中的4种塑性变形行为:大间隙不贴模不饱满内筋塑性变形行为、小进给不贴模不饱满内筋塑性变形行为、饱满内筋塑性变形行为和不稳定塑性变形行为,如图13~16所示[17, 37]。其中,大间隙不贴模不饱满内筋塑性变形行为发生在旋轮和芯模间隙值较大时。此时,不论旋轮进给比和芯模转速如何变化,在内筋成形阶段,工件的内表面在内筋成形阶段不与芯模接触,塑性变形区的金属都不能完全充满芯模凹槽,如图13所示。小进给不贴模不饱满内筋塑性变形行为发生在当旋轮进给比较小时。在此条件下,非筋区域成形过程中,塑性变形区的切向拉应变很大,导致工件产生扩径现象,使得工件内表面在成形过程中不与芯模接触,最终也不能获得充填饱满的内筋,如图14所示。饱满内筋塑性变形行为发生在旋轮和芯模的间隙较小,但旋轮进给比较大时。在此成形过程中,塑性变形区的切向拉应变很小,工件的内表面一直与芯模接触,在内筋成形阶段,塑性变形区中的金属易于流入芯模凹槽形成饱满内筋,如图15所示。不稳定塑性变形行为在旋轮和芯模的间隙很小的条件下发生。在此条件下,无论旋轮进给率和芯模转速如何取值,塑性变形过程都开始变得不稳定,在成形区,工件产生局部过度减薄甚至拉裂,如图16所示。

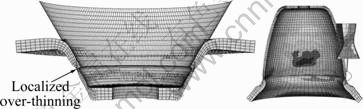

3.3 缺陷形成机理

研究发现,在大型复杂薄壁壳体多道次复合旋压和特征结构旋压成形过程中,除了易于出现上述起皱、局部过度减薄甚至拉裂、筋部充填不满等缺陷外,还易于出现筋部内凹、筋部外凸、拉弯局部减薄和贴模度差等缺陷,如图17~20所示。采用数值模拟和实验相结合的方法,揭示了这些缺陷与大型复杂薄壁壳体复合旋压过程中不均匀变形与成形质量和成形缺陷的关联关系[17, 38]。其中,拉弯局部减薄是由于在以拉弯为主的大型复杂薄壁壳体复合旋压成形过程中,不断增加的切向拉应力导致工件已成形区的壁部出现局部减薄,如图17所示。工件筋部的内凹变形(见图18),主要是由于预成形坯料的壁厚过小,导致塑性变形区中的金属较少,难以充满芯模凹槽。工件筋部的外凸变形(见图19)则是由于预成形坯料的壁厚较小,导致成形过程中塑性变形区的金属在径向压应力作用下失稳所致。而较大的正、负偏离引起的凸缘不均匀附加变形以及卸载回弹的影响,易造成工件局部较大的不贴模缺陷,如图20所示。

图12 第3道次旋压成形中的等效应变塑性分布

Fig.12 Equivalent plastic strain distribution during the third pass spinning: (a) t=10.29 s; (b) t=30.98 s; (c) t=45.98 s; (d) t=56.27 s; (e) t=61.07 s; (f) t=63.82 s; (g) t=67.25 s

图13 大间隙不贴模不饱满内筋塑性变形行为

Fig.13 Plastical deformation behavior of unfittability and under-filled inner rib at large spinning clearance: (a) Before deformation of inner rib; (b) During deformation of inner rib

图14 小进给不贴模不饱满内筋塑性变形行为

Fig.14 Plastic deformation behavior of unfittability and under-filled inner rib at small feed ratio: (a) Before deformation of inner rib; (b) During deformation of inner rib

图15 饱满内筋塑性变形行为

Fig.15 Plastic deformation behavior of full filled inner rib: (a) Before deformation of inner rib; (b) During deformation of inner rib

图16 局部过渡减薄不稳定塑性变形行为

Fig.16 Unstable plastic deformation behavior of localized over-thinning: (a) Before localized over-thinning; (b) During localized over-thinning

图17 拉弯造成的局部减薄及筋部充填不饱满

Fig.17 Localized over-thinning and under-fill of inner rib caused by stretch bending

图18 工件筋部位内凹

Fig.18 Inside-curve in region of inner rib

图19 工件筋部位外凸

Fig.19 Outside-curve in region of inner rib

图20 大偏离下的不贴模缺陷

Fig.20 Defect of unfittability at large deviation

4 带横向内筋大型复杂薄壁壳体多道次复合旋压预成形毛坯优化

在带横向内筋大型复杂薄壁壳体和特征结构旋压成形过程中,预成形坯料的形状和尺寸对塑性变形区金属的应力、应变状态和流动特征以及成形缺陷具有重要的影响。

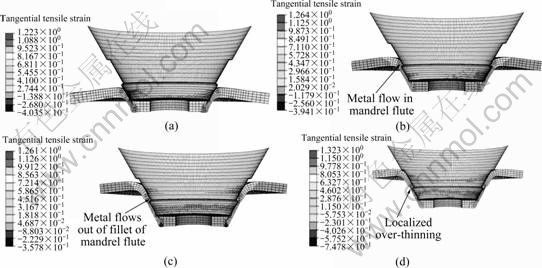

为此,首先基于有限元数值模拟方法研究了不同形状和尺寸的预成形坯料对带横向内筋构件强旋成形过程的影响规律(见图21和22),确定了带横向内筋构件强旋成形过程预成形坯料的最佳形状为与芯模等半锥角的锥形[17, 39]。对不同壁厚与芯模等半锥角锥形的预成形坯料进行了系统研究,结果表明,在同样的成形条件下,内筋圆角1(见图21)是最不易充填饱满的区域[17, 39]。因此,内筋圆角1成形阶段是带横向内筋特征结构强旋成形过程能否获得合格工件的关键。在此基础上,确定了预成形坯料壁厚t0的合理取值范围为h/δ2<t0<h/δ1 (h为内筋高度,δ1和δ2分别为预成形毛坯壁厚减薄率的最小和最大值)。还研究了毛坯直径对大型复杂薄壁壳体旋压过程中不均匀变形以及缺陷的影响规律[19, 40](见图23和24)。研究发现,随着坯料直径的增加,成形区与成形外端之间连续不间断的相互影响、相互作用更加明显,因此,增加了质量控制的难度,由此确定在满足大型复杂薄壁壳体成形要求的基础上,应尽量选用直径较小的初始毛坯。此研究结果为进一步研究工艺和旋轮几何参数对带横向内筋锥形件强旋成形过程的影响规律奠定了基础,对研究和揭示该过程的成形机理具有重要的意义。

图21 平板毛坯在旋压不同阶段的切向拉应变

Fig.21 Tangential tensile strain of blank workpiece during spinning: (a) Forming stage of non-rib region; (b) Forming of round corner in inner rib region; (c) Stage after forming of round corner in inner rib region; (d) Localized over-thinning

图22 半锥角较大的锥形预成形坯料成形过程示意图

Fig.22 Schematic illustration of spinning process of performed blank with large semi-cone angle: (a) Before flange bending; (b) After flange bending

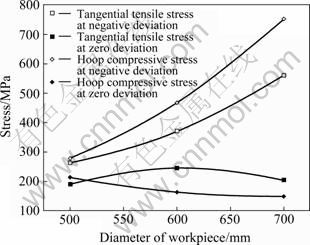

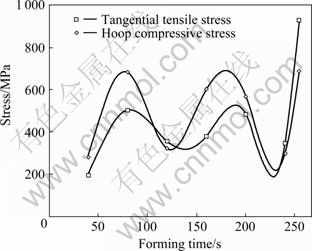

图23 毛坯直径对应力的影响

Fig.23 Effect of workpiece diameters on stress

图24 周向压应力和切向拉应力最大值的变化

Fig.24 Variation of maximum hoop compressive stress and tangential tensile stress

5 带横向内筋大型复杂薄壁壳体多道次复合旋压过程优化

在带横向内筋大型复杂薄壁壳体旋压成形过程中,内筋成形阶段和非筋成形阶段的变形方式有很大不同,其成形机理较传统的普旋和强旋成形过程复杂得多。且该成形过程对工艺参数非常敏感,其合理的工艺参数范围很窄。如果不能合理地匹配工艺参数,就容易导致工件产生缺陷。因此,研究工艺参数对带横向内筋大型复杂薄壁壳体多道次复合旋压成形过程的影响规律并确定合理工艺参数的选择准则是一项挑战性很高的工作。

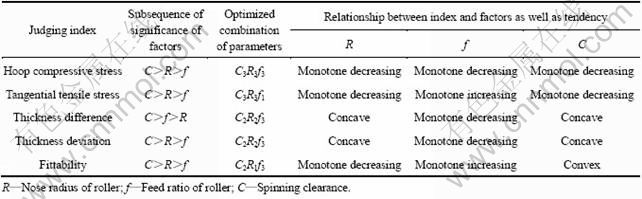

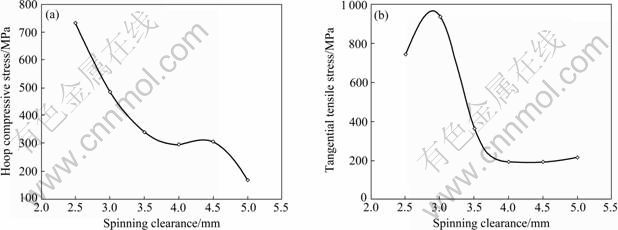

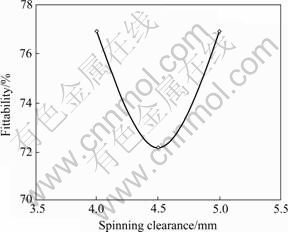

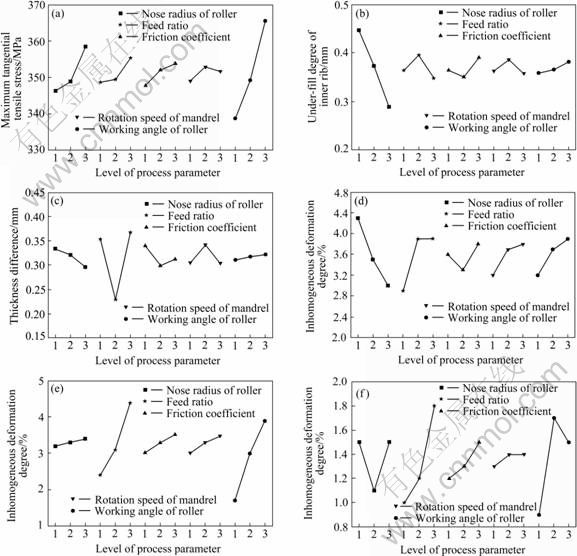

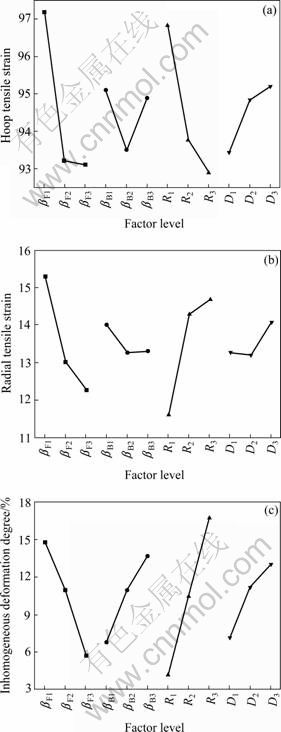

为此,采用数值模拟仿真为主并结合理论分析和实验,研究了对大型复杂薄壁壳体复合旋压成形质量和成形精度具有显著影响的因素及其影响规律,优化确定了旋压道次、旋压方式、道次内变形量的分配、旋轮运动方式以及各道次芯模转速、旋轮进给比、偏离率等工艺参数,表1所列为工艺参数对剪切旋压预成形锥形工件的正交实验优化结果[19, 22]。图25~27所示为不同旋压间隙下由单锥形件旋压成形双锥形件的周向压应力、切向拉应力、壁厚和贴模度[20, 22]。图28所示为工艺参数(旋轮圆角半径R、旋轮进给比f、旋轮与坯料之间的摩擦因数μ、旋轮安装角β和芯模转速n,其取值见表2)对双锥形件旋压成形带横向内筋构件的正交实验优化结果[23, 33]。

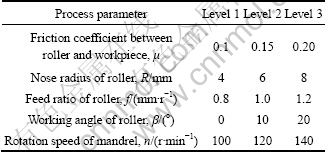

研究了工艺参数对带内筋特征旋压件不均匀变形程度和表面质量的影响,结果如图29和30所示[17]。由图29和30可知,随着旋轮和芯模间隙的增加,工件的不均匀变形程度先减小后增大。随着旋轮进给比的增加,工件的不均匀变形程度逐渐减小,芯模转速对工件的不均匀变形程度基本没有影响;随着旋轮与芯模间隙的增加或者旋轮进给比的减小,工件表面的粗糙度减小。芯模转速对工件的表面质量影响不大。

表1 确定合理工艺参数的分析表

Table 1 Analytical table for proper parameters

图25 不同旋压间隙下的周向压应力和切向拉应力

Fig.25 Hoop compressive stress(a) and tangential tensile stress(b) at different spinning clearances

图26 不同旋压间隙下的壁厚

Fig.26 Thickness at different spinning clearances

图27 不同旋压间隙下的贴模度

Fig.27 Fittability at different spinning clearances

图28 工艺参数对由双锥形件旋压成形带横向内筋构件成形质量的影响

Fig.28 Effect of process parameters on forming quality of workpiece with inner ribs: (a) Maximum tangential tensile stress; (b) Under-filled degree of inner rib; (c) Thickness difference in non-rib region; (d) Inhomogeneous deformation degree in large tapered angle; (e) Inhomogeneous deformation degree in small tapered angle; (f) Inhomogeneous deformation degree in inner rib region

表2 模拟过程中的各参数水平取值

Table 2 Values of parameters during simulation process

图29 工艺参数对工件不均匀变形程度的影响

Fig.29 Effect of process parameters on inhomogeneous deformation degree: (a) f=1.0 mm/r, n=100 r/min; (b) f=2.0 mm/r, n=100 r/min; (c) C=2.0 mm, f=1.0 mm/r

图30 工艺参数对工件表面粗糙度的影响

Fig.30 Effect of process parameters on surface roughness of workpiece: (a) f=1.0 mm/r, n=100 r/min; (b) C=2.0 mm, n=100 r/min; (c) C=2.0 mm, f=1.0 mm/r

根据工艺参数对工件内筋成形质量、不均匀变形程度和表面质量的影响规律,确定了带横向内筋特征结构强旋成形过程合理工艺参数的选择准则[17]:旋轮与芯模间隙C的值在Cmin<C<t0-ts-Dg(Cmin为饱满内筋变形行为与不稳定变形行为的临界值,ts为成形过程中材料和设备的回弹值,Dg 为芯模凹槽深度)范围内越大越好;在能够获得良好表面质量的前提下,旋轮进给比f越大越好;在带横向内筋特征结构强旋成形过程中,芯模转速n对成形过程的影响很小,一般尽量取较大值以提高成形效率。

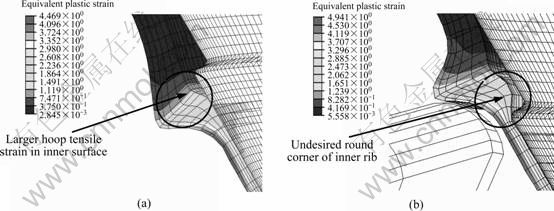

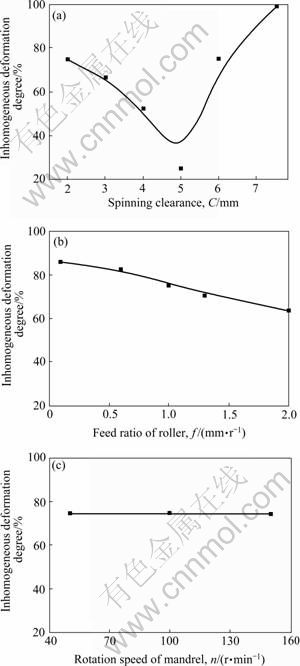

6 带横向内筋大型复杂薄壁壳体多道次复合旋压芯模与旋轮的优化

带横向内筋大型复杂薄壁壳体多道次复合旋压及特征结构旋压成形过程涉及带横向内筋构件难以从整体芯模上脱模的难题。且旋轮参数对变形区的应力应变状态和金属流动仍有一定的影响,进而影响工件的成形质量。如果旋轮的形状和尺寸参数选择不合理,则很可能会降低该过程的成形极限,甚至导致内筋充填不够饱满、工件壁部拉裂和内部裂纹等成形缺陷的产生。因而,很有必要设计合理的分瓣组合芯模,并研究旋轮结构参数对成形过程的影响[17, 41-43]。

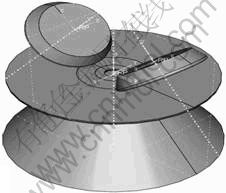

因此,为了保证带横向内筋大型复杂曲母线薄壁构件旋压成形后能顺利脱模,提出了一种针对带横向内筋大型复杂曲母线薄壁构件旋压成形的芯模[41],如图31所示。推导计算得到了脱模过程中夹块与工件和芯模各部件不干涉的条件。在此基础上,采用横、纵组合的分瓣技术设计芯模,确定了夹板及芯模头部的脱模顺序与方法,以保证带横向内筋大型复杂曲母线薄壁构件旋压成形后可顺利脱模。所提出的芯模分瓣后易于机械加工,制造成本低,且易于装配。

图31 带横向内筋大型复杂薄壁壳体旋压芯模的结构示意图

Fig.31 Structural diagram of mandrel for spinning of large-sized complicated workpiece with inner ribs

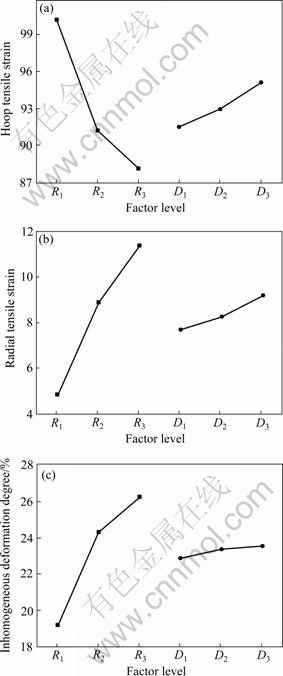

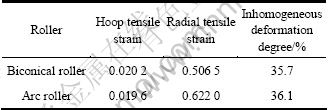

采用实验和数值模拟相结合的方法,开展大型复杂薄壁壳体复合旋压旋轮优化研究。研究了双锥面旋轮和圆弧旋轮对内筋成形质量、壁部拉裂趋势、不均匀变形程度的影响规律(见图32和33),确定了双锥面和圆弧旋轮的最佳旋轮参数,发现旋轮圆角半径(R)和成形角(βF)对该过程影响最显著,旋轮直径(D)和退出角(βB)对该过程的影响较小,并且在带横向内筋锥形件强旋成形过程中,圆弧旋轮能使工件获得最佳的内筋成形性能,但双锥面旋轮有利于降低工件的壁部拉裂趋势和不均匀变形程度,如表3所列[17, 42]。

图32 双锥面旋轮不同质量指标对因素水平的平均响应

Fig.32 Average response of different quality indexes with biconical roller to factor levels: (a) Hoop tensile strain; (b) Radial tensile strain; (c) Inhomogeneous deformation degree

图33 圆弧旋轮不同质量指标对因素水平的平均响应

Fig.33 Average response of different quality indexes with arc roller to factor levels: (a) Hoop tensile strain; (b) Radial tensile strain; (c) Inhomogeneous deformation degree

表3 双锥面旋轮和圆弧旋轮比较[17, 42]

Table 3 Comparison between biconical roller and arc roller[17, 42]

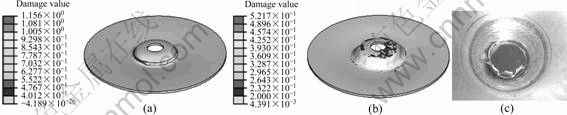

7 带横向内筋大型复杂薄壁壳体多道次复合旋压试验验证

为了验证上述研究结果的适用性和可靠性,选取某无人机用设备舱头罩作为大型复杂薄壁壳体的代表,进行缩比件物理模拟和实际件的多道次复合旋压试验,获得了满足质量要求的旋压件,如图34所 示[17, 22-25]。由此证明,在建立带内筋大型复杂薄壁壳体复合旋压全过程仿真平台与模型的基础上,研究获得的不均匀塑性变形行为以及毛坯、过程和模具优化结果是可靠的。

图34 旋压样件

Fig.34 Spun workpieces

8 结束语

高性能、轻量化构件是航空航天等高技术产业永恒的追求和发展目标。构件的大型化、复杂化、整体化、薄壁化和构件成形过程的精确化、短流程、低成本是实现该目标的主要途径。然而,这却导致此类构件成为难成形结构,而其成形过程是多因素耦合作用下的复杂成形过程。带筋大型复杂薄壁壳体复合旋压就是其中的典型代表。本文作者综述了采用数值模拟和实验相结合的方法,在带横向内筋大型复杂薄壁壳体复合旋压全过程仿真平台研发与有限元建模,不均匀塑性变形行为和成形缺陷的关联关系,毛坯、工艺和模具参数影响规律与优化研究方面的研究进展。对发展大型复杂薄壁壳体多道次复合旋压精确成形技术,全面提高我国大型复杂薄壁壳体的高质量、低成本、短周期制造技术水平和能力具有重大战略意义和十分迫切的现实意义。

REFERENCES

[1] 王振杰, 马世成, 杨 俊, 王东坡. 带内加强筋曲母线零件旋压成形技术[J]. 航天制造技术, 2006(6): 42-43.

WANG Zhen-jie, MA Shi-cheng, YANG Jun, WANG Dong-po. Spinning technology for curvilinear shape workpiece with inner ribs[J]. Astronavigation Manufacturing Technology, 2006(6): 42-43.

[2] 张 涛, 刘智冲, 马世成. 旋压成形带内筋筒形件的工艺研究及数值模拟[J]. 机械工程学报, 2007, 43(4): 109-112, 118.

ZHANG Tao, LIU Zhi-chong, MA Shi-cheng. Technologic research and numerical analysis of spinning of cylinders with inner ribs[J]. Chinese Journal of Mechanical Engineering, 2007, 43(4): 109-112, 118.

[3] 张利鹏, 刘智冲. 带内筋铝合金筒形件强力旋压成形工艺研究[J]. 塑性工程学报, 2007, 14(6): 109-113.

ZHANG Li-peng, LIU Zhi-chong. Research on power spinning forming process of aluminum alloy cylinders with inner ribs[J]. Journal of Plasticity Engineering, 2007, 14(6): 109-113.

[4] 马世成, 唐志红, 王东坡, 王振杰, 孙 昂, 刘 苗. 带纵向内加强筋零件旋压成形数值模拟分析[J]. 塑性工程学报, 2005, 12(S): 172-174.

MA Shi-cheng, TANG Zhi-hong, WANG Dong-po, WANG Zhen-jie, SUN Ang, LIU Miao. Simulation analysis of forming process of parts with lengthways inner flange[J]. Journal of Plasticity Engineering, 2005, 12(S): 172-174.

[5] JIANG Shu-yong, ZHENG Yu-feng, REN Zheng-yi, LI Chun-feng. Multi-pass spinning of thin-walled tubular part with longitudinal inner ribs[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(1): 215-221.

[6] 薛克敏, 江树勇, 康达昌. 带纵向内筋薄壁筒形件强旋成形[J]. 材料科学与工艺, 2002, 10(3): 287-290.

XUE Ke-min, JIANG Shu-yong, KANG Da-chang. Power spinning deformation of thin-walled cylinders with longitudinal inner ribs[J]. Materials Science and Technology, 2002, 10(3): 287-290.

[7] 江树勇, 顾向东, 李春峰, 张 军. 纵向内筋薄壁筒反向滚珠旋压成形机理研究[J]. 锻压技术, 2008, 33(5): 88-91.

JIANG Shu-yong, GU Xiang-dong, LI Chun-feng, ZHANG Jun. Study of deformation mechanism of backward ball spinning of thin-walled tube with longitudinal inner ribs[J]. Forging & Stamping Technology, 2008, 33(5): 88-91.

[8] 夏琴香, 杨明辉, 胡 昱, 程秀全. 杯形薄壁矩形内齿旋压成形数值模拟与试验[J]. 机械工程学报, 2006, 42(12): 192-196.

XIA Qin-xiang, YANG Ming-hui, HU Yu, CHENG Xiu-quan. Numerical simulation and experimentation cup-shaped thin-walled inner rectangular gear formed by spinning[J]. Chinese Journal of Mechanical Engineering, 2006, 42(12): 192-196.

[9] WONG C C, DANNO A, TONG K K, TSUYOSHI M, LIM K B, YONG M S. A study into cold rotary forming of precision metal components[J]. SIMTech Technical Reports, 2007, 8(2): 65-70.

[10] 李亚非, 陈 辉. 薄壁铝合金锥形件旋压过程的缺陷分析[J]. 锻压技术, 2008, 33(1): 56-59.

LI Ya-fei, CHEN Hui. Defect analysis of spinning aluminum alloy taper parts with thin wall[J]. Forging and Stamping Technology, 2008, 33(1): 56-59.

[11] 李亚非, 陈 辉, 徐新泰, 杜新亮. 曲面薄壁异形件旋压成形工艺研究[J]. 锻压技术, 2005(5): 58-60.

LI Ya-fei, CHEN Hui, XU Xin-tai, DU Xin-liang. Spinning process research on the circumgyration sheet metal of thin wall[J]. Forging and Stamping Technology, 2005(5): 58-60.

[12] 李亚非, 陈 辉. 一种曲面薄壁异形件可旋性试验研究[J]. 现代制造工程, 2005(6): 55-57.

LI Ya-fei, CHEN Hui. Feasibility research of spinning on circumgyrate sheet abnormity metal[J]. Modern Manufacturing Engineering, 2005(6): 55-57.

[13] DAVIDSON M J, BALASUBRAMANIAN K, TAGORE G R N. An experimental study on the quality of flow-formed AA6061 tubes[J]. Journal of Materials Processing Technology, 2008, 203: 321-325.

[14] 宋玉泉. 连续局部塑性成形的发展前景[J]. 中国机械工程, 2000, 11(1/2): 65-67.

SONG Yu-quan. The prospect of successive partial plastic forming[J]. China Mechanical Engineering, 2000, 11(1/2): 65-67.

[15] 詹 梅, 李 虎, 杨 合, 陈 岗. 大型复杂薄壁壳体多道次旋压过程中的壁厚变化[J]. 塑性工程学报, 2008, 15(2): 115-121.

ZHAN Mei, LI Hu, YANG He, CHEN Gang. Wall thickness variation during multi-pass spinning of large complicated shell[J]. Journal of Plasticity Engineering, 2008, 15(2): 115-121.

[16] ZHAN Mei, YANG He, ZHANG Jin-hui. Establishment of 3D FEM model of multi-pass spinning[J]. Chinese Journal of Mechanical Engineering, 2007, 20(4): 19-23.

[17] 马 飞. 复杂锥形件强旋成形过程关键问题研究[D]. 西安: 西北工业大学, 2009: 75-79.

MA Fei. Research on the key problems for power spinning process of complex conical parts with transverse inner rib[D]. Xi’an: Northwestern Polytechnical University, 2009: 75-79.

[18] 蒋华兵, 詹 梅, 杨 合. 基于ABAQUS的数控弯管专用前处理模块开发[J]. 航空工程进展, 2010, 1(2): 184-189.

JIANG Hua-bing, ZHAN Mei, YANG He. Development of pre-process module of NC tube bending based on ABAQUS software using python[J]. Advances in Aeronautical Science and Engineering, 2010, 1(2): 184-189.

[19] 吴统超, 詹 梅, 古创国, 蒋华兵, 杨 合. 大型复杂薄壁壳体多道次旋压第一道次成形质量分析[J]. 材料科学与工艺, 2011, 19(1): 121-126.

WU Tong-chao, ZHAN Mei, GU Chuang-guo, JIANG Hua-bing, YANG He. Forming quality of the first pass spinning of large-sized complicated thin-walled shell[J]. Materials Science and Technology, 2011, 19(1): 121-126.

[20] 吴统超, 詹 梅, 蒋华兵, 古创国, 杨 合. 旋压间隙对大型复杂薄壁壳体多道次旋压中第二道次成形质量的影响[J]. 西北工业大学学报: 自然科学版, 2011, 29(1): 74-81.

WU Tong-chao, ZHAN Mei, JIANG Hua-bing, GU Chuang-guo, YANG He. Exploring effects of spinning gap on forming quality of second pass spinning of large-sized complicated thin-walled shell[J]. Journal of Northwestern Polytechnical University: Natural Science, 2011, 29(1): 74-81.

[21] 马明娟. 大型复杂薄壁壳体多道次旋压成形机理及规律的三维有限元分析[D]. 西安: 西北工业大学, 2007: 33.

MAMing-juan. 3D FE analysis on deformation mechanism and laws of multi-pass spinning of large complex thin-walled shell[D]. Xi’an: Northwestern Polytechnical University, 2007: 33.

[22] 吴统超. 铝合金大型复杂薄壁壳体旋压预成形有限元分析及试验研究[D]. 西安: 西北工业大学, 2010: 39, 84-89.

WU Tong-chao. FE analysis and experimental study on spin performing of large-sized complicated thin-walled aluminum alloy shell[D]. Xi’an: Northwestern Polytechnical University, 2010: 39, 84-89.

[23] 古创国. 带横向内筋曲母线薄壁壳体旋压成形不均匀变形研究[D]. 西安: 西北工业大学, 2010: 34, 38, 54-62.

GU Chuang-guo. Research on inhomogeneous deformation during spinning of curvilinear generatrix thin-walled shell with transverse inner rib[D]. Xi’an: Northwestern Polytechnical University, 2010: 34, 38, 54-62.

[24] 蒋华兵. 铝合金大型复杂薄壁壳体旋压成形关键技术研究[D]. 西安: 西北工业大学, 2011: 40, 68-69.

JIANG Hua-bing. Research on key technical problems of large complex thin-walled aluminum alloy shell spinning[D]. Xi’an: Northwestern Polytechnical University, 2011: 40, 68-69.

[25] 陈 飞. 带横向内筋铝合金构件充筋机理与规律研究[D]. 西安: 西北工业大学, 2011: 37.

CHEN Fei. Research on forming mechanism and law of rib during spinning of parts with transverse inner rib[D]. Xi’an: Northwestern Polytechnical University, 2011: 37.

[26] BAI Qian, YANG He, ZHAN Mei. Finite element modeling of power spinning of thin-walled shell with hoop inner rib[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(1): 6-13.

[27] BAI Q, YANG H, ZHAN M. Specific techniques in FE process modeling for spin-forming of a thin walled shell part with an inner hoop rib[J]. Steel Research International, 2008(1): 609-615.

[28] 周 强. 突变壁厚锥形件强力旋压成形有限元模拟与试验研究[D]. 西安: 西北工业大学, 2007: 38.

ZHOU Qiang. Research on the power spinning of cone parts with discontinuous wall thickness using 3D FEM and experimental investigation[D]. Xi’an: Northwestern Poly- technical University, 2007: 38.

[29] 吴 卷, 詹 梅, 蒋华兵, 陈 飞, 杨 合. 一种改进的Lemaitre韧性断裂准则及其在旋压成形中的应用[J]. 航空学报, 2011, 32(7): 1309-1317.

WU Juan, ZHAN Mei, JIANG Hua-bing, CHEN Fei, YANG He. A modified Lemaitre crack criterion and its application in spinning[J]. Journal of Aviation, 2011, 32(7): 1309-1317.

[30] 吴 卷. 铝合金锥形件复合旋压破裂成形极限研究[D]. 西安: 西北工业大学, 2011: 29-38, 58-66.

WU Juan. The study on crack and forming limit of complex cone spinning based on damage theory[D]. Xi’an: Northwestern Polytechnical University, 2011: 29-38, 58-66.

[31] 胡莉巾. 基于损伤理论的分形旋压开裂预测与成形极限分析[D]. 西安: 西北工业大学材料学院, 2009: 42-49.

HU Li-jin. Prediction of radial crack and analysis of forming limit during splitting spinning[D]. Xi’an: Northwestern Polytechnical University, 2009: 42-49.

[32] ZHAN Mei, GU Chuang-guo, JIANG Zhi-qiang, HU Li-jin, YANG He. Application of ductile fracture criteria in spin- forming and tube-bending processes[J]. Computational Materials Science, 2009, 47(2): 353-365.

[33] 陈 飞, 詹 梅, 古创国, 杨 合. 工艺参数对带横向内筋薄壁复杂构件旋压不均匀变形的影响[J]. 材料科学与工艺, 2010, 18(S1): 29-33.

CHEN Fei, ZHAN Mei, GU Chuang-guo, YANG He. Effects of process parameters on the inhomgeneous deformation of thin-walled complicated workpiece with inner ribs[J]. Materials Science and Technology, 2010, 18(S1): 29-33.

[34] 徐银丽, 詹 梅, 杨 合, 张晋辉, 马 飞. 锥形件变薄旋压回弹的三维有限元分析[J]. 材料科学与工艺, 2008, 16(2): 167-171.

XU Yin-li, ZHAN Mei, YANG He, ZHANG Jin-hui, MA Fei. Springback law analysis of cone spinning using 3D FEM[J]. Materials Science & Technology, 2008, 16(2): 167-171.

[35] 陈 岗, 詹 梅, 杨 合, 李 虎, 黄 亮. 基于正交优化的异型薄壁壳体强力旋压成形有限元分析[J]. 塑性工程学报, 2008, 15(4): 67-71.

CHEN Gang, ZHAN Mei, YAND He, LI Hu, HUANG Liang. FEA of power spinning of complicated thin-walled shell based on orthogonal optimization[J]. Journal of Plasticity Engineering, 2008, 15(4): 67-71.

[36] ZHAN Mei, YANG He, JIANG Zhi-qiang, ZHANG Jin-hui. 3D FEM analysis of forming parameters on cone spinning based on orthogonal experimental design method[C]//Proceedings of the 9th International Conference on Technology of Plasticity. Gyeongju: Korean Society for Technology of Plasticity, 2008: 197.

[37] MA Fei, YANG He, ZHAN Mei. Plastic deformation behaviors and their application in power spinning process of conical parts with transverse inner rib[J]. Journal of Materials Processing Technology, 2010, 210(1): 180-189.

[38] MA Fei, YANG He, ZHAN Mei. Research on the metal flow in power spinning process of parts with transverse inner rib[C]//Proceedings of the 8th International Conference on Frontiers of Design and Manufacturing. Tianjin, 2008: 453-459.

[39] MA Fei, YANG He, ZHAN Mei. Research on the blank selection in the power spinning process of parts with transverse inner rib[J]. Materials Science Forum, 2007, 561/565: 885-888.

[40] 詹 梅, 吴统超, 陈 岗, 杨 合. 铝合金异型薄壁壳体强旋成形的毛坯形状尺寸与工艺参数研究[C]//第九届全国冲压学术年会论文集. 长沙, 2008: 223-229.

ZHAN Mei, WU Tong-chao, CHEN Gang, YANG He. Research on the workpiece shape and size and process parameters for shear spinning of aluminum alloy type thin-walled shell[C]// Proceedings of the 9th National Annual Conference on Stamping. Changsha, 2008: 223-229.

[41] 詹 梅, 杨 合, 马 飞, 周 强, 韩 冬. 一种带横向内筋构件旋压成形芯模: 中国, ZL 200810017454.4[P]. 2011-02-23.

ZHAN Mei, YANG He, MA Fei, ZHOU Qiang, HAN Dong. Mandrel for the spinning of workpieces with inner ribs: China, ZL 200810017454.4[P]. 2011-02-23.

[42] 马 飞, 杨 合, 詹 梅, 胡莉巾. 带横向内筋锥形件强旋成形过程旋轮优化设计[J]. 机械科学与技术, 2009, 28(12): 1580-1583.

MA Fei, YANG He, ZHAN Mei, HU Li-jin. Optimum design of a forming roller for power spinning process of conical parts with transverse inner ribs[J]. Mechanical Science and Technology, 2009, 28(12): 1580-1583.

[43] 詹 梅, 马明娟, 杨 合, 徐银丽. 旋轮参数对异型薄壁壳体强力旋压成形的影响[J]. 锻压技术, 2006(5): 144-147.

ZHAN Mei, MA Ming-juan, YANG He, XU Yin-li. Influence of roller parameters on power spinning of thin-walled shell with special shape[J]. Forging and Stamping Technology, 2006(5): 144-147.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2008AA04Z122);国家自然科学基金资助项目(50405039);高等学校学科创新引智计划资助项目(B08040)

收稿日期:2011-05-18;修订日期:2011-07-16

通信作者:杨 合,教授,博士;电话:029-88495632;E-mail: yanghe@nwpu.edu.cn

杨合教授简介

杨合,长江学者,国家杰出青年基金获得者,国家基金委学科评审专家组专家,国家“973”复评和终评专家组专家,国家基金委“十二五”规划“高性能精确成形制造”领域负责人、国家“973”制造领域“十二五”规划“高性能构件跨尺度制造与航空航天运载装备”方向负责人、中国机械工程学科发展报告(2010—2011成形制造)综合报告负责人,中德“材料成形”研讨会主席,中国塑性工程学会副理事长,4个国家重点实验室学术委员会副主任或委员。在高性能轻量化整体构件局部加载精确塑性成形及全过程多尺度建模仿真与优化方面取得重要进展,发表论文400多篇,在塑性成形领域Top1 期刊IJP发表论文3篇,获国家发明奖、国家及省部级科技进步奖9项,获国家发明专利9项,获ICTP六佳论文奖,JMPT十佳审稿人。