文章编号:1004-0609(2014)04-0878-10

汽车用6xxx系铝合金薄壁件的韧性断裂行为

叶 拓1,王 冠1,姚再起2,李落星1

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 杭州吉利汽车研究院有限公司 NVH及材料工程部,杭州 311228)

摘 要:针对汽车用6xxx铝合金薄壁件,采用准静态拉伸实验获得材料的真实应力—应变曲线,通过线性回归拟合的方法得到6061和6063材料的Johnson-Cook本构参数A、B、n值分别为90 MPa、422.58 MPa、0.5234和60 MPa、323.57 MPa、0.428。为了准确地预测铝合金变形过程中的开裂行为,将Crockroft-Latham韧性断裂准则引入到数值模拟中,计算出6061和6063铝合金材料的韧性断裂常数分别为334.09 MPa和309.79 MPa。对铝合金缺口试样拉伸实验和汽车铝合金薄壁件压缩实验进行数值模拟和实验验证,发现试样的力和位移曲线以及断裂位置与仿真预测结果吻合度较高,该方法能够方便、准确地预测两种铝合金材料薄壁件的开裂行为。在实际的工程应用中,该方法成为判断材料的断裂失效的一种有效的方法。

关键词:铝合金;薄壁件;韧性断裂;数值模拟

中图分类号:TG146.21 文献标志码:A

Ductile fracture behavior of 6xxx aluminum alloy thin-walled components of automobile

YE Tuo1, WANG Guan1, YAO Zai-qi2, LI Luo-xing1

(1. State Key Laboratory Design and Manufacture for Vehicle Body, Hunan University, Changsha 410082, China;

2. NVH and Material Engineering Department, Hangzhou Geely Automobile Research Institute Co.Ltd.,

Hangzhou 311228, China)

Abstract: The true stress—strain curve of automobile 6xxx aluminum alloy thin-walled components was obtained by tensile tests. Johnson-Cook constitution parameters of aluminum alloys 6061 and 6063 were analyzed by means of linear regression analysis method, the values of A, B, n of each alloy are 90 MPa, 422.58 MPa, 0.5234 and 60 MPa, 323.57 MPa, 0.428, respectively. In order to estimate the fracture behavior of aluminum alloy during the deformation, Crockroft- Latham ductile damage criterion was incorporated into the numerical simulation. The calculated ductile fracture parameters of 6061 and 6063 aluminum alloys are 334.09 MPa and 309.79 MPa. Simulation approach was employed to predict the fracture of notched sample tensile tests and compression tests of thin-walled aluminum components. The numerical results, such as load-displacement curves and fracture position, are in good agreement with experimental measurements. This method, which provides a valid way to forecast the fracture of material in engineering application, can be used to predict fracture behavior of thin-walled aluminum alloy with satisfactory convenience and accuracy.

Key words: aluminum alloy; thin-walled component; ductile fracture; numerical simulation

铝合金因其密度小、塑性和比强度较高已成为汽车制造业的重要轻质材料[1]。与传统钢材相比,铝合金具有较低的屈服极限和抗拉强度,且伸长率也低于传统钢材,因此,铝合金件在汽车发生碰撞时,有更大的开裂倾向。断裂失效是针对汽车零部件在进行工艺生产和安全评价过程中的重要指标和依据。因此,研究铝合金的失效行为,对预测铝合金件在碰撞过程中的开裂变形极为重要。

工程材料的宏观断裂机制主要分为脆性断裂和韧性断裂。铝合金材料属于典型的韧性断裂。采用性能优异的铝合金薄壁吸能结构是提高汽车耐撞性的重要途径[2]。在变形过程中,一般将铝合金薄壁结构的受力简化为平面应力状态,在面内拉应力的作用下,材料依次经历均匀变形、分散性失稳变形和集中性失稳变形后发生失效[3-4]。

关于薄壁结构的失效问题,最早且目前仍在广泛应用的是以连续介质力学为基础建立的拉伸失稳理论。SUNG等[5]提出的分散性与集中性失稳理论,具有重要的里程碑意义。在他们工作的基础上,众多学者提出了新的失效准则,例如SING等理论[6]、STOREN理论[7]、M-K理论[8]、C-H失稳模型[9]、RAMAEKERS理论[10]和eMMFC理论[11]等。

在汽车设计领域,通常将材料的极限塑性应变作为材料的失效准则,该方法虽然参数求解简单,但是精度较低,尤其在考虑应变速率对材料性能的影响时,会出现较大的误差。另一种广泛运用的失稳准则是成形极限图(Forming limit diagram, FLD)[12],但FLD应用于薄壁结构变形具有很多的局限性,对于试样的非平面变形区域以及非线性应变加载等情况,FLD准则均不适用,此外,获得材料FLD参数的实验也相对复杂。因此,采用FLD作为铝合金薄壁结构的失效准则会严重影响材料变形性能评估的准确性,极大地限制了汽车用铝合金部件的工艺设计。因此,迫切需要找到一种简单准确的方法来评判铝合金薄壁结构在变形过程中的失效行为,以指导汽车车身结构的设计。

现有的韧性断裂准则在实际工程中多是针对某一具体工艺,不同的加工工艺和变形路径可能需要选择不同的断裂准则,同时还需要进行大量的工艺实验与成形工艺参数反复对比研究,最后才能确定出比较合适的韧性断裂准则。本文作者提出一种将简单拉伸实验和数值模拟相结合的方法,即通过实验获得材料的本构参数和韧性断裂应变能,然后将获得的材料参数代入到铝合金缺口拉伸件和汽车铝合金薄壁结构的压缩仿真模型中,最后通过仿真对成形极限进行预测。通过实验验证预测结果的准确性,从而验证了该方法的适用性。

1 实验

本文作者采用半连续铸造加工方法,获得6061和6063铝合金圆柱形铝锭,表1所列为两种铝合金各元素质量分数实测值。

在XJ-2500挤压机上经在线淬火,所有样品进行180 ℃、30 min的人工时效,得到铝合金多胞薄壁型材。该型材用于汽车保险杠吸能盒装置,在碰撞过程中,通过吸能盒的压缩变形达到吸能缓冲作用。由图1可知,型材试样由内外两个八边形组成,内外层八边形沿轴心成22.5°,内层八边形棱边通过四条加强 筋与外层八边形平面相连。挤压具体工艺参数如表2所列。

表1 铝合金主要化学成

Table 1 Chemical composition of aluminum alloy (mass fraction,%)

图 1 铝合金型材的尺寸与几何形状

Fig. 1 Dimensions and geometric shape of aluminum alloy profile (Unit: mm)

表2 铝合金挤压工艺参数

Table 2 Extrusion process parameter of aluminum alloy

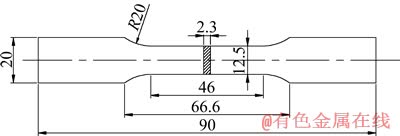

采用DK7716D型电火花数控线切割沿铝合金多胞薄壁型材的挤压方向截取准静态拉伸试样,取样位置为多胞薄壁型材外八边形中无加强筋的4个面,拉伸试样尺寸参考GB/T 228—2002《金属拉伸实验方法》的规定,试样尺寸如图2所示。通过DK7716D型电火花数控线切割机床加工成型。室温准静态拉伸实验在WDW-E200型微机控制电子万能实验机进行,为排除应变速率和温度对损伤断裂的影响,拉伸速度采用2 mm/min,加载至试样断裂为止。拉伸实验数据均取3组稳定实验的平均值。

图2 准静态拉伸试样尺寸图

Fig. 2 Dimensions of quasi-static tensile specimen (Unit: mm)

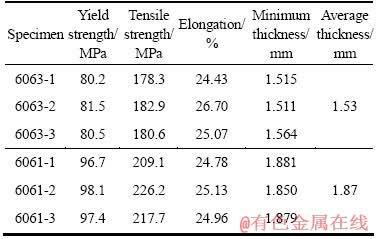

由图3所示两种合金型材拉伸应力—应变曲线可知,6061铝合金的力学性能高于6063铝合金的,但两种材料的伸长率相近。试样发生断裂失效前出现明显的塑性变形,当应力超过抗拉强度极限时,试样局部开始发生缩颈,颈缩区域厚度不断减薄,并最终发生断裂。图4所示为拉伸断裂后的铝合金试样。由图4可知,试样的断裂面与拉伸轴方向约成45°角。拉伸变形后6061铝合金试样的表面较粗糙,呈现橘皮形貌,而6063铝合金表面光滑,与变形前相比无明显变化。使用低倍光学显微镜测量6063和6061铝合金试样在断后的刃口厚度(如表3所列),放大倍数为50倍。

图3 铝合金型材的拉伸应力—应变曲线

Fig. 3 Strain—stress curves of aluminum alloy profile

图4 拉伸断裂后的铝合金试样

Fig. 4 Failed aluminum alloy quasi-static tensile specimen

表3 6063与6061合金力学性能的对比

Table 3 Comparison of mechanical properties between 6063 and 6061 aluminum alloy

2 材料的本构模型

在汽车结构设计中,为考虑材料的加工硬化、应变速率硬化以及温升软化效应的影响,材料的本构模型常采用Johnson-Cook模型[13-14]。该模型建立于传统无序金属材料的力学性能基础之上,是针对金属材料在大变形、高应变速率的流变行为提出的一种经验模型。模型参数求解方便、精度高,因此,被广泛应用于汽车车身安全结构的设计中。本文作者主要研究的薄壁件结构通常作为汽车结构安全件。因此,采用Johnson-Cook模型以保证材料本构模型的精度和可靠性。该模型可用下式表达:

(1)

(1)

式中:A、B、n和C为常温变形条件下的材料参数,其中A为材料的屈服极限,B和n为材料应变硬化模量和硬化指数; 和

和 分别为等效塑性应变和应变率;C为材料应变速率强化参数;T*、m是与温度相关的变量,其中T*为同系温度,m为材料热软化指数。

分别为等效塑性应变和应变率;C为材料应变速率强化参数;T*、m是与温度相关的变量,其中T*为同系温度,m为材料热软化指数。

由于本研究主要针对准静态变形,且实验在常温下进行,忽略应变速率以及变形温升对材料性能的影响。因此,只需要求解模型的静力学部分。

(2)

(2)

对式(2)两边求自然对数可得

(3)

(3)

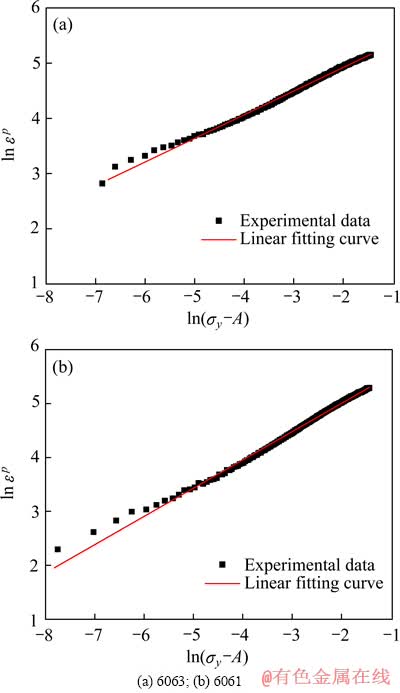

根据式(3)绘制 与

与 的关系曲线,如图5所示。通过线性拟合求解公式中的参数A、B和n,其中ln B为线性拟合函数曲线与纵坐标的截距,n为线性拟合函数曲线的斜率,各本构参数如表4所列。

的关系曲线,如图5所示。通过线性拟合求解公式中的参数A、B和n,其中ln B为线性拟合函数曲线与纵坐标的截距,n为线性拟合函数曲线的斜率,各本构参数如表4所列。

图5 铝合金材料的本构模型参数曲线拟合

Fig. 5 Linear fitting curves of constitutive parameters of aluminum alloy material

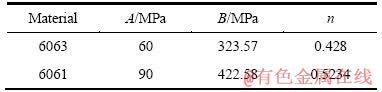

表4 铝合金材料的本构模型参数

Table 4 Constitutive parameters of aluminum alloy material

通过回归相关性分析可知,线性回归相关系数大于0.98,说明拟合得到的结果与实验数据具有非常好的一致性,参数精度较高。同时也说明,铝合金在准静态变形条件下的力学性能能够通过式(2)准确地描述,如图6所示。

图6 拟合曲线与实验结果对比

Fig. 6 Comparison of results between no-linear fitting curve and experimental date

3 韧性断裂准则与数值仿真

3.1 韧性断裂准则

与拉伸失稳理论相比,韧性断裂准则能够应用于非线性加载历史,非常适合处理复杂应力状态下材料的断裂失效问题。同时,由于模型简单,参数求解方便,被广泛应用于板材成型、金属加工等的数值仿真分析中。通常,韧性断裂准则中的损伤累积量D可以通过等效塑性应变、变形能、第一主应力和等效应力等描述。

Crockroft-Latham断裂准则是应用最为广泛的韧性断裂准则,该准则认为,对于给定的材料,在一定的温度、应变速率下,塑性变形最大拉应力是导致材料破坏的主要因素,体积拉应力功达到某一临界值时材料便发生破坏[15]。该准则计算结果比较理想,材料常数的确定也较为简单,因此,在本文材料变形断裂的预测中选用该准则。该准则认为破裂产生的条件是

(4)

(4)

式中: 为最大主应力,Wc为断裂应变能积分量W的临界值,

为最大主应力,Wc为断裂应变能积分量W的临界值, 为等效塑性应变。

为等效塑性应变。

3.2 单向拉伸数值仿真

3.2.1 几何模型和网格划分

利用三维造型软件UG建立工件的几何模型,尺寸如图7所示。将几何模型导入Hypermesh中进行前处理,采用单元平均尺寸为2 mm的四边形网格。

图7 准静态拉伸有限元模型

Fig. 7 FEM model of quasi-static tensile test

3.2.2 材料模型

采用壳单元16号全积分算法,厚度方向上采用5个积分点以保证求解的精度。对应单元算法沙漏使用8号控制模式,系数为0.1。采用mat107材料模型,该模型能以材料的断裂应变能Wc做为失效判据,并且通过经典的Johnson-Cook本构模型来描述弹塑性材料的力学性能。试件的两夹持端在仿真过程中可简化为不变形物体,所以试件的两端采用mat20刚体材料模型。

3.2.3 加载方式和边界条件

约束两端刚体的转动自由度,只允许在拉伸方向的平动,并通过prescribed motion关键字赋予一端的刚体部分沿拉伸方向以1 mm/s的速度运动,另一端静止。其余边界条件与实际物理实验一致。

3.2.4 模型求解

使用LS-DYNA的隐式计算模块,生成关键字文件,在求解器中提交计算任务,求解标准拉伸试样在准静态拉伸过程中的变形行为。

3.3 有限元计算结果及讨论

单向拉伸仿真过程的目的就是求解Wc值。本文作者采用的方法是仿真模型中不输入Wc值,如图8所示,在拉伸仿真过程中,试样的厚度不断减小,且断口处的厚度值减小最快,试样会被无限拉长,但不会发生断裂。测量拉伸实验中试样断口处厚度的最小值,将其作为有限元模拟中确定临界损伤值的外形尺寸。仿真过程中试件断口处厚度值达到实测值的时刻就是仿真断裂时刻。

图8 试样厚度的分布云图

Fig. 8 Thickness distribution contours of sample

图9所示为实验与数值仿真得到的准静态轴向拉伸载荷—位移曲线。由于没有设置断裂应变能,数值仿真得到的载荷位移曲线没有下降段。但仿真曲线与实验数据具有较好的一致性,说明仿真模型具有较高的精度,能够准确预测材料在单向准静态轴向拉伸过程中的变形行为及载荷变化。

图10所示为拉伸试样在整个变形过程中最小厚度随时间的变化曲线。由图10可知,试样初始厚度都是2.3 mm,在试样变形前期,材料发生均匀变形,厚度变化较小。但随着变形量的增大,试样缩颈区发生大应变,壁厚迅速减薄。6063铝合金试样在变形至20 s时,减薄速度迅速增加,而6061铝合金进入塑性段23 s时,试样的厚度才开始发生急剧减薄。在图10中读出两种材料的样件达到实测的最小厚度值所对应的时刻,6063材料的为22.4 s,6061材料的为23.1 s,该时刻就是发生韧性断裂的时刻。

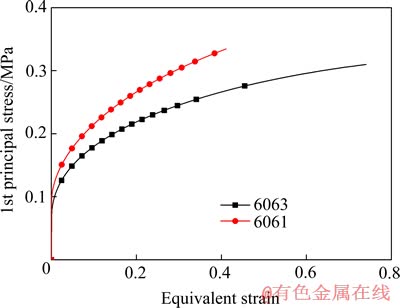

在拉伸数值仿真过程中,模型中每个单元上的应力和应变都是随时间不断变化的,分别导出模型中第一主应力和等效塑性应变的最大值随时间变化的曲线,再以第一主应力为纵坐标,等效应变为横坐标,获得6063铝合金与6061铝合金的等效塑性应变—第一主应力曲线,如图11所示。根据韧性断裂时刻可知,6063和6061材质试样断裂时的等效应变分别为0.41和0.73。对两条应力应变曲线进行积分,求得6063和6061的断裂应变能分别为309.79和334.09 MPa(如表5所列)。

图9 仿真和实验获得的拉伸载荷—位移曲线对比

Fig. 9 Comparison of tensile loading—displacement curves between experiment and simulation results

图10 准静态拉伸仿真分析试样最小厚度变化

Fig. 10 Minimum thickness change curves in numerical quasi-static tensile test

图11 铝合金等效塑性应变—第一主应力线

Fig. 11 Equivalent strain—1st principal stress curves of aluminum alloy

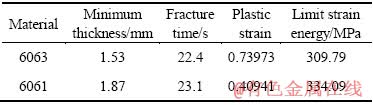

表5 铝合金失效模型的参数

Table 5 Parameters of fracture model in aluminum alloy

4 两种试样断裂失效预测

为研究两种材料的铝合金薄壁件的失效变形行为,结合标准试样准静态拉伸实验及其仿真,获得了两种材料的本构参数和断裂应变能。为了验证结果的准确性和适用性,对缺口拉伸实验和汽车铝合金薄壁件压缩实验分别进行数值仿真,并通过实验对模拟结果进行验证。

4.1 缺口试样拉伸预测

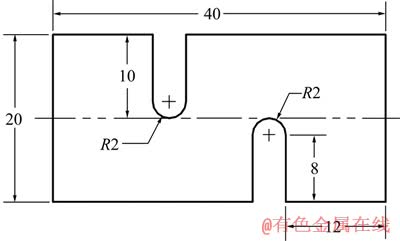

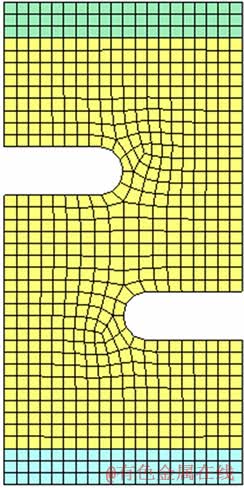

缺口试样准静态拉伸仿真与标准拉伸模拟过程基本相似,使用LS-DYNA的隐式计算模块,求解缺口试样在准静态拉伸过程中的变形行为。试样尺寸如图12所示,对几何模型进行有限元网格划分,单元平均尺寸为1 mm。厚度与试样保持一致为2.3 mm。单元采用16号全积分算法,厚度方向上采用5个积分点以保证求解的精度。选用mat107号材料模型,忽略应变速率和变形温升对材料性能的影响,同时采用Cockcroft-Latham韧性断裂准预测铝合金的开裂极限。材料参数使用上述实验求得的A、B、n和Wc值。采用沙漏控制,通过两端刚体的同时运动,实现双向拉伸。缺口试样的有限元模型如图13所示。

图12 缺口试样尺寸图

Fig. 12 Size of notched sample in biaxial tensile test (Unit: mm)

图13 缺口试样双向拉伸仿真模型

Fig. 13 FEM model of notched sample in biaxial tensile test

通过数值仿真分析,可以得到缺口试样的准静态变形过程。图14所示为数值仿真缺口试样模型在双向拉伸过程中的变形行为及失效准则判据W/Wc的云图,红色区域表示材料局部断裂应变能W已经超过失效准则Wc,材料在该位置发生失效。有限元软件会自动删除失效的单元,并释放周围相关节点的自由度,以模拟裂纹的扩展。由图14可知,初始时刻可能发生失效变形的位置主要集中在两个U形诱导处,随着变形量的增加,在两个U型应力集中处出现了一个新的剪切带,但是根据失效判据,最危险的区域依然是U形诱导圆角处的前端。当变形量达到一定程度时,U形端部变成红色,发生失效。随着拉伸变形量的增加,裂纹垂直拉伸方向扩展,最终试样的上下两端几乎同时断裂。

通过缺口拉伸试样实验来验证仿真结果的准确性,缺口拉伸试样的长方向与挤压方向平行,试样尺寸如图12所示。实验在WDW-E200型微机控制电子万能实验机上进行,拉伸速率为2 mm/min。每种材料的试样均做3组实验,以保证实验结果的稳定性。

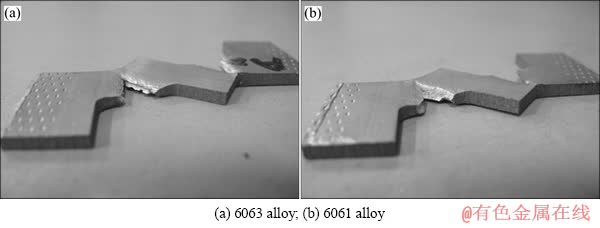

图15所示为缺口试样拉伸变形结果。由图15可知,试样在拉伸变形后发生了明显的颈缩,宏观断口均表现为沿宽度方向的正断,两种材料的变形模式相同。6063铝合金试样在刃口附近厚度出现了明显的减薄,而6061铝合金试样的厚度变化不明显,与材料标准试样单向拉伸结果相近。6063铝合金试样在发生开裂的位置刃口较平整,6061铝合金试样刃口表现出不规则的起伏。

图16所示为缺口试样拉伸数值仿真与实验结果的对比。由图16可知,数值仿真与实验结果一致性较好,在拉伸实验结束后,上下两个U形诱导位置均出现完全的失效开裂,说明数值仿真模型具有较高的精度。

图14 缺口试样轴向拉伸仿真失效过程

Fig. 14 Fracture process of notched sample in axial tensile simulation

图15 缺口试样拉伸实验结果

Fig. 15 Experiment results of notched sample in tensile test

图16 缺口试样拉伸数值仿真与实验变形结果对比

Fig. 16 Comparison of deformation results of notched sample in tensile test

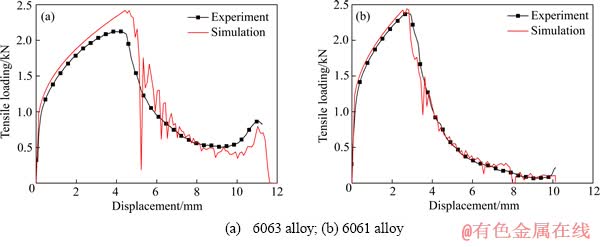

图17 缺口试样准静态拉伸仿真与实验获得的拉伸载荷—位移曲线对比

Fig. 17 Comparison of tensile loading—displacement curves between experiment and simulation in notched sample tensile test

图17所示为6063和6061铝合金缺口试样拉伸实验和数值仿真测得的力—位移曲线。由图17可知,虽然6061铝合金与6063铝合金具有相同的伸长率,但是在该实验条件下,材料的变形性能出现了较大的差异。在试样变形前期,6061试样拉伸载荷增加的速度高于6063试样的,但随着变形量的增大,二者拉伸载荷的增加速度均有明显降低,当位移达到3 mm左右时,6061试样首先达到载荷峰值,约为2.4 kN;而6063试样当变形位移达到4.8 mm时才达到峰值2.1 kN,说明6061铝合金的抗拉强度大于6063铝合金的。随着裂纹的不断扩展,6061铝合金由于变形协调能力不足,拉伸载荷迅速降低至0.1 kN,而6063铝合金由于具有较高的韧性及协调变形能力,拉伸载荷下降速度较慢,且降至0.6 kN时达到稳定状态。随后,两者的载荷均稍有提高,但6063铝合金试样的增幅较大。这可能与材料在变形过程中的微观组织演变有关。最终,6063铝合金试样的最大变形位移为11.6 mm,略高于6061铝合金试样的变形量(10.2 mm)。

由图17可知,仿真结果与实验数据具有较好的一致性。载荷峰值和试样失效时刻的仿真预测结果与实验数据基本相同,说明数值仿真分析具有较高的精度,同时也说明了上述实验得到的A、B、n和Wc值较为合理,使用Cockcroft-Latham韧性断裂准则能够准确预测铝合金的开裂失效。

4.2 汽车用铝合金多胞薄壁结构压缩预测

铝合金构件在移动装置如汽车中的安全问题已成为国内外研究和关注的焦点。特别是铝合金构件在动载条件下的大变形力学行为对研究发生碰撞的车体损伤预测及防护有着十分重要的应用价值。汽车前部薄壁吸能盒通过压缩变形来充分吸收碰撞动能。因此,对碰撞过程中吸能盒的压缩变形和断裂情况的准确预测,有助于提高该结构设计的合理性和安全性。

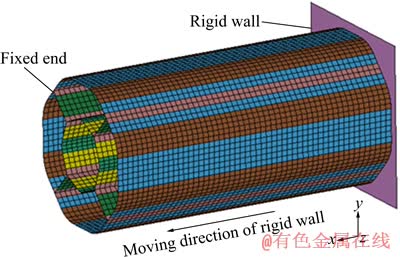

图18 多胞薄壁结构压缩有限元模型

Fig. 18 Compression FEM model of thin-walled multi-cell structure

使用LS-DYNA有限元分析工具,建立数值仿真模型,求解多胞薄壁结构在准静态压缩过程中的失效行为。有限元网格单元平均尺寸为2 mm。材料模型选用MAT107。材料参数使用上述实验求解得到的A、B、n和Wc值。壳单元采用16号全积分单元,8号沙漏控制算法。在材料的厚度方向上,设置5个积分点。接触采用自动单面算法。约束试样一端节点的自由度,另一端通过刚性墙以2 mm/min垂直下压,直至压缩充分。

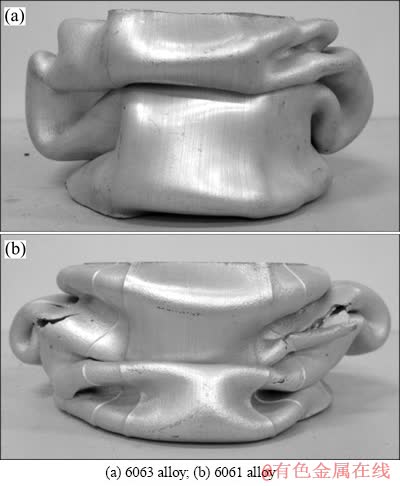

图19所示为200 mm长试样压缩完全后仿真分析得到的失效准则判据W/Wc的云图。由图19可知, 6063铝合金在压缩变形后,大部分区域均在安全区域,褶皱一层接着一层,直至压缩充分也未出现开裂现象。而6061试样在压缩变形过程中,变形不规则,未能充分压缩,鼓形较大,而且在中下部的内陷严重,发生了明显的开裂,部分褶皱圆角区域接近失效判据的临界值。

图19 铝合金薄壁试样压缩仿真结果

Fig. 19 Compression simulation results of aluminum alloy thin-walled sample

采用压缩实验验证仿真预测结果。沿挤压方向截取长度约为202 mm的多胞薄壁结构试样,经切削加工后得到两端平行且长为200 mm的准静态轴向压缩试样,以保证实验与仿真的一致性,从而对仿真预测结果进行验证。实验在WAW-E600型微机控制电液伺服万能实验机进行,压缩速率为5 mm/min。

图20所示为铝合金薄壁试样压缩变形结果。由图20可看出,6061试样在轴向压缩过程中,试样首先在褶皱尖角位置发生开裂,裂纹不断扩展,试样迅速失去承载能力。在变形过程中,试样内部的八边形结构出现了多处裂纹,最终压缩到致密状态。而6063试样则每一层皱褶都压缩得非常充分,变形均匀,未出现开裂现象,与仿真预测结果一致。由此可知,6061铝合金试样在压缩变形过程易出现开裂现象,其变形不稳定,因此不适合作为汽车吸能结构件。

图20 铝合金薄壁试样压缩变形结果

Fig. 20 Compression experiment results of aluminum alloy thin-walled samples

5 结论

1) 通过对6061和6063铝合金真实应力—应变曲线进行线性拟合,获得材料的Johnson-Cook本构参数,两种挤压薄壁型材(在线淬火+180 ℃、30 min时效)的A、B、n值分别为90 MPa、422.58 MPa、0.5234和60 MPa、323.57 MPa、0.428。将Crockroft-Latham韧性断裂准则引入到有限元数值模拟中,求出了6061和6063铝合金的断裂应变能分别为334.09和309.79 MPa。

2) 分别对6061和6063铝合金材质的带缺口拉伸试样和薄壁件进行数值仿真和实验验证,发现拉伸试样的力和位移曲线以及薄壁件的开裂位置与仿真预测结果都高度吻合。

3) 基于Johnson-Cook模型和Cockcroft-Latham韧性断裂准则的数值模拟能够对铝合金的开裂极限进行预测,该方法参数求解方便、计算精度高,可用于汽车及其零部件断裂行为的预测。

REFERENCES

[1] LE M N, T S, MANACH P Y. Aluminum alloy damage evolution for different strain paths-Application to hemming process[J]. Engineering Fracture Mechanics, 2009, 76(9): 1202-1214.

[2] 向 东, 傅定发, 娄 燕, 王 冠, 李 灿, 李落星. Al-Mg-Si 多胞截面型材准静态轴向压缩[J]. 中国有色金属学报, 2012, 22(9): 1843-1854.

XIANG Dong, FU Ding-fa, LOU Yan, WANG Guan, LI Can, LI Luo-xing. Quasi static axial compression of Al Mg Si profiles with multi cell section[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 1843-1854.

[3] HU X, LIN Z Q, LI S H, ZHAO Y X. Fracture limit prediction for roller hemming of aluminum alloy sheet[J]. Materials & Design, 2010, 31(3): 1401-1416.

[4] HU X, ZHAO Y X, LI S H, LIN Z Q. Numerical simulation of ductile fracture behavior for aluminum alloy sheet under cyclic plastic deformation[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1595-1601.

[5] SUNG J H, KIM J H, WAGONER R H. A plastic constitutive equation incorporating strain, strain-rate and temperature[J]. International Journal of Plasticity, 2010, 26(12): 1746-1771.

[6] SING W M, RAO K P. Prediction of sheet metal formability using tensile test results[J]. Journal of Materials Processing Technology, 1993, 37(1/4): 37-51.

[7] JANSEN Y, LOGE R E, MILESI M, MASSONI E. An anisotropic stress based criterion to predict the formability and the fracture mechanism of textured zinc sheets[J]. Journal of Materials Processing Technology, 2013, 213(6): 851-855.

[8] EBNOETHER F, MOHR D. Predicting ductile fracture of low carbon steel sheets: Stress-based versus mixed stress/strain-based Mohr–Coulomb model[J]. International Journal of Solids and Structures, 2013, 50(7): 1055-1066.

[9] 陈光南, 胡世光. 成形极限曲线的新概念[J]. 机械工程学报, 1994, 30(4): 82-85.

CHEN Guang-nan, HU Shi-guang. New concept of forming limit curve[J]. Journal of Mechanical Engineering, 1994, 30(4): 82-85.

[10] HOGSTROM P, RINGSBERG J W, JOHNSON E. An experimental and numerical study of the effects of length scale and strain state on the necking and fracture behaviours in sheet metals[J]. International Journal of Impact Engineering, 2009, 36(10): 1194-1203.

[11] KRAUER J, HORA P. Enhanced material models for the process design of the temperature dependent forming behavior of metastable steels[J]. International Journal of Material Forming, 2012, 5(4): 361-370.

[12] FANG G, LIU Q, LEI L, ZENG P. Comparative analysis between stress-and strain-based forming limit diagrams for aluminum alloy sheet 1060[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S1): s343-s349.

[13] LIN Y C, CHEN X M. A combined Johnson-Cook and Zerilli-Armstrong model for hot compressed typical high-strength alloy steel[J]. Computational Materials Science, 2010, 49(3): 628-633.

[14] 朱 浩, 齐芳娟, 张 洋. 剪应力状态下6061铝合金的力学性能及断裂行为[J]. 中国有色金属学报, 2012, 22(6): 1570-1576.

ZHU Hao, QI Fang-juan, ZHANG Yang Mechanical properties and fracture behavior of 6061 aluminum alloy under shear stress state[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1570-1576.

[15] FAGERHOLT E, DORUM C, BORVIK T, HI L, HOPPERSTAD O S. Experimental and numerical investigation of fracture in a cast aluminum alloy[J]. International Journal of Solids and Structures, 2010, 47(24): 3352-3365.

(编辑 李艳红)

基金项目:国家“十二五”科技支撑计划资助项目(2011BAG03B02);国家自然科学基金面上资助项目(51075132);长沙市科技重大专项(K1204008-11-1);湖南大学汽车车身先进设计与制造国家重点实验室自主课题资助项目(61075005)

收稿日期:2013-07-18;修订日期:2013-11-04

通信作者:李落星,教授,博士;电话:0731-8821445;E-mail: llxly2000@163.com