DOI: 10.11817/j.issn.1672-7207.2017.02.013

加工形态对铝合金薄壁件加工变形的影响

肖峰1, 2, 3,吴运新1, 2, 3,龚海1, 2, 3,李晨4,刘瑶琼1, 4,姬浩4

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

3. 中南大学 有色金属先进结构材料与制造协同创新中心,湖南 长沙,410083;

4. 中国航空工业集团公司 西安飞机设计研究所,陕西 西安,710089)

摘要:针对航空铝合金薄壁件加工变形的问题,采用三维有限元方法,仿真分析加工形态(材料去除率、构件框数和铣削深度)对铝合金薄壁件加工变形的影响,并通过铣削实验对仿真结果的准确性进行验证。研究结果表明:构件长度方向翘曲变形量随着宽度方向材料去除率减小而减小;随着长度方向材料去除率减小,构件宽度方向变形量减小,而长度方向的变形量基本不变;当构件材料去除率大于85%时,材料去除率一致,框数不一致,构件底面翘曲变形量基本一致;当材料去除率小于85%时,同材料去除率的多框体变形比单框体的变形大;随着铣削深度增大,框类件长度和宽度方向变形量都是先增大后减小;模型仿真计算变形量与实验结果较吻合,本研究可为控制薄壁件加工变形提供参考。

关键词:铝合金薄壁件;加工形态;有限元方法;加工变形

中图分类号:TG501;V261 文献标志码:A 文章编号:1672-7207(2017)02-0355-06

Influence of processing form on milling distortion of aluminum alloy thin-walled workpiece

XIAO Feng1, 2, 3, WU Yunxin1, 2, 3, GONG Hai1, 2, 3, LI Chen4, LIU Yaoqiong1, 4, JI Hao4

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance Complex Manufacturing, Central South University, Changsha 410083, China;

3. Nonferrous Metal Oriented Advanced Structural Materials and Manufacturing Cooperative Innovation Center,

Central South University, Changsha 410083, China;

4. Avic the First Aircraft Institute, Aviation Industry Corporation of China, Xi’an 710089, China)

Abstract: In view of the milling deformation of aeronautical thin-walled workpiece, the influence of processing form (material removal rate, milling slot number and milling depth) on milling deformation was simultaneously analyzed by using finite element method. The accuracy of the simulation results was verified by the experiment. The results show that when material removal rate in width direction decreases, the bend deformation in length direction drops. When material removal rate in length direction decreases, the deformation in width direction decreases, but the deformations in length direction are uniform. When material removal rate is greater than 85%, bend deformation is the same at different slot numbers. When material removal rate is less than 85%, the deformations of the multi-frame components are bigger than those of the single-frame components. Both length and width bend deformations increase and then decrease with the increase of the milling depth. The simulation results coincide with the experimental results. The study can provide useful references for controlling milling deformation of the thin-walled workpieces.

Key words: aluminum alloy thin-walled workpiece; processing form; finite element method; milling deformation

随着航空航天制造业的不断发展,结构复杂的薄壁件如整体框、整体梁、整体壁板等[1-2]在飞机零部件中得到广泛使用。这类零件具有尺寸大﹑结构复杂、壁薄、精度要求高等特点,而整体结构件尺寸大且去除率高,因此,在加工过程中很容易产生翘曲变形。引起翘曲变形的因素比较多,工件的加工形态是其中之一,在加工构件后要增加校正程序,这既降低了生产率,又增加了零件的报废率,造成了巨大的经济损失[3-5]。因此,研究工件加工形态(材料去除率、构件框数和铣削深度)对加工变形的影响规律很有必要。针对加工变形问题,研究人员进行了相关的仿真和实验。SEBASTIAN[6]研究了整体结构件加工变形受残余应力释放的影响;胡权威等[7]分析了铣削参数对加工变形的影响,并进行了优化研究;YOUNG[8]研究了加工过程中薄壁件内产生的加工应力及其所产生的加工变形。CUS等[9]研究了刀具的几何参数对工件加工变形的影响,通过优化刀具几何参数来控制工件的变形;张以都等[10]对初始残余应力引起的铣削变形进行了研究;丁子昀等[11]利用有限元分析方法,分析了多点装夹方案引起的多框件铣削变形的规律;钱玲楠等[12]研究了走刀路径和装夹方案对薄壁框体件的变形的影响。目前,人们对航空铝合金薄壁件加工变形及其影响因素进行了大量研究,但关于加工形态对加工变形影响的研究较少。为此,本文作者通过利用有限元软件MSC.Marc[13]仿真分析及相关实验,研究得到工件加工形态(材料去除率、构件框数和铣削深度)对加工变形的影响规律。

1 铣削加工的有限元模型

1.1 有限元模型的建立

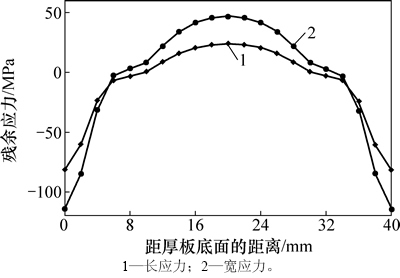

采用有限元软件MSC.Marc对铣削加工进行仿真模拟。用于铣削的7075铝合金厚板的长×宽×高为450 mm×112 mm×40 mm,材料弹性模量E=71 GPa,泊松比ν=0.33。采用六面体单元划分网格,利用生死单元法模拟铣削过程。铝合金厚板经过475 ℃、保温2 h+20 ℃水浴淬火,再进行拉伸率为1%的预拉伸处理。据文献[14-15],经过预拉伸后,板内的残余应力分布见图1。将该残余应力曲线进行离散和自平衡处理,作为有限元模型的初始残余应力。

图1 初始残余应力沿厚度方向的分布

Fig. 1 Distribution of residual stress along thickness direction

1.2 铣削变形的评估参数

采用挠度作为铝合金板铣削变形的评估标准。由板上表面或下表面单元沿板厚方向的位移能够确定厚板变形的挠度△d。

式中:zmax为厚度方向的最大位移;zmin为厚度方向的最小位移。

2 有限元仿真分析

航空铝合金结构件主要加工成框类件的形式[16],但用途不同,框类件的形式就不一样。对框类零件的加工变形进行分析时,已知零件的初始残余应力一样,尺寸相同,加工形式一致,仅加工形态不同,下面分别从材料去除率、铣削框数和铣削深度3个方面分析加工形态对加工变形的影响。

2.1 材料去除率对加工变形的影响

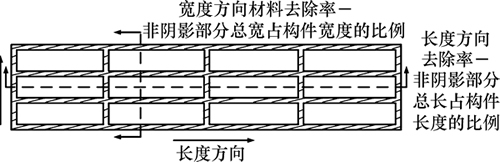

本文所讨论的材料去除率包括长度方向材料去除率和宽度方向材料去除率。长度方向材料去除率定义为:在一条平行于构件长度的路径上,框槽累计长度占构件总长的比例。同理,可定义宽度方向材料去除率。材料去除率定义的示意图如图2所示。

图2 材料去除率定义示意图

Fig. 2 Definition diagram of material removal rate

2.1.1 宽度方向材料去除率对加工变形的影响

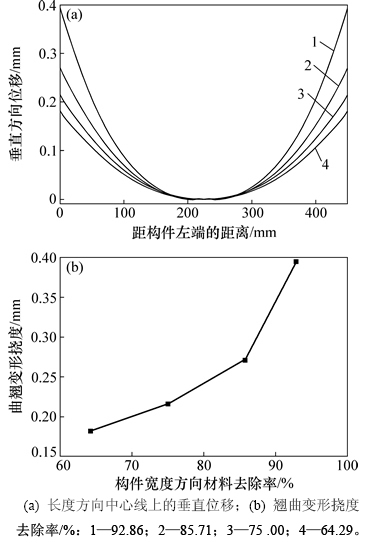

将铝合金厚板进行铣削,框槽铣削深度为30 mm,平行长度方向的槽壁和肋板厚均为4 mm,平行宽度方向的槽壁厚为10 mm。将厚板分别铣削成单框、3框、6框、9框构件,同一构件上各个框槽的长度和宽度一样,多框件只在宽度方向增加框槽。

各组构件均无平行宽度方向的肋板,平行长度方向的肋板数分别为0,2,5和8,则构件宽度方向的材料去除率分别为92.86%,85.71%,75 .00%和64.29%。图3所示为仿真得到的构件长度方向翘曲变形结果。从图3可见:随着平行长度方向的肋板数增多即宽度方向材料去除率逐渐减小,构件长度方向的翘曲变形量逐渐减小。因为平行长度方向的肋板数增多,去除的材料就越少,从而导致构件的刚性越大,刚性越大,构件的变形就越小。

图3 宽度方向材料去除率不同的4个构件的长度方向翘曲变形

Fig. 3 Bend deformation in length direction under four different material removal rates in width direction

图4所示为构件宽度方向翘曲变形结果。从图4可见:宽度方向材料去除率对构件宽度方向的变形影响较小,其变形挠度范围为0.18~0.22 mm,而且变形挠度随着宽度方向材料去除率的增大整体呈减小趋势。

图4 宽度方向材料去除率不同的4个构件宽度方向翘曲变形

Fig. 4 Bend deformation in width direction under four different material removal rates in width direction

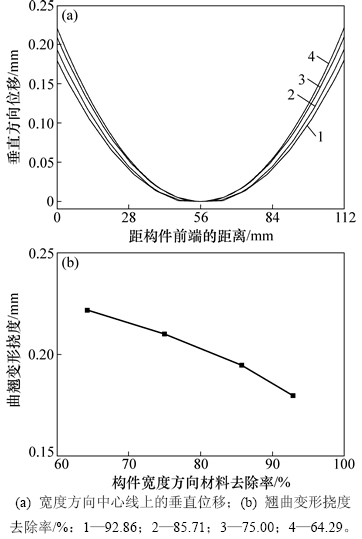

2.1.2 长度方向材料去除率对加工变形的影响

将铝合金厚板进行铣削,框槽铣削深度为30 mm,平行长度方向的槽壁及肋板厚均为4 mm,平行宽度方向的槽壁厚为10 mm,进行4组仿真。将厚板分别加工成单框、2框、4框、5框构件,同一构件上各个框槽的长度和宽度一样。多框件只在长度方向增加框槽,4组构件均无平行长度方向的肋板。长度方向的材料去除率分别为95.56%,93.33%,88.89%和86.67%。图5所示为4组构件铣削后的翘曲变形。从图5可见:构件长度方向的翘曲变形挠度基本相同,而宽度方向的翘曲变形挠度随着长度方向材料去除率的增大而增大。

图5 长度方向材料去除率不同的4个构件的翘曲变形

Fig. 5 Bend deformation under four different material removal rates in length direction

2.2 构件框数对加工变形的影响

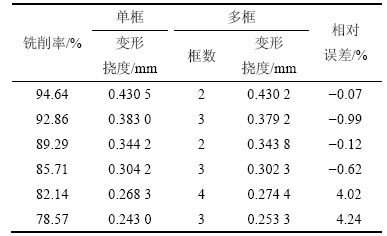

构件平行宽度方向的槽壁厚保持为10 mm,即长度方向的材料去除率为95.56%,铣削深度为30 mm,选取不同的宽度方向材料去除率(94.64%,92.86%,89.29%,85.71%,82.14%和78.57%,对应的长度方向槽壁厚分别为3,4,6,8,10和12 mm),铣成单框件。而在相应的多框件中,保持宽度方向铣削率和单框件的一致,仅改变长度方向的肋板数。表1所示为单框件与多框件的翘曲变形量的对比情况。

从表1可见:当构件的材料去除率大于85%时,若材料去除率一致,则不论框数是多少,构件底面的翘曲变形挠度基本相同,误差很小;当材料去除率小于85%时,多框件的变形比相同材料去除率下单框件的大;而当材料去除率越大时,多框件的变形比同铣削率的单框件的变形略小。

由上述模拟结果可知:当长度和宽度方向的材料去除率一致时,在一定的材料去除率范围内,不管构件被铣成单框件还是多框件,构件的底面翘曲变形挠度基本相同。所以,在有限元分析中,保证相同的变形特征,忽略框槽的影响,将多框件简化成单框件,仅讨论材料去除率对加工变形的影响,能够节省分析成本。

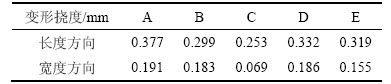

表1 单框件与多框件的加工变形挠度对比

Table 1 Comparison of deformation between single frame and multi-frame components

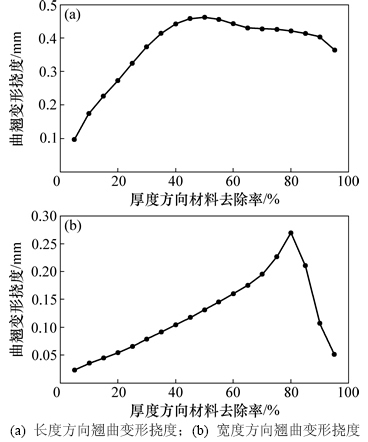

2.3 铣削深度对加工变形的影响

选取上述有限元模型,沿厚度方向将铝板等分为20层,每层厚度为2 mm。铣削出平行宽度方向的槽壁厚为10 mm,平行长度方向的槽壁厚为4 mm的单框槽,逐层铣削,铣削深度从2 mm增加到38 mm。图6所示为不同厚度方向材料去除率下构件底面的翘曲变形结果。从图6可见:随着铣削深度增大,框类件长度方向翘曲变形量先增大后减小;当厚度方向材料去除率为50%左右时,翘曲变形挠度达到最大;当材料去除率为70%~90%时,变形变化较小;而随着铣削深度增大,框类件宽度方向翘曲变形量逐渐增大;当材料去除率大于80%时,翘曲变形挠度急剧减小。

图6 框类件的加工变形与铣削深度的关系

Fig. 6 Relationship between deformation of frame components and milling depth

3 铣削加工实验验证

3.1 实验过程

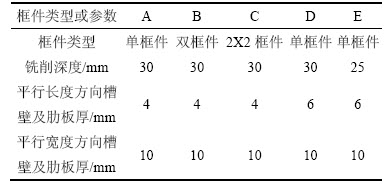

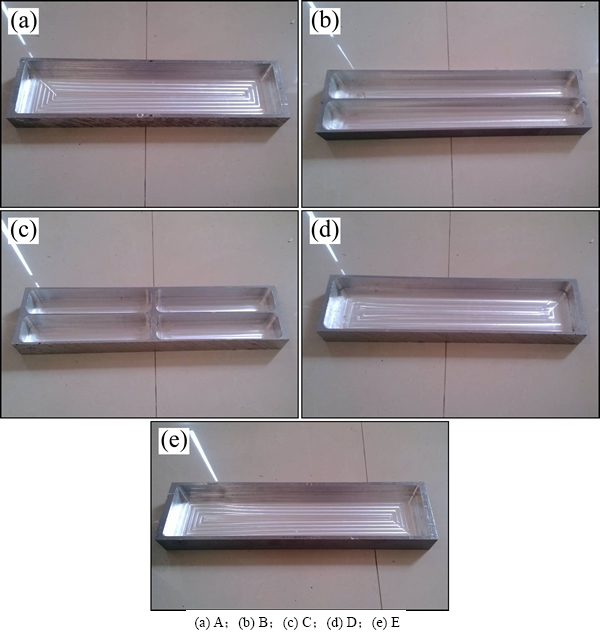

将2块长×宽×高均为1 200 mm×230 mm×40 mm的7075铝合金厚板进行475 ℃保温2 h+20 ℃水浴淬火,接着进行拉伸率为1% 的预拉伸处理,对铝板进行线切割,得到5组同尺寸的铝合金厚板,其长×宽×高均为450 mm×112 mm×40 mm,编号分别为A,B,C,D和E。对5组铝合金厚板进行铣削加工,工件的几何参数如表2所示,5组构件铣削后的实物图如图7所示。A和B这2组铣削件长度方向材料去除率和铣削深度一样,仅宽度方向材料去除率不一样;B和C铣削件宽度方向材料去除率和铣削深度一样,仅长度方向材料去除率不一样;B和D铣削件长度方向和宽度方向材料去除率以及铣削深度都一致,仅铣削框数不一样;D和E铣削件长度方向和宽度方向材料去除率以及铣削深度都一样,仅铣削深度不一样。

铣削加工前后,采用三坐标测量仪测得构件底面的轮廓,经过数据处理得到变形。

3.2 实验结果

表3所示为5组构件铣削后翘曲变形挠度。从表3可知:A构件和B构件仅宽度方向的材料去除率不同,且A构件宽度方向材料去除率比B构件的大,铣削后A构件长度方向的加工变形挠度比B构件的大,而铣削后A构件宽度方向的加工变形挠度比B构件的略大;B构件和C构件仅长度方向的材料去除率不同,且B构件长度方向材料去除率比C构件的大,铣削后B构件长度和宽度方向的加工变形挠度都比C构件的大;B构件和D构件仅铣削框数不一样,且B构件的铣削框数比D构件的多,铣削后B构件的长度和宽度方向的加工变形挠度都比D构件的小;D构件和E构件仅铣削深度不一样,且D构件铣削深度大于E构件的铣削深度,铣削后,D构件长度和宽度方向的加工变形挠度都比E构件的大,这与材料去除率、铣削框数和铣削深度对构件加工变形的影响规律较相符,进一步验证了所得规律的准确性。

表2 工件几何参数

Table 2 Geometric parameters of components

图7 5组铣削件实物图

Fig. 7 Pictures of five real products after milled

表3 不同构件铣削后的长宽翘曲变形量

Table 3 Bend deformation in length and width direction of different components after the milling mm

根据铣削仿真分析结果,构件A,B,C,D 和E的铣削后长度方向翘曲变形挠度仿真结果分别为0.395,0.316,0.270,0.344和0.334 mm,铣削后宽度方向翘曲变形挠度仿真结果分别为0.180,0.198,0.062,0.178和0.146 mm。由此可得到构件加工变形的仿真值与实测值比较接近,误差比较小,验证了建立的仿真模型的有效性及仿真分析结果的准确性。

4 结论

1) 构件长度方向翘曲变形量随着宽度方向材料去除率的减小而减小,而宽度方向材料去除率对宽度方向的整体变形影响较小,变形挠度随着宽度方向材料去除率的增大整体上呈减小趋势。

2) 构件宽度方向翘曲变形量随着长度方向材料去除率减小而减小,而长度方向的变形量基本保持一致。

3) 当构件材料去除率大于85%时,若材料去除率一致,则框数量、构件底面的翘曲变形量基本一致。当材料去除率小于85%时,材料去除率相同的多框体与单框体相比,多框体的变形反而越大。

4) 框类件长度方向翘曲变形量随着铣削深度先增大后减小,当厚度方向材料去除率为50%左右时,翘曲变形量达到最大;当材料去除率为70%~90%时,变形量变化较小。宽度方向翘曲变形量随着剥除量的增大逐渐增大,而当材料去除率大于80%时,变形量急剧减小。

参考文献:

[1] 杨勇, 李剑锋. 航空整体结构件加工技术[J]. 航空制造技术, 2008(24): 50-54.

YANG Yong, LI Jianfeng. Machining technology for aviation integrated structures[J]. Aeronautical Manufacturing Technology, 2008(24): 50-54.

[2] LEQUEU P, LASSINEC P, WARNER T, et al. Engineering for the future:weight saving and cost reduction initiative[J]. Aircraft Eng Aerospace Tech, 2001, 73(2): 147-159.

[3] 车现发. 高强度铝合金航空薄壁件铣削加工变形控制的工艺研究[D]. 南京: 南京航空航天大学机电学院, 2011: 1-7.

CHE Xianfa. Milling machining deformation control technology of high-strength aluminum alloy aeronautical thin-wall components[D]. Nanjing: Nanjing University of Aeronautics and Astronautics. College of Mechanics and Electrics, 2011: 1-7.

[4] 毕运波, 柯映林, 董辉跃. 航空铝合金薄壁件加工变形的有限元仿真与分析[J]. 浙江大学学报(工学版), 2008, 42(3): 397-402.

BI Yunbo, KE Yinglin, DONG Huiyue. Finite element simulation and analysis of deformation in machining of aeronautical aluminum alloy thin-walled workpiece[J]. Journal of Zhejiang University(Engineering Science), 2008, 42(3): 397-402.

[5] 尚钰淇. 大型薄壁零件铣削加工变形数值分析[D]. 大连: 大连理工大学机械工程学院, 2012: 1-4.

SHANG Yuqi. Numerical analysis of large thin-walled parts’ deformation in milling process[D]. Dalian: Dalian University of Technology. School of Mechanical Engineering, 2012: 1-4.

[6] SEBASTIAN N. A mathematical model for the estimation of residual stresses in aluminum parts[D]. Washington: Department of Mechanical and Aerospace Engineering, Washington University, 2005.

[7] 胡权威, 乔立红, 张洪伟. 薄壁结构件铣削参数有限元正交优势分析及优化[J]. 机械工程学报, 2013, 49(21): 176-184.

HU Quanwei, QIAO Liwei, ZHANG Hongwei. Optimization of thin-walled part milling parameters based on finite element and orthogonal dominance analysis[J]. Chinese Journal of Mechanical Engineering, 2013, 49(21): 176-184.

[8] YOUNG K A. Machining-induced residual stress and distortion of thin parts[D]. Washington: Department of Mechanical and Aerospace Engineering, Washington University, 2005: 32-39.

[9] CUS F, ZUPERL U. Approach to optimization of cutting conditions by using artificial neural networks[J]. Journal of Materials Processing Technology, 2006, 173(3): 281-290.

[10] 张以都, 张洪伟. 航空整体结构件加工变形有限元数值仿真[J]. 北京航空航天大学学报, 2009, 35(2): 188-192.

ZHANG Yidu, ZHANG Hongwei. Finite element simulation of machining deformation for aeronautical monolithic component[J]. Journal of Beijing University of Aeronautics and Astronautics, 2009, 35(2): 188-192.

[11] 丁子昀, 左敦稳, 郭魂, 等. 多点装夹方案对多框体铣削变形影响的有限元分析[J]. 南京航空航天大学学报, 2009, 41(5): 639-643.

DING Ziyun, ZUO Dunwen, GUO Hun, et al. Finite element analysis of multi-point clamping scheme effect on milling deformation of multi-frame components[J]. Journal of Nanjing University of Aeronautics&Astronautics, 2009, 41(5): 639-643.

[12] 钱玲楠, 李蓓智, 杨建国, 等. 薄壁框体零件优质高效加工工艺方法[J]. 东华大学学报(自然科学版), 2011, 37(4): 412-415.

QIAN Lingnan, LI Beizhi, YANG Jianguo, et al. Processing method for high quality and efficiency manufacturing of thin walled frame component[J]. Journal of Donghua University (Natural Science), 2011, 37(4): 412-415.

[13] 冯超, 孙丹丹, 陈火红. 全新Marc实例教程与常见问题解析[M]. 北京: 中国水利水电出版社, 2012: 323-360.

FENG Chao, SUN Dandan, CHEN Huohong. New Marc instance tutorial and common problem resolution[M]. Beijing: China Water & Power Press, 2012: 323-360.

[14] 龚海, 吴运新, 廖凯. 预拉伸对7075铝合金厚板残余应力分布的影响[J]. 材料热处理学报, 2009, 30(6): 201-205.

GONG Hai, WU Yunxin, LIAO Kai. Influence of pre-stretching on residual stress distribution in 7075 aluminum alloy thick-plate[J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 201-205.

[15] 廖凯, 吴运新, 龚海, 等. 铝合金厚板淬火-预拉伸应力预测与测试[J]. 中国有色金属学报, 2010, 20(10): 1901-1906.

LIAO Kai, WU Yunxin, GONG Hai, et al. Prediction and measurement of quenching-prestretching stress in aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1901-1906.

[16] 吴红兵, 柯映林, 刘刚, 等. 航空框类整体结构件铣削加工变形研究[J]. 浙江大学学报(工学版), 2009, 43(3): 546-550.

WU Hongbing, KE Yinglin, LIU Gang, et al. Study on milling deformation of aerospace frame monolithic components[J]. Journal of Zhejiang University (Engineering Science), 2009, 43(3): 546-550.

(编辑 陈灿华)

收稿日期:2016-02-10;修回日期:2016-04-24

基金项目(Foundation item):国家自然科学基金资助项目(51405520,51327902);国家国际科技合作专项(2014DFA51250)(Projects(51405520, 51327902) supported by the National Natural Science Foundation of China; Project(2014DFA51250) supported by the International Science & Technology Cooperation Program of China)

通信作者:龚海,讲师,硕士生导师,从事航空铝材残余应力及加工变形研究;E-mail:gonghai@csu.edu.cn