600 MW机组锅炉管排偏斜引起的磨损模拟分析

李相鹏,蓝立伟,高增梁

(浙江工业大学 机械工程学院,浙江 杭州,310032)

摘要:以商用软件Fluent为平台,运用用户自定义函数(UDF)模拟分析600 MW机组锅炉低温再热器管排发生偏斜对气固两相流场分布、飞灰运动轨迹、碰撞速度等的影响,进一步研究飞灰碰撞造成的管束磨损分布。研究结果表明:当管排偏斜角从1.6°增加到6.5°,管排通道内最大气流速度由16 m/s增至20 m/s,最大飞灰质量浓度由5.8 g/m3增至6.8 g/m3。同时颗粒平均碰撞速度增大,较多颗粒平均碰撞角集中于最大磨损发生角附近,造成偏斜管束年磨损量有较大增加。

关键词:管排偏斜;磨损;气固两相流

中图分类号:TK223.3 文献标志码:A 文章编号:1672-7207(2012)01-0159-06

Simulation analysis of tubes erosion induced by bundle deflexion in 600 MW boiler

LI Xiang-peng, LAN Li-wei, GAO Zeng-liang

(College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract: The influences of bundle deflexion of a 600 MW boiler low-pressure reheater on the distribution of gas-solid two-phase flow fields, moving tracks and impact velocities of fly ash particles were simulated and analyzed using commercial software package Fluent and user defined function (UDF). The tubes erosion caused by impingement of ash particles was further studied. The results show that the maximum flow velocity in the channel between tube bundles increases from 16 m/s to 20 m/s, the maximum particle mass concentration increases from 5.8 g/m3 to 6.8 g/m3. Meanwhile, the average impingement velocity of particles increases and the average impingement angels of most particles are close to the maximum erosion angle, resulting in a relatively large erosion rate of boiler tubes.

Key words: bundle deflexion; erosion; gas-solid two-phase flow

在燃煤锅炉中,受热面飞灰碰撞磨损是一种常见的现象,由此发生的锅炉管破损泄漏事故约占锅炉总事故的45%~50%[1]。锅炉受热面设计工作寿命一般为100 kh,而许多锅炉在实际运行5~20 kh后,部分受热面就发生严重磨损,导致爆管泄漏事故[2]。锅炉管过早的破损和因此而造成的停炉检修,将给电厂造成巨大经济损失。因此,针对含灰气流对锅炉受热面冲击磨损的研究具有重要意义。国内外已有许多学者对气固两相流中颗粒与壁面发生碰撞而造成磨损的问题进行了实验和模拟研究。Mbabazi等[3-4]用三组不同类型的飞灰测试了它对钢表面的磨损速率,实验结果表明磨损速率与粒子碰撞角、碰撞速度和飞灰粒子大小、形状、硅含量等有关。Tabakoff等[5-6]采用不同颗粒和不同金属板先后进行了一系列的磨损实验,结果表明飞灰的碰撞速度和碰撞角度是影响磨损率的主要因素,并根据实验结果拟合出了磨损速率预测半经验公式,获得了广泛应用。Nagarajan等[7-9]采用CFD模拟的方法研究了颗粒与管壁面的碰撞磨损,模拟结果表明飞灰粒子大小、浓度、碰撞速度和角度、金属表面粗糙度是磨损的主要影响因素。Oka等[10-13]提出了自己的颗粒碰撞磨损预测模型。嵇峰等[14-15]通过对颗粒与管束的碰撞磨损进行数值模拟,证实了颗粒对管壁的碰撞磨损与碰撞频率因子、碰撞速度和碰撞角度有关。目前对于飞灰碰撞引起的锅炉管束磨损研究方法已经比较成熟,针对相关因素对磨损速率的影响也已有较多研究。然而,针对锅炉管束磨损的研究基本均是针对规则排列管束,忽略了管排在安装过程及运行时由于热胀冷缩形成的部分管排偏斜错位的影响,而实际证明该因素对管束磨损速率影响较大。在此,本文作者以600 MW锅炉低温再热器为例,采用商用流体计算软件Fluent结合用户自定义函数(UDF)对管排偏斜对烟气流场分布、飞灰运动轨迹、碰撞速度等的影响进行模拟分析,对管排偏斜引起的锅炉管束磨损分布进行深入研究。

1 计算模型

1.1 建模

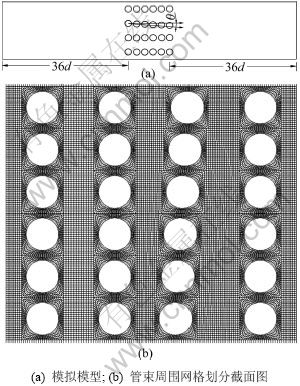

建立600 MW锅炉低温再热器中部管排发生偏斜的CFD模拟模型,如图1所示。取4排6层管作为计算对象,计算域在管道上游和下游分别取32d(d为管外径63.5 mm)的长度以减小入口和出口边界对计算结果的影响,模型厚度为200 mm(π×d)。管排距为141.75 mm,层距为82.5 mm。取第三列管排为偏斜管排,偏斜角θ分别为1.6°,3.2°和6.5°。模型采用三维正交结构化网格,管束周围网格划分截面如图1(b)所示。整个模型共有节点数约为82万,六面体单元数约为76万。

图1 模拟模型和管束周围网格划分截面图

Fig.1 Simulation model and meshed grid around tubes

1.2 边界条件及磨损模拟方法

进口施加速度入口边界条件 (根据锅炉烟气流量计算);出口施加压力出口边界条件为0;定义锅炉管为无滑移固定壁面;在上下、前后四个切面上施加对称边界,该面上法向速度和压力梯度均为0;定义飞灰颗粒从流体入口均匀射入,射流总质量流量为3.52 g/s (根据模型入口边界面积占总烟道面积比例计算得到),飞灰密度为1 666 kg/m3,颗粒粒径服从Rosin-Rammler分布,飞灰颗粒平均粒径为14 μm,分散系数取3,初始速度与流体初始速度相同,同时定义出口边界为颗粒的非反弹边界,即颗粒和涡结构可以顺利通过这些界面而不致反弹。采用离散颗粒模型描述气固两相流动。离散颗粒模型是把流体相视为连续相,用欧拉法描述流体的流动;颗粒视为离散相,采用拉格朗日法描述,根据牛顿运动定律直接追踪每个颗粒。Frank等[16]通过采用该模型进行数值模拟得到的结果与实验值进行比较,证明离散颗粒模型用于气固两相流模拟准确、可靠。

气相湍流流场的通用控制方程为:

(1)

(1)

式中: 为各因变量;

为各因变量; 为

为 的湍流扩散系数;

的湍流扩散系数; 和

和 为气相场本身的源项和颗粒相的源项。

为气相场本身的源项和颗粒相的源项。

湍流模型采用 双方程模型

双方程模型

k-方程:

(2)

(2)

ε-方程:

(3)

(3)

式中: ;

; ;

;

;

; ;

; ;

; ;

; ;

; 。

。

颗粒的运动是由惯性力、阻力、重力、压力梯度力、虚假质量力和升力等综合作用的结果。在颗粒密度和空气密度比远大于1的情况下,可只考虑惯性力、阻力和重力,其他力可以忽略不计。本文采用脉动频谱随机颗粒轨道模型来描述颗粒的运动。

(4)

(4)

若把气流的瞬时速度ug分成时均值 和脉动值

和脉动值 2个部分,则对于气流脉动速度

2个部分,则对于气流脉动速度 采用下述的随机傅里叶级数来模拟,写成分量形式为

采用下述的随机傅里叶级数来模拟,写成分量形式为

(5)

(5)

(6)

(6)

式中:R1~R4为正态分布的随机数;ω为湍流脉动频率; 为脉动相位角;Ui和v i为根据湍流脉动频谱所确定的频率为ω时的脉动幅值。

为脉动相位角;Ui和v i为根据湍流脉动频谱所确定的频率为ω时的脉动幅值。

另外,颗粒的运动轨迹方程为:

(7)

(7)

由式(4)和(7)就可以求出颗粒的运动速度和运动轨迹。积分采用四阶Runge-Kutta法。

Grant等[6]曾对煤灰颗粒冲蚀磨损金属材料进行了大量的实验研究, 并回归总结出计算管壁磨损量的公式。本文颗粒碰撞引起的磨损分布即采用文献[6]中提出的磨损速率半经验公式:

(8)

(8)

式中:ε为单位质量的冲击颗粒对金属的磨损量;v和β1分别为颗粒的碰撞速度和碰撞角度;KC为碰撞角度影响因子;β0=25°为最大的磨损发生角,当β1≤3β0时,KC=1,当β1>3β0时,KC=0;对于同一种材料,k1,k12和k3是常数,与金属的材料有关。在本文计算飞灰粒子对不锈钢管的冲蚀中,取k1=1.505 101× 10-6,k12=0.296 077,k3=5.0×10-12。从式(8)可见:磨损速率与颗粒碰撞速度、碰撞频率和碰撞入射角度密切相关。

管束磨损速率的模拟采用VC++编制的用户自定义函数(UDF)实现。UDF可以动态连接到Fluent求解器以提高求解器性能。通过自定义宏,将Fluent求解器得到的颗粒碰撞速度、碰撞入射角度代入磨损速率计算公式并返回所得结果。

2 计算结果分析

2.1 气相流场分布

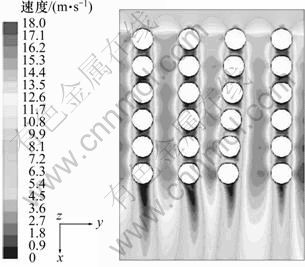

锅炉烟道内,固体颗粒随烟气流动,气流速度对颗粒在管壁的碰撞速度具有重要影响,因此针对管排偏斜后,相邻气流通道内气流速度变化趋势的研究很有意义。图2所示为管束偏斜3.2°时管段区域的流体流动速度分布云图。从图2可知:管排偏斜后左侧气流通道有所变窄,气流进入管道区域后,速度明显增大,由管排进口处约为12 m/s增加到约为18 m/s。

图2 速度分布云图

Fig.2 Contours of gas velocity

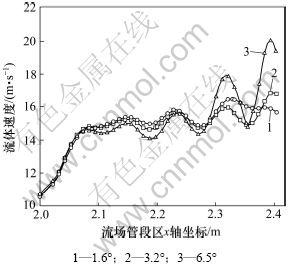

图3所示为管束偏斜角度分别为1.6°,3.2°和6.5°时,第二与第三列管排(图2)之间通道内沿x轴正方向流体的速度分布曲线图。从图3可以看出:管束偏斜1.6°时,流体进入该通道的入口速度为10.5 m/s,流体流经该通道的最大速度增至16 m/s,最大速度比入口速度增大了52.4%。管束偏斜6.5°时,流体进入该通道的入口速度为10.5 m/s,流体流经该通道的最大速度增至20 m/s,最大速度比入口速度增大了约90%,管束偏斜6.5°的最大速度比偏斜1.6°时的最大速度增大了约25%。颗粒浓度一定的流体,流体速度增大时,颗粒对管壁的撞击力、冲刷力加大,磨损速率加剧。

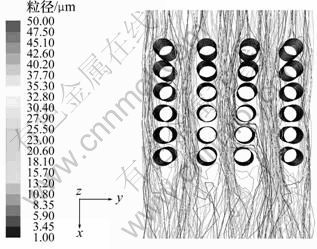

2.2 飞灰运动分布分析

管排偏斜也对颗粒运动分布特征具有较大影响,如图4所示。可见:在管排未偏斜的通道内,颗粒沿通道直行,与管束碰撞的颗粒较少;而在管排发生偏斜的通道,有较多的颗粒与偏斜管束发生碰撞,并沿偏斜管束间隙运动到相邻的通道中。碰撞颗粒的增多,对于管束磨损具有重要影响。

图3 流体速度分布曲线

Fig.3 Fluid velocity graph

图4 管束周围飞灰运动轨迹

Fig.4 Fly ash track around tubes

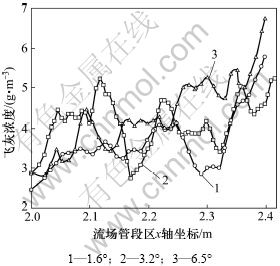

管排偏斜也导致了相关通道内飞灰浓度增大。图5所示为管束偏斜角度分别为1.6°,3.2°和6.5°时,第二与第三列管排(图2)通道内沿x轴正方向流体中飞灰的浓度分布曲线图。从图5可以看出:当管束偏斜1.6°时,通道的入口飞灰浓度为2.5 g/m3,出口飞灰浓度增加到5.8 kg/m3。当管束偏斜6.5°时,通道的入口飞灰浓度为2.9 kg/m3,出口飞灰浓度为6.8 kg/m3。偏斜角增大到6.5°后,最大飞灰浓度相比1.6°时增加了约17%。飞灰浓度的增大,也会导致颗粒碰撞频率增加,进而引起更大的磨损速率。

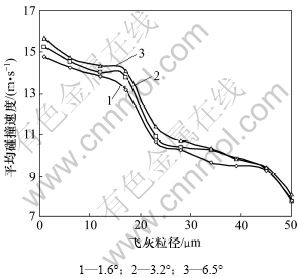

磨损速率不仅与颗粒浓度有关,还与颗粒平均碰撞速度有关。由经验公式可知:冲蚀磨损量与粒子碰撞速度二次方成正比。图6所示为管束偏斜角度分别为1.6°,3.2°和6.5°时,第二与第三列管排(图2)通道间沿x轴正方向流体中10组不同粒径的飞灰对偏斜管的平均碰撞速度。从图6可以看出:随着第三列管束偏斜角度的变大,流体中飞灰颗粒与偏斜管发生碰撞的平均速度均有所增大。而随着粒径的增加,颗粒碰撞速度逐渐减小,这主要是因为小颗粒运动受气流影响较大,在偏斜通道内,小颗粒运动速度会随气流速度增大而增大,较大的颗粒则惯性较大,受气流速度影响较小。

图5 飞灰的浓度分布曲线

Fig.5 Distribution of fly ash concentration

图6不同粒径飞灰的平均碰撞速度分布曲线

Fig.6 Average impingement velocity of fly ash with different diameters

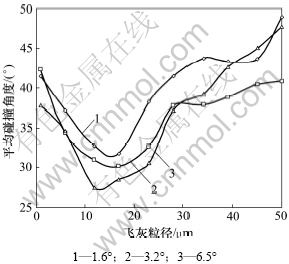

飞灰碰撞角也是引起磨损的一个重要参数。当碰撞角度小于最大磨损发生角时,磨损率随飞灰粒子碰撞角度的增大而增大;当碰撞角度大于最大磨损发生角时,磨损率随飞灰粒子碰撞角度的增大而减小。图7所示为管束偏斜角度分别为1.6°,3.2°和6.5°时,第二与第三列管排(图2)通道间沿x轴正方向流体中10组不同粒径的飞灰对偏斜管的平均碰撞角度。前面提到的粒子平均直径为14 μm,从图7可看出:粒径在14 μm左右的颗粒平均碰撞角更接近于25°的磨损最大发生角,这表明随着管排偏斜角增大,更多的颗粒碰撞角接近于磨损最大发生角。

图7 不同粒径飞灰的平均碰撞角度分布曲线

Fig.7 Average impingement angle of fly ash with different diameters

2.3 磨损计算结果分析

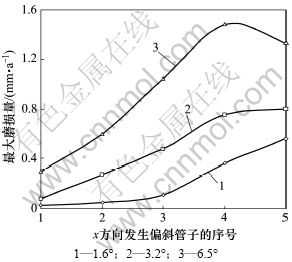

图8所示为不同偏斜角度下,偏斜管排上每根锅炉管最大磨损速率分布曲线图。由于第一根管迎风面受到颗粒碰撞量较多,与管排偏斜无关,故图中未标出。计算结果表明:最大磨损速率位于偏斜管排末端管束上,当偏斜角度为1.6°和3.2°时,最大磨损速率出现于末端最后一根管上,分别为0.58 mm/a和0.79 mm/a;而偏斜角增大到6.5°时,最大磨损速率出现于倒数第二根管,达到1.48 mm/a,相比1.6°时增大了约155%。可见:随着管排偏斜角度的增多,磨损速率明显增大。生产实际中,偏斜管排均为小角度偏斜。通过与未偏斜管束比较得知偏斜管束的平均磨损速率约为1 mm/a,模拟结果与工程实际基本吻合,但由于模拟中颗粒形状及粒径分布等与工程实际存有一定差异导致结果有小的误差。随着偏斜角度的增大,管束磨损加剧。因此,提高管排的安装精度及改善运行工况避免管排发生偏斜均能减小锅炉管束的磨损量。

图8 偏斜管最大磨损速率分布曲线

Fig.8 Maximum erosion rate of deflected tubes

3 结论

(1) 管束的偏斜造成通道内流体速度增大,最大流体速度由偏斜1.6°时的16 m/s增至偏斜6.5°时的20 m/s,增加了25%,而不同粒径飞灰碰撞速度也有所 增大。

(2) 管束偏斜也使相关通道内飞灰浓度增大,偏斜角从1.6°增加到6.5°时,最大飞灰质量浓度由5.8 g/m3增至6.8 g/m3,增加了17%。

(3) 随着管束偏斜角度增大,偏斜管上的磨损速率明显增大,最大磨损速率由偏斜1.6°时的0.58 mm/a增至偏斜6.5°时的1.48 mm/a,增加了155%。

参考文献:

[1] 岑可法, 樊建人, 池作和, 等. 锅炉和热交换器的积灰、结渣、磨损和腐蚀的防止原理与计算[M]. 北京: 科学出版社, 1994: 4-5.

CEN Ke-fa, FAN Jian-ren, CHI Zuo-he, et al. Prevention theory and calculation of ash accumulation, slagging, erosion and corrosion of boiler and heat exchanger[M]. Beijing: Science Press, 1994: 4-5.

[2] 陈丽华, 金军, 樊建人, 等. 电站锅炉受热面管束防磨技术的研究[J]. 中国电机工程学报, 1999, 19(7): 67-71.

CHEN Li-hua, JIN Jun, FAN Jian-ren, et al. Study on the erosion protection technique for the boiler tube bundles of power plant[J]. Proceedings of the CSEE, 1999, 19(7): 67-71.

[3] Mbabazi J G, Sheer T J, Shandu R. A model to predict erosion on mild steel surfaces impacted by boiler fly ash particles[J]. Wear, 2004, 257(1): 612-624.

[4] Mbabazi J G, Sheer T J. Computational prediction of erosion of air heater elements by fly ash particles[J]. Wear, 2006, 261(1): 1322-1336.

[5] Tabakoff W, Kotwal R, Hamed A. Erosion study of different materials affected by coal ash particles [J]. Wear, 1979, 52(1): 161-173.

[6] Grant G, Tabakoff W. Erosion prediction in turbo machinery resulting from environmental solid particles[J]. Aircraft, 1975, 12(1): 471-478.

[7] Nagarajan R, Ambedkar B, Gowrisankar S, et al. Development of predictive model for fly-ash erosion phenomena in coal-burning boilers[J]. Wear, 2009, 267(1): 122-128.

[8] Byeong E L, Fletcher C A J, Behnia M. Computational study of solid particle erosion for a single tube in cross flow[J]. Wear, 2000, 240(1): 95-99.

[9] Masoud R, Abbas K, Seyed M S. CFD modeling of a boiler’s tubes rupture[J]. Applied Thermal Engineering, 2006, 26(1): 2192-2200.

[10] Oka Y I, Okamura K, Yoshida T. Practical estimation of erosion damage caused by solid particle impact. Part 1: Effects of impact parameters on a predictive equation[J]. Wear, 2005, 259(1): 95-101.

[11] Molinari J F, Ortiz M. A study of solid-particle erosion of metallic targets[J]. International Journal of Impact Engineering, 2002, 27(1): 347-358.

[12] Das S K, Godiwalla K M, Shubha S, et al. A mathematical model to characterize effect of silica content in the boiler fly ash on erosion behavior of boiler grade steel[J]. Journal of Materials Processing Technology, 2008, 204(1): 239-247.

[13] Oka Y I, Mihara S, Yoshida T. Impact-angle dependence and estimation of erosion damage to ceramic materials caused by solid particle impact[J]. Wear, 2009, 267(1): 129-135.

[14] 嵇峰, 樊建人, 任安禄, 等. 气固两相圆柱绕流转捩两种模式的三维直接数值模拟[J]. 中国电机工程学报, 2006, 26(23): 55-60.

JI Feng, FAN Jian-ren, REN An-lu, et al. Three-dimensional direct numerical simulation of circular cylinder wake transition in gas particle flow[J]. Proceedings of the CSEE, 2006, 26(23): 55-60.

[15] 王则力, 罗坤, 樊建人. 颗粒与顺列管束磨损的数值模拟[J]. 工程热物理学报, 2008, 29(9): 1518-1520.

WANG Ze-li, LUO Kun, FAN Jian-ren. Numerical study of the particulate erosion on aligned tube bank[J]. Journal of Engineering Thermophysics, 2008, 29(9): 1518-1520.

[16] Frank T H, Schade K P, Petrak D. Numerical simulation and experimental investigation of a gas-solid two-phase flow in a horizontal channel[J]. Int J Multiphase Flow, 1993, 19(1): 187-198.

(编辑 杨幼平)

收稿日期:2010-11-02;修回日期:2011-02-24

基金项目:国家自然科学基金资助项目(20876146)

通信作者:李相鹏(1977-),男,湖南宁乡人,博士,副教授,从事热能工程、化工过程等数值模拟与优化研究;电话:0571-88320474;E-mail: rocleexp@zjut.edu.cn