超音速吹灰及其引起的锅炉管束磨损模拟分析

李相鹏,汪蓉梅,蓝立伟

(浙江工业大学 机械工程学院,浙江 杭州,310032)

摘要:采用数值模拟方法和经典磨损模型对超音速吹灰过程气固两相流分布及其引起的锅炉管束磨损进行模拟分析,研究喷口与管排相对位置的影响。并采用文献试验结果对数值模型进行验证。模拟结果表明:在研究吹灰压力条件下,喷口气流马赫数达到1.6,接近管排处,最大射流速度达到283.91 m/s以上。颗粒的平均碰撞速度和平均碰撞角度随喷口轴线与管排距离的减小而增大。颗粒碰撞频率在射流与管排相切(c位置)吹扫时最大。相切吹扫时造成管排的磨损速率也最大,最大值比其余4个位置吹扫时大2.74倍以上,当喷口轴线与管排不相交(d和e位置)吹扫时,磨损速率明显减小。

关键词:吹灰;磨损;气固两相流;超音速射流

中图分类号:TK223.3 文献标志码:A 文章编号:1672-7207(2013)08-3179-07

Simulation analysis of tubes erosion induced by supersonic soot blowing in boiler

LI Xiangpeng, WANG Rongmei, LAN Liwei

(College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract:The influences of different jet positions in 600 MW boiler were simulated and analyzed using Classical wear model with numerical simulation method. The results show that the nozzle Mach is 1.6 in jet pressure, the jet speed is more than 283.91 m/s close to the nozzle. The average impact velocity, and angle of impact particle is increase when the distance of the axis line of nozzle with the tube decreases. When the axis line of nozzle is tangent to tube (position c) the number of impact particle is most. And the speed of erosion is also the most as the axis line of nozzle is tangent to tube, the maximum value is more 2.74 times than the one in the other four positions. When the axis line of nozzle and the tube do not intersect (position d, e), the speed of erosion reduces quickly.

Key words: soot blowing; erosion; gas-solid two-phase flow; supersonic jet

锅炉作为火力发电厂三大主要设备之一,在燃煤锅炉中,容易形成锅炉受热面的沾污、结渣和积灰。为了减缓这种现象电站锅炉多采用超音速吹灰的方式清洁受热面,以提高锅炉安全经济性。吹灰是指锅炉运行时利用蒸汽或水、压缩空气、声波等的能量清除锅炉受热面烟气侧的积灰和结渣的过程。然而,在吹灰过程中,吹灰射流卷吸夹带飞灰颗粒高速冲刷炉管壁面,将引起炉管磨损严重,出现泄漏和爆管现象。因锅炉受热面飞灰碰撞磨损爆管而停炉的事故占锅炉总事故的45%~50% [1]。锅炉受热面设计工作寿命一般为100 kh,而许多锅炉在实际运行5~20 kh后,部分受热面就发生严重磨损,导致爆管泄漏事故[2]。锅炉管过早破损及因此而造成的停炉检修,将给电厂造成巨大经济损失。因此,针对含灰气流对锅炉受热面冲击磨损的研究具有重要意义。国内外已有许多学者对气固两相流中颗粒与壁面发生碰撞而造成磨损的问题进行了实验和模拟研究。Tabakoff等[3]对各种金属材料在常温以及高温下受颗粒高速冲击的问题进行了大量的实验研究,并得到了一些工程实际计算可用的回归经验公式。Mbabazi等[4-5]使用3种形状、粒径分布和化学成分有很大不同的电站飞灰粒子测定了粒子碰撞速度和碰撞角度对金属表面磨损的影响。根据实验数据及理论分析提出了一预测磨损速率模型。Nagarajan等[6]通过使用3种不同电站飞灰粒子研究了飞灰物性和运动特征对3种低合金钢造成磨损的作用。Oka等[7-8]研究了碰撞参数对磨损的影响。认为碰撞速度和粒子尺寸是相互独立的,碰撞速度对磨损的影响与粒子尺寸无关而与粒子物性和材料硬度有关。Meng等[9]研究了粒子转动对磨损的影响。Das等[10]研究了硅含量对磨损的影响。嵇峰等[11-12]通过对颗粒与管束的碰撞磨损进行数值模拟,证实了颗粒对管壁的碰撞磨损与碰撞频率因子、碰撞速度和碰撞角度有关。岑可法等[1]运用计算机辅助优化数值试验方法,把多相流体力学原理和材料冲蚀磨损理论相结合,较成功的对换热管束受飞灰颗粒冲击的碰撞频率及磨损问题进行了数值试验,得到了一些新的结果,为材料的冲蚀磨损研究提出了一种新的研究方法。李相鹏等[13-14]对锅炉省煤器出口后包覆管的磨损进行了分析,得出受附壁效应的影响,后包覆管处靠近后墙和侧墙的烟气中飞灰浓度较大,同时,由于烟道尾部气流通道变窄,气流速度增大,使颗粒在后包覆管上的碰撞速度增大,并且提出了一系列防磨措施。同时对锅炉管排偏斜引起的磨损也进行了模拟分析,得出管排偏斜角1.6°增加到6.5°,管排通道内最大气流速度,管排通道内最大气流速度都有所增加,同时颗粒平均碰撞速度增大,较多颗粒平均碰撞角集中于最大磨损发生角附近,造成偏斜管束年磨损量有较大增加。目前对于飞灰碰撞引起的锅炉管束磨损研究方法已经比较成熟,针对相关因素对磨损速率的影响也已有较多研究。而针对超音速吹灰过程气固两相流场分布及其引起的锅炉管排磨损研究很少。通过对超音速吹灰条件下的飞灰颗粒冲刷管束磨损模拟分析,为生产实际探寻出一种即能保证有效清除积灰又不严重减少锅炉管使用寿命的合理吹灰方案,可实现锅炉的安全、高效、经济运行。本文作者以某电厂二期600 MW锅炉低温再热器为例,采用商用流体计算软件Fluent结合用户自定义函数(UDF)对喷口处于管排间5个不同位置时,进行了超音速射流吹扫管排数值模拟计算。从射流速度分布、颗粒平均碰撞速度、角度及颗粒碰撞数以及管壁的磨损方面进行了分析。

1 计算模型

1.1 建模

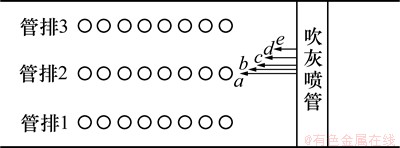

由于吹灰管在伸缩过程中,喷口与管排的相对位置将发生变化,因此吹灰射流携带颗粒碰撞引起炉管的磨损也将随之发生变化。模型采用在喷口处于管排2和3间5个不同位置进行吹扫时,对吹灰射流影响区域流场及管磨损进行模拟,以此分析喷口处于不同位置吹扫时射流流场及管排上磨损的变化情况。图2所示为计算区域模型,a表示喷管上喷口正对管排2第一根管壁面吹扫的位置,c表示喷口中心线与管排2壁面相切吹扫时的位置,e表示喷口中心线处于管排2与管排3中间吹扫时的位置,b和d分别表示喷口中心线处于a和c,c和e中间吹扫时的位置。

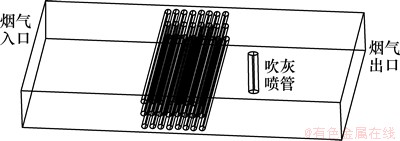

根据某电厂600 MW锅炉结构参数(见表1)为准,建立锅炉内吹灰区域简化的CFD模型,如图1所示。取3排8层管作为计算对象,取计算模型长为3 242 mm,宽为2 000 mm,高为426 mm。喷口中心距第1根管排顶点为吹灰间距,为330 mm。烟气流速取为8 m/s;吹灰压力为0.8 MPa。

图1 喷口位于不同位置吹扫示意图

Fig. 1 Schemes of jet at different positions

图2 计算区域模型

Fig. 2 Model of calculated regional

表1 锅炉结构参数

Table 1 Parameter of boiler structure

1.2 边界条件及磨损模拟方法

烟气入口设置速度入口边界;烟气出口设置压力出口边界; 吹灰喷口设为压力进口;管排及吹灰喷管均设为无滑移反弹壁面;在上、下、前、后共4个切面上施加对称边界。颗粒入口质量流量为0.026 43 kg/s,根据电厂飞灰物理性质[15],取密度均值ρ=2.1 g/cm3,G表示煤粉在筛孔尺寸为d的筛子筛后剩余量的质量分数,G45=55.1%,G80=22.7%,飞灰粒径0.3~200 μm。在Fluent离散相模型中设置颗粒参数为:dmin=3×10-7 m,dmax=2×10-4 m,d50=4.95×10-5 m,分散系数为1.584,颗粒直径组数取10。采用离散颗粒(DPM)模型描述气固两相流动。离散颗额粒模型是把流体相视为连续相,用欧拉法描述流体的流动;颗粒视为离散相,采用拉格朗日法描述,根据牛顿运动定律直接追踪每个颗粒。Tabakoff等通过对煤灰颗粒冲蚀磨损金属材料进行了大量的实验研究,得到半经验模型。Tabakoff半经验模型对飞灰冲蚀磨损量具有较好的预测能力并已得到广泛的应用。

煤灰碰撞管壁磨损率的计算公式:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:k1=3.792 9×10-4,k12=-0.132 1,k3=1.7×10-8,k4=0.025 2;vp为颗粒与金属壁面的碰撞速度;α1为颗粒与金属壁面的碰撞角度;α0为最大磨损发生角,α0=25°。模拟采用VC++编写的用户自定义函数(UDF)将Tabakoff经验公式编译成Fluent求解器能够调用的子程序。自定义函数通过编译导入计算模型,湍流采用可实现k-ε湍流模型。

2 模型验证

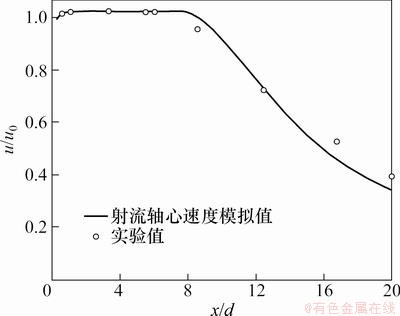

2.1 湍流模型验证

图3所示为模拟得到的射流中心轴线上速度与清华大学气动中心实验值[16]的比较,图中横坐标为射流x轴坐标值与喷嘴直径d的比值,纵坐标为轴心线上速度与流场最大速度的比值。二者吻合较好,证明了射流计算模型的准确性。

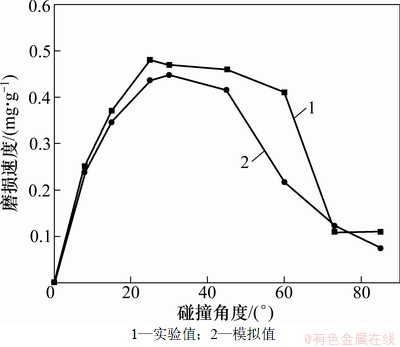

2.2 磨损模型验证

以Tabakoff半经验公式为冲蚀磨损计算公式,应用Fluent软件模拟Schade等[17]实验条件下颗粒的冲蚀过程。将模拟计算得到的磨损速率值与实验值进行比较,以此检验在Fluent中应用Tabakoff磨损公式计算颗粒冲蚀磨损过程模拟方法的正确性。图4所示为模拟8个不同冲蚀角度下,Schade实验所得颗粒磨损速率及相同碰撞条件下数值模拟计算所得颗粒平均磨损速率。通过比较可知,颗粒磨损速率随冲蚀角度的变化模拟计算值与实验值基本吻合。只在60°冲蚀角时磨损速率存在较大差异,颗粒磨损速率实验测得值为0.44 mg/kg,而模拟计算值为0.21 mg/kg。其主要原因是由于颗粒冲蚀磨损的影响因素众多,在模拟计算时对部分因素进行了简化甚至忽略,如将有棱角的飞灰颗粒简化为球形颗粒,忽略颗粒转动对磨损的影响等。这是颗粒磨损速率模拟计算值小于实验值的主要原因。此验证说明将该磨损模型引入Fluent模型是准确可行的。

图3 亚音速射流速度模拟值与实验值的比较

Fig. 3 Comparison of simulation value with experimental

图4 平均磨损速率随冲蚀角度的变化

Fig. 4 Change of rate in average erosion with angle value of jet speed in subsonic

3 计算结果分析

3.1 气固两相相流场分布

射流自喷口进入空间后,由于飞灰颗粒的不规则运动,特别是颗粒的横向脉动速度所引起的与周围介质的动量交换,使周围介质流动,导致射流质量增加,宽度变大,射流的速度逐渐减小。因此核心区越来越小,而边界层则越来越厚。

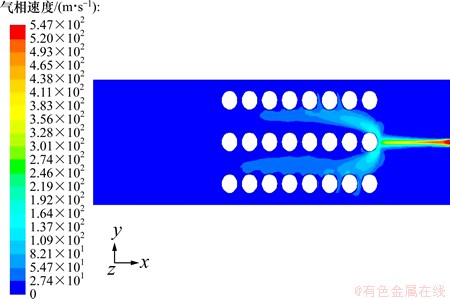

图5所示为喷口处于a位置时管段区截面的气相速度云图。从图5可以看出:喷口处射流最大速度达547 m/s,射流核心区逐渐减小直至消失,在开始区域射流宽度基本维持原状,而在基本区域射流宽度增加明显。当喷口正对管排吹扫时,射流撞击管壁后原始射流被分成两股支流,每股支流的动能与原始主流相比有较大的减小,因此射流在x轴负方向的影响范围也随之减小。

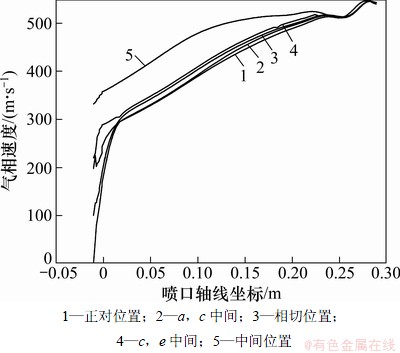

图6所示为喷口分别处于两管排间不同位置吹扫时,喷口至第1根管壁间轴线上的速度曲线。从图6可以看出:射流喷出后,a,b,c和d轴向速度曲线在x轴坐标0.29~0.014 m段变化趋势基本相似,喷口处射流最大速度达547 m/s,射流过程中气速减小,气相速度值随着喷口偏离管排2距离的增大有少量的增大,在拐点处(x轴坐标0.014 m),a,b,c,d和e处气相速度分别为283.91,288.67,289.11,301.41和373.26 m/s。当射流运动至管壁附近时(x轴坐标0.014~-0.01 m)气相速度均出现大幅降低。其中,曲线e轴向气相速度沿x轴负方向减小趋势较平缓。由此说明,喷口与管束相对位置对射流运动有重要影响,当管束处于喷口射流轴心线上时射流速度衰减幅度最大,当射流喷口位于两排管中间时其轴向速度所受管阻滞作用最小。结合气相云图分析可知,管排离喷口轴线位置越近,射流在管段区x轴负方向影响,范围越小且冲刷作用集中在离喷口较近的几根管壁面。

图5 a位置吹扫时,管区射流气相速度云图

Fig. 5 Contours of gas velocity in sweep of position a

图6 喷口位于不同位置吹扫时喷口轴线速度曲线

Fig. 6 Curve of spout speed of axis in different sweep position

3.2 颗粒运动特性

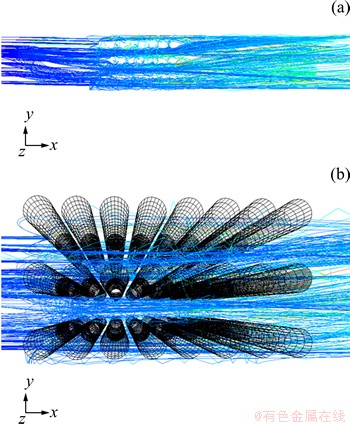

锅炉内飞灰颗粒对锅炉管壁的碰撞是造成炉管壁面磨损的主要原因。而超音速射流对射流附近的飞灰具有卷吸能力并在自身速度迅速衰减的同时将大部分动量传递给飞灰,对飞灰起到加速作用。因此,锅炉内部处于吹灰状态时,在吹灰影响范围内的炉管壁面受到飞灰粒子碰撞的数量将增多,碰撞速度也将变大。从Tabakoff磨损预测公式可以知道,单个颗粒对管壁面的冲蚀磨损与颗粒的碰撞速度及颗粒与壁面的碰撞角度有关。颗粒的碰撞速度越大,其造成壁面的磨损率越大。当颗粒碰撞角度小于磨损最大发生角(25°)时,颗粒碰撞角度越大,颗粒冲蚀磨损速率越大;当颗粒碰撞角度大于磨损最大发生角时,颗粒碰撞角度越大,颗粒冲蚀磨损速率越小。图7所示为d位置吹灰时稳态下锅炉内飞灰运动轨迹,此时喷口轴线与管排2不相交,射流中心处于两管排通道间流动,从运动轨迹图中可以看出:飞灰颗粒对各管排均有不同程度的冲刷磨损,由于射流正前方无管束阻滞,颗粒对两管排内侧冲刷较均衡。

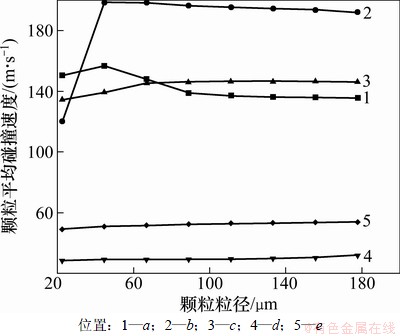

图8所示为喷口处于管排间5个不同位置吹扫时,不同粒径颗粒与磨损最严重管壁的统计平均碰撞速度。由于最大及最小组粒径颗粒总量的比例均很小,所以图8只选取中间8组粒径颗粒的统计值进行比较。从图8可以看到:喷口处于b位置时,多数颗粒组的平均碰撞速度约为190 m/s;喷口处于a和c位置时,各组颗粒的平均碰撞速度约为140 m/s;喷口处于d和e位置时,颗粒的平均碰撞速度分别约为30和50 m/s。

图7 锅炉内飞灰运动轨迹

Fig. 7 Fly ash track in boiler

图8 不同位置吹扫时颗粒的平均碰撞速度

Fig. 8 Average collision speed of particle at different position

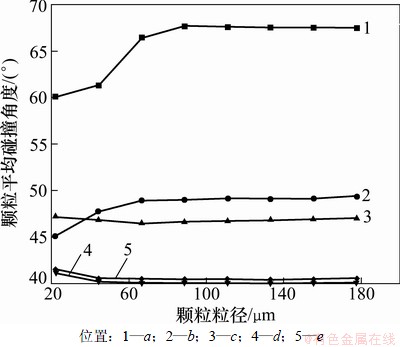

图9所示为喷口处于管排间5个不同位置吹扫时,不同粒径颗粒的统计平均碰撞角度。从图9可见:所有颗粒的平均碰撞角度均大于磨损最大发生角。喷口正对管排2(a位置)吹灰时,各组颗粒平均碰撞角度最大,约为67°。随着喷口偏离管排2移至两排管中间吹扫时,颗粒与磨损最严重管壁面的碰撞角逐渐减小至约40°。

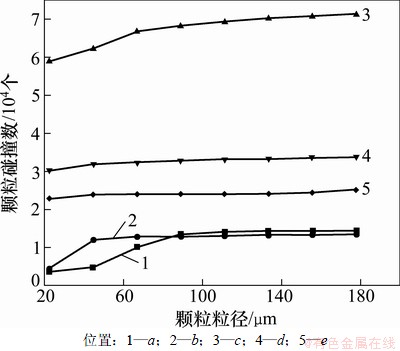

图10所示为喷口处于管排间5个不同位置吹灰时,1 s时间内与磨损最严重管壁面发生碰撞的颗粒数。由于与管壁发生碰撞的颗粒数众多,为减小统计输出结果文件大小,统计函数中采用颗粒碰撞数每增加10个记录输出一次数据的方法。从图10可以看到:当喷口处于c位置吹扫时即喷口轴线与管排2壁面相切位置,与管发生碰撞的颗粒数最多,各组粒径颗粒数约为7万个。当喷口处于a和b位置吹扫时,与磨损最严重管壁面碰撞的各组粒径颗粒数约为1.2万个。当喷口处于d和e位置吹扫时,与磨损最严重管壁面碰撞的各组粒径颗粒数分别约为3.4万及2.4万个。

图9 不同位置吹扫时颗粒的平均碰撞角度

Fig. 9 Average collision angle of particle in different sweep sweep position

图10 不同位置吹扫时各组颗粒碰撞数

Fig. 10 Number of each particle collisions at different sweep position

3.3 管壁磨损结果分析

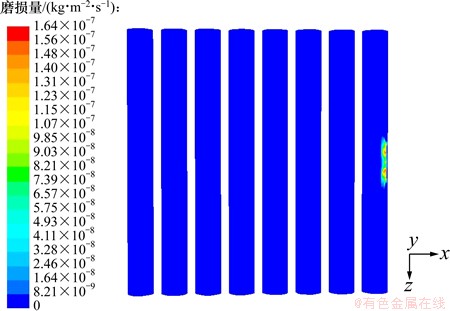

当喷口处在a,b和c位置时,管排2受到磨损较明显,其中a位置吹扫时管壁面磨损最大值为3.97×10-8 kg/(m2·s),磨损位置集中于第1根管喷口正对部位。从图5也能发现:气相射流冲刷管的部位与磨损云图中磨损部位相对应。b位置吹扫时,管排最大磨损量为5.98×10-8 kg/(m2·s),最大磨损量位置依然集中于第1根管中间部位,但与a位置吹扫磨损图相比,最大磨损部位在管壁面向y轴正方向发生偏移。图11所示为c位置吹扫时磨损分布云图,管排最大磨损量为1.64×10-7 kg/(m2·s)。

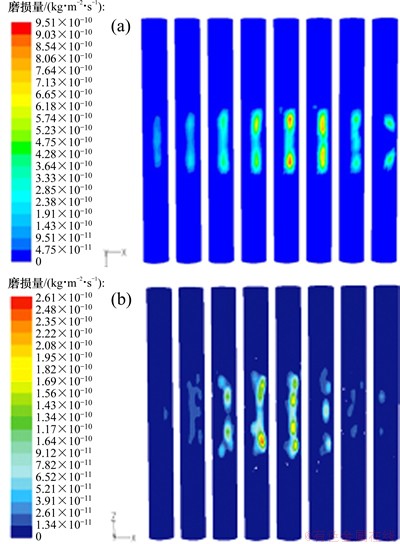

当喷口处在d和e位置时,管排2和3均受到磨损。d位置吹扫时(磨损分布云图如图12所示),管排2的8根管均有不同程度的磨损,主要磨损部位集中在第3和4根管壁面上,最大磨损量为9.51×10-10kg/(m2·s);管排3中最大磨损量为2.68×10-10 kg/(m2·s),主要磨损部位集中在第4和5根管壁面。e位置吹扫时,管排2磨损部位集中在最后3根管壁面,最大磨损量为2.13×10-9 kg/(m2·s);管排3上磨损状况与管排2相类似,而最大磨损量有微小增加为2.9×10-9 kg/(m2·s)。

图11 c位置吹扫时管排2磨损分布

Fig. 11 Contours of erosion in tube 2 at sweep position c

图12 d位置吹扫时,管排2和管排3磨损分布

Fig. 12 Contours of erosion in tube 2 and tube 3 in sweep position d

4 结论

(1) 在研究吹灰压力条件下,喷口气流马赫数达到1.6,射流过程中气速减小,喷口处达547 m/s,在拐点前气速减小趋势缓慢,拐点后气速大幅降低,在拐点处(x轴坐标0.014 m),a,b,c,d和e气相速度分别为283.91,288.67,289.11,301.41和373.26 m/s。

(2) 从颗粒的平均碰撞速度而言,喷口轴线与管排2相交(即a,b和c 3个位置)吹扫比不相交(即d和e位置)吹扫的大,其中b位置时颗粒平均碰撞速度达到最大。颗粒对管壁的碰撞角度随着喷口轴线与管排2偏离距离的增大而变小但都大于最大磨损发生角。当喷口轴线与管排2相交(即a,b和c 3个位置)吹扫时,颗粒碰撞频率随着喷口轴线与管排2偏离距离而增大,其中c位置吹扫时为5个位置最大。

(3) 当喷口轴线与管排2相交(即a,b和c 3个位置)吹扫时,随着喷口轴线偏离管排2,管排2中第1根管壁的最大磨损量成增大的趋势。b位置吹扫时管壁最大磨损值是a位置吹扫时的1.5倍,c位置吹扫时管壁最大磨损值是b位置吹扫的2.74倍。而不相交吹扫时磨损量明显减小。

参考文献:

[1] 岑可法, 樊建人, 池作和, 等. 锅炉和热交换器的积灰、结渣、磨损和腐蚀的防止原理与计算[M]. 北京: 科学出版社, 1994: 4-5.

CEN Kefa, FAN Jianren, CHI Zuohe, et al. Prevention theory and calculation of ash accumulation, slagging, erosion and corrosion of boiler and heat exchanger[M]. Beijing: Science Press, 1994: 4-5.

[2] 陈丽华, 金军, 樊建人, 等. 电站锅炉受热面管束防磨技术的研究[J]. 中国电机工程学报, 1999, 19(7): 67-71.

CHEN Lihua, JIN Jun, FAN Jianren, et al. Study on the erosion protection technique for the boiler tube bundles of power plant[J]. Proceedings of the CSEE, 1999, 19(7): 67-71.

[3] Tabakoff W, Kotwal R, Hamed A. Erosion study of different materials affected by coal ash particles[J]. Wear, 1979, 52(1): 161-173.

[4] Mbabazi J G, Sheer T J, Shandu R. A model to predict erosion on mild steel surfaces impacted by boiler fly ash particles[J]. Wear, 2004, 257(1): 612-624.

[5] Mbabazi J G, Sheer T J. Computational prediction of erosion of air heater elements by fly ash particles[J]. Wear, 2006, 261(1): 1322-1336.

[6] Nagarajan R, Ambedkar B, Gowrisankar S, et al. Development of predictive model for fly-ash erosion phenomena in coal-burning boilers[J]. Wear, 2009, 267(1): 122-128.

[7] Oka Y I, Olmogi H, Hosokawa T, et al. The impact angle dependence of erosion damage caused by solid particle impact[J]. Wear, 1997, 203(1): 573-579.

[8] Oka Y I, Mihara S, Yoshida T. Impact-angle dependence and estimation of erosion damage to ceramic materials caused by solid particle impact[J]. Wear, 2009, 267(1): 129-135.

[9] Meng H C, Ludema K C. Wear models and predictive equations: their form and content[J]. Wear, 1995, 181(1): 443-457.

[10] Das S K, Godiwalla K M, Shubha S, et al. A mathematical model to characterize effect of silica content in the boiler fly ash on erosion behavior of boiler grade steel[J]. Journal of Materials Processing Technology, 2008, 204(1): 239-247.

[11] 嵇峰, 樊建人, 任安禄, 等. 气固两相圆柱绕流转捩两种模式的三维直接数值模拟[J]. 中国电机工程学报, 2006, 26(23): 55-60.

JI Feng, FAN Jianren, REN Anlu, et al. Three-dimensional direct numerical simulation of circular cylinder wake transition in gas particle flow[J]. Proceedings of the CSEE, 2006, 26(23): 55-60.

[12] 王则力, 罗坤, 樊建人. 颗粒与顺列管束磨损的数值模拟[J]. 工程热物理学报, 2008, 29(9): 1518-1520.

WANG Zeli, LUO Kun, FAN Jianren. Numerical study of the particulate erosion on aligned tube bank[J]. Journal of Engineering Thermophysics, 2008, 29(9): 1518-1520.

[13] 李相鹏, 蓝立伟, 高增梁. 600 MW机组锅炉管排偏斜引起的磨损模拟分析[J]. 中南大学学报: 自然科学版, 2012, 43(1): 159-164.

LI Xiangpeng, LAN Liwei, GAO Zengliang. Simulation analysis of tubes erosion induced by bundle deflexion in 600 MW boiler[J]. Journal of Central South University: Science and Technology, 2012, 43(1): 159-164.

[14] 李相鹏, 陈江, 高增梁, 等. 600MW机组锅炉省煤器出口后包覆管磨损分析[J]. 中南大学学报: 自然科学版, 2009, 40(2): 417-421.

LI Xiangpeng, CHEN Jiang, GAO Zengliang, et al. Erosion analysis of 600 MW boiler tubes at exit of economizer[J]. Journal of Central South University: Science and Technology, 2009, 40(2): 417-421.

[15] 左其武, 张殿印. 锅炉除尘技术[M]. 北京: 化学工业出版社, 2010: 2-9.

ZUO Qiwu, ZHANG Dianyin. The technology of boiler dedusting[J]. Beijing: Chemical Industry Press, 2010: 2-9.

[16] 谢峻石, 何枫. 应用FLUENT进行射流流场的数值模拟[R]. 北京: 清华大学工程力学系, 2009: 1-7.

XIE Junshi, HE Feng. The simulation of application for flow field in jet with FLUENT[R]. Beijing: Tsinghua University. The Department of Engineering Mechanics, 2009: 1-7.

[17] Schade K P, Erdmann H J, et al. Experimental and numerical investigation of particle erosion caused by pulverized fuel in channels and pipework of coal-fired power plant[J]. Powder Technology, 2002, 125(2): 242-250.

(编辑 陈爱华)

收稿日期:2012-10-11;修回日期:2012-12-30

基金项目:国家自然科学基金资助项目(20876146)

通信作者:李相鹏(1977-),男,湖南宁乡人,博士,副教授,从事热能工程、化工过程等数值模拟与优化研究;电话:0571-88320474;E-mail:rocleexp@zjut.edu.cn