文章编号: 1004- 0609(2005)04- 0584- 06

气固两相流雾化法制备微细不锈钢粉末

陈 刚, 苏 斌, 陈 鼎, 张福全, 陈振华

(湖南大学 材料科学与工程学院, 长沙 410082)

摘 要: 采用含有固体食盐颗粒的气固两相流雾化工艺制备不锈钢粉末, 并讨论了金属液流量、 固体介质流量、 气体介质流量以及气压等工艺参数对粉末粒度和形貌的影响。 研究结果表明: 在同等气体压力和流量的条件下, 与普通气体雾化相比, 气固两相流雾化所得不锈钢粉末具有更小的粒度和更好的球形度; 随着气体介质流量及压力的增加, 所制备的不锈钢粉末粒度越小, 粉末的分布更集中; 随固体介质盐流量的增大, 所得粉末的粒度呈现先减小后增大的趋势。 在熔体温度为1550℃~1600℃, 气体压力为0.9MPa, 气体介质流量为6m3/min, 金属液流量为42g/s, 盐流量为58g/s条件下, 制备出平均粒径为20μm和球形度良好的不锈钢粉末。

关键词: 气固两相流雾化; 不锈钢; 气雾化 中图分类号: TG146.23

文献标识码: A

Fabrication of fine stainless steel powder by gas and

solid dual-phase atomization

CHEN Gang, SU Bin, CHEN Din, ZHANG Fu-quan, CHEN Zhen-hua

(School of Materials Science and Engineering,Hunan University, Changsha 410082, China)

Abstract: A novel gas and solid dual-phase atomization technology with solid salt (NaCl) particles was used to fabricate the stainless steel powders. The effects of the liquid metal flow rate, the solid medium mass flow rate, the gas medium mass flow rate and gas pressure on granularity and morphology of the as-prepared stainless steel powders were discussed. The results show that the finer stainless steel powders with higher sphericity are produced by the gas and solid dual-phase atomization than those produced by the conventional gas atomization technology under the same gas pressure and flowing rate. The stainless steel powder becomes finer and the size distribution is narrower with the mass flow rate and pressure of gas medium increasing. With the increase of the solid medium mass flow rate, the mean size of the as-atomized stainless steel powder tends to decrease firstly and then increase. When the liquid metal temperature is 1550- 1600℃, the pressure of gas with flow rate of 6m3/min is 0.9MPa, the molten metal flow rate is 42g/s and the salt flow rate is 58g/s, the smooth and spherical stainless steel powders with the grain size of 20μm are prepared.

Key words: gas and solid dual-phase atomization; stainless steel; gas atomization

不锈钢粉末因具有优异的耐腐蚀性, 优越的成型性及良好的流动性[1]成为粉末冶金、 注射成形和涂料等行业中的重要原材料, 广泛地应用于粉末冶金机械零件, 汽车零部件, 飞机机翼过滤器和建筑, 交通运输, 食品工业, 医疗器械等领域[2- 4]。 且由于不锈钢熔点高, 粘度大, 普通雾化法制备微细不锈钢粉末存在较大的困难。 我国不锈钢粉末的生产主要是采用气雾化和水雾化, 但还没形成生产规模, 制得的不锈钢粉末的平均粒度为200μm左右, 因此微细不锈钢粉末主要靠进口[5]。 而世界主要不锈钢粉末的生产公司, 如日本太平洋金属公司, 瑞典Anval Nyby粉末公司和美国SCN金属制品公司等主要采用高压水雾化和气雾化法制粉, 由于在制备过程中水的压力达150MPa以上, 因此对生产设备有很高要求, 从而使得制备成本升高[6]。 本文作者采用自行发明的气固两相流雾化技术[7, 8], 制得了微细和球形度良好的不锈钢粉末, 且该工艺与水雾化和气雾化相比较具有微细粉末产出高和低能耗等优点, 可望发展成为一种制备微细不锈钢粉末的有效方法。

1 实验

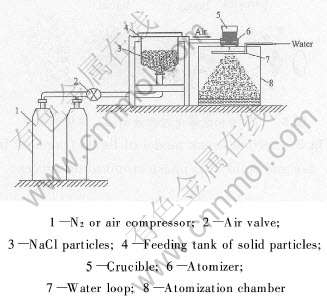

实验在自行设计的气固两相流雾化装置上进行, 实验装置如图1所示。

图1 气固两相流雾化装置示意图

Fig.1 Schematic diagram of gas and olid dual-phase atomization device

不锈钢采用中频炉熔炼, 温度为1550~1600℃, 气固两相流雾化用的固体介质颗粒为干燥的食盐(NaCl)颗粒, 并预先装入发送罐中。 雾化制粉时, 压缩空气瓶或罐装N2瓶发送的高速气流通过发送罐, 挟带罐中的食盐颗粒形成高压气固两相流, 从雾化器喷嘴的环缝中喷出, 对浇入漏包并从导液管中流出的不锈钢熔液进行雾化而制得粉末, 粉末经水环喷出的冷却水冷却, 落入雾化室底部的水中, 经过清洗、 过滤和干燥处理后, 得到纯净的不锈钢粉末。 作为对比研究的普通气雾化, 则是将发送罐置空, 雾化介质成为单一的气体。

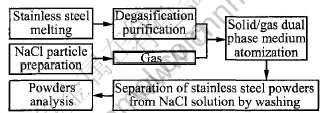

用KYKY- 2800型扫描电镜分析粉末形貌, 采用激光衍射粒度测定仪测定其粒度, 气固两相流雾化工艺流程如图2所示。

图2 气固两相流雾化工艺流程图

Fig.2 Flowchart of gas-solid medium tomization process

2 结果与讨论

2.1 金属液流量对粉末粒度的影响

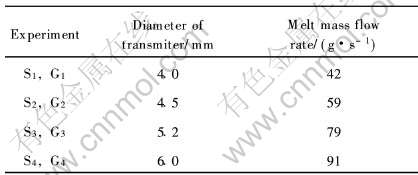

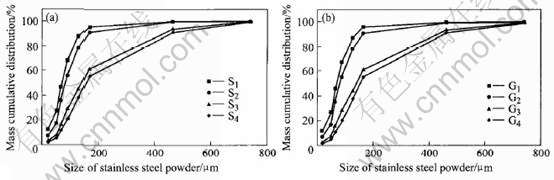

根据4次不同金属液流量, 分别采用了气固两相流雾化和气雾化进行对比实验, 将气固两相流雾化的实验编号分别标为S1, S2, S3, S4; 普通气体雾化标记为G1, G2, G3, G4, 气体压力均为0.7MPa, 其它工艺参数相同。 金属液流量通过采用不同的导液管直径进行控制, 各标号所对应的导液管直径与金属液流量如表1所列。

表1 不同直径导液管对应的金属液流量

Table 1 Melt mass flow rate of transmiter ith different diameter

图3所示为在金属液流量为42和59g/s, 其它工艺参数(如熔体过热度、 雾化气体压力)相同的条件下, 气固两相流雾化和相应的气雾化所制得的不锈钢粉末粒度的质量累计分布图。

图3 气固两相流雾化与气雾化所制得粉末粒度的质量累积分布

Fig.3 Mass cumulative distribution f stainless steel powders fabricated by as and solid dual-phase atomization and gas atomization

由图3可看出, 当喷嘴直径为4.0mm, 金属液流量为42g/s时, 固气双流雾化法制得粒径小于75μm的粉末达50%, 普通气雾化的仅为11.5%左右; 当金属液流量为59g/s时, 固气双流雾化法制得粒径小于75μm粉末含量为17.9%, 而普通气雾化的仅为5.5%。 这说明在雾化气体介质中添加NaCl颗粒后, 提高了对液流的冲击破碎力。 为研究两相流破碎模型, 首先分析单个颗粒撞击液体的情况。 当具有一定速度的固体颗粒撞击相对静止的金属液体表面时, 存在垂直撞击破碎和成一定角度撞击破碎两种方式。 垂直撞击时, 液体表面受到固体颗粒的冲击先产生凹陷, 然后在表面张力的作用下, 形成“雷利射流”, 射流继而破碎成为液滴, 整个过程可称之为“飞溅液滴形成模型”; 而当固体颗粒成一定角度撞击液体表面时, 表面液体受到冲击和剪切的双重作用, 液面刮削出波形附属部分, 附属部分在表面能的作用下形成液滴, 称之为“刮削液滴形成模型”。

初始液滴在聚焦处的二次雾化是决定最终粉末粒径的重要阶段, 对于普通气体雾化, 二次雾化在决定最终粒径时非常重要。 根据Gordon等研究二次破碎过程所建立的破碎模型, 雾化气流主要作用是增加液滴前沿压力, 使液粒变平, 压力继续增加则使液粒变成反置碗状, 最后中心越来越薄, 碗爆裂, 其边缘形成几个大液滴。 Yule等[9]完善了该模型, 当处于高气体韦伯数的情况下, 高速气流的冲击使得液滴在开始阶段变平而成为“碟状”, 然后在气流的进一步作用下变成类似“章鱼”的形状, 并最终破碎成细小的微滴(见图4)。

图4 气体雾化过程液滴的二次破碎模型

Fig.4 Second-break model of liquid fragment in gas atomization process

在气固两相流雾化过程的二次雾化阶段, 在雾化气体作用下所形成的反置碗状液滴将会被前述的大量固体颗粒碰撞, 碰撞促使初始液滴产生大量的飞溅刮削, 直至破碎(见图5)。 金属液体在气流和颗粒流的双重作用(即两相流的雾化下), 破碎更充分, 雾化效果更好。

图5 气固两相流雾化过程液滴的二次破碎模型

Fig.5 Second-break model of liquid fragment in gas and solid dual-phase atomization process

此外, 由于不锈钢的熔点高, NaCl的热膨胀系数为44×10-6/K, 因此当NaCl颗粒遇到高达1700℃的不锈钢熔液时, 迅速膨胀爆裂, 产生激烈的盐爆现象, 这也是气固两相流雾化细粉收得率高的原因之一。

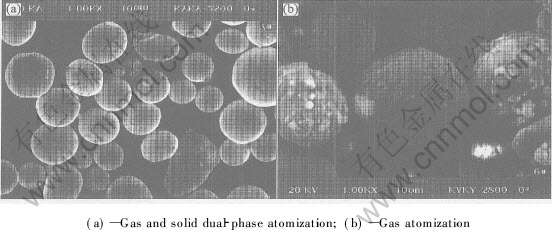

图6所示为金属液流量为42g/s时, 两种不同工艺所制备的不锈钢粉末形貌的SEM像。 由图6可见, 气固两相流雾化所得的不锈钢粉末比气雾化的细小且球形度高。 同时, 粉末颗粒表面洁净, 没有“卫星”颗粒粘附现象, 有利于提高粉末的流动性。

图7所示为气固两相流雾化及气雾化所制备的不锈钢粉末在不同金属液流量下的粒度累计分布。 从图7中可看出, 金属液流量对气固两相流雾化的影响较大, 粉末的平均粒度随液流量的减小而很快变细; 而气雾化受金属液流量的影响则不十分明显, 平均粒度为160μm左右, 说明普通的气雾化仅通过减少液流量难以使粉末变细。

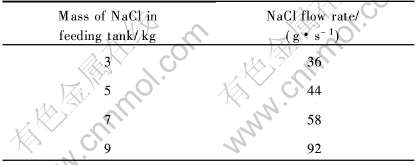

2.2 盐流量对粉末粒度的影响

当雾化气体压力为0.7MPa, 熔体温度为1550~1600℃, 金属液流量为42g/s时, 在粉末发送罐中分别装入3、 5、 7和9kg的NaCl颗粒, 使发送罐中的固体介质浓度增加, 从而使得气固两相流介质中固体介质盐流量也随之增加, 结果如表2所列。 所得粉末的粒度分布如图8所示。

图6 两种不同工艺所制得的不锈钢粉末形貌的SEM像

Fig.6 SEM morphologies of stainless steel powder fabricated by different technologies (melt flow rate 41.05g/s)

图7 气固两相流雾化及气雾化所制备不锈钢粉末在不同金属液流量下粒度的质量累积分布

Fig.7 Mass cumulative distribution of stainless steel powder fabricated by gas and solid dual-phase atomization(a) and gas atomization(b) at different melt flow rates

表2 不同装盐量所对应的盐流量

Table 2 NaCl flow rate corresponding to different mass in feeding tank

图8 不同盐流量时气固两相流雾化不锈钢粉末粒度的质量累积分布

Fig.8 Mass cumulative distribution of

stainless steel powder fabricated by gas and solid dual-phase atomization at different salt flow rates

从图8中可看出, 随盐量的增加所得粉末粒度越细小, 但当它增加到一定程度后, 所得不锈钢粉末粒度又呈增大的趋势, 这是因为在一定气体压力和流量下, 气固两相流中固体介质NaCl颗粒运动速度随浓度增加而降低。 当加入少量固体粒子时, 虽然固体粒子速度很高, 但是固体介质浓度低, 与液滴碰撞次数小, 不能充分破碎液流, 雾化过程主要由气体完成, 得到的粉末粒度和气体雾化所得粉末粒度相差不大。 当加入过多固体介质时, 分配到单个固体颗粒的能量变小, 速度减慢, 不能克服液滴的表面张力, 破碎效果不好, 同时也使气体速度降低, 雾化更不充分, 所得粉末粒度甚至比普通气体雾化的粉末还要粗, 因此只有当输送的固体介质既拥有足够击穿液滴的速度, 又有一定浓度, 能充分撞击撕裂金属液流时, 才能起到最佳的雾化效果[10]。

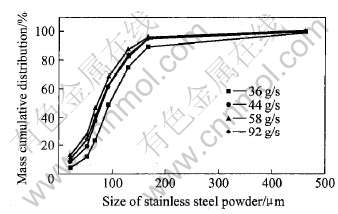

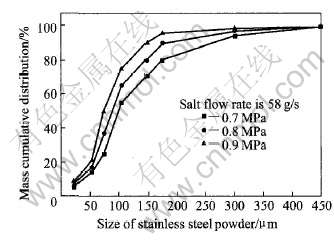

2.3 气体压力及流量对粉末粒度的影响

将雾化气压分别控制在0.7、 0.8和0.9MPa, 进行了气固两相流雾化实验, 盐流量均为58g/s, 所制得的不锈钢粉末粒度分布如图9所示。

图9 气固两相流雾化在不同气压时不锈钢粉末粒度的质量累积分布

Fig.9 Mass cumulative distribution of stainless steel powder fabricated by gas and solid dual-phase atomization at different gas pressures

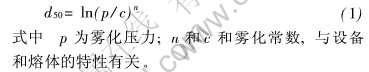

在实验气压范围内, 随气压的增大, 所得粉末的平均粒度越细小, 且粒度分布范围更集中。 筛分析结果表明, 当气压增加了0.1MPa, 45~75μm的粉末增加10%左右, 中位径d50减少了6~8μm。 Small等通过实验得到了气体雾化压力与粉末平均粒度的关系:

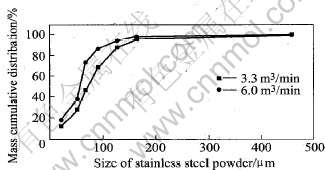

从实验结果分析可知, 式(1)在一定条件下同样适合于气固两相流雾化。 为了获得不同气流量, 采用空气压缩机和瓶装N2进行比较, 气压均保持为0.7MPa, 喷嘴直径为4.0mm, 温度为1550℃~1600℃, 气流量分别为6.0和3.3m3/min, 所得不锈钢的粉末粒度分布如图10所示。

图10 气固两相流雾化不锈钢粉末在不同气流量时粒度的质量累积分布

Fig.10 Mass cumulative distribution of stainless steel powder fabricated by gas and solid dual-phase atomization at different gas flow rates

由图10可看出, 当气流量增大时, 粉末粒度随之减小, 在气流量为6.0m3/min 时, 0~200μm的粉末为90%, 小于74μm的粉末量达80%, 比气流量为3.3m3/min 时的细粉率增加30%。

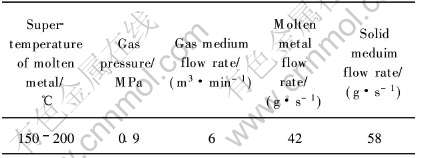

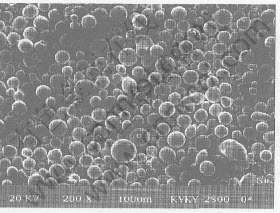

据上所述, 本文作者采用以食盐为固体介质的气固两相流雾化工艺(工艺参数如表3所列), 制备了平均粒度为20μm, 球形度良好的微细不锈钢粉末, 粉末的SEM像如图11所示。

表3 气固两相流雾化制备微细不锈钢粉末的工艺参数

Table 3 Process parameters of preparing fine stainless steel powders by gas and solid dual-phase atomization

图11 气固两相流雾化制备微细不锈钢粉末的SEM像

Fig.11 SEM morphology of fine stainless steel powder fabricated by gas and solid dual-phase atomization

2.4 雾化后粉末中的氯离子的浓度

由于Cl-对不锈钢产生点腐蚀[11], 且点腐蚀一旦萌生, 就可能以自持的机理扩散[12], 因此分析粉末的纯度是必要的。 采用实验S1, G1以及S2, G2所得不锈钢粉末为分析对象, 经化学分析, 不同雾化方式得到的粉末中残余Cl-含量如表4所列。 从表4中可看出, 气固两相流雾化粉末经水洗处理后, 粉末中Cl-残余含量相对气雾化的要高一些, 但是总体含量仍很低。

表4 不同雾化方式得到的粉末中残余Cl-含量

Table 4 Content of residual Cl- by different atomization methods(mass fraction, %)

3 结论

1) 在同等气体压力和流量的条件下, 气固两相流雾化所得不锈钢粉末和普通气体雾化所得的相比, 粉末粒度更小, 球形度更好。

2) 气固两相流雾化介质的密度由于固体盐颗粒的加入而得到了提高, 从而提高了雾化介质的动能。 固体颗粒的撞击粉碎和爆裂粉碎为液体雾化重要机制。

3) 在气固两相流雾化过程中, 随着气体介质流量及压力的增加, 所制备的不锈钢粉末粒度越小, 粉末分布更为集中。 随盐流量的增大, 所得粉末粒度越细小, 但当盐流量增加到一定程度后, 所得粉末粒度又呈增大的趋势。

4) 在熔体过热温度为150~200℃, 气体压力为0.9MPa, 气体介质流量为6×10-3 m3/min, 金属液流量为42g/s, 盐流量为58g/s的条件下, 可制备出平均粒径为20μm, 球形度良好的不锈钢粉末。

5) 所添加的NaCl可通过水洗有效去除, 不会过多影响粉末的纯度。

REFERENCES

[1] 唐纳德, 皮克纳, I M 伯恩斯坦. 不锈钢手册[M]. 北京: 机械工业出版社, 1987. 1019- 1043.

Peckner D, Bernstein I M. Handbook of Stainless Steels[M]. Beijing: Machine Industry Press, 1987. 1019- 1043.

[2] 曹勇家. 金属注射成型用不锈钢[J]. 粉末冶金技术, 2000, 8(4): 274- 282.

CAO Yong-jia. Metal injection molding of stainless steels[J]. Powder Metallurgy Technology, 2000, 8(4): 274- 282.

[3] 何 朋, 王均安, 徐新平. 粉末冶金制备不锈钢的研究及发展[J]. 金属热处理, 2004, 29(7): 1- 5.

HE Peng, WANG Jun-an, XU Xin-ping. Research and development of powder metallurgy for stainless steels[J]. Heat Treatment of Metals, 2004, 29(7): 1- 5.

[4] Wohlfromm H, Blomacher M, Weinand D. 粉末注射成形不锈钢——制取工艺、 性能、 应用[J]. 粉末冶金工业, 2002, 12(4): 7- 15.

Wohlfromm H, Blomacher M, Weinand D. Powder injection molding of stainless steels—processing, properties, applications[J]. Powder Metallurgy Industry, 2002, 12(4): 7- 15.

[5] 王洪海. 不锈钢粉末的生产和应用[J]. 粉末冶金工业, 1992, 110(2): 24- 29.

WANG Hong-hai. The application and production of the stainless steels powder[J]. Powder Metallurgy Industry, 1992, 110(2): 24- 29.

[6] 东建中. 不锈钢粉的高压水雾化制作及应用[J]. 新材料产业, 2003, 4(1): 33- 35.

DONG Jian-zhong. The application of the stainless steels powder fabricated by high pressure water atomization[J]. Advanced Materials Industry, 2003, 4(1): 33- 35.

[7] 陈振华, 陈 刚, 康智涛, 等. 液体金属与合金的固体雾化方法[P]. 中国: ZL01106868.X, 2001, 1.

CHEN Zhen-hua, CHEN Gang, KANG Zhi-tao, et al. A Novel Atomization Technology of Melts and Alloy by Solid-atomization[P]. China: ZL01106868.X, 2001, 1.

[8] 陈振华, 陈 刚, 严红革, 等. 液体金属和合金的盐雾化[J]. 湖南大学学报(自然科学版), 2001, 28(4): 30- 34.

CHEN Zhen-hua, CHEN Gang, YAN Hong-ge, et al. A novel atomization technology of melts and alloy by solid salt particles[J]. Journal of Hunan University(Natural Science), 2001, 28(4): 30- 34.

[9] Yule A J, Dunkley J J. Atomization of melts for powder production and spray deposition[J]. Int Journal of Powder Met, 1996, 32(1): 70- 77.

[10] 陈振华, 陈 刚, 严红革, 等. 固气两相流雾化工艺规律[J]. 中国有色金属学报 , 2004, 14(2): 204- 209.

CHEN Zhen-hua, CHEN Gang, YAN Hong-ge, et al. Process regularities of gas-solid dual media atomization[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 204- 209.

[11] 肖纪美. 不锈钢的金属学问题[M]. 北京: 冶金工业出版社, 1983. 263- 264.

XIAN Ji-mei. Physical Metallurgy of Stainless Steel[M]. Beijing: Metallurgical Industry Press, 1983. 263- 264.

[12] A·约翰·塞德赖克斯. 不锈钢的腐蚀[M]. 北京: 机械工业出版社, 1986. 94- 95.

Sedriks A J. Corrosion of Stainless Steel[M]. Beijing: Mechanical Industry Press, 1986. 94- 95.

基金项目: 国家自然科学基金项目(50174035); 博士点基金资助项目

收稿日期: 2004- 10- 08; 修订日期: 2004- 12- 28

作者简介: 陈 刚(1965- ), 男, 副教授, 博士研究生.

通讯作者: 陈 刚, 电话: 0731- 8821487; E-mail: chengang@hunu.edu.cn

(编辑 李艳红)