文章编号:1004-0609(2011)12-3087-07

碳化钙骨架碳负极材料的制备及电化学性能

李姣姣,王先友,杨顺毅,龙晚妹,王 宏,白 俐,吴 强

(湘潭大学 化学学院 环境友好化学与应用教育部重点实验室,湘潭 411105)

摘 要:以碳化钙为原料、新鲜氯气为刻蚀剂,在400~700 ℃范围内制备碳化钙骨架碳作为锂离子电池新型负极材料。用X射线衍射(XRD)、扫描电镜(SEM)、氮气吸附实验、恒流充放电、交流阻抗(EIS)等对碳化钙骨架负极材料进行表征及电化学性能测试,并探讨制备温度对碳化钙骨架碳结构和电化学性能的影响。结果表明:所有温度下制备的碳化钙骨架碳均为无定形碳材料,但随着制备温度的升高,材料出现部分石墨化倾向;600 ℃制备的碳化钙骨架碳具有良好的电化学性能,在0.1 C充放电时,首次放电比容量为890.9 mA·h/g,可逆容量为335.4 mA·h/g,循环30次后的可逆容量为266.8 mA·h/g。

关键词:锂离子电池;负极材料;无定形碳;骨架碳;电化学性能

中图分类号:O646 文献标志码:A

Preparation and electrochemical performance of calcium carbide skeleton carbon anode material for lithium ion battery

LI Jiao-jiao, WANG Xian-you, YANG Shun-yi, LONG Wan-mei, WANG Hong, BAI Li, WU Qiang

(Key Laboratory of Environmentally Friendly Chemistry and Applications, Ministry of Education,

School of Chemistry, Xiangtan University, Xiangtan 411105, China)

Abstract: The calcium carbide-derived-carbon was synthesized from CaC2 in a freshly prepared chlorine environment at the temperature range of 400-700 ℃. The influences of temperature on the structure and electrochemical properties of calcium carbide-derived-carbon were studied, and the properties of sample were characterized by X-ray diffractometry (XRD), scanning electron microscopy (SEM), nitrogen sorption experiment, constant current charge-discharge and AC impedance, respectively. The results show that all the calcium carbide-derived-carbons are disorder carbon. The carbide-derived-carbon appears partly graphitization tendency with the increase of the temperature. The carbide-derived-carbon synthesized at 600 ℃ has good electrochemical performance. It delivers lithium insertion and deinsertion capacities of 890.9 mA·h/g and 335.4 mA·h/g, respectively, during the first cycle at a rate of 0.1 C, and the deinsertion capacity is 266.8 mA·h/g after 30 cycles.

Key words: Li-ion battery; anode material; disordered carbon; carbide derived-carbon; electrochemical performance

锂离子电池由于具有比能量高、充放电性能好、自放电小、循环寿命长、绿色环保等优点不但在移动电话、数码产品、笔记本电脑等便携式电子设备上得到了广泛的应用[1-4],而且在混合动力车、纯电动汽车等大型设备上也展示出越来越广阔的应用前景。锂离子电池能够迅速实现商品化得益于SONY公司1990年关于石墨材料研究的突破性进展[5]。目前,商品化的锂离子电池大多采用天然石墨或人造石墨作负极,但使用过程中发现天然石墨与电解液的相容性差[6],碳负极上易发生有机溶剂的不可逆分解和溶剂在石墨层间的共插入,导致石墨层的膨胀和收缩增大,从而影响其循环寿命;而人造石墨是由易石墨化碳在惰性气氛中高温(2 800 ℃以上)石墨化得到的,这样所得到的人造石墨可逆容量仅为300 mA·h/g左右[7],而且价格昂贵,因此,寻找比容量高且廉价易得的新型碳材料是目前锂离子电池负极材料研究的重点之一。无定形碳由于制备温度低(一般在500~1 200 ℃范围内),比容量较高[8-10],与电解液相容性较好,可在碳酸丙烯酯(PC)等有机电解液体系中正常工作等优点而备受研究者的青睐。目前见诸于文献并用作锂离子电池负极材料的无定形碳大多是有机物通过低温裂解而来,而用无机碳化物如碳化物骨架碳制备无定形碳,并应用于负极材料的研究则未见报道。

碳化物骨架碳是近年来发展进来的一种无定形新型多孔碳材料[11-12],该材料以碳化物(Mo2C、TiC、Ti2AlC等)[13-17]为前驱体,在150~1 650 ℃之间用卤素、超临界水蒸气或其它刻蚀剂将碳化物中的非碳原子逐层移出,得到骨架碳。并且通过控制工艺条件,可在原子级水平调控碳化物骨架碳的孔结构。碳化物骨架碳由于成本低、比表面积大、孔径分布窄且精确可调等优点,广泛用于分子筛、气体储存、催化剂、吸附剂、超级电容器、水/气体的净化及制药等领域。本文作者所在课题组近年来选择廉价的碳化钙为前驱体,新鲜制备的高活性氯气为刻蚀剂,采用低温一步法制备了碳化钙骨架碳[18](Calcium carbide derived carbon,CCDC),并将其应用于超级电容器中取得了良好的结果[19-20]。

本文作者根据锂离子电池对负极材料结构的要求,用碳化钙作碳源,新鲜制备的氯气作刻蚀剂制备碳化骨架碳作锂离子负极材料,讨论制备工艺条件对碳化钙骨架碳形貌、结构及电化学性能的影响。

1 实验

1.1 碳化钙骨架碳的制备

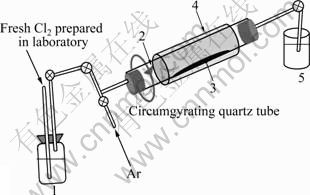

碳化钙样品(相对分子质量64.10 g/mol,密度2.22 g/cm)由Alfa Aesar提供。碳化物骨架碳的制备工艺示意图如图1所示。将研细的碳化钙粉末放入石英管 内,置于管式炉中。用三通管分别连接石英管、氩气瓶和氯气发生装置。通10 min的氩气排尽石英管内的空气,开启管式炉。继续通氩气至管式炉升温至设定的温度(400~700 ℃),然后改通反应气体—氯气。为了保证氯气的高活性,氯气是由浓盐酸和二氧化锰反应并直接使用。反应一定时间后,停止通入氯气,再次通入氩气至管式炉自然冷却至室温。将制得的CCDC用蒸馏水洗涤后,再用浓盐酸洗涤数次以除去未反应的CaC2,干燥备用。

图1 CCDC的制备装置图

Fig.1 Schematic diagram of CCDC preparation process: 1—Sulfuric acid; 2—Quartz tube; 3—CaC2; 4—Tube furnace; 5—Exhaust gas adsorption

1.2 材料的表征

采用日本理学D/Max-3C型X射线衍射仪(XRD)对负极活性物质进行结构分析,射线源为Cu Ka,管电流20 mA,管电压为36 kV,扫描速度为8 (°)/min,扫描范围10°~80°。用FEI Tecnai G2(加速电压200 kV)透射电镜(TEM)观察样品的形貌和微观结构。采用日本JEOL公司的型号为JSM-5600LV型扫描电子显微镜观察样品的颗粒尺寸和表面形貌。采用Quantachrome NovaWin2物理吸附仪,以液氮为吸附介质,77 K下进行吸附,测试之前样品在200 ℃真空下处理2 h。以BET法测算样品的比表面积。用上海辰华仪器公司生产的CHI660A电化学工作站进行交流阻抗测试,交流阻抗测试的频率范围为0.01 Hz~100 kHz,扰动振幅±5 mV。

1.3 电池的组装及性能测试

将活性物质、导电炭黑(SP)和聚偏氟乙烯 (PVDF)按质量比为 92:3:5的比例混合均匀,然后滴加适量的N-甲基-2-吡咯烷酮(NMP),超声波分散20 min后再搅拌20 min,然后将其均匀涂膏于铜箔上,于120 ℃真空干燥24 h。把干燥好的极片在充满氩气的手套箱(MIKROUNA 1220/750)中以金属锂片为负极,电解液为1 mol/L LiPF6的EC/DEC(体积比为1:1,韩国三星公司生产) 的混合液为电解液,聚丙烯多孔膜(Celgard2400)为隔膜组装成2025型扣式电池,采用深圳新威公司电池充放电测试系统对组装的模拟电池进行充放电测试,电压测试范围为0.01~2.0 V;用上海辰华公司的CHI660A电化学工作站进行交流阻抗测试,测试温度:(25±2) ℃。

2 结果与讨论

2.1 碳化钙骨架碳的结构分析

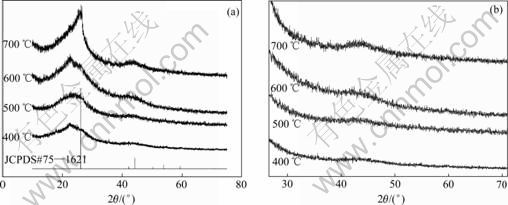

图2(a)所示为不同温度下制备的CCDC的XRD谱以及石墨的标准XRD谱。当合成温度为400和500 ℃时,CCDC的XRD谱在2θ≈26°和2θ≈44°有两个宽化的衍射峰,类似于石墨的(002)峰和(101)峰,表明在此温度下合成的CCDC为无定形结构;当合成温度为600 ℃时,(002)峰出现窄化的趋势,(101)峰逐渐明显;在700 ℃时,(002)峰明显变窄,CCDC出现了明显的石墨化倾向。上述结果表明在较高的反应温度下,碳原子排列趋于规则有序化。图2(b)所示为不同温度下制备的CCDC的XRD谱中(101)峰的放大图。

从图2(a)可见,尽管在400~700 ℃之间制备的CCDC皆为具有无定形结构的碳材料,但随着反应温度的升高,逐步有一定量的石墨微晶存在。

2.2 碳化钙骨架碳的形貌表征

图3所示为不同温度下制备的CCDC的TEM像。由图3可知,在400~700 ℃下制备的CCDC主要为无定形结构,由大量的微孔组成。这主要是因为在制备温度比较低时,碳原子扩散比较缓慢,稍微偏离CaC2晶格中碳原子的初始位置,所以主要形成无定形结构。当温度升高时,碳原子的扩散速率增大,逐渐向有序的碳结构转化。

图2 不同温度下合成的CCDC的XRD谱以及XRD谱中(101)峰的放大图

Fig.2 XRD patterns of CCDC prepared at different temperatures(a) and enlarged (101) peaks of CCDC prepared at different temperatures(b)

图3 不同温度下制备的CCDC的TEM像

Fig.3 TEM images of CCDC prepared at different temperatures: (a) 400 ℃; (b) 500 ℃; (c) 600 ℃; (d) 700 ℃

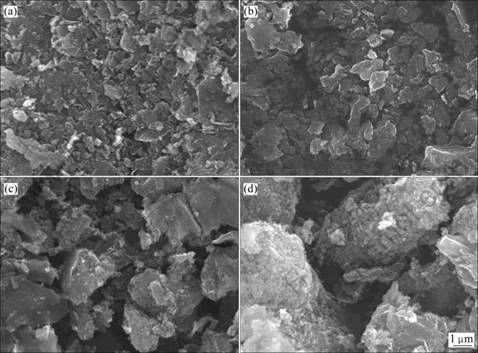

图4所示为不同温度下制备的CCDC的扫描电镜照片。由图4可知,随着温度的升高,CCDC的颗粒逐渐变大,这是因为随着温度的升高,碳原子获得的能量更多,发生的位移更显著,导致骨架碳形成较大的孔洞结构,所以颗粒明显变大。当CCDC的制备温度升高到700 ℃时,团聚现象明显,且粒径增大。

2.3 碳化钙骨架碳微孔结构分析

图5(a)所示为不同温度下合成的CCDC的氮气吸附等温线。根据IUPAC对于吸附等温线的分类,在所有温度范围内的吸附曲线均属于第Ⅳ类吸附等温线。由图5(a)可知,所有曲线的前半段在相对压力0~0.5范围内缓慢上升,吸附量变化不大。在等温线的后半段,由于毛细孔凝聚,随着压力的增大,发生多层吸附,吸附量迅增加速。吸附曲线和脱附曲线之间出现明显的滞后现象,这与碳材料沿(101)峰方向的堆垛有关,表明随着制备温度升高,CCDC的中孔含量增加。图5(b)所示为采用BJH法计算得到的不同温度下制备的CCDC的孔径分布曲线。在所有制备温度范围内,CCDC均表现出较窄的单峰孔径分布,孔径范围为1.9~17 nm。随着制备温度的升高,碳原子获得了更多的能量,排列趋于规整。孔径分布逐渐变窄,但平均孔径变大。将CCDC的比表面积(SBET)及孔结构参数列于表1。由表1可知,随着制备温度的升高,CCDC的比表面积逐渐下降, 平均孔径(dave)逐渐变大,总孔容逐渐减小。

图4 不同温度下制备的CCDC的SEM像

Fig.4 SEM images of CCDC prepared at different temperatures: (a) 400 ℃; (b) 500 ℃; (c) 600 ℃; (d) 700 ℃

图5 不同温度下制备的CCDC的氮气吸附等温线图及孔径分布图

Fig.5 Nitrogen adsorption isotherms(a) and pore size distribution(b) of CCDC prepared at different temperatures

表1 不同温度下制备的CCDC的孔结构参数

Table 1 Pore structure parameters of CCDC prepared at different temperatures

2.4 电化学性能分析

2.4.1 充放电曲线

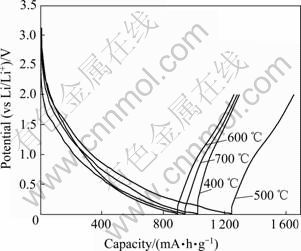

图6所示为不同温度下制备的CCDC在0.1 C首次充放电曲线。由图6可见,所有温度下制备的CCDC的首次放电曲线都为平滑的斜线,没有明显的放电平台。随着制备温度的升高,CCDC的首次充电比容量先逐渐增加,当制备温度为600 ℃时,其首次充电比容量达到最大,为335.4 mA·h/g,当制备温度继续升高到700 ℃,其首次充电比容量减小到319.7 mA·h/g。这主要是因为随着温度的升高,CCDC的平均孔径逐渐增大,孔径增大有利于有机电解质离子的扩散和锂离子的嵌入和脱嵌。但当温度升高到700 ℃,由图4可知,CCDC发生明显的团聚,从而导致首次充电比容量下降。所以,600 ℃制备的CCDC具有最佳的电化学性能。

图6 不同温度下制备的CCDC在0.1 C下的首次充放电 曲线

Fig.6 First charge-discharge curves of CCDC prepared at different temperatures and 0.1 C

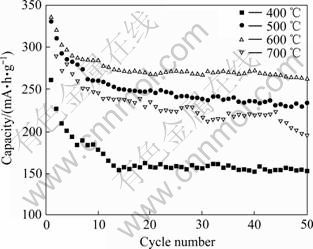

2.4.2 循环寿命

图7所示为不同温度下制备的CCDC在0.1 C电流密度下的循环寿命曲线。由图7可见,所有温度下制备的CCDC在前10个循环容量衰减较快,这主要是因为无定形碳材料微孔周围为不稳定的缺陷结构,锂在嵌入和脱嵌的过程中导致这些结构的破坏,这种破坏导致可逆容量发生衰减,10次循环后,CCDC的结构趋于稳定,容量衰减较少。其中,600 ℃制备的CCDC的可逆容量和循环性能最好,在0.1 C电流密度下,30次循环后可逆容量稳定在266.8 mA·h/g,而且保持平稳的状态。

图7 不同温度下制备的CCDC在0.1 C电流密度下的循环寿命曲线

Fig.7 Cyclic life curves of CCDC prepared at different temperatures and 0.1 C

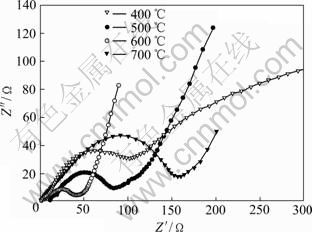

2.4.3 交流阻抗

图8所示为不同温度下制备的CCDC的Nyquist图。通常高频区的半圆半径的大小反应了材料表面的电化学反应电阻的大小,与材料表面SEI膜的形成直接相关。由图8可见,在400~700 ℃制备的样品的阻抗谱图均是由高频区的半圆和低频区的直线组成,其中600 ℃制备的CCDC代表容抗弧的半圆半径最小,表明600 ℃制备的CCDC形成SEI膜的电化学阻抗要远远小于其他温度的,因此,600 ℃制备的CCDC材料电荷传递及锂离子的嵌入和脱出容易得多,从而表明600 ℃制备的CCDC具有最好的电化学性能。

图8 不同温度下制备的CCDC的交流阻抗谱

Fig.8 AC impedance spectra of CCDC prepared at different temperatures

3 结论

1) 以碳化钙为前驱体,实验室制备的新鲜氯气为反应气体,在400~700 ℃的低温下制备了锂离子电池新型负极材料—碳化钙骨架碳。在制备温度范围内,材料呈现无定形碳结构。随着制备温度的升高,CCDC由明显的无定形结构转化为具有一定石墨化倾向的多孔碳结构,且CCDC的比表面积逐渐降低,孔径逐渐变大,总孔容逐渐下降。

2) 600 ℃制备的CCDC前10个循环容量衰减较快,之后容量趋于稳定,衰减比较少。在0.1 C下,首次放电比容量为890.9 mA·h/g,可逆容量容量为335.4 mA·h/g,不可逆容量最小。经30次循环后,容量稳定在266.8 mA·h/g,因此,600 ℃下制备的CCDC是一类有前景的锂离子电池新型负极材料。

REFERENCES

[1] RITCHIE A, HOWARD W. Recent developments and likely advances in lithium-ion batteries[J]. Journal of Power Sources, 2006, 162(2): 809-812.

[2] 林 燕, 高明霞, 李玉凤, 潘洪革, 李寿权. 铁源对溶胶-凝胶法制备LiFePO4/C的结构和电化学性能的影响[J]. 中国有色金属学报, 2008, 18(3): 546-550.

LIN Yan, GAO Ming-xia, LI Yu-feng, PAN Hong-ge, LI Shou-quan. Effects of iron sources on structure and electrochemical properties of LiFePO4/C prepared by sol-gel method[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 546-550.

[3] 王志兴, 李向群, 常晓燕, 郭华军, 彭文杰, 李新海, 陈启元. 锂离子电池橄榄石结构正极材LiMnPO4的合成与性能[J]. 中国有色金属学报, 2008, 18(4): 660-665.

WANG Zhi-xing, LI Xiang-qun, CHANG Xiao-yan, GUO Hua-jun, PENG Wen-jie, LI Xin-hai, CHEN Qi-yuan. Synthesis and characterization of olivine type positive material LiMnPO4 for lithium ion batteries[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 660-665.

[4] 卓海涛, 王先友, 唐安平, 刘志明. NaV1-xCrxPO4F的合成及电化学性能[J]. 中国有色金属学报, 2006, 16(7): 1276-1280.

ZHUO Hai-tao, WANG Xian-you, TANG An-ping, LIU Zhi-ming. Synthesis and electrochemical performance of NaV1-xCrxPO4F[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1276-1280.

[5] SUN Hao, HE Xiang-ming, REN Jian-guo, LI Jian-jun, JIANG Chang-yin, WAN Chun-rong. Hard carbon/lithium composite anode materials for Li-ion batteries[J]. Electrochimica Acta, 2007, 52(13): 4312-4316.

[6] SHIM J, STRIEBEL K A. Cycling performance of low-cost lithium ion battery with natural graphite and LiFePO4[J]. Journal of Power Sources, 2003, 119/121: 955-958.

[7] MARKEVICH E, POLLAK E, SALITRA G, AURBACH D. On the performance of graphitized meso carbon microbeads (MCMB)-meso carbon fibers(MCF) and synthetic graphite electrodes at elevated temperatures[J]. Journal of Power Sources, 2007, 174(2): 1263-1269.

[8] ZHENG Feng, WANG Kai-xue, LI Guo-dong, CHEN Jie-sheng. Hierarchical porous carbon derived from rice straw for lithium ion batteries with high-rate performance[J]. Electrochemistry Communications, 2009, 11(1): 130-133.

[9] WATANABE I, DOI T, YAMAKI J, LIN Y Y, FEY G T. Thermal stability of disordered carbon negative-electrode materials prepared from peanut shells[J]. Journal of Power Sources, 2008, 176(1): 347-352.

[10] GUERIN K, FEVRIER B A, SERGE F, SIMON B, BIENSAN P. On the irreversible capacities of disordered carbons in lithium-ion rechargeable batteries[J]. Electrochimica Acta, 2000, 45(10): 1607-1615.

[11] CHENG Guo, LONG Dong-hui, LIU Xiao-jun, LING Li-cheng. Fabrication of hierarchical porous carbide-derived carbons by chlorination of mesoporous titanium carbides[J]. New Carbon Materials, 2009, 24(3): 243-250.

[12] GIOVANNA L, RANJAN K D, JONATHAN P S. Carbide-derived carbons: A comparative study of porosity based on small-angle scattering and adsorption isotherms[J]. Langmuir, 2006, 22(21): 8945-8950.

A comparative study of porosity based on small-angle scattering and adsorption isotherms[J]. Langmuir, 2006, 22(21): 8945-8950.

[13] THOMBERG T, JANES A, LUST E. Energy and power performance of electrochemical double-layer capacitors based on molybdenum carbide derived carbon[J]. Electrochimica Acta, 2010, 55(9): 3138-3143.

[14] LEIS J, ARULEPP M, KAARIK M, PERKSON A. The effect of Mo2C derived carbon pore size on the electrical double-layer characteristics in propylene carbonate-based electrolyte[J]. Carbon, 2010, 48(14): 4001-4008.

[15] KORMANN M, POPOVSKA N. Processing of carbide-derived carbons with enhanced porosity by activation with carbon dioxide[J]. Microporous and Mesoporous Materials, 2010, 130(1): 167-173.

[16] YACHAMANENI S, YUSHIN G, YEON S, GOGOTSI Y, HOWELL C, SANDEMAN S, PHILLIPS G, MIKHALOVSKY S. Mesoporous carbide-derived carbon for cytokine removal from blood plasma[J]. Biomaterials, 2010, 31(18): 4789-4794.

[17] DASH R K, YUSHIN G, GOGOTSI Y. Synthesis, structure and porosity analysis of microporous and mesoporous carbon derived from zirconium carbide[J]. Microporous and Mesoporous Materials, 2005, 86(1/3): 50-57.

[18] DAI Chun-ling, WANG Xian-you, WANG Ying, LI Na, WEI Jian-liang. Synthesis of nanostructured carbon by chlorination of calcium carbide at moderate temperatures and its performance evaluation[J]. Materials Chemistry and Physics, 2008, 112(2): 461-465.

[19] 王先友, 杨顺毅, 李 娜. 一种超级电容器用高性能骨架碳材料的制备方法: 中国, 200810143636[P]. 2009-04-08.

WANG Xian-you, YANG Shun-yi, LI Na. A preparation method of high-performance skeleton carbon materials for supercapacitor: CN 200810143636[P]. 2009-04-08.

[20] ZHENG Li-ping, WANG Ying, WANG Xian-you, LI Na, AN Hong-fang, CHEN Hua-jie, GUO Jia. The preparation and performance of calcium carbide-derived carbon/polyaniline composite electrode material for supercapacitors[J]. Journal of Power Sources, 2010, 195(6): 1747-1752.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(20871101);国家科技部科技计划项目(2009GJD20021);湖南省科技厅重点项目(2009WK2007);湖南省自然科学市州联合基金重点项目(09JJ8001)

收稿日期:2010-12-07;修订日期:2011-03-05

通信作者:王先友,教授;电话:0731-58292060;E-mail: wxianyou@yahoo.com