具有电容和脱嵌锂特性的锂离子电池复合负极材料性能

方杰,王志兴,李新海,郭华军,彭文杰

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:以中间相炭微球和活性炭为原料,采用物理混合的方法制备锂离子电池复合负极材料。用扫描电镜、X线衍射仪、恒电流充放电和循环伏安(CV)测试来表征材料的表面形貌、结构和电化学性能。研究结果表明:制备复合材料的中间相炭微球和活性炭混合均匀;复合材料首次放电和充电比容量分别为549和290 mA?h/g,当电压为0.25~3.00 V时,复合材料充电曲线斜率介于中间相炭微球和活性炭的充电曲线斜率之间,比容量为93 mA?h/g,显示复合负极材料同时具有脱嵌锂特性和双电层特性;循环30次后,复合材料的放电容量为240 mA?h/g;在充放电电流密度为4 A/g时,复合材料的电化学极化较中间相炭微球的极化显著降低,是一种具有发展前途的锂离子电池负极材料。

关键词:复合负极材料;电容特性;脱嵌锂特性

中图分类号:TM912.9 文献标志码:A 文章编号:1672-7207(2010)06-2091-05

Anode composition with capacitance and (de)lithiation for lithium ion battery

FANG Jie, WANG Zhi-xing, LI Xin-hai, GUO Hua-jun, PENG Wen-jie

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: An anode composite sample was prepared by means of physical mix using carbon microbeads and activated carbon as precursors. Scanning electron microscope, X-ray diffractrometry, the constant current charge/discharge and cyclic voltammmogram (CV) testing were adopted to investigate the morphology, structure and electrochemical performance of samples. The results showed that carbon microbeads and activated carbon for preparation of composites are mixed evenly. The initial specific discharge and charge capacity of composites are 549 and 290 mA?h/g respectively. Besides, the composites possess performance of (de)lithiation and double layer. In 0.25-3.00 V, the slope of charge curves for composites is between slopes of carbon microbeads and activated carbon, and the capacity from 0.25 to 3 V of composites is 93 mA?h/g. After 30 cycles, the specific capacity of 240 mA?h/g is obtained for composites. At charge/discharge current rate of 4 A/g, the electrochemical that of composites is apparently smaller than polarization of carbon microbeads, which indicates that composites are promising anode materials for lithium ion battery.

Key words: anode composites; capacitance; (de)lithiation

由于石油资源的日益耗竭,开发新的二次能源成为必然趋势。人们对锂离子电池和超级电容器作为新型的储能器件开展了大量的研究[1-3]。目前,它们在便携式电子设备和电动工具领域都有着重要的应用[4]。锂离子电池具有电压高、能量密度大和自放电小等优点;超级电容器具有功率密度高、充电时间短、使用寿命长等优点[5-6]。但它们作为电动工具(EV)和混合电动工具(HEV)的电源或辅助电源还存在一些缺陷,这些缺陷主要有:快速的充放电导致电池的循环寿命和电化学性能变差;锂离子电池具有较高的能量密度,但功率密度比超级电容器的低;超级电容器单独作为电源时,能量密度又显不足[7]。针对这些缺陷,有人提出了一些改进措施,如通过增加电池组的数量实现大电流放电[8];将超级电容器与电池组并联实现瞬间大功率的需求[9]。这些改进措施都是通过增加器件来实现,因此,本文作者拟开发具有高比能量和高比功率的贮能材料,在一个器件中同时实现高能量密度和高功率密度。电极材料是决定其储能效果的关键因素之一,锂离子电池中使用最广泛的负极活性材料是石墨,包括天然石墨和人工石墨[10]。石墨的理论嵌锂容量为372 mA?h/g,相对于其他的负极材料,石墨具有价格低廉、来源广泛、导电性好以及库仑效率高和良好的循环性能等优点[11]。具有大的比表面积、发达的微孔结构的活性炭(AC)是目前商业化超级电容器的主要电极材料。在此,本文作者将中间相炭微球(CMS)和活性炭的优点结合起来,采用物理混合方法制备CMS /AC复合负极材料,利用活性炭形成的电化学双电层放电实现电池瞬间的大倍率放电的要求。电化学性能测试结果表明:这种材料同时具有活性炭的电容特性和石墨负极的脱嵌锂特性的特点,瞬间倍率性能得到了很大改善,并有望成为一种新型的锂离子动力电池的负极材料。

1 实验

1.1 材料制备及物理性能测试

按质量比4?1称取中间相炭微球(上海杉杉科技)和活性炭(辽宁朝阳森塬活性碳有限公司) 200 g在研钵中研磨、过筛,得到复合负极材料。

利用扫描电子显微镜(SEM:JSM-5600LV)表征材料的表面形貌;采用X线衍射仪(Rigaku公司,日本)对合成材料进行物相分析,以Cu Kα靶作为辐射源,电压为40 kV,电流为50 mA,步宽为0.02(°),扫描速度为2 (°)/min,衍射角的扫描范围2θ为10°~85°。材料的粒度和比表面积分别在Mastersize-2000激光粒度测定仪(Malvern Instruments Ltd.)和3H-2000型气体吸附分析仪(北京汇海宏纳米科技有限公司)上进行表征。

1.2 电池的装配和电化学性能的测试

电极的制备过程如下:将活性物质(复合负极材料或石墨或活性炭)、聚偏氟乙烯(PVDF)和乙炔黑按质量比8?1?1混合,向其中滴入适当的NMP(氮甲基吡咯烷酮)后,制成均匀的浆料,将浆料均匀地涂在铜箔上,再将涂好的电极片制成直径为14 mm的工作电极,在120 ℃的真空干燥箱中干燥12 h备用。测试电池采用2025型扣式电池,以金属锂箔为对电极,电解液为1 mol/L LiPF6的EC-EMC-DMC(体积比为1?1?1)溶液。以Celgard2400聚丙烯多孔膜为隔膜,在充满氩气的手套箱中组装电池。

电池的脱嵌锂特性在武汉蓝电电池测试系统上进行,充放电采用恒流方式进行,充放电电流的倍率为0.1C(1C=372 mA?h/g),充放电的截止电压范围为 0~2 V;电池的电容特性和循环伏安测试在上海辰华仪器公司生产的CHI660A型电化学工作站上进行,电位扫描范围为0~2.5 V(vs Li+/Li),扫描速率为0.1 mV/s。

2 结果与讨论

2.1 样品和复合材料的形貌分析

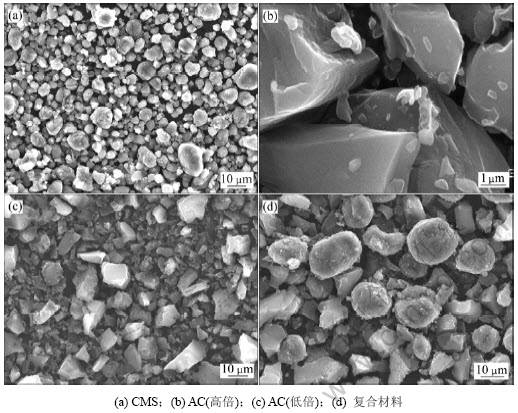

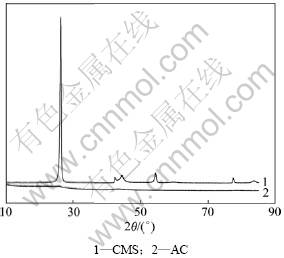

图1所示为样品的SEM像。从图1(a)可以看出:CMS由颗粒粒径较为均匀的微球组成,其粒径范围为4~15 μm,并且表面比较光滑;图1(b)和(c)所示为活性炭的表面形貌像。由图1可知:活性炭呈不规则的形态;将CMS 和活性炭按质量比4?1混合后的复合材料的SEM像如图1(d)所示。活性炭均匀地分散在CMS中间,有些活性炭吸附在CMS的表面,样品混合均匀。图2所示为制备复合材料的原料XRD谱。由图2可以看出:CMS为典型的石墨结构,活性炭没有明显的衍射峰,为无定形结构。

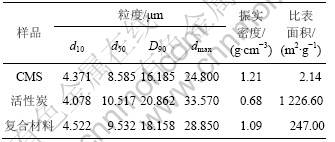

表1列出了CMS、活性炭和复合材料的部分物理性能。从表1可以看出:复合材料的一些物理指标介于CMS和活性炭的物理指标之间,振实密度为1.09 g/cm3,采用BET法测得复合材料的比表面积为247 m2/g,远大于CMS比表面积,这主要是复合材料中活性炭具有较大的比表面积而引起的。

2.2 复合材料、CMS和AC的电化学性能

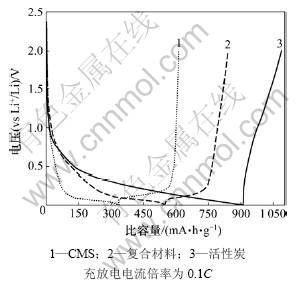

图3 所示为复合材料、CMS和活性炭的首次充放电曲线。从图3可以看出:活性炭的首次放电容量为911 mA?h/g,而CMS 和复合材料的首次放电容量分别为336和549 mA?h/g。CMS的首次充放电曲线如图3所示,放电容量主要由在0.7 V附近形成固体电解质中间相(SEI)的容量以及0.2 V左右的嵌锂容量组成。活性炭的首次放电容量主要由形成SEI膜的容量和双电层的容量2个部分组成。 活性炭具有很大比表面积,所以,形成SEI膜会产生较大的容量[12]。同时双电层的形成也会产生放电容量。活性炭不具有石墨的层状结构,因此,放电过程中没有嵌锂容量,主要表现为曲线上没有明显的嵌锂平台。另外,在活性炭充电曲线上明显存在由内阻引起的压降,表明此时活性炭容量主要由电化学双电层引起。由图3中曲线2可见:复合材料在0.2 V附近具有明显的脱嵌锂平台;另外,在充电曲线上,复合材料和CMS在0~0.25 V之间容量分别为197和232 mA?h/g,在0.25~2.00 V之间容量分别为93和42 mA?h/g,而活性炭的容量主要在0.25~2.00 V之间,复合材料在高电压区间容量的增加主要是由活性炭引起,此外,复合材料充电曲线在0.25~2.00 V之间的斜率介于CMS和活性炭在此电压区间的2个斜率之间,这种斜率的变化也主要由活性炭的双电层特性引起,表明复合材料的电化学性能具有CMS和活性炭2种材料的混合特性。应当说明的是,活性炭的双电层容量很容易释放,因此,可以利用活性炭的双电层特性改善复合材料的瞬间倍率性能。

图1 样品和复合材料的SEM像

Fig.1 SEM images of sample and composites

图2 CMS和AC的XRD谱

Fig.2 XRD patterns of CMS and AC

表1 样品的主要物理性能

Table 1 Major parameters of samples

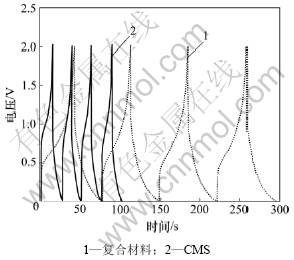

图4所示为CMS和复合材料在4 A/g放电倍率下的恒流充放电多次循环曲线。从图4可以看出:复合材料在大电流放电条件下的极化较纯CMS的极化明显降低。主要表现为复合材料的初始充电电压平台明显降低;充放电过程时间明显延长,接近此电流下纯CMS充放电过程时间的3倍,因此,复合材料较CMS瞬间倍率性能得到了很大改善。主要原因在于:复合材料中活性炭的存在,一方面活性炭提供双电层容量;另一方面,具有多孔疏松的结构的活性炭均匀分散在CMS中,有利于电解质的传输,改善了材料极化性能。

图3 CMS,AC和复合材料的首次充放电曲线

Fig.3 Initial discharge and charge curves of CMS, AC and composites

图4 CMS和复合材料在4 A/g条件下充放电曲线

Fig.4 Charge and discharge curves of CMS and composites at rate of 4 A/g

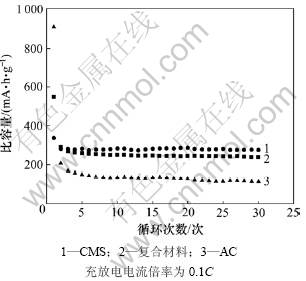

图5所示为复合材料、CMS和活性炭的循环性能。结合图3可以看出:复合材料和活性炭的首次充放电不可逆容量很大,分别达到47.5%和77.2%,这些不可逆容量主要由3部分构成:(1) 锂离子不可逆地嵌入活性炭的部分微孔中;(2) 锂离子与活性物质表面的一些官能团(如羟基、羧基)反应;(3) 活性炭具有大的比表面积,在充放电过程中形成SEI膜[13-14]。经过首次充放电后,3种材料的循环性能都表现得很优异,30次循环后基本没有衰减。

图5 复合材料、CMS和AC的比容量与循环次数的关系

Fig.5 Relationship between specific capacity and cycles of composites, CMS and AC

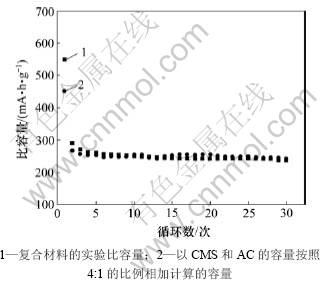

图6所示为复合材料放电容量实验结果和以CMS和AC的放电容量按4?1的比例计算的容量的比较结果。从图6可以看出:2条曲线基本吻合,表明复合材料的放电容量由CMS和AC 2种活性物质的放电容量复合组成,也再次证明复合材料具有2种材料的电化学性能,即脱嵌锂特性和双电层特性。

图6 复合材料的比容量和由CMS和AC按一定比例计算的比容量与循环数的关系

Fig.6 Relationships between specific capacity and cycles of composites and CMS and AC according to special rate

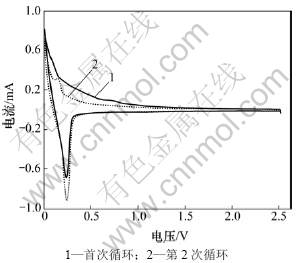

图7所示为复合材料的循环伏安曲线。由图7可以看出:首次放电过程在0.7 V左右出现1个较小的不可逆氧化峰,这与首次充放电曲线上0.7 V左右的电位平台相对应,这个平台由2个不可逆反应产生,一是电解质的分解以及在复合材料表面形成SEI膜的反应, 另一个是活性炭中含氧官能团与电解质的反 应[15-16]。2个反应产生的容量构成了复合材料首次充放电不可逆容量的一部分,经过首次充放电后,0.7 V氧化还原峰基本消失,表明不可逆容量主要产生在首次充放电过程中。在0.2~0.3 V出现的1对可逆氧化还原峰对应于锂离子在CMS中可逆的脱嵌。

图7 复合材料的循环伏安曲线

Fig.7 CV curves of composites

3 结论

(1) 以CMS和活性炭为原料,采用物理混合的方法制备了锂离子电池复合负极材料,复合材料的首次充放比电容量为549 mA?h/g,经过首次充放电后,复合材料的循环性能较好,30 次循环后容量基本没有衰减。

(2) 复合负极材料同时具有CMS和活性炭2种活性物质的电化学性能,即同时具有脱嵌锂特性和双电层特性。

(3) 复合负极材料中活性炭的存在,一方面提供了双电层容量;另一方面,疏松多孔的活性炭均匀分散在CMS中,有利于电解质的传输,降低了复合材料的极化,改善了复合材料的瞬间倍率性能。从应用的角度看,这种材料的首次充放电效率还有待进一步提高。

参考文献:

[1] Armand M, Tarascon J M. Building better batteries[J]. Nature, 2008, 451(7): 652-657.

[2] Nohara S, Wada H, Furukawa N, et al. Electrochemical characterization of new electric double layer capacitor with polymer hydrogel electrolyte[J]. Electrochimica Acta, 2003, 48(6): 749-753.

[3] Arabale G, Wagh D, Kulkarni M, et al. Enhanced supercapacitance of multiwalled carbon nanotubes functionalized with ruthenium oxide[J]. Chemical Physics Letters, 2003, 376(1/2): 207-213.

[4] Ibrahim H, Ilinca A, Perron J. Energy storage systems: Characteristics and comparisons[J]. Renewable and Sustainable Energy Reviews, 2008, 12(5): 1221-1250.

[5] Pell W G, Conway B E. Peculiarities and requirements of asymmetric capacitor devices based on combination of capacitor and battery-type electrodes[J]. J Power Sources, 2004, 136(2): 334-345.

[6] Zhou S Y, Li X H, Wang Z X, et al. Comparison of capacitive behavior of activated carbons with different pore structures in aqueous and nonaqueous systems[J]. Journal of Central South University of Technology, 2008, 15(5): 674-678.

[7] Balducci A, Dugas R, Tabern P L, et al. High temperature carbon–carbon supercapacitor using ionic liquid as electrolyte[J]. J Power Sources, 2007, 165(2): 922-927.

[8] Chu A, Braatz P. Comparison of commercial supercapacitors and high-power lithium-ion batteries for power-assist applications in hybrid electric vehicles (Ⅰ): Initial characterization[J]. J Power Sources, 2002, 112(1): 236-246.

[9] Jung D Y, Kim Y H, Kim S W, et al. Development of ultracapacitor modules for 42 V automotive electrical systems[J]. J Power Sources, 2003, 114(2): 366-373.

[10] Takamura T, Endo K, Fu L J, et al. Identification of nano-sized holes by TEM in the graphene layer of graphite and the high rate discharge capability of Li-ion battery anodes[J]. Electrochimica Acta, 2007, 53(3): 1055-1061.

[11] Zaghib K, Song X, Guerfi A, et al. Purification process of natural graphite as anode for Li-ion batteries: chemical versus thermal[J]. J Power Sources, 2003, 119/121: 8-15.

[12] Lee J H, Lee H Y, Oh S M, et al. Effect of carbon coating on electrochemical performance of hard carbons as anode materials for lithium-ion batteries[J]. J Power Sources, 2007, 166(1): 250-254.

[13] Guerin K, Feerier-Bouvier A, Flandrois S, et al. On the irreversible capacities of disordered carbons in lithium-ion rechargeable batteries[J]. Electrochimica Acta, 2000, 45(10): 1607-1615.

[14] Xing W, Dahn J R. Study of irreversible capacities for Li insertion in hard and graphitic carbons[J]. J Electrochemical Society, 1997, 144(4): 1195-1201.

[15] Winter M, Novak P, Monnier A. Graphites for lithium-ion cells: the correlation of the first-cycle charge loss with the brunauer-emmett-teller surface area[J]. J Electrochemical Society, 1998, 145(2): 428-436.

[16] 杨静, 刘亚非, 陈晓妹, 等. 高能量密度和功率密度炭电极材料[J]. 物理化学学报, 2008, 24(1): 13-19.

YANG Jing, LIU Y-fei, CHEN Xiao-mei, et al. Carbon electrode material with high densities of energy and power[J]. Acta Phys-Chim Sinica, 2008, 24(1): 13-19.

(编辑 陈爱华)

收稿日期:2009-10-01;修回日期:2009-12-28

基金项目:国家科技支撑计划重点项目(2007BAE12B01-2)

通信作者:王志兴(1970-),男,湖南双峰人,教授,从事新能源材料及电化学研究;电话:0731-88836633;E-mail: zxwang@mail.csu.edu.cn