AZ31B合金的铸轧组织

娄花芬1, 2,汪明朴1,马可定2,刘 阳2,郭明星1,唐 宁1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中铝洛阳铜业有限公司,河南 洛阳,471039)

摘 要:利用金相及扫描电镜对AZ31B合金热模拟和铸轧样组织结构进行研究。研究结果表明:在不同应变量下,热模拟样品的晶粒粒度均随应变速率的增加而减小,而当其他条件相同时,变形量越大晶粒粒度越小,冷却强度降低,合金呈典型铸态组织;利用铸轧技术生产的AZ31B合金,当应变速率一定时,随着初始铸轧温度的降低,铸轧态板材的树枝晶粒度逐渐减小;而在初始铸轧温度一定时,随着应变速率的增大,铸轧态合金板材的树枝晶粒度也逐渐减小;而随着应变速率的提高,树枝晶沿轧向呈流线状排列的趋势增强;在AZ31B合金铸轧过程中,轧制力不能太大,否则容易引起热裂。

关键词:镁合金;热模拟;铸轧;显微组织

中图分类号:TG146.2+2; TG292; TG335.19 文献标识码:A 文章编号:1672-7207(2008)01-0012-06

Microstructure of roll casting for AZ31B alloy

LOU Hua-fen1, 2, WANG Ming-pu1, MA Ke-ding2, LIU Yang2, GUO Ming-xing1, TANG Ning1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. CHINALCO Luoyang Copper Co., LTD, Luoyang 471039, China)

Abstract: The microstructures of thermal simulation and roll casting AZ31B alloys were investigated by optical microscope (OM) and scanning electron microscopy (SEM) observation. The results show that with the increase of strain rate, the grain sizes of thermal simulation AZ31B alloys with different deformation all decrease; however, when other conditions are the same, the higher deformation will lead to the formation of the smaller grain size, and as the cooling intensity decreases, typical cast structure of AZ31B will appear. With the decrease of roll casting temperature, the dendritic size of roll casting AZ31B alloy sheet prepared by the same strain rate is also reduced, but with the increase of strain rate, the dendritic size of the alloy sheet prepared by the same initial roll casting temperature is decreased, and the tendency of dendritic streamline is strengthened. During the roll casting process of AZ31B alloy, rolling force should not be large, otherwise it will cause heat cracking.

Key words: Mg alloy; thermal simulation; roll casting; microstructure

镁是地壳中含量最丰富的元素之一,其熔点为650 ℃,密度仅为铝的64%(1.75~1.85 g/cm3),是目前密度最低的金属材料之一。它具有比强度和比刚度高,以及优良的阻尼、抗振、电磁屏蔽和抗蚀性能[1],同时易于回收利用。在迫切要求节能、降污和节约地球有限资源的今天,镁合金结构材料的开发和利用越来越受到世界各国的重视。目前,镁及镁合金的需求量以每年20%以上的速度增长。我国的镁资源十分丰富,但远没有充分开发利用。20世纪90年代末,我国年产镁锭就达10万t左右,而在随后的几年中其年产量以惊人的速度不断增长[1-2]。但是,我国的镁合金材料,特别是新型的镁合金结构材料和新产品的研制开发工作远远落后于工业发达国家。

镁的晶体结构属于密排六方结构,滑移系少,在低温时塑性比较差,变形镁合金材料生产工艺难度大。传统的变形镁合金板材的生产方式采用半连续铸锭进行热轧开坯-温控轧制,由于流程长,耗能高,成品率低,价格昂贵,严重制约了其推广应用,因此,开发新型的短流程、低成本和高质量的镁合金带坯铸轧技术,是当前世界范围内变形镁合金研发的热点。铸轧是一种低投入、低成本、节能型的短流程生产工艺,是目前研究最多的先进生产技术之一[3-6]。目前,利用铸轧短流程技术生产铝合金和钢铁已经相对比较成熟,但国内外利用该技术生产镁合金的研究则刚刚起步[1-2, 7-12]。为此,本文作者采用Gleeble1500热模拟机对AZ31B合金的铸轧变形行为进行热模拟,然后,根据热模拟结果确定的铸轧变形规律,进行工业化生产AZ31B合金铸轧薄板,对不同工艺参数下获得的热模拟和铸轧AZ31B合金样的组织变化规律进行研究。

1 材料制备与实验方法

实验所用原始态合金采用工业纯镁(纯度为99.9%)、纯铝、纯锌熔炼而成。所有的合金均在电阻坩埚炉内熔炼,熔炼温度为1 023~1 053 K,熔炼时加入覆盖剂以防止氧化,待完全熔化后,进行搅拌确保成分均匀,然后将熔体浇注成铸锭。热模拟和铸轧样均取自此铸锭。热模拟在Gleeble1500热模拟实验机上进行,分别模拟不同始轧温度、冷却强度以及变形量(ε)和应变速率( )下AZ31B合金的变形行为。在不同工艺条件下,利用铸轧技术制备的AZ31B合金薄板厚度约为6 mm。

)下AZ31B合金的变形行为。在不同工艺条件下,利用铸轧技术制备的AZ31B合金薄板厚度约为6 mm。

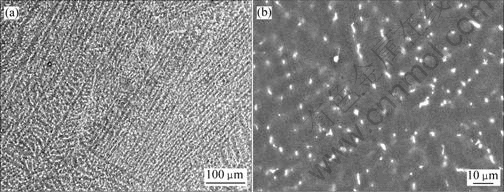

AZ31B合金成分见表1。

表1 AZ31B合金的成分

Table 1 Component of AZ31B alloys w/%

热模拟试验用AZ31B合金样品的尺寸(直径×长度)为10 mm×15 mm,热模拟具体试验条件见表2。

表 2 热模拟工艺参数

Table 2 Technical parameters of thermal simulation

为了更好地研究不同加工工艺条件下AZ31B合金组织的变化规律,分别采用金相和扫描电镜对其低倍和高倍组织进行观察。金相观察在NEOPHEOT21金相显微镜上进行,腐蚀剂为1 mL乙酸+9 mL蒸馏水。背散射电子形貌像以及能谱分析均在Sirion200场发射扫描电镜上进行,操作电压为25 kV。

2 结果与分析

2.1 AZ31B合金热模拟实验结果

在半固态AZ31B合金试样压缩变形时,应变速率是一个非常重要的工艺参数,其对变形后合金组织影响效果显著。图1所示为AZ31B合金经4 min加热至640 ℃保温20 s,冷却至610 ℃开始变形,在不同的应变速率下变形50%所得到的金相组织照片。由图1可以看出,随着应变速率的提高,枝晶破碎较易,晶粒粒度有一定程度的减小。

(a)  =0.005 s-1; (b)

=0.005 s-1; (b)  =0.1 s-1

=0.1 s-1

图1 不同应变速率下变形50% 的AZ31B合金热模拟金相组织

Fig.1 Metallographical microstructures of thermal simulation AZ31B alloy deformed 50% at different strain rates

图2所示为AZ31B合金经4 min加热至640 ℃保温20 s,冷却至610 ℃开始变形,在不同的应变速率下变形20%所得到的金相组织照片。由图2可见,即使在小应变条件下随着应变速率的提高,也同样存在晶粒粒度减小的趋势,但晶粒粒度较变形量为50%压缩后的组织略大。在铸轧热模拟过程中,应变速率的变化主要是模拟铸轧辊的冷却条件,应变速率大,则夹头移动得快,凝固壳与夹头间接触紧密,散热情况得到改善,冷却能力提高。这使得熔体在凝固过程中由液相L生成固相α-Mg时,溶质Al 在尚未凝固的液相中难以高度富集,枝晶组织细小。

(a)  =0.005 s-1; (b)

=0.005 s-1; (b)  =0.1 s-1

=0.1 s-1

图2 不同应变速率下变形20% 的AZ31B合金热模拟金相组织

Fig.2 Metallographical microstructures of thermal simulation AZ31B alloy deformed 20% at different strain rates

图3所示为AZ31B合金在经4 min加热至630 ℃保温20 s,以 =0.1 s-1的速率变形ε=50%,夹头不通水冷却的情况下获得的金相组织照片。由于热模拟机夹头未进行通水冷却,该组织已成为典型的铸态组织。可见,增大冷却强度,有利于获得组织细小、成分均匀的合金。

=0.1 s-1的速率变形ε=50%,夹头不通水冷却的情况下获得的金相组织照片。由于热模拟机夹头未进行通水冷却,该组织已成为典型的铸态组织。可见,增大冷却强度,有利于获得组织细小、成分均匀的合金。

图3 AZ31B合金以 =0.1 s-1的速率变形50%金相照片

=0.1 s-1的速率变形50%金相照片

Fig.3 Metallographical microstructure of thermal simulation AZ31B alloy deformed 50% at strain rate of 0.1 s-1

2.2 AZ31B合金铸轧带坯的金相组织

图4所示为在工业化生产条件下按不同边界工艺条件生产的AZ31B镁合金铸轧板的金相组织形貌。从图4(a)~(c)可见,在应变速率一定的情况下,随着初始铸轧温度的降低,铸轧态板材的树枝晶粒度逐渐减小。从图4(d)~(f)可见,在初始铸轧温度一定时,随着应变速率的增大,铸轧态合金板材的树枝晶粒度也逐渐减小。这些结果与热模拟的结果一致。此外,由于铸轧变形时轧辊是不断旋转的,因此,随着应变速率的提高,树枝晶沿轧向呈流线状排列的趋势增强。

(a) 700 ℃,0.3 s-1;(b) 670 ℃,0.3 s-1;(c) 640 ℃,0.3 s-1;(d) 670 ℃,0.05 s-1;(e) 670 ℃,0.3 s-1;(f) 670 ℃,1 s-1

图4 不同铸轧温度和应变速率下获得铸轧态AZ31B镁合金的金相组织

Fig.4 Metallographical microstructures of roll casting AZ31B at different roll casting temperatures and strain rates

双辊铸轧时,辊隙的控制对铸轧薄板的质量有很重要的影响,若控制不当,则容易导致铸轧板中心或者边部开裂。施加合理的轧制力可以改善铸轧薄板的表面质量并提高其力学性能。但轧制力也不能太大。实验结果表明,在靠近双辊附近的熔体会较早完成凝固,如果轧制力过大,一方面凝固壳中间的熔体会被挤开,在随后的铸轧过程中熔体来不及补充从而形成热裂纹;另一方面,由于在铸轧过程中铸轧板边部与中心的状态差别较大,轧制太大同样容易引起热裂,结果如图5所示。

图 5 铸轧态AZ31B镁合金热裂情况

Fig.5 Metallographical microstructure of heat cracking for roll casting AZ31B alloy

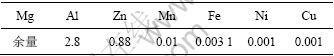

为了弄清铸轧生产的AZ31B合金成分偏析以及铸轧后合金的高倍组织,利用SEM对不同应变速率下的组织进行研究。图6所示为应变速率较小时所获的样品的背散射电子形貌像与能谱分析结果。从图6可以看出,其为典型的枝晶胞组织,枝晶的方向性并不显著,面扫的平均成分与宏观化学成分基本一致。

(a) 背散射电子形貌像;(b) EDS结果

图6 应变速率为0.05 s-1时铸轧态样品的扫描电镜照片及能谱面分析

Fig.6 SEM image and EDS analysis of roll casting AZ31B alloy at strain rate of 0.05 s-1

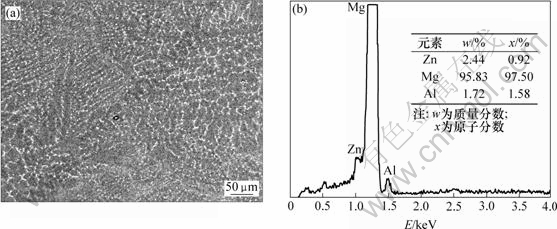

但随着应变速率的增加,其组织有所变化。图7所示为应变速率为1 s-1时所获得的样品的SEM背散射电子形貌像。可见,所获得组织依然是枝晶状组织,但与应变速率较慢时的组织相比,应变速率较快时,枝晶组织有所细化。且枝晶生长方向性增强,这与合金的金相组织相类似。对其进行高倍放大后,发现铸轧态样品晶界处偏聚有白色析出物(见图7(b))。对其进行能谱分析,发现析出物Al和Zn含量均较高(图8),根据文献报道该析出物可能为β-Al12Mg17和MgZn相的混合物。在铸轧过程中,应变速率的变化主要影响铸轧过程中的冷却强度,应变速率大,凝固壳与铸轧辊之间接触紧密, 散热情况得到改善,冷却能力提高,整个熔体的凝固在较短时间内就会完成。在此过程中,后凝固的熔体即使因为溶质Al和Zn的富集有共晶转变趋势,但这种共晶转变也只是小部分发生,致使合金组织以α-Mg的过饱和固溶体为主,晶界处分布有少量的α-Mg+β-Al12Mg17共晶(包含部分MgZn相的细小共晶组织)[13-15]。

(a) 低倍像;(b) 高倍像

图7 应变速率为1 s-1时铸轧态样品的扫描电镜照片

Fig.7 SEM images of roll casting AZ31B alloy at strain rate of 1 s-1

(a) 析出相SEM照片;(b) EDS结果

图8 铸轧AZ31合金晶界处析出物的能谱分析

Fig.8 EDS analysis of segregated phase on grain boundary for roll casting AZ31B alloy

3 结 论

a. 利用Gleeble1500热模拟机对AZ31B合金进行压缩变形热模拟,在不同的应变量下,晶粒粒度均随应变速率的增加而减小,枝晶破碎容易。而当其他变形条件相同时,变形量为50%的合金晶粒粒径较20%变形量的小;夹头不通水导致冷却强度降低,合金呈典型铸态组织。

b. 利用铸轧技术生产的AZ31B合金,在应变速率一定的情况下,随着初始铸轧温度的降低,铸轧薄板的树枝晶粒度逐渐减小。而在初始铸轧温度一定时,随着应变速率的增大,铸轧板材的树枝晶粒度也逐渐减小。而随着应变速率的提高,树枝晶沿轧向呈流线状排列的趋势增强。

c. 在AZ31B合金铸轧过程中,施加合理的轧制力可以提高铸轧薄板的表面质量和其力学性能,但轧制力不能太大,否则很容易导致铸轧薄板出现热裂 缺陷。

d. 利用SEM对铸轧态AZ31B合金进行背散射电子形貌观察,晶界处存在白色析出相;对其进行能谱分析,发现除Mg之外,其Al和Zn含量也较高。

参考文献:

[1] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 2-5, 289-295, 302-308.

LI Wen-xian. Magnesium and magnesium alloys[M]. Changsha: Central South University Press, 2005: 2-5, 289-295, 302-308.

[2] Mordike B L. Magnesium and magnesium alloys[J]. Journal of Japanese Institute of Light Metals, 2001, 51(1): 2-13.

[3] Yun M, Lokyer S, Hunt J D. Twin roll casting of aluminium alloys[J]. Materials Science and Engineering, 2000, A280: 116-123.

[4] Fan F, Zhou S, Liang X, et al. Thin strip casting of high speed steels[J]. Journal of Materials Processing Technology, 1997, 63(1/3): 792-796.

[5] 陈绪宏, 丁培道, 杨春楣. 双棍快速凝固AZ31镁合金薄带试验研究[J]. 轻合金加工技术, 2003, 31(5): 19-21.

CHEN Xu-hong, DING Pei-dao, YANG Chun-mei. Experimental study on twin-roll strip casting process for AZ31 Magnesium alloy[J]. Light Alloy Fabrication, 2003, 31(5): 19-21.

[6] 丁培道, 蒋 斌, 杨春楣, 等. 薄带连铸技术的发展现状与思考[J]. 中国有色金属学报, 2004, 14(S1): 192-196.

DING Pei-dao, JIANG Bin, YANG Chun-mei, et al. Development and thought of thin-strip continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S1): 192-196.

[7] Mordike B L, Ebert T. Magnesium properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[8] Brown R. Australian magnesium projects-update[J]. Light Metal Age, 2000, 9/10: 54-57.

[9] Kojima Y. Platform science and technology for advanced magnesium alloys[J]. Materials Science Forum, 2000, 350/351: 3-18

[10] Koike J, Ohyama R, Kobayashi T, et a1. Grain boundary sliding in AZ31 magnesium alloys at room temperature to 523 K[J]. Materials Transactions, 2003, 44(4): 445-451.

[11] Park S S, Oh Y S, Kang D H, et al. Microstructural evolution in twin-roll strip cast Mg-Zn-Mn-Al alloy[J]. Materials Science and Engineering: A, 2007, 449-451: 352-355.

[12] Liang D, Cowley C B. The twin-roll strip casting of magnesium [J]. JOM, 2004, 56(5): 26-28.

[13] Chen F K, Huang T B, Chang C K. Deep drawing of square cups with magnesium alloy AZ31 sheets[J]. International Journal of Machine Tools & Manufacture, 2003, 43: 1553-1559.

[14] Doege E, Droder K. Sheet metal forming of magnesium wrought alloys-formability and process technology[J]. Journal of Materials Processing Technology, 2001, 115: 14-19.

[15] Yoshihara S, Yamamoto H, Manabe K. Formability enhancement in magnesium alloy deep drawing by local heating and cooling technique[J]. Journal of Materials Processing Technology, 2003, 143/144: 612-615.

收稿日期:2007-03-16;修回日期:2007-05-10

基金项目:国家“十五”重大科技攻关项目(2004BA311A11-1)

作者简介:娄花芬(1970-),女,河南洛阳人,博士研究生,高级工程师,从事铜、镁等有色金属材料研制、产品开发和技术研发工作

通信作者:娄花芬,女,博士研究生;电话:0379-64939304;E-mail: louhuafen@163.com