双辊铸轧和热轧处理AZ31B镁合金的动态拉伸性能

来源期刊:中国有色金属学报(英文版)2016年第11期

论文作者:Ping ZHOU Elmar BEEH Meng WANG Horst E. FRIEDRICH

文章页码:2846 - 2856

关键词:镁合金;双辊铸轧;动态拉伸;应变速率敏感性;断口形貌

Key words:magnesium alloy; twin-roll casting; dynamic tensile; strain-rate sensitivity; fractography

摘 要:研究双辊铸轧和热轧处理AZ31B镁合金板材在室温和应变速率从0.001 s-1到375 s-1条件下的动态拉伸力学行为,以及力学性能与显微结构之间的关系。实验发现,该镁合金板材具有很强的初始基面纤维织构,并且在高应变速率条件下机械孪生成为主要的变形机理。材料的屈服强度和拉伸极限强度随应变速率的提高而提高;然而,孪生诱导的软化效应导致应变强化指数随应变速率的提高而成比例地降低。在准静态拉伸条件下,断裂伸长率随应变速率的提高而明显地降低;而在动态拉伸条件下应变速率对断裂伸长率的影响却不明显。最后,应用扫描电镜对拉伸试样进行了断口形貌分析。分析结果表明,该加工状态下的AZ31B镁合金板材的拉伸断裂是一种韧性与脆性混合断裂模式。

Abstract: The dynamic tensile behavior of twin-roll cast-rolled and hot-rolled AZ31B magnesium alloy was characterized over strain rates ranging from 0.001 to 375 s-1 at room temperature using an elaborate dynamic tensile testing method, and the relationship between its mechanical properties and microstructures. It is observed that the sheet has a strong initial basal fiber texture and mechanical twinning becomes prevalent to accommodate the high-rate deformation. The yield strength and ultimate tensile strength monotonically increase with increasing the strain rate, while the strain hardening exponent proportionally decreases with increasing the strain rate due to twinning-induced softening. The total elongation at fracture distinctly decreases as the strain rate increases under quasi-static tension, while the effect of strain rate on the total elongation is not distinct under dynamic tension. Fractographic analysis using a scanning electron microscope reveals that the fracture is a mixed mode of ductile and brittle fracture.

Trans. Nonferrous Met. Soc. China 26(2016) 2846-2856

Ping ZHOU, Elmar BEEH, Meng WANG, Horst E. FRIEDRICH

German Aerospace Center (DLR), Institute of Vehicle Concepts, Pfaffenwaldring 38-40, 70569 Stuttgart, Germany

Received 19 November 2015; accepted 15 June 2016

Abstract: The dynamic tensile behavior of twin-roll cast-rolled and hot-rolled AZ31B magnesium alloy was characterized over strain rates ranging from 0.001 to 375 s-1 at room temperature using an elaborate dynamic tensile testing method, and the relationship between its mechanical properties and microstructures. It is observed that the sheet has a strong initial basal fiber texture and mechanical twinning becomes prevalent to accommodate the high-rate deformation. The yield strength and ultimate tensile strength monotonically increase with increasing the strain rate, while the strain hardening exponent proportionally decreases with increasing the strain rate due to twinning-induced softening. The total elongation at fracture distinctly decreases as the strain rate increases under quasi-static tension, while the effect of strain rate on the total elongation is not distinct under dynamic tension. Fractographic analysis using a scanning electron microscope reveals that the fracture is a mixed mode of ductile and brittle fracture.

Key words: magnesium alloy; twin-roll casting; dynamic tensile; strain-rate sensitivity; fractography

1 Introduction

An urgent task in the automotive industry is to reduce vehicle weight without compromising performance. Magnesium (Mg) alloys have attracted increasing attention due to their low density (~1.77 g/cm3) and high specific strength [1,2]. However, Mg alloys exhibit low ductility and formability at room temperature due to the hexagonal closed-packed crystal structure, resulting in difficulties with structural applications. Moreover, high cost and limited corrosion resistance of conventional Mg products, especially sheet materials, have also restricted their large scale applications.

One strategy to improve the ductility of Mg alloys is to change the forming conditions, such as elevated temperature forming [3,4] and high strain-rate forming [5,6]. But this results in high energy consumption. Another promising strategy is to improve the microstructures, such as grain refinement [7] and texture modification [8,9] by alloy design and enhanced manufacturing processes. Equal channel angular pressing/extrusion (ECAP/ECAE) [10], asymmetric rolling (ASR) [11] and accumulative roll bonding (ARB) [12] are advanced wrought processes to fabricate Mg alloys with refined grains and controlled textures. Twin-roll casting (TRC) [13,14] is currently a developing production technology which offers a cost- efficient way to increase the capacity of Mg strips and sheets. In contrast to conventional rolling, TRC does not need the rough rolling of billets in several steps. It combines casting and hot rolling into a single step, i.e. the so-called TRC+R or TRC+R+HT for sequential heat treatment. Therefore, TRC substantially reduces the production costs and energy consumption. Furthermore, TRC has beneficial effects on the microstructure such as reducing segregation and grain size, improving inclusion size distribution and refining microstructural homogeneity, owing to its much faster solidification rate than conventional ingot-casting [15,16]. In this regard, it is believed that TRC can be a promising process to fabricate Mg sheet products.

As far as vehicle crashworthiness is concerned; however, the introduction of Mg alloys in automotive body structures is still a challenge [17]. In crash events, impacted structures generally experience severe plastic deformation within the local failure zones at intermediate strain rates ranging up to 500 s-1 and room temperature [18]. In such circumstances, Mg alloys exhibit low ductility and fracture toughness, consequently causing premature failures of impacted structures. To support the design of Mg crashworthy components, extensive studies have been carried out on the dynamic mechanical behavior of Mg alloys. EL-MAGD and ABOURIDOUANE [19] presented that the ductility of extruded AZ80 decreased with increasing the strain rate lower than 103 s-1; while it increased at strain rates higher than 103 s-1. ULACIA et al [4] reported that the tensile ductility of rolled AZ31 increased as the strain rate increased from 4 × 101 s-1 to 1.5 × 103 s-1. FENG et al [20] found that the fracture pattern of the rolled AZ31B was mainly quasi-cleavage pattern in the quasi-static/dynamic tensile tests at room temperature, while mainly ductile fracture pattern at high strain rates and temperatures. GENG et al [6] observed that extruded AZ31B had less dimple patterns but more cleavage patterns on the fracture surfaces of ultra-rapidly tensioned specimens. As-reviewed above, it can be concluded that Mg alloys have a positive effect of strain rate on the tensile strength, but the effect of strain rate on the ductility and fracture mechanisms is scattered. To the authors’ knowledge, the research on the dynamic mechanical behavior of TRC Mg alloys is very little in the open literature, although much researches on their microstructures, textures and mechanical behavior at different quasi-static strain rates and temperatures has been carried out [3,14,21]. Therefore, to investigate their dynamic mechanical behavior is of significance for designing crashworthy components in automotive body structures with TRC Mg alloys.

The present study aims to characterize the dynamic tensile behavior of TRC+R+HT AZ31B Mg alloy. Both quasi-static and dynamic tensile tests were conducted to study the flow stress behavior at room temperature and intermediate strain rates ranging from 0.001 s-1 to 375 s-1. The effects of strain rate and texture on the essential mechanical properties such as yielding, strain hardening and ductility were discussed. The microscopic examinations were performed to analyze the microstructures, texture and fracture surface morphologies and their relationship with the strain rate.

2 Experimental

2.1 Material and microstructures

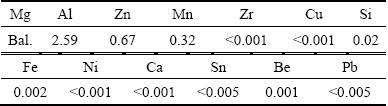

A commercial-grade AZ31B Mg alloy in the form of cast-rolled and annealed (O temper) sheet with a thickness of 1.8 mm was investigated. The AZ31B sheet was produced by twin-roll casting and sequential hot rolling in MgF Magnesium Flachprodukte GmbH in Germany. Its chemical composition is listed in Table 1. To consider the plastic anisotropy, the material specimens were tested along both the rolling direction (RD) and transverse direction (TD).

Table 1 Chemical composition of twin-roll cast-rolled AZ31B Mg alloy [22] (mass fraction, %)

The as-received material was analyzed by optical metallography (OM) and electron backscatter diffraction (EBSD). It can be seen from Fig. 1(a) that the material was fully recrystallized during annealing, resulting in an equiaxed grain structure and a broad grain size distribution with an average intercept size of around 9.5 μm. Figures 1(b) and (c) show the inverse pole figure map and crystallographic texture, respectively. The basal {0001} figure, prismatic  pole figure and pyramidal

pole figure and pyramidal  pole figure were analyzed. It is evident that the material exhibits a strong basal fiber texture. The intensity distribution of the basal pole is slightly broader between the ND and TD than between the ND and RD. This is different from the basal textures analyzed by KURUKURI et al [23] and STEGLICH et al [24] for rolled AZ31B sheets, in which the initial basal poles preferentially spread along the RD. The different basal textures might be caused by different rolling processes and/or heat treatments.

pole figure were analyzed. It is evident that the material exhibits a strong basal fiber texture. The intensity distribution of the basal pole is slightly broader between the ND and TD than between the ND and RD. This is different from the basal textures analyzed by KURUKURI et al [23] and STEGLICH et al [24] for rolled AZ31B sheets, in which the initial basal poles preferentially spread along the RD. The different basal textures might be caused by different rolling processes and/or heat treatments.

2.2 Uniaxial tensile tests

For dynamic tensile testing, no international testing standards are available. This work developed an elaborate dynamic uniaxial tensile testing method. It employed a servo-hydraulic testing machine Instron VHS 100/20. As shown in Figs. 2(a) and (b), the testing system mainly comprised of a Kistler 9361B piezo-electric load cell, an upper grip, a lower grip, a hydraulic actuator, a high speed camera photon FASTCAM SA-Z and two high-power lamps. The specimen geometry shown in Fig. 2(c) was carefully designed using finite element simulation and experimental verification. The function of the holes at two ends is to clamp and connect the specimen to the upper and lower grips by screws, nuts and pins. The dynamic tensile tests were conducted at room temperature and velocities of 0.035, 0.2, 1, 3, 6.3 and 14 m/s, and it obtained averaged strain rates of 1, 5, 27, 93, 186 and 375 s-1, respectively.

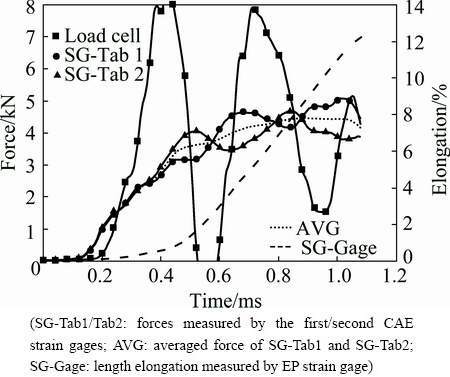

As shown in Fig. 2(b), the length elongation in the parallel section was measured by a high-elongation strain gage, Vishay measurement EP-08-125AD-120. Force measurement is a crucial procedure in dynamic tensile testing. The tensile force measured by the Kistler load cell generally exhibits significant oscillations due to the “ringing” of the loading system when the testing velocity is higher than 1.0 m/s. To reduce the oscillations, the tensile force was indirectly measured by measuring the elastic tensile strain in the upper grip section. To compensate the bending effect, the elastic tensile strain was measured by two general-used strain gages CAE-06-125UN-120, which were attached to both side-surfaces of the upper grip section. To guarantee uniform elastic deformation on the cross-section where the CAE strain gages were attached, the position of the CAE strain gages was optimized using finite element simulation and experimental verification. As shown in Fig. 3, the averaged force measured by the two CAE strain gages is distinctly smoother than the force measured by the load cell.

Fig. 1 Initial microstructure (a), initial EBSD inverse pole figure map in ND (b) and crystallographic texture plots of as-received AZ31B Mg alloy (c)

Fig. 2 Dynamic uniaxial tensile testing setup

Fig. 3 Strain and force signals at strain rate of 186 s-1

For quasi-static tensile testing, the specimen geometry designed for dynamic tensile testing was also employed to keep consistency. The specimens were tested using a universal testing machine Zwick/Roell Z250. The crosshead velocities of 0.035, 0.35 and 3.5 mm/s were set to obtain averaged strain rates of 0.001, 0.01 and 0.1 s-1 in the gage section respectively.

2.3 Microscopic examination

The microstructures of both the as-received and deformed materials were observed via an optical metallographic microscope Zeiss Axiovert 200MAT after etching with an acetic-picral solution. To analyze the texture, the AZ31B samples were carefully prepared via grinding with 2000 SiC paper, mechanical polishing with 0.05 μm silica suspension and final electro-chemical polishing for 90 s at 33 V and -30 °C using a 10% perchloric acid and 90% methanol. The prepared sample was measured by EBSD using a Hitachi scanning electron microscope (SEM) and AZtecHKL Channel 5 software. The fracture surface morphologies of the broken specimens were analyzed using a SEM (Shimadzu Superscan SSX-550) equipped with an energy dispersive X-ray spectroscopy (EDS) analyzer.

3 Results

3.1 Effect of strain rate on mechanical properties

3.1.1 Strength and ductility

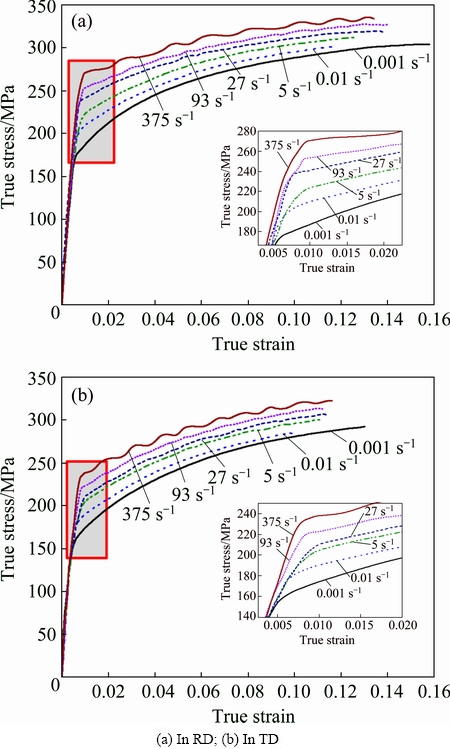

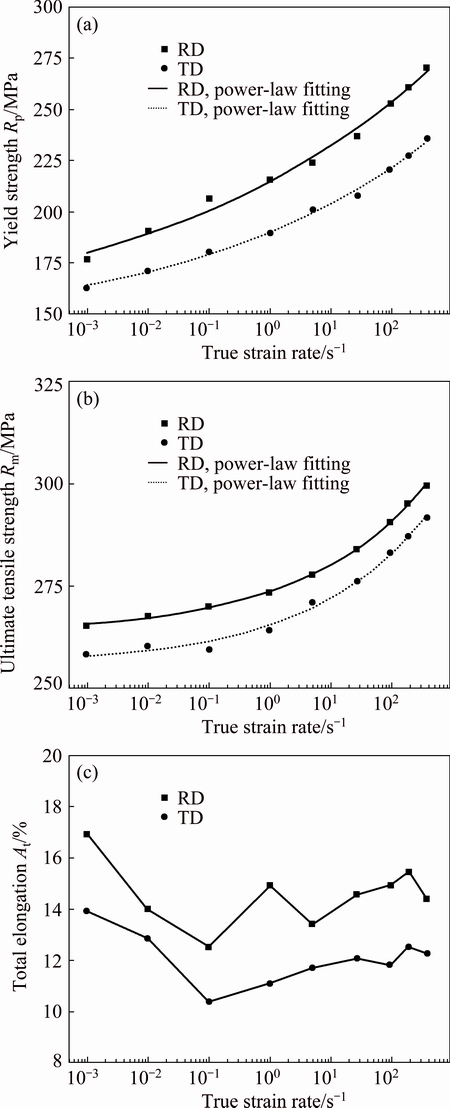

The selected true stress-strain curves of the AZ31B sheet at different strain rates ranging from 0.001 s-1 to 375 s-1 are shown in Fig. 4. It can be seen that the flow stress increases with increasing the strain rate in both orientations. The effect of strain rate on the 0.2% offset yield strength, ultimate tensile strength and total elongation at fracture are illustrated in Fig. 5. As shown in Figs. 5(a) and (b), the yield strength and ultimate tensile strength increase with increasing the logarithm of the true strain rate. The increasing tendency is approximately a power-law relationship. The values of yield strength in the RD and TD are increased by 94 MPa and 73 MPa, respectively, when increasing the strain rate from 0.001 s-1 to 375 s-1. As shown in Fig. 5(c), the total elongation distinctly decreases as the strain rate increases from 0.001 s-1 to 0.1 s-1, then it slightly increases as the strain rate increases from 0.1 s-1 to 375 s-1 in general. It seems that in the dynamic strain rate range (1-375 s-1), the effect of strain rate on the total elongation is not distinct. Moreover, the total elongations at dynamic strain rates are slightly higher than that at a strain rate of 0.1 s-1, but lower than that at a strain rate of 0.001 s-1. In the same strain-rate level, similar fracture behavior was also reported by KURUKURI el al [23].

It can be seen from Fig. 5 that the material exhibits anisotropy of strength and ductility. At each strain rate, the yield strength, ultimate tensile strength and total elongation at fracture are higher in the RD than in the TD, which is in agreement with the recent observations for twin-roll cast-rolled AZ31 [25] and for rare earth alloy ZE10 [24].

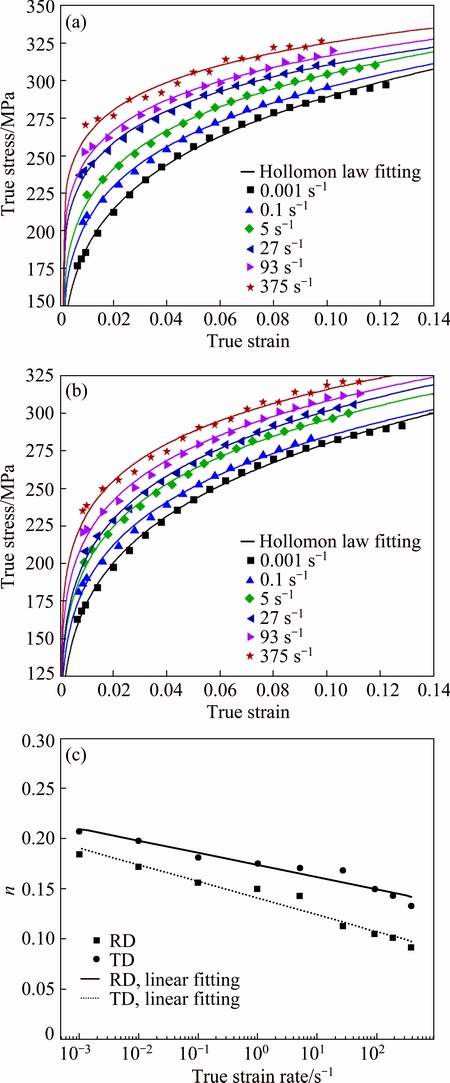

Fig. 4 True stress-strain curves of AZ31B sheet at selected strain rates

3.1.2 Strain hardening exponent

The true stress-strain relationship in the absence of strain-rate hardening can be described by the Hollomon’s power-law.

σ=Kεn

where ε is the true strain in the uniform plastic deformation region, K is the strength coefficient and n is the strain hardening exponent. One can calculate that the n-value with the standard method outlined in ASTM E646-07. As can be seen from Figs. 6(a) and (b), the Hollomon’s power-law equation correlates well the true stress and true strain at each strain rate. The evaluated n-values as a function of true strain rate are shown in Fig. 6(c) for both orientations. It can be seen that the n-values approximately range from 0.09 to 0.21 and they proportionally decrease with increasing the logarithm of the true strain rate. This indicates that the material has lower strain hardening capacity at a higher strain rate. Moreover, the n-value at a constant strain rate is lower in the RD than in the TD and the difference tends to increase with increasing the true strain rate. It is generally accepted that a material with a higher n-value has better formability than that with a lower n-value.

Fig. 5 Yield strength (a), ultimate tensile strength (b) and total elongation (c) at fracture with respect to true strain rate in RD and TD

Fig. 6 Hollomon law fitting of true stress-strain at selected strain rates in RD (a) and in TD (b) and evaluated n-values with respect to true strain rate (c)

However, as shown in Fig. 5(c), the total elongation at fracture of this material is higher in the RD than in the TD. The inconsistent results may be attributed to the brittle fracture behavior, i.e., the material tends to break prior to necking in the tensile tests.

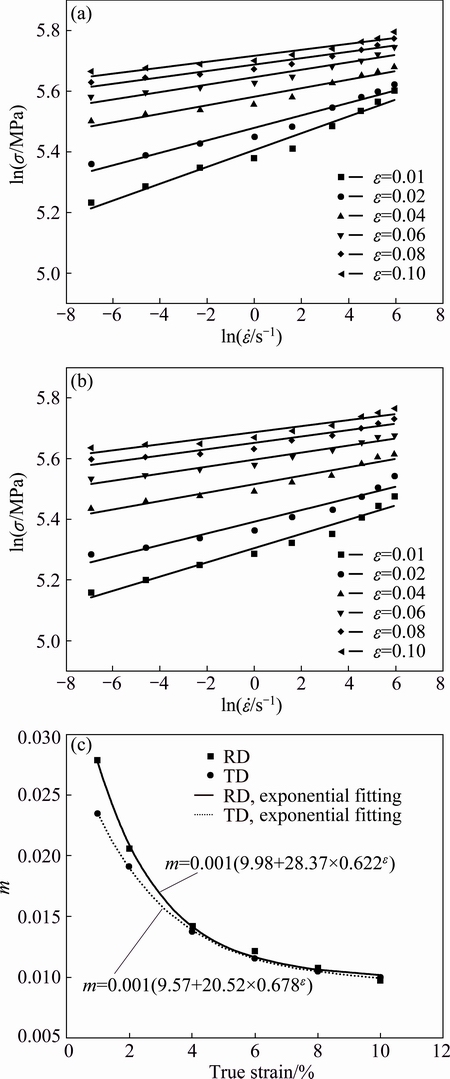

3.1.3 Strain-rate sensitivity

The strain-rate sensitivity of the AZ31B sheet in the absence of strain hardening can be described by Backofen’s constitutive law:

where σ and  are the true stress and true strain rate, respectively, C is a material constant, and m is the strain-rate sensitivity exponent. To evaluate the m-values, the true stress-strain rate data at six different true strains were plotted in the lnσ -

are the true stress and true strain rate, respectively, C is a material constant, and m is the strain-rate sensitivity exponent. To evaluate the m-values, the true stress-strain rate data at six different true strains were plotted in the lnσ - curves, as shown in Figs. 7(a) and (b) for the cases in the RD and TD respectively. The averaged m-value at each true strain was determined as the slope of the straight line that was obtained by a linear regression of the experimental data. It seems likely that the relationship between lnσ and

curves, as shown in Figs. 7(a) and (b) for the cases in the RD and TD respectively. The averaged m-value at each true strain was determined as the slope of the straight line that was obtained by a linear regression of the experimental data. It seems likely that the relationship between lnσ and  can be described well with a linear law, especially at higher true strains. The evaluated m-values with respect to true strain are also shown in Fig. 7(c). It can be seen that the material exhibits positive strain-rate sensitivity and the m-value decreases with increasing the true strain at an exponential rate. Moreover, unlike the n-value, the m-value at a constant true strain is higher in the RD than in the TD; however, the difference tends to decrease with increasing the true strain. At a true strain higher than 6%, the m-values tend to be nearly the same in both orientations.

can be described well with a linear law, especially at higher true strains. The evaluated m-values with respect to true strain are also shown in Fig. 7(c). It can be seen that the material exhibits positive strain-rate sensitivity and the m-value decreases with increasing the true strain at an exponential rate. Moreover, unlike the n-value, the m-value at a constant true strain is higher in the RD than in the TD; however, the difference tends to decrease with increasing the true strain. At a true strain higher than 6%, the m-values tend to be nearly the same in both orientations.

Fig. 7 lnσ - plots at different true strains in RD (a) and TD (b) and evaluated m-values with respect to true strain (c)

plots at different true strains in RD (a) and TD (b) and evaluated m-values with respect to true strain (c)

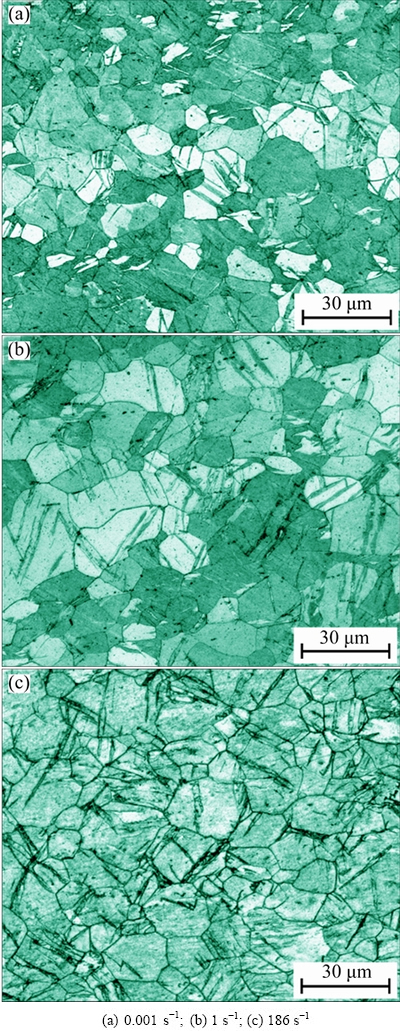

3.2 Deformed microstructures

The microstructures at the fracture zones (RD-ND cross-section) of the deformed specimens tested at strain rates of 0.001, 1 and 186 s-1 are shown Fig. 8. It can be seen that a small number of twins are visible under an optical microscope in the deformed specimens. Moreover, the number of twins increases with increasing the strain rate. This indicates that mechanical twinning becomes prevalent to accommodate the high-rate deformation. Similar results were also reported by ULACIA et al [4] for rolled AZ31 alloy, and by JIANG et al [26] for extruded AM30 alloy.

Fig. 8 Microstructures at fracture zones (RD-ND cross-section) of RD specimens tested at different strain rates

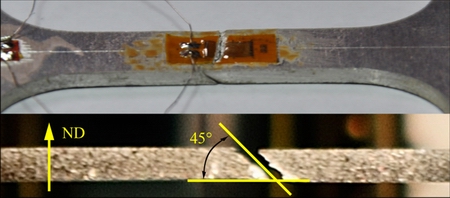

3.3 Fractographic analysis

The representative macro-fracture characteristic of the deformed specimen at a strain rate of 186 s-1 is shown in Fig. 9. Similar characteristic was also observed under other loading conditions. The fracture surface has a 45° angle from the tensile axis of the RD or TD specimen, which is the result of shear-off fractures. Moreover, no significant macroscopic necking was observed in both the width and thickness directions. On a macro-level, the fracture of the AZ31B sheet can be characterized as ductile since it exhibits moderate plasticity, as can be seen from Fig. 5(c). In the meanwhile, it can be characterized as brittle since no significant macroscopic necking was observed prior to fracturing.

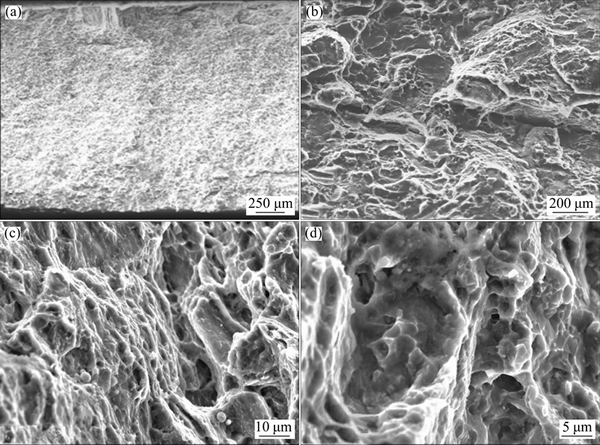

The typical SEM fracture morphologies of the RD specimen tested at a strain rate of 0.001 s-1 are shown in Fig. 10. In the low magnification image (Fig. 10(a)), a relatively smooth fracture surface was observed. In the medium magnification image (Fig. 10(b)), a small number of small cleavage facets with thin river patterns and a large number of small quasi-cleavage facets were observed on the fracture surface. In the high magnification images (Figs. 10(c) and (d)), a large number of dimples with different sizes and tearing edges were observed. This indicates that the material in these regions experienced considerable plastic deformation. Small cleavage cracks near some flat facets were also observed in Figs. 10(b) and (d). These micro-cracks could be the origins of the fracture. The cleavage cracks grew and propagated into the material matrix, and finally split the material apart, resulting in quasi-cleavage facets and plastic deformation regions with dimples and tearing edges.

Fig. 9 Macro-fracture characteristic of RD specimen at strain rate of 186 s-1

Similar characteristics of fracture surfaces were observed in the RD specimens tested at higher strain rates of 1 s-1 and 186 s-1, as shown in Figs. 11 and 12, respectively. However, more flat facets but fewer dimples were observed at strain rates of 1 s-1 and 186 s-1 compared with those at a strain rate of 0.001 s-1. This indicates that the material experienced less plastic deformation at strain rates of 1 s-1 and 186 s-1. As analyzed above, it can be concluded that the fracture surfaces of the RD specimens in tension are mainly composed of cleavage facets with thin river patterns and quasi-cleavage facets with dimples and tearing edges. These characteristics reveal that the fracture of the AZ31B sheet in the RD is a mixed mode of ductile and brittle fracture.

Fig. 10 Typical SEM fracture morphologies of RD specimen tested at strain rate of 0.001 s-1

Fig. 11 Typical SEM fracture morphologies of RD specimen tested at strain rate of 1 s-1

Fig. 12 Typical SEM fracture morphologies of RD specimen tested at strain rate of 186 s-1

The typical SEM fracture morphologies of the TD specimens tested at different strain rates are shown in Fig. 13. Like the RD specimens, dimples and flat facets were also observed on the fracture surfaces of the TD specimens as shown Figs. 13(d) and (e); therefore, the fracture of the AZ31B sheet in the TD is also a mixed mode of ductile and brittle fracture. However, unlike the RD specimens, a large number of medium-size cleavage-like bands along the width direction were observed on the fracture surfaces of the TD specimens as shown in Figs. 13(a)-(c). Furthermore, the number of the cleavage-like bands significantly increases with the strain rate. It seems likely that the existence of these strings of cleavage-like bands leads to the lower total elongations in the TD than those in the RD.

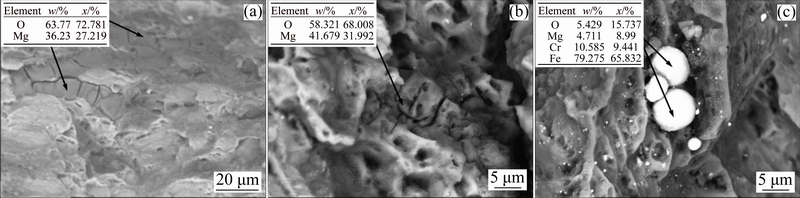

To identify the chemical compositions of the second phase particles which could be the origins of the fracture, EDS spectrum analysis was performed on some selected samples. Figure 14 shows the backscattered electron (BSE) images which provide atomic number contrast wherein regions of higher average atomic number appear brighter. The chemical composition tables obtained from the EDS spectrum analysis are embedded in the BSE images. Oxide inclusions/particles in the forms of lump, cluster, lamellar and granular particles were observed on the fracture surfaces of the AZ31B specimens after tensile tests. In Figs. 14(a) and (b), the particles are rich in O and Mg; therefore, the particles are mainly fractured magnesium oxide clusters. In Fig. 14(c), the particles are rich in Fe and O with a smaller amount of Mg and Cr; therefore, the particle may be mainly composed of ferric oxide. In general, the majority of the second phase particles in the selected samples are composed of magnesium oxide inclusions.

4 Discussion

It is known that the mechanical properties of Mg alloys are strongly dependent upon the deformation mechanisms, particularly for wrought Mg alloys because textures are unavoidably produced in rolling and extrusion processes. Dislocation slip and mechanical twinning are two common deformation mechanisms which are highly related to the orientation of deformed grains with respect to the direction of applied stresses, i.e., the so-called Schmidt factor. It can be seen from Fig. 1(c) that the tensile axes are nearly parallel to the basal planes of most grains in both the RD and TD specimens, corresponding to very small Schmidt factors for basal slip. In this case, it is unfavorable to activate basal slip and  extension twinning; therefore, non-basal slip (prismatic <a> slip and pyramidal <a+c> slip),

extension twinning; therefore, non-basal slip (prismatic <a> slip and pyramidal <a+c> slip),  contraction twinning and

contraction twinning and  double twinning should be activated due to their favorable orientations under in-plane tension [27]. This is in good agreement with the presence of twins in the deformed specimens as shown in Fig. 8. The increase of twins with increasing the strain rate could be interpreted via dislocation dynamics. It is known that at a higher strain rate, the dislocation movement or slip deformation cannot follow the higher loading speed; therefore, the twinning-induced deformation can be developed to accommodate the deformation.

double twinning should be activated due to their favorable orientations under in-plane tension [27]. This is in good agreement with the presence of twins in the deformed specimens as shown in Fig. 8. The increase of twins with increasing the strain rate could be interpreted via dislocation dynamics. It is known that at a higher strain rate, the dislocation movement or slip deformation cannot follow the higher loading speed; therefore, the twinning-induced deformation can be developed to accommodate the deformation.

Fig. 13 Typical SEM fracture morphologies of TD specimens tested at different strain rates

Fig. 14 Typical BSE images and EDS spectrum analysis of AZ31B specimens after tensile tests

The effect of strain rate on the yield strength can be interpreted by the texture and Schmidt law. It has been reported that the critical resolved shear stress (CRSS) of basal slip and twinning have little or insignificant strain-rate dependence, while the CRSS of non-basal slip has positive strain-rate dependence [28]. Therefore, the positive effect of strain rate on the yield strength for the AZ31B sheet under in-plane tension may be attributed to the positive strain-rate dependence of the CRSS of non-basal slip. Moreover, it is noted from Fig. 1(c) that the intensity distribution of the basal pole is broader between the ND and TD than between the ND and RD, resulting in a higher Schmidt factor for basal slip in the TD than in the RD. This allows relatively easier activation of basal slip if the load is applied in the TD. As the CRSS of basal slip is lower than that of non-basal slip, it would result in higher yield strength in the RD than in the TD. This is in agreement with the present results.

In general, the strain hardening rate increases with increasing the strain rate. In the present case, the strain hardening rate decreases with increasing the strain rate, as shown in Fig. 6(c). Such unusual behavior was observed when twinning was prevalent [26]. This means that twinning plays an important role in the hardening behavior of Mg alloys. It can influence the hardening behavior in two different ways: 1) twinning-induced hardening via twin boundaries that act as obstacles to dislocation motion; and 2) twinning-induced softening via accommodating strains along the c-axis of grains and promoting the dislocation slip of reoriented grains that are originally unfavorable oriented for dislocation slip. As for the studied AZ31B sheet under in-plane tension, it can be speculated that twinning-induced softening is predominant compared with the twinning-induced hardening, since the strain hardening exponent n decreases with increasing the strain rate.

5 Conclusions

1) A small number of twins are visible in the deformed specimens and their number increases with increasing the strain rate, which indicates that mechanical twinning becomes prevalent to accommodate the high-rate deformation.

2) The strain hardening exponent proportionally decreases with increasing the strain rate due to twinning-induced softening. The strain-rate sensitivity decreases with increasing the true strain at an exponential rate. The strength, ductility and strain-rate sensitivity are higher in the rolling direction, while the strain hardening exponent is higher in the transverse direction.

3) The total elongation at fracture distinctly decreases as the strain rate increases in quasi-static tension (0.001-0.1 s-1), while the effect of strain rate on the total elongation is not distinct in dynamic tension (1-375 s-1).

4) SEM fractographic analysis reveals that the fracture is a mixed mode of ductile and brittle fracture. EDS spectrum analysis observed that the main second phase particles in the material are magnesium oxide inclusions, which could be the origin of the fracture.

Acknowledgements

This work is supported by the German Aerospace Center (DLR) project “Next Generation Car”. The authors would like to thank Harald Kraft at the DLR-Institute of Structures and Design, Thomas  at the DLR-Institute of Vehicle Concepts for their kind assistance in the material mechanical tests.

at the DLR-Institute of Vehicle Concepts for their kind assistance in the material mechanical tests.

References

[1] FRIEDRICH H E, MORDIKE BARRY L. Magnesium technology— metallurgy, design data, applications [M]. Heidelberg: Springer- Verlag, 2006.

[2] LUO A A. Applications: Aerospace, automotive and other structural applications of magnesium, in fundamentals of magnesium alloy metallurgy [M]. PEKGULERYUZ M O, KAINER K U, KAYA A A. Cambridge, UK: Woodhead Publishing Limited, 2013: 266-316.

[3] LIU Zhi-min, XING Shu-ming, BAO Pei-wei, LI Nan, YAO Shu-qing, ZHANG Mi-lan. Characteristics of hot tensile deformation and microstructure evolution of twin-roll cast AZ31B magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 776-782.

[4] ULACIA I, SALISBURY C P, HURTADO I, WORSWICK M J. Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures [J]. Journal of Materials Processing Technology, 2011, 211(5): 830-839.

[5] MENG Zheng-hua, HUANG Shang-yu, HU Jian-hua, HUANG Wei, XIA Zhi-lin. Effects of process parameters on warm and electromagnetic hybrid forming of magnesium alloy sheets [J]. Journal of Materials Processing Technology, 2011, 211(5): 863-867.

[6] GENG Chang-jian, WU Bao-lin, LIU Fang, TONG Wen-wei, HAN Zhen-yu. Dynamic tensile behavior of AZ31B magnesium alloy at ultra-high strain rates [J]. Chinese Journal of Aeronautics, 2015, 28(2): 593-599.

[7] YU Zheng-wen, TANG Ai-tao, WANG Qin, GAO Zheng-yuan, HE Jie-jun, SHE Jia, SONG Kai, PAN Fu-sheng. High strength and superior ductility of an ultra-fine grained magnesium–manganese alloy [J]. Materials Science and Engineering A, 2015, 648(11): 202-207.

[8] AGNEW S R, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing [J]. Scripta Materialia, 2004, 50(3): 377-381.

[9] STANFORD N. The effect of rare earth elements on the behaviour of magnesium-based alloys: Part 2—Recrystallisation and texture development [J]. Materials Science and Engineering A, 2013, 565(10): 469-475.

[10] GZYL M, ROSOCHOWSKI A, BOCZKAL S, OLEJNIK L. The role of microstructure and texture in controlling mechanical properties of AZ31B magnesium alloy processed by I-ECAP [J]. Materials Science and Engineering A, 2015, 638(25): 20-29.

[11] MA R, WANG L, WANG Y N, ZHOU D Z. Microstructure and mechanical properties of the AZ31 magnesium alloy sheets processed by asymmetric reduction rolling [J]. Materials Science and Engineering A, 2015, 638(25): 190-196.

[12] ZHAN Mei-yan, LI Yuan-yuan, CHEN Wei-ping. Improving mechanical properties of Mg-Al-Zn alloy sheets through accumulative roll-bonding [J]. Transactions of Nonferrous Metals Society of China, 2008, 18(2): 309-314.

[13] KAWALLA R, OSWALD M, SCHMIDT C, ULLMANN M, VOGT H P, CUONG N D. New technology for the production of magnesium strips and sheets [J]. Metalurgija, 2008, 47(3): 195-198.

[14] BERGE F,  L, OUAZIZ H, ULLRICH C. Influence of temperature and strain rate on flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 1-13.

L, OUAZIZ H, ULLRICH C. Influence of temperature and strain rate on flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 1-13.

[15] PARK S S, PARK W J, KIM C H, YOU B S, KIM N J. The twin-roll casting of magnesium alloys [J]. JOM, 2009, 61(8): 14-18.

[16] NEH K, ULLMANN M, KAWALLA R. Twin-roll-casting and hot rolling of magnesium alloy WE43 [J]. Procedia Engineering, 2014, 81(1): 1553-1558.

[17] FORSMARK J H, LI M, SU X, WAGNER D A, ZINDEL J, LUO A A, QUINN J F, VERMA R, WANG Y M, LOGAN S D, BILKHU S, MCCUNE R C. The USAMP magnesium front end research and development project-results of the magnesium “demonstration” structure [C]//Magnesium Technology 2014, Hoboken, NJ, USA: John Wiley & Son, 2014.

[18] PARRISH A, RAIS-ROHANI M, NAJAFI A. Crashworthiness optimisation of vehicle structures with magnesium alloy parts [J]. International Journal of Crashworthiness, 2012, 17(3): 259-281.

[19] EL-MAGD E, ABOURIDOUANE M. Characterization, modelling and simulation of deformation and fracture behaviour of the light-weight wrought alloys under high strain rate loading [J]. International Journal of Impact Engineering, 2006, 32(5): 741-758.

[20] FENG Fei, HUANG Shang-yu, MENG Zheng-hua, HU Jian-hua, LEI Yu, ZHOU Meng-cheng, WU Dan, YANG Zhen-zhen. Experimental study on tensile property of AZ31B magnesium alloy at different high strain rates and temperatures [J]. Materials & Design, 2014, 57: 10-20.

[21] RODRIGUEZ A K, KRIDLI G, AYOUB G, ZBIB H. Effects of the strain rate and temperature on the microstructural evolution of twin-rolled cast wrought AZ31B alloys sheets [J]. Journal of Materials Engineering and Performance, 2013, 22(10): 3115-3125.

[22] ULLMANN M, SALEH H, SCHMITDCHEN M, KAWALLA R, VOGT H P. Improvement of ductility for twin roll cast and rolled AZ31 strips by use of Taguchi method [J]. Archives of Civil and Mechanical Engineering, 2013, 13(1): 1-6.

[23] KURUKURI S, WORSWICK M J, GHAFFARI T D, MISHRA R K, CARTER J T. Rate sensitivity and tension-compression asymmetry in AZ31B magnesium alloy sheet [J]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2014, 372(2015): 20130216.

[24] STEGLICH D, TIAN X, BOHLEN J, KUWABARA T. Mechanical testing of thin sheet magnesium alloys in biaxial tension and uniaxial compression [J]. Experimental Mechanics, 2014, 54(7): 1247-1258.

[25] BERGE F,  L, ULLMANN M, KRBETSCHEK C, KAWALLA R. Anisotropy of the mechanical properties of twin-roll cast, rolled and heat-treated AZ31 as a function of temperature and strain rate [J]. Materials Today: Proceedings, 2015, 2: s233-s241.

L, ULLMANN M, KRBETSCHEK C, KAWALLA R. Anisotropy of the mechanical properties of twin-roll cast, rolled and heat-treated AZ31 as a function of temperature and strain rate [J]. Materials Today: Proceedings, 2015, 2: s233-s241.

[26] JIANG L, JONAS J J, LUO A A, SACHDEV A K, GODET S. Twinning-induced softening in polycrystalline AM30 Mg alloy at moderate temperatures [J]. Scripta Materialia, 2006, 54(5): 771-775.

[27] BARNETT M R. Twinning and its role in wrought magnesium alloys, in Advances in wrought magnesium alloys: Fundamentals of processing, properties and applications [M]. BETTLES C. Cambridge, UK: Woodhead Publishing Limited, 2012.

[28] BARNETT M R. A taylor model based description of the proof stress of magnesium AZ31 during hot working [J]. Metallurgical and Materials Transactions A, 2003, 34(9): 1799-1806.

Ping ZHOU, Elmar BEEH, Meng WANG, Horst E. FRIEDRICH

German Aerospace Center (DLR) - Institute of Vehicle Concepts, Pfaffenwaldring 38-40, 70569 Stuttgart, Germany

摘 要:研究双辊铸轧和热轧处理AZ31B镁合金板材在室温和应变速率从0.001 s-1到375 s-1条件下的动态拉伸力学行为,以及力学性能与显微结构之间的关系。实验发现,该镁合金板材具有很强的初始基面纤维织构,并且在高应变速率条件下机械孪生成为主要的变形机理。材料的屈服强度和拉伸极限强度随应变速率的提高而提高;然而,孪生诱导的软化效应导致应变强化指数随应变速率的提高而成比例地降低。在准静态拉伸条件下,断裂伸长率随应变速率的提高而明显地降低;而在动态拉伸条件下应变速率对断裂伸长率的影响却不明显。最后,应用扫描电镜对拉伸试样进行了断口形貌分析。分析结果表明,该加工状态下的AZ31B镁合金板材的拉伸断裂是一种韧性与脆性混合断裂模式。

关键词:镁合金;双辊铸轧;动态拉伸;应变速率敏感性;断口形貌

(Edited by Xiang-qun LI)

Corresponding author: Ping ZHOU; Tel: +49-711-6862-8311; Fax: + 49-711-6862-258; E-mail: pingchou83@gmail.com

DOI: 10.1016/S1003-6326(16)64413-8