温度和应变速率对双辊铸轧、轧制和热处理态AZ31镁合金流动应力行为的影响

来源期刊:中国有色金属学报(英文版)2015年第1期

论文作者:F. BERGE L. KRüGER H. OUAZIZ C. ULLRICH

文章页码:1 - 13

关键词:AZ31镁合金;双辊铸轧;应变速率;温度;动态再结晶;流动应力

Key words:AZ31 magnesium alloy; twin-roll casting; strain rate; temperature; dynamic recrystallization; flow stress

摘 要:在单轴拉伸条件下研究温度和应变速率对双辊铸轧、轧制和热处理AZ31镁合金流动应力行为的影响。结果表明,在高温下,动态回复、连续动态再结晶、晶界滑移和附加滑移系的活化使合金的延展得到改善。在473~523 K和10-2~10-1 s-1条件下,合金的断裂伸长率几乎与应变速率无关,而与应变速率依赖于临界剪切应的非基面滑移有关。由于经上述工艺加工的AZ31镁合金具有较低的临界剪切应力,因此在573 K和10-3 s-1条件下出现了孪晶。

Abstract: The effects of temperature and strain rate on the flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys were investigated under uniaxial tension. At high temperatures, dynamic recovery, continuous dynamic recrystallization, grain boundary sliding and the activation of additional slip systems lead to an improvement of the ductility of the alloys. The elongation to failure is nearly independent of the strain rate between 473 and 523 K at 10-2 s-1 and 10-1 s-1, which is related to the strain rate dependence of the critical resolved shear stress (CRSS) for nonbasal slip. Despite the high temperature, twins are even observed at 573 K and 10-3 s-1 because they have a low CRSS.

Trans. Nonferrous Met. Soc. China 25(2015) 1-13

F. BERGE1, L.  1, H. OUAZIZ1, C. ULLRICH2

1, H. OUAZIZ1, C. ULLRICH2

1. Faculty of Materials Science and Technology, Institute of Materials Engineering,

Technical University Bergakademie Freiberg, Freiberg 09599, Germany;

2. Faculty of Materials Science and Technology, Institute of Materials Science,

Technical University Bergakademie Freiberg, Freiberg 09599, Germany

Received 24 February 2014; accepted 23 June 2014

Abstract: The effects of temperature and strain rate on the flow stress behavior of twin-roll cast, rolled and heat-treated AZ31 magnesium alloys were investigated under uniaxial tension. At high temperatures, dynamic recovery, continuous dynamic recrystallization, grain boundary sliding and the activation of additional slip systems lead to an improvement of the ductility of the alloys. The elongation to failure is nearly independent of the strain rate between 473 and 523 K at 10-2s-1 and 10-1s-1, which is related to the strain rate dependence of the critical resolved shear stress (CRSS) for nonbasal slip. Despite the high temperature, twins are even observed at 573 K and 10-3s-1 because they have a low CRSS.

Key words: AZ31 magnesium alloy; twin-roll casting; strain rate; temperature; dynamic recrystallization; flow stress

1 Introduction

In the last decade magnesium alloys were brought into focus by the automotive and aircraft industries because of their high lightweight potential. In contrast with other structural materials, magnesium alloy has high specific strength, low density (1.74 g/cm3), good damping quality, respectable machinability, and excellent recyclability [1].

Because of the hexagonal close packing, magnesium and its alloys have a low formability at low temperatures. Magnesium does not exhibit five independent slip systems at room temperature, and according to von Mises criterion, it cannot produce uniform polycrystalline plastic deformation [2]. Therefore, dislocation glide on the basal plane and twinning are the most common deformation mechanisms in wrought magnesium alloys at low temperatures and strain rates. Furthermore, prismatic and pyramidal glide is also possible for hexagonal metals depending on the c/a axial ratio and the stacking fault energy [3,4]. Depending on the temperature, different deformation mechanisms are active because of their critical resolved shear stress (CRSS). In general, at low temperatures, this assumption is made: CRSSbasal < CRSStwinning < CRSSprismatic ≤ CRSSpyramidal [5]. It is assumed that the CRSS of basal slip is nearly independent of the temperature. In contrast to this, with rising temperature the CRSS of prismatic and pyramidal slip decreases. This results in an activation of additional slip systems above 498 K depending on alloying elements, and grain size, which causes an improvement of ductility and a decrease of flow stress [6]. ULACIA et al [7] suggested that the decrease of CRSSnonbasal with increasing temperatures is less distinct at high strain rates than at low strain rates.

Beside the dislocation motion on the basal plane, mechanical twinning plays an important role because of its low CRSS [8,9]. The CRSS for twinning is not a function of the temperature and twins are even active at high temperatures due to their low CRSS compared with nonbasal slip [5,10]. Twinning influences the texture development by changing the orientation of twinned grains which can cause hardening or softening [11]. In addition, twins can act as barriers for the dislocation motion because they interrupt the slip length [12,13]. Depending on the c/a axial ratio, different twin-types can occur [3]. With rising c/a axial ratio, tensile twinning is enhanced because of the decrease of individual shear. A compression of the c-axis results in the formation of contraction twins. Tension twins are formed when the c-axis is extended by external loading [9]. With decreasing the grain size, twinning is increasingly inhibited [14]. Below a critical grain size twins do no longer occur. BARNETT [5] found that the CRSStwinning is not a function of the strain rate.

Other mechanisms during high temperature deformation of magnesium alloys are dynamic recovery (DRV) and dynamic recrystallization (DRX) [15]. DRV is represented by the rearrangement and the annihilation of moving dislocations. DRX can be divided into continuous (CDRX) and discontinuous dynamic recrystallization (DDRX) [16]. CDRX leads to the formation of high-angle grain boundaries out of subgrains. Therefore, a strong movement of low-angle grain boundaries is required. Consequently, CDRX is actually a distinct recovery process [17]. DDRX induces the nucleation and the growth of new undeformed fine grains which also cause an enhancement of the ductility. All DRX mechanisms are influenced by the temperature, strain rate, predeformation and dislocation density, grain size, and texture [7,17]. For AZ31 magnesium alloy, DRX starts above 473 K [18].

As noted by KOIKE [19], a fine grained microstructure can improve the ductility of magnesium alloys as well. Grain refinement and texture control in magnesium alloys can be achieved by alloy design [20,21], equal channel angular pressing (ECAP) also known as equal channel angular extrusion (ECAE) [22-25], conventional extrusion [26], accumulative roll-bonding (ARB) [27] or conventional hot rolling [28].

As described above, because of the existing deformation mechanisms, drawing of magnesium parts is only useful at elevated temperatures [29]. This results in high energy costs for the producers. The main goal of the manufacturing industry is to establish a cost-effective production of these lightweight alloys. In contrast to conventional hot rolling, twin-roll casting (TRC) does not need the roughing rolling of billets in several steps [30]. It is a combination of casting and rolling and influences the microstructure, e. g. the grain size, by rapid solidification on the sheet surface and Scheil solidification in the sheet thickness [30,31]. It has the advantage that alloying elements with limited solid solubilities, which are prevented in ingot-casting, can be used [32]. In comparison to cast magnesium alloys, wrought magnesium alloys show a strong basal texture, which can influence the anisotropy and formability [33,34]. This can be reduced by alloy design or specific rolling and subsequent heat-treatment after TRC processing [35-37].

Previous studies determined the deformation behavior of the conventional rolled AZ31 magnesium alloy. However, there are no investigations on the influence of temperature and strain rate on the flow stress behavior of TRC+R+HT AZ31 magnesium alloy. These results are necessary for modeling and simulation of material behavior regarding to prospective applications.

The main objective of this study was to investigate the flow stress behavior according to the microstructural evolution of TRC, rolled and heat-treated AZ31 magnesium alloy in a wide range of temperatures and strain rates. The occurrence of the different deformation mechanisms was discussed.

2 Experimental

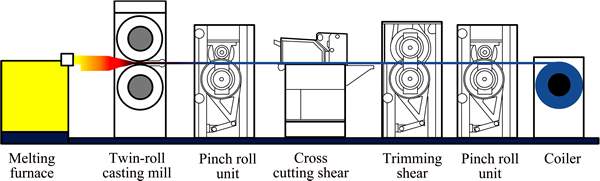

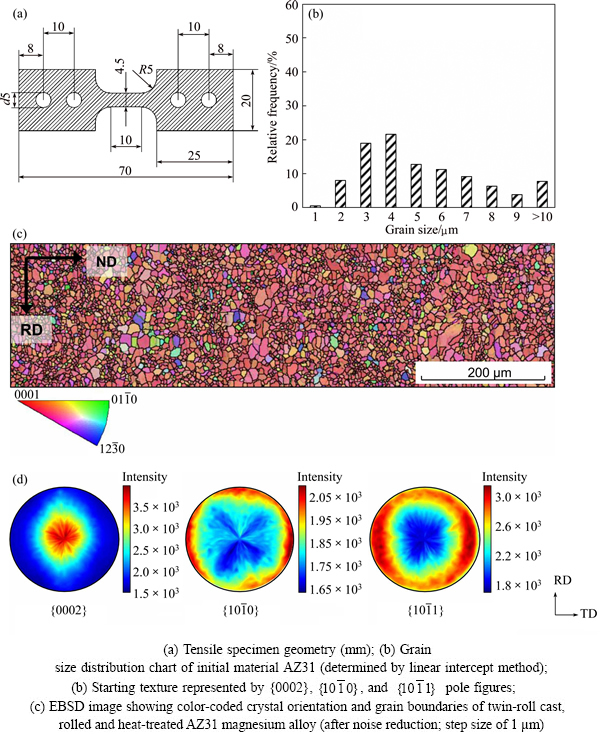

AZ31 (Mg-3Al-1Zn-0.3Mn, mass fraction, %) sheets with 720 mm in width and 4.5 mm in thickness were produced by twin-roll casting technology) (Fig. 1 [38]). In this process, AZ31 sheet was melted in a gas-fired furnace and passed the water-cooled vertical rotating rolls through a casting nozzle. Subsequently, the material was solidified in the roll gap. In order to dissolve existing segregations and obtain a recrystallized microstructure, the sheets were homogenized at 743 K for 2 h. After cutting to 600 mm×100 mm (length×width) and rolling to 2 mm in thickness in three roll passes at a roll speed of 5 m/s, a final heat-treatment was carried out at 603 K for 45 min. Previous investigations show that a roll speed of 5 m/s tended to enhance dynamic recrystallization, resulting in better ductility in comparison to 1 m/s [37]. Out of these sheets tensile specimens were fabricated along the rolling direction (RD, 0°) via water jet cutting. The specimen geometry is presented in Fig. 2(a). Quasi-static tensile tests were performed in air with the electromechanical universal testing devices Zwick 1476 and Zwick Z020 with 100 kN and 20 kN loading cells, respectively. For validation of the strain rate to 0.76×10-3 s-1, 0.73×10-2s-1 and 0.72× 10-1 s-1, strain gauge measurements were conducted at room temperature. In common production processes magnesium alloys are formed below 573 K. Due to this fact, the flow stress behavior under tensile loading was investigated in a temperature range of 293-573 K. Immediately after the tests, all specimens were quenched in water.

Fig. 1 Principle of twin-roll casting process [38]

Fig. 2 Characterization of initial material (referring to Web version of this article)

For qualitative and quantitative microstructure evaluations, the deformed gauge lengths were studied with optical microscopy (OM), scanning electron microscopy (SEM) including electron backscatter diffraction (EBSD), and X-ray diffraction analysis (XRD) with a Seifert-FPM URD 6 in the area of uniform elongation. For this procedure, the samples were ground under water with SiC paper using 500, 800, 1200, 2400, and 4000 grit size at a pressure of 0.08 MPa for 60 s, respectively. Finally, a polishing with OP-S suspension (130 mL OP-S, 130 mL H2O, 10 mL H2O2, 1 mL 25% NH3·H2O solution) followed using 0.31 MPa pressure for 3.5 min. Etching was performed with picric acid for 15 s. EBSD measurements were conducted with a FEG SEM LEO 1530 Gemini (acceleration voltage of 20 kV) at step size of 0.2 and 1 μm with additionally ion-beam polished samples [39]. Grain size measurements were accomplished with the linear intercept method on 500-700 grains in optical micrographs in the area of uniform elongation.

3 Results and discussion

3.1 Material characterization

The initial sheet has a recrystallized and twin-free grain structure with an average grain size of 7 μm. Figure 2(b) presents the grain size distribution of the initial material. It can be seen that the fraction of fine grains (≤2 μm) is 9 %. It must be noted, that there is a difference in the grain size distribution between the middle section of the sheet and the sheet surface, which was also reported by SCHWARZ et al [40] for TRC AZ31 magnesium alloy. Larger amount of coarse grains (d>10 μm) in the middle section of the sheet are ascribed to the lower cooling rate in comparison to the sheet surface in the TRC, rolling and heat-treatment process [41]. Figure 2(c) presents an EBSD map showing the orientation of the microstructure. This map was performed with an indexing rate of 85 %. Al8Mn5 particles were detected with transmission electron microscopy (TEM), which are in agreement with the findings of CAO et al [42] and PARK et al [32]. In addition, Mg-Si-based particles were also observed by SEM. There are no known data available which explain the influence of these Mg-Si particles on the mechanical properties of AZ31 magnesium alloy [43]. As shown in Fig. 2(d), the entire AZ31 material has a strong basal texture, which means that most of the unit cells in the c-axis are orientated roughly parallel to the sheet normal direction (ND).

3.2 Influence of temperature on flow stress behavior

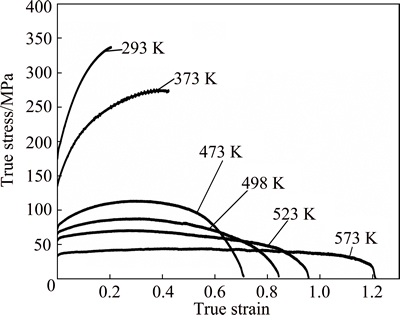

True stress-true strain curves of the deformed AZ31 magnesium alloy at a strain rate of 0.76×10-3 s-1 and various temperatures are displayed in Fig. 3. With increasing temperature, the material shows lower stresses and higher deformability. At 293 K strong hardening occurs in the early stages of deformation below the ultimate tensile strength. This is related to dislocation hardening in combination with a rising degree of twinning (Figs. 4(a) and (b). Twins act as barriers for dislocation motion on the {0002} basal planes [12]. Because of the initial basal texture and the probable contraction of the c-axis during tensile deformation,  compression twins are expected. However,

compression twins are expected. However,  tensile twins were mainly observed with EBSD measurements (Fig. 5). This is also related to the c/a axial ratio, which is higher than the ideal value [3]. This type of twins actually need an extension of the c-axis. KOIKE [19] suggested that the twin type did not depend on the loading direction in relation to the HCP unit cell. Twins are rather formed by internal stresses which act in various directions [3]. Furthermore, the low CRSS of

tensile twins were mainly observed with EBSD measurements (Fig. 5). This is also related to the c/a axial ratio, which is higher than the ideal value [3]. This type of twins actually need an extension of the c-axis. KOIKE [19] suggested that the twin type did not depend on the loading direction in relation to the HCP unit cell. Twins are rather formed by internal stresses which act in various directions [3]. Furthermore, the low CRSS of  tensile twinning (2 MPa) is responsible for their formation [44]. In contrast to this,

tensile twinning (2 MPa) is responsible for their formation [44]. In contrast to this,  compression twins are inhibited because of their high CRSS at 76-153 MPa [45].

compression twins are inhibited because of their high CRSS at 76-153 MPa [45].

Fig. 3 True stress-true strain curves at strain rate of 0.76 × 10-3 s-1 and various temperatures

As a result of DRV, which provides dislocation annihilation and rearrangement above 373 K, the hardening rate decreases significantly. Another reason for the rising deformability is the increasing dislocation motion with rising temperature. KOIKE et al [46] investigated the deformed ECAE AZ31 magnesium alloy by TEM and assumed that the occurrence of DRV is also possible at room temperature. Further examinations are needed for proof on wrought alloys. With rising temperatures, the value difference between 0.2 % yield stress (σ0.2) and ultimate tensile strength decreases [47]. As can be seen in Fig. 4(c), incomplete DRX takes place at 473 K. Above 498 K fully recrystallized grains are present (Figs. 4(d)-(f)). The current DRX mechanism can be identified as CDRX because of the formation of low-angle boundaries within the grains (Fig. 6).

Fig. 4 Optical micrographs of fractured AZ31 magnesium alloy at 0.76 × 10-3 s-1 and various temperatures in area of uniform elongation (arrows showing rolling direction)

Fig. 5 EBSD image of AZ31 magnesium alloys showing formation of  tensile twins (red color) and high-angle grain boundaries (black color), grey color corresponding to Kikuchi band contrast at

tensile twins (red color) and high-angle grain boundaries (black color), grey color corresponding to Kikuchi band contrast at  =0.76 × 10-3 s-1, T=293 K and εpl = 20 %

=0.76 × 10-3 s-1, T=293 K and εpl = 20 %

In contrast to low temperatures (293 and 373 K), the ultimate tensile strength is not related to the beginning of the specimens necking above 473 K. Interrupted tensile tests show that there is a uniform extension of the specimens. HUANG et al [48] suggested that the stress softening is related to dynamic recrystallization. Because of the dramatic decrease in the CRSS of the nonbasal slip systems, the activation of additional slip systems takes place above 498 K. GALIYEV et al [16] implied that cross slip of dislocations on the nonbasal planes is the dominating deformation mechanism between 473 K and 523 K. Cross slip at grain boundaries with high stress concentration leads to a transformation of screw dislocations to edge dislocations. Because of the high stacking fault energy of the nonbasal planes, climbing and cross slip are promoted. The consequence is the formation of low-angle grain boundaries which result in the CDRX. Furthermore, the improved dislocation movement causes a dramatic reduction of twinning which results in less hardening. However, because of their low CRSS, twins are still active at 573 K and 0.76×10-3 s-1 (Fig. 7). Above 523 K, bulging of grains is slightly visible, which was also found by GALIYEV et al [16] and YI et al [49]. TAN and TAN [50] suggested that the occurrence of precipitations is not inevitably necessary for DRX of AZ31 magnesium alloy. This is caused by the hexagonal structure and the lack of active slip systems. Furthermore, the low stacking fault energy and the high grain boundary diffusion rate are more important than the occurrence of precipitation. YI et al [49] investigated the formability as a function of the precipitation structure in the extruded AZ31 magnesium alloy. At 473 K, the deformation takes place in the two-phase area (Mg+γ). In contrast to this, precipitates are not visible at 523 K because the deformation was performed in the single-phase region (Mg). This results in an enhancement of dislocation slip at 523 K because of the missing precipitation hardening. Such a change in the Al8Mn5 precipitate structure cannot be observed in the current investigation. In addition, Mg17Al12 precipitate is not detected with EBSD.

Fig. 6 Microstructures of AZ31 magnesium alloys measured by EBSD in area of uniform elongation at 473 K (a) and 573 K (b) and strain rate of 0.76 × 10-3 s-1

Fig. 7 Optical micrograph of fractured AZ31 magnesium alloy at 0.76 × 10-3 s-1 and 573 K in area of uniform elongation

With decreasing the grain size, the driving force for grain boundary sliding (GBS) is increased, but the driving force for twinning is reduced [49,51]. The combination of DRV, DRX, GBS, and the activation of additional slip systems above 498 K leads to a high deformability of εpl, 498 K=0.82, εpl, 523 K=0.95, and εpl, 573K =1.14. GBS can result in the formation of voids (Fig. 4(f), Fig. 7) because of the high stresses, which are induced at the triple points of three moving grains [52]. In combination with the formation of recrystallized grains, these stress concentrations can cause crack initiation. This phenomenon is also a function of temperature. High temperatures provide a large fraction of DRX (small grains), which activates large amount of GBS. Fine grains (d<10 μm) and high misorientations are the requirement for GBS [53]. KOIKE et al [19,54] reported that GBS is also visible under tensile loading at room temperature where recrystallization does not occur.

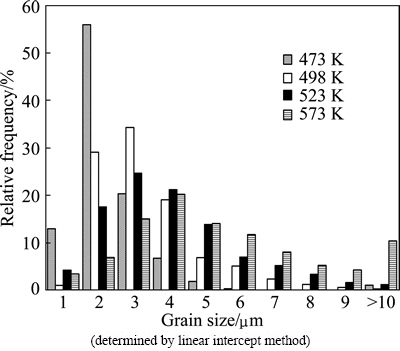

The grain size distribution of fractured AZ31 samples is shown in Fig. 8. In comparison to Fig. 2(c), the relative fraction of fine grains (≤2 μm) increases from 9% (initial state) to 69 % (473 K) and to 30 % (498 K). At 523 and 573 K, CDRX takes place combined with large grain growth. This results in a lower fraction of fine grains and a higher fraction of coarse grains (≥4 μm).

Fig. 8 Grain size distribution chart of AZ31 magnesium alloys (fracture) at strain rate of 0.76 × 10-3 s-1 and different temperatures

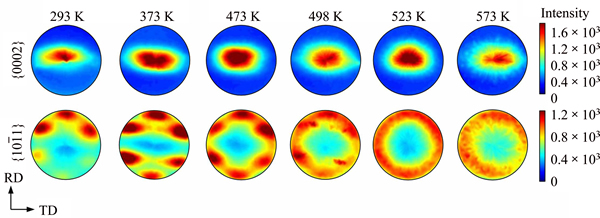

Fig. 9 Pole figures of AZ31 magnesium alloys corresponding to failure at different temperatures and strain rate of 0.76 × 10-3 s-1

The measured textures (Fig. 9) show differences to the initial texture (Fig. 2(d)). At each deformation temperature the maximum intensities of the {0002} pole figure are stretched in the transversal direction (TD) that is orthogonal to the deformation direction. This phenomenon is probably related to prismatic slip which was also reported by JAIN et al [55] and ULACIA et al [7]. At 573 K, the maximum intensity of the basal plane is reduced, which is implied by grain rotation as a consequence of GBS and CDRX [56]. As can be seen below 498 K, the orientation of  pyramidal planes reflects the hexagonal symmetry and the

pyramidal planes reflects the hexagonal symmetry and the  Burgers vector is always in TD. Above 498 K, the hexagonal regularity of the

Burgers vector is always in TD. Above 498 K, the hexagonal regularity of the  planes disappears. The basal planes are mostly oriented roughly parallel to the deformation direction, resulting in a strong basal texture. Therefore, the Schmid factor of basal slip and the effective shear stress are nearly zero. Despite its low CRSS, basal slip is prevented. Combined with fine grains, which have an inhibitory effect on twinning, only insufficient deformation mechanisms are active [57]. Consequently, the activation of prismatic slip systems is possible [46], so that the rotation of the grains takes place [48,58]. This was confirmed by in-situ measurements of KESHAVARZ and BARNETT [59]. As a result of CDRX, grain growth, GBS, and activation of additional slip systems, the pyramidal planes are rotationally symmetric at 523 and 573 K as in the initial sheet material. DUDAMELL et al [60] showed that additional basal texture components can be formed by extension twinning. This cannot be confirmed at any temperature or strain rate in this investigation. The reason is that

planes disappears. The basal planes are mostly oriented roughly parallel to the deformation direction, resulting in a strong basal texture. Therefore, the Schmid factor of basal slip and the effective shear stress are nearly zero. Despite its low CRSS, basal slip is prevented. Combined with fine grains, which have an inhibitory effect on twinning, only insufficient deformation mechanisms are active [57]. Consequently, the activation of prismatic slip systems is possible [46], so that the rotation of the grains takes place [48,58]. This was confirmed by in-situ measurements of KESHAVARZ and BARNETT [59]. As a result of CDRX, grain growth, GBS, and activation of additional slip systems, the pyramidal planes are rotationally symmetric at 523 and 573 K as in the initial sheet material. DUDAMELL et al [60] showed that additional basal texture components can be formed by extension twinning. This cannot be confirmed at any temperature or strain rate in this investigation. The reason is that  twinning is more pronounced at dynamic strain rate of 103 s-1. Larger amount of twins lead to higher degree of grain reorientation and texture modification.

twinning is more pronounced at dynamic strain rate of 103 s-1. Larger amount of twins lead to higher degree of grain reorientation and texture modification.

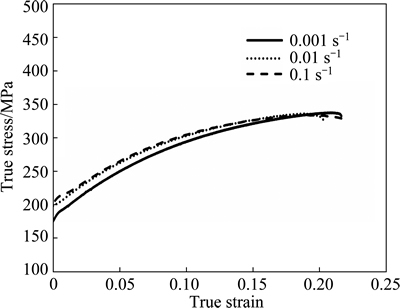

3.3 Influence of strain rate

The effect of strain rate on the flow stress behavior of AZ31 magnesium alloy at room temperature is presented in Fig. 10. With increasing strain rate, the flow stress rises. Below plastic strains of 0.1, the hardening rate, which is the slope of the σ-ε curve, is equal for every strain rate. Above plastic strain of 0.17, the curves intersect, which is not related to measurement errors or value spreading. This is related to the energy conversion during plastic deformation at various strain rates [61]. The result is that an increase of strain rate leads to a temperature rise ΔT during deformation depending on plastic work (∫σdε) as a function of strain, density ρ, specific heat capacity cV and the factor η which describes the strain rate dependent degree of energy conversion. With the thermodynamic equation ΔT=(η∫σdε)/(ρcV), the temperature rises of 4 K (10-3 s-1), 8 K (10-2 s-1), and 13 K (10-1 s-1) were calculated for room temperature deformation. This increase of temperature leads to softening the flow stress at higher deformation degrees as a result of reduced twinning as a consequence of enhanced dislocation motion.

Fig. 10 True stress-true strain curves of AZ31 magnesium alloys at various strain rates and 293 K

For analysis of the deformation mechanisms, Fig. 11 shows the influence of strain rate on the yield stress (σ0.2) of AZ31 magnesium alloys at various temperatures. With increasing strain rate, the σ0.2 rises. The strain rate does not influence the CRSS of basal slip [5]. However, it affects the CRSS of the nonbasal planes. Therefore, an activation of nonbasal slip systems requires different stresses at various strain rates so that the flow stress increases with increasing the strain rate. Higher strain rates also lead to larger amount of twins due to the stress concentration at the grain boundary, where dislocation accumulation occurs [60]. In contrast to 10-3 s-1,  compression twins (green) and

compression twins (green) and  -

- double twins (pink) are additionally found at 10-1 s-1 because of the high stresses (Fig. 12).

double twins (pink) are additionally found at 10-1 s-1 because of the high stresses (Fig. 12).

Fig. 11 Effect of strain rate on yield stress (σ0.2) of AZ31 magnesium alloys at various temperatures

Twins interrupt the free path length of the dislocations so that the number of piled-up dislocations at one boundary decreases at constant loading, which results in lower local stresses [12,13,62]. The smaller the stresses are, the lower the activation of neighboring grains is. According to this, fewer grains were deformed by dislocation motion on the slip systems so that the external stress for plastic deformation must rise [63]. In addition, twins reorient the parent grains which can lead to softening or hardening. BARNETT [64] suggested that hardening as a result of grain reorientation is much more pronounced than for grain refining. Higher strain rates enhance dislocation hardening in terms of dislocation interactions and dislocation-twin interactions. Furthermore, DRV, DRX and GBS are diffusion- controlled mechanisms, and therefore time and inversely strain rate dependent [54]. High strain rates tend to enhance the dislocation generation, which induces a distinct formation of subgrains at 10-1 s-1.

To present the influence of strain rate on the flow stress of AZ31 magnesium alloys, the flow stress at a plastic strain of 0.1 is plotted as a function of the strain rate (Fig. 13(a)). As described above, the flow stress decreases with rising temperature. The slope of the double logarithmic flow stress vs strain curve is defined as the strain rate sensitivity (m) and shown in Fig. 13(b). The parameter m increases with decreasing plastic strain [65]. At 293 K, the true stress is nearly independent of the strain rate. With increasing temperature, m rises, which indicates a change of the deformation mechanisms [66,67]. From 293 K (m =0.009) to 573 K (m=0.170), m rises by a factor of nearly 19, which is responsible for the enhanced ductility at high temperatures [67]. An average stress exponent n (n = 1/m) was calculated to be 7.87 (m = 0.127) for hot deformation between 473 K and 573 K. BARNETT [64] (486 K ≤ T ≤ 677 K, 10-3 s-1 ≤ ≤10-1 s-1), and MAKSOUD et al [66] (486 K ≤ T ≤ 677 K, 10-4 s-1 ≤

≤10-1 s-1), and MAKSOUD et al [66] (486 K ≤ T ≤ 677 K, 10-4 s-1 ≤ ≤10-2 s-1) determined stress exponent to be approximately 7. ISHIKAWA et al [10] (523 K ≤ T ≤723 K, 10-3 s-1 ≤

≤10-2 s-1) determined stress exponent to be approximately 7. ISHIKAWA et al [10] (523 K ≤ T ≤723 K, 10-3 s-1 ≤ ≤ 10-1 s-1) calculated n values of 5-7 and recommended climbing-controlled dislocation creep as a possible deformation mechanism.

≤ 10-1 s-1) calculated n values of 5-7 and recommended climbing-controlled dislocation creep as a possible deformation mechanism.

Fig. 12 Microstructures measured by EBSD in area of uniform elongation at 293 K, plastic strain of 20 % and strain rates of 0.76 × 10-3 s-1 (a) and 0.72 × 10-1 s-1 (b)

Fig. 13 Relationship between ln σ and  (a) and strain rate sensitivity m vs temperature (b) at εpl = 0.1 for AZ31 magnesium alloys

(a) and strain rate sensitivity m vs temperature (b) at εpl = 0.1 for AZ31 magnesium alloys

Fig. 14 Elongation to failure vs strain rate at various temperatures (a) and deformed specimens fractured at 573 K and various strain rates (b)

The influence of strain rate on the ductility is presented in Fig. 14(a). Below 323 K, the elongation to failure reaches approximately 20% and is not influenced by the strain rate as it was found in Ref. [48]. As described above, with increasing temperature the formability is significantly improved. Between 473 K and 523 K, it seems that the elongation to failure is less affected by temperature at 10-2 and 10-1 s-1 [48]. Compared with the investigations of  et al [47], this phenomenon should be also a function of the grain size because it occurred already at 10-4 s-1 and a grain size of 53 μm in their study. This has not been investigated yet, but it may be related to the dependence on strain rate for dislocation glide. The activation of nonbasal slip is more pronounced at low strain rates because of the decrease of the CRSSnonbasal at elevated temperatures [7]. Therefore, high temperatures and high strain rates are opposed factors for dislocation motion. At 573 K, the formability rises at 10-3 s-1 and 10-2 s-1, but stagnates at 10-1 s-1. The influence of strain rate on the ductility at 573 K can be observed on the deformed specimen (Fig. 14(b)). As noted above, the specimen failed by local necking after exhibiting a uniform elongation [68].

et al [47], this phenomenon should be also a function of the grain size because it occurred already at 10-4 s-1 and a grain size of 53 μm in their study. This has not been investigated yet, but it may be related to the dependence on strain rate for dislocation glide. The activation of nonbasal slip is more pronounced at low strain rates because of the decrease of the CRSSnonbasal at elevated temperatures [7]. Therefore, high temperatures and high strain rates are opposed factors for dislocation motion. At 573 K, the formability rises at 10-3 s-1 and 10-2 s-1, but stagnates at 10-1 s-1. The influence of strain rate on the ductility at 573 K can be observed on the deformed specimen (Fig. 14(b)). As noted above, the specimen failed by local necking after exhibiting a uniform elongation [68].

Below 473 K, a fracture surface at a 45° angle is visible independent of the strain rate [65]. This can be explained by the formation of twins which trigger the crack initiation. Above 293 K, an increasing ductile behavior is recognizable because of the activation of additional slip systems. Therefore, the fraction of twins is reduced, which causes a ductile fracture with distinct necking.

In comparison to Fig. 8, the grain size distribution at strain rates of 10-2 s-1 and 10-1 s-1 and different temperatures is presented in Figs. 15 and 16, respectively. At these strain rates, DRX is visible below 523 K because of larger amount of fine recrystallized grains (≤ 2 μm). Nevertheless, grain growth takes place at 523 K and particularly at 573 K. Especially with rising strain rate, grain growth is increasingly inhibited.

Compared with Fig. 9 (10-3 s-1), pole figures at different temperatures and a strain rate of 10-1 s-1 are shown in Fig. 17. The maximum intensities are independent of the strain rate [60]. In addition, the rotational symmetry of pyramidal planes is a function of strain rate because of the time dependence of DRX and the activation of additional slip systems. With increasing strain rate to 10-1 s-1, the rotational symmetry can be observed only at 573 K. This is related to the high thermal energy which reduces the CRSS of nonbasal slip and increases the extent of grain growth. Therefore, a reorientation of the unit cell is not necessary for plastic deformation.

Fig. 15 Grain size distribution of fractured AZ31 magnesium alloys after deformation at different temperatures and 0.73 × 10-2 s-1

Fig. 16 Grain size distribution of fractured AZ31 magnesium alloys after deformation at different temperatures and 0.72 × 10-1 s-1

4 Conclusions

1) With increasing temperature and decreasing strain rate, the flow stress of TRC+R+HT AZ31 decreases and the ductility increases. This is related to the occurrence of DRV, CDRX, GBS and the enhanced reduction of the CRSS for dislocation motion. The change of the deformation mechanisms with increasing temperature is indicated by the rise of the strain rate sensitivity.

2) CDRX-induced GBS enhances the formation of voids.

3) With increasing strain rate, dislocation hardening and mechanical tensile twinning take place which cause an increase of the yield stress. Compared with 10-3 s-1,

tensile twinning take place which cause an increase of the yield stress. Compared with 10-3 s-1,  compression twins and

compression twins and  -

-  double twins are additionally found at 10-1 s-1 because of the high stresses.

double twins are additionally found at 10-1 s-1 because of the high stresses.

4) At 10-2 and 10-1 s-1, the elongation to failure is nearly independent of the strain rate between 473 and 523 K. This is related to the strain rate dependence of CRSS for nonbasal slip.

5) Under each deformation condition, the maximum intensities of the {0002} pole figure are stretched in the transversal direction (TD) that is orthogonal to the deformation direction. This is probably related to the prismatic slip.

6) Below 498 K (10-3 s-1) and 573 K (10-1 s-1), the orientation of  pyramidal planes reflects the hexagonal symmetry which is probably related to the prismatic slip. Above this strain rate dependent transition temperature, the hexagonal regularity of the

pyramidal planes reflects the hexagonal symmetry which is probably related to the prismatic slip. Above this strain rate dependent transition temperature, the hexagonal regularity of the  planes disappears because CDRX, grain growth, GBS, and the activation of additional slip systems take place.

planes disappears because CDRX, grain growth, GBS, and the activation of additional slip systems take place.

Fig. 17 Pole figures of fractured AZ31 magnesium alloy at different temperatures and 0.72 × 10-1 s-1

Acknowledgments

The authors want to acknowledge the financial support by the European Social Fund (project No. 080943441). They also wish to thank Mr. A. SALOMON, Mr. G. SCHADE, Ms. K. BECKER, and Mr. G. SCHREIBER for experimental support.

References

[1] Mordike B L, Ebert T. Magnesium: Properties-applications- potential [J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] Mises R V. Mechanism of plastic deformation of crystal [J]. Zeitschrift für Angewandte Mathematik und Mechanik, 1928, 8(3): 161-185.

[3] Yoo M H. Slip, twinning, and fracture in hexagonal close-packed metals [J]. Metallurgical Transactions A, 1981, 12(3): 409-418.

[4] Vitek V, Igarashi M. Core structure of

screw dislocations on basal and prismatic planes in h.c.p. metals: An atomistic study [J]. Philosophical Magazine A, 1991, 63(5): 1059-1075.

screw dislocations on basal and prismatic planes in h.c.p. metals: An atomistic study [J]. Philosophical Magazine A, 1991, 63(5): 1059-1075.

[5] Barnett M R. A Taylor model based description of the proof stress of magnesium AZ31 during hot working [J]. Metallurgical and Materials Transactions A, 2003, 34(9): 1799-1806.

[6] Dieringa H. Cornparative studies on the tensile and compressive creep behavior of reinforced and non-reinforced magnesium alloy AE42 [M]. Hamburg-Harburg: VDM Verlag, 2006.

[7] Ulacia I, Dudamell N V,  M T, Hurtado I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates [J]. Acta Materialia, 2010, 58(8): 2988-2998.

M T, Hurtado I. Mechanical behavior and microstructural evolution of a Mg AZ31 sheet at dynamic strain rates [J]. Acta Materialia, 2010, 58(8): 2988-2998.

[8] Barnett M R. Twinning and the ductility of magnesium alloys:

[9] Barnett M R. Twinning and the ductility of magnesium alloys: Part II. “Contraction” twins [J]. Materials Science and Engineering A, 2007, 464(1-2): 8-16.

[10] Ishikawa K, Watanabe H, Mukai T. High temperature compressive properties over a wide range of strain rates in an AZ31 magnesium alloy [J]. Journal of Materials Science, 2005, 40(7): 1577-1582.

[11] Jiang L, Jonas J J, Luo A A, Sachdev A K, Godet S. Influence of  extension twinning on the flow behavior of AZ31 Mg alloy [J]. Materials Science and Engineering A, 2007, 445-446: 302-309.

extension twinning on the flow behavior of AZ31 Mg alloy [J]. Materials Science and Engineering A, 2007, 445-446: 302-309.

[12] Salem A A, Kalidindi S R, Semiatin S L. Strain hardening due to deformation twinning in α-titanium: Constitutive relations and crystal-plasticity modeling [J]. Acta Materialia, 2005, 53(12): 3495-3502.

[13] Serra A, Bacon D J, Pond R C. Twins as barriers to basal slip in hexagonal-close-packed metals [J]. Metallurgical and Materials Transactions A, 2002, 33(3): 809-812.

[14] Ecob N, Ralph B. The effect of grain size on deformation twinning in a textured zinc alloy [J]. Journal of Materials Science, 1983, 18(8): 2419-2429.

[15] Bruni C, Forcellese A, Gabrielli F, Simoncini M. Effect of temperature, strain rate and fibre orientation on the plastic flow behaviour and formability of AZ31 magnesium alloy [J]. Journal of Materials Processing Technology, 2010, 210(10): 1354-1363.

[16] Galiyev A, Kaibyshev R, Gottstein G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60 [J]. Acta Materialia, 2001, 49(7): 1199-1207.

[17] Al-Samman T, Li X, Chowdhury S G. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy [J]. Materials Science and Engineering A, 2010, 527(15): 3450-3463.

[18] Siegert K, Jaeger S. Pneumatic bulging of magnesium AZ31 sheet metal at elevated temperatures [C]//Magnesium Technology 2004. Warrendale, PA: TMS, 2004: 87-90.

[19] Koike J. Enhanced deformation mechanisms by anisotropic plasticity in polycrystalline Mg alloys at room temperature [J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1689-1696.

[20] Bae G, Bae J, Kang D, Lee H, Kim N. Effect of Ca addition on microstructure of twin-roll cast AZ31 Mg alloy [J]. Metals and Materials International, 2009, 15(1): 1-5.

[21] Huang Y, Kainer K U, Hort N. Mechanism of grain refinement of Mg-Al alloys by SiC inoculation [J]. Scripta Materialia, 2011, 64(8): 793-796.

[22] Segal V M. Materials processing by simple shear [J]. Materials Science and Engineering A, 1995, 197(2): 157-164.

[23] Balogh L, Figueiredo R B,  T, Langdon T G. The contributions of grain size, dislocation density and twinning to the strength of a magnesium alloy processed by ECAP [J]. Materials Science and Engineering A, 2010, 528(1): 533-538.

T, Langdon T G. The contributions of grain size, dislocation density and twinning to the strength of a magnesium alloy processed by ECAP [J]. Materials Science and Engineering A, 2010, 528(1): 533-538.

[24]  L, Schwarz F, Martin U, Roven H J. Strain rate effects on the flow behaviour and microstructure of ECAPed magnesium alloys [J]. Materials Science Forum, 2011, 690: 323-326.

L, Schwarz F, Martin U, Roven H J. Strain rate effects on the flow behaviour and microstructure of ECAPed magnesium alloys [J]. Materials Science Forum, 2011, 690: 323-326.

[25] Schwarz F,  L, Roven H J, Martin U. Microstructural and mechanical characterization of ECAPed AZ-magnesium alloys [C]//Mg2012: 19th International Conference on Magnesium Alloys and their Application. Vancouver, 2012: 1129-1135.

L, Roven H J, Martin U. Microstructural and mechanical characterization of ECAPed AZ-magnesium alloys [C]//Mg2012: 19th International Conference on Magnesium Alloys and their Application. Vancouver, 2012: 1129-1135.

[26] Watanabe H, Takara A, Somekawa H, Mukai T, Higashi K. Effect of texture on tensile properties at elevated temperatures in an AZ31 magnesium alloy [J]. Scripta Materialia, 2005, 52(6): 449-454.

[27] Zhan M Y, Li Y Y, Chen W P, Chen W D. Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by accumulative roll-bonding [J]. Journal of Materials Science, 2007, 42(22): 9256-9261.

[28] Cho J H, Chen H M, Choi S H, Kim H W, Kang S B. Aging effect on texture evolution during warm rolling of ZK60 alloys fabricated by twin-roll casting [J]. Metallurgical and Materials Transactions A, 2010, 41(10): 2575-2583.

[29] Stutz L, Bohlen J, Letzig D, Kainer K U. Formability of magnesium sheet ZE10 and AZ31 with respect to initial texture [C]//Magnesium Technology 2011. Warrendale, PA: TMS, 2011: 373-378.

[30] Di H S, Li Y L, Ning Z L, Li Z, Liu X H, Wang G D. New processing technology of twin roll strip casting of AZ31B magnesium strip [J]. Materials Science Forum, 2005, 488-489: 615-618.

[31] Masoumi M, Zarandi F, Pekguleryuz M. Microstructure and texture studies on twin-roll cast AZ31 (Mg-3wt.%Al-1wt.%Zn) alloy and the effect of thermomechanical processing [J]. Materials Science and Engineering A, 2011, 528(3): 1268-1279.

[32] Park S S, Bae G T, Kang D H, Jung I H, Shin K S, Kim N J. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn-Al alloys [J]. Scripta Materialia, 2007, 57(9): 793-796.

[33] Bohlen J,  M R, Senn J W, Letzig D, Agnew S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets [J]. Acta Materialia, 2007, 55(6): 2101-2112.

M R, Senn J W, Letzig D, Agnew S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets [J]. Acta Materialia, 2007, 55(6): 2101-2112.

[34] Agnew S R, Duygulu  . Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

[35] Masoumi M, Hoseini M, Pekguleryuz M. The influence of Ce on the microstructure and rolling texture of Mg-1%Mn alloy [J]. Materials Science and Engineering A, 2011, 528(7-8): 3122-3129.

[36] Masoumi M, Pekguleryuz M. The effect of Sr on texture development of Mg sheet alloys [C]//Mg2012: 19th International Conference on Magnesium Alloys and their Applications. Vancouver, 2012: 993-997.

[37] Kawalla R, Oswald M, Schmidt C, Ullmann M, Vogt H P, Cuong N D. Development of a strip-rolling technology for Mg alloys based on the twin-roll-casting process [C]//Magnesium Technology 2008. Warrendale, PA: TMS, 2008: 177-182.

[38] Schmidt C. Texture and microstructure evolution of during forming of twin-roll cast magnesium strip [M]. Freiberg, 2012.

[39] Ullrich C, Schwarz F, Franke A, Marr T, Rafaja D,  L, Freudenberger J. The preparation of magnesium specimens for EBSD using ion polishing [J]. Practical Metallography, 2012, 5: 290-304.

L, Freudenberger J. The preparation of magnesium specimens for EBSD using ion polishing [J]. Practical Metallography, 2012, 5: 290-304.

[40] Schwarz F, Lange K,  L. Material behaviour of twin-roll cast AZ31-magnesium sheets over a wide range of strain rates [C]//Mg2012: 19th International Conference on Magnesium Alloys and their Application. Vancouver, 2012: 587-592.

L. Material behaviour of twin-roll cast AZ31-magnesium sheets over a wide range of strain rates [C]//Mg2012: 19th International Conference on Magnesium Alloys and their Application. Vancouver, 2012: 587-592.

[41]  D, Couture A, Carbonneau Y, Fiset M, Angers R, Tremblay R. Secondary dendrite arm spacings in magnesium alloy AZ91D: From plaster moulding to laser remelting [J]. International Journal of Cast Metals Research, 1998, 11(3): 139-144.

D, Couture A, Carbonneau Y, Fiset M, Angers R, Tremblay R. Secondary dendrite arm spacings in magnesium alloy AZ91D: From plaster moulding to laser remelting [J]. International Journal of Cast Metals Research, 1998, 11(3): 139-144.

[42] Cao P, StJohn D H, Qian M. The effect of manganese on the grain size of commercial AZ31 alloy [J]. Materials Science Forum, 2005, 488-489: 139-142.

[43] Marya M, Hector L G, Verma R, Tong W. Microstructural effects of AZ31 magnesium alloy on its tensile deformation and failure behaviors [J]. Materials Science and Engineering A, 2006, 418(1-2): 341-356.

[44] Reed-Hill R E, Robertson W D. Additional modes of deformation twinning in magnesium [J]. Acta Metallurgica, 1957, 5(12): 717-727.

[45] Wonsiewicz B C, Backofen W A. Plasticity of magnesium crystals [J]. Transactions of the Metallurgical Society of AIME, 1967, 239(9): 1422-1433.

[46] Koike J, Kobayashi T, Mukai T, Watanabe H, Suzuki M, Maruyama K, Higashi K. The activity of non-basal slip systems and dynamic recovery at room temperature in fine-grained AZ31B magnesium alloys [J]. Acta Materialia, 2003, 51(7): 2055-2065.

[47]  V, Bohlen J, Kainer K U. Tensile properties of hot rolled AZ31 Mg alloy sheets at elevated temperatures [J]. Journal of Alloys and Compounds, 2004, 378(1-2): 184-187.

V, Bohlen J, Kainer K U. Tensile properties of hot rolled AZ31 Mg alloy sheets at elevated temperatures [J]. Journal of Alloys and Compounds, 2004, 378(1-2): 184-187.

[48] Huang Guang-sheng, Li Hong-cheng, Song Bo, Zhang Lei. Tensile properties and microstructure of AZ31B magnesium alloy sheet processed by repeated unidirectional bending [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(1): 28-33.

[49] Yi S B, Zaefferer S, Brokmeier H G. Mechanical behaviour and microstructural evolution of magnesium alloy AZ31 in tension at different temperatures [J]. Materials Science and Engineering A, 2006, 424(1-2): 275-281.

[50] Tan J C, Tan M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet [J]. Materials Science and Engineering A, 2003, 339(1-2): 124-132.

[51] Ohyama R, Koike J, Kobayashi T, Suzuki M, Maruyama K. Enhanced grain-boundary sliding at room temperature in AZ31 magnesium alloy [J]. Materials Science Forum, 2003, 419-422: 237-242.

[52] Ion S E, Humphreys F J, White S H. Dynamic recrystallisation and the development of microstructure during the high temperature deformation of magnesium [J]. Acta Metallurgica, 1982, 30(10): 1909-1919.

[53] Nieh T G, Wadsworth J, Sherby O D. Superplasticity in metals and ceramics [M]. New York: Cambridge University Press, 1997.

[54] Koike J, Ohyama R, Kobayashi T, Suzuki M, Maruyama K. Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523 K [J]. Materials Transactions, 2003, 44(4): 445-451.

[55] Jain A, Duygulu O, Brown D W, Tomé C N, Agnew S R. Grain size effects on the tensile properties and deformation mechanisms of a magnesium alloy, AZ31B, sheet [J]. Materials Science and Engineering A, 2008, 486(1-2): 545-555.

[56] Zelin M G. Processes of microstructural evolution during superplastic deformation [J]. Materials Characterization, 1996, 37(5): 311-329.

[57] Barnett M R, Stanford N, Cizek P, Beer A, Xuebin Z, Keshavarz Z. Deformation mechanisms in Mg alloys and the challenge of extending room-temperature plasticity [J]. Journal of the Minerals, Metals and Materials Society, 2009, 61(8): 19-24.

[58] Mayama T, Aizawa K, Tadano Y, Kuroda M. Influence of twinning deformation and lattice rotation on strength differential effect in polycrystalline pure magnesium with rolling texture [J]. Computational Materials Science, 2009, 47(2): 448-455.

[59] Keshavarz Z, Barnett M R. In-situ investigation of twinning behaviour in Mg-3Al-1Zn [C]//Magnesium Technology 2005. Warrendale, PA: TMS, 2005: 171-175.

[60] Dudamell N V, Ulacia I,  F, Yi S, Bohlen J, Letzig D, Hurtado I,

F, Yi S, Bohlen J, Letzig D, Hurtado I,  M T. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature [J]. Acta Materialia, 2011, 59(18): 6949-6962.

M T. Twinning and grain subdivision during dynamic deformation of a Mg AZ31 sheet alloy at room temperature [J]. Acta Materialia, 2011, 59(18): 6949-6962.

[61] Ulacia I, Salisbury C P, Hurtado I, Worswick M J. Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures [J]. Journal of Materials Processing Technology, 2011, 211(5): 830-839.

[62] Christian J W, Mahajan S. Deformation twinning [J]. Progress in Materials Science, 1995, 39(1-2): 1-157.

[63] Gottstein G. Physical foundations of materials science [M]. Berlin: Springer, 2004.

[64] Barnett M R. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31 [J]. Journal of Light Metals, 2001, 1(3): 167-177.

[65] Yokoyama T. Impact tensile stress-strain characteristics of wrought magnesium alloys [J]. Strain, 2003, 39(4): 167-175.

[66] Maksoud I A, Ahmed H,  J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2009, 504(1-2): 40-48.

J. Investigation of the effect of strain rate and temperature on the deformability and microstructure evolution of AZ31 magnesium alloy [J]. Materials Science and Engineering A, 2009, 504(1-2): 40-48.

[67] Duygulu O, Agnew S R. The effect of temperature and strain rate on the tensile properties of textured magnesium alloy AZ31B sheet [C]//Magnesium Technology 2003. Warrendale, PA: TMS, 2003: 237-242.

[68] Watanabe H, Tsutsui H, Mukai T, Kohzu M, Tanabe S, Higashi K. Deformation mechanism in a coarse-grained Mg-Al-Zn alloy at elevated temperatures [J]. International Journal of Plasticity, 2001, 17(3): 387-397.

F. BERGE1, L.  1, H. OUAZIZ1, C. ULLRICH2

1, H. OUAZIZ1, C. ULLRICH2

1. Faculty of Materials Science and Technology, Institute of Materials Engineering,

Technical University Bergakademie Freiberg, Freiberg 09599, Germany;

2. Faculty of Materials Science and Technology, Institute of Materials Science,

Technical University Bergakademie Freiberg, Freiberg 09599, Germany

摘 要:在单轴拉伸条件下研究温度和应变速率对双辊铸轧、轧制和热处理AZ31镁合金流动应力行为的影响。结果表明,在高温下,动态回复、连续动态再结晶、晶界滑移和附加滑移系的活化使合金的延展得到改善。在473~523 K和10-2~10-1 s-1条件下,合金的断裂伸长率几乎与应变速率无关,而与应变速率依赖于临界剪切应的非基面滑移有关。由于经上述工艺加工的AZ31镁合金具有较低的临界剪切应力,因此在573 K和10-3 s-1条件下出现了孪晶。

关键词:AZ31镁合金;双辊铸轧;应变速率;温度;动态再结晶;流动应力

(Edited by Wei-ping CHEN)

Corresponding author: F. BERGE; Tel: +49-03731-394177; Fax: +49-03731-393703; E-mail: Franz.Berge@imf.tu-freiberg.de

DOI: 10.1016/S1003-6326(15)63572-5