文章编号:1004-0609(2009)11-1887-07

AZ31镁合金铸轧和常规轧制板的变形组织及形变特征

赵 虎,李培杰,何良菊

(清华大学 新材料国际研发中心,北京 100084)

摘 要:在变形温度为150~400 ℃、应变速率为0.3~0.000 3 s-1条件下,在Gleeble1500热模拟机上采用等温拉伸试验对AZ31镁合金铸轧和常规轧制板的高温塑性及组织演变进行研究。结果表明:两种AZ31镁合金板的峰值应力和峰值应变均随着变形温度的降低和应变速率的增加而逐渐增大。铸轧板的应变硬化指数和应变速率敏感系数均大于常规轧制板的。在高温低应变速率变形条件下,铸轧板的晶界滑移引起的空洞尺寸、体积分数和密度均大于常规轧制板的。低应变速率下拉伸变形后的动态再结晶晶粒尺寸随温度的升高逐渐增加;不同变形条件下铸轧板的晶粒尺寸均小于常规轧制板的;再结晶晶粒尺寸和Z参数呈幂律关系。

关键词:AZ31镁合金;铸轧;高温塑性

中图分类号:TG 146.2 文献标识码:A

Deformation microstructure and characteristics of cast-rolling and

normal rolling AZ31 magnesium alloy sheets

ZHAO Hu, LI Pei-jie, HE Liang-ju

(National Center of Novel Materials for International Research, Tsinghua University, Beijing 100084, China)

Abstract: The elevated temperature plasticity and microstructure evolution of cast-rolling and normal rolling AZ31 magnesium alloy sheets were analyzed by Gleeble1500 using tension test with deformation temperature of 150-400 ℃ and strain rate of 0.3-0.000 3 s-1. The results show that the peak stress and peak strain of cast-rolling and normal rolling AZ31 magnesium alloys both increase with decreasing the deformation temperature and increasing the strain rate. The strain hardening exponent value and strain rate sensitivity value of cast rolling sheet are larger than those of normal rolling sheet. Cavity size, volume fraction and density of cast-rolling sheet caused by grain boundary sliding under deformation condition of high temperature and low strain rate are bigger than those of normal rolling sheet. The dynamic recrystallization grain size deformed in low strain rate increases with increasing the deformation temperature. The dynamic recrystallization grain size of cast rolling sheet is less than that of normal rolling sheet. The dynamic recrystallization grain size has power law relation with Z parameter.

Key words: AZ31 magnesium alloy; cast rolling; high temperature plasticity

镁和多数镁合金具有密排六方结构,室温滑移系少,塑性较差,难以成形,通常情况下通过热加工来生产变形镁合金产品[1],因此,研究镁合金的热变形行为具有重要价值。很多研究者采用等温压缩或等温拉伸试验研究了镁合金的高温变形行为及组织演变。郭强等[2]采用高温热压缩试验,较系统地分析了AZ31镁合金在不同变形条件下的流变应力及动态再结晶行为。黄光胜等[3]通过单向压缩试验建立了AZ31镁合金的高温本构方程。汪凌云等[4]采用高温压缩试验数据构建加工图分析了AZ31镁合金在不同变形条件下的塑性行为。还有研究者对AZ31镁合金压缩变形过程中组织演化、织构变化、初始晶粒尺寸对流变应力的影响进行了较为系统的研究[5-11]。

以往研究者主要以常规铸造方法生产的AZ31镁合金铸锭为研究对象,且主要采用等温压缩试验,而对AZ31镁合金铸轧板的高温塑性及组织演变研究较少。本文作者采用等温拉伸试验,以便更加真实地反应AZ31镁合金板的热变形过程。为了全面认识AZ31镁合金板的高温塑性,对比分析了不同变形条件下AZ31铸轧板和常规轧制板的流变曲线、应变硬化指数、应变速率敏感系数、组织演变以及再结晶晶粒尺寸与Z参数的关系;特别是对于应变硬化指数和应变速率敏感系数的求解,为制定AZ31镁合金铸轧和常规轧制板的热塑性加工工艺参数提供指导。

1 实验

实验所选用的材料是厚度为0.8 mm的AZ31镁合金铸轧板和常规轧制板,其化学成分如表1所列。选取厚度为6 mm的AZ31镁合金铸轧板坯,在400 ℃均匀化退火处理10 h后进行轧制,道次变形量为20%~30%,轧制过程中进行多次中间退火,中间退火温度为350 ℃、退火时间为30 min,最终轧板厚度为0.8 mm。常规轧制板坯为铸造扁锭,在400 ℃均匀化退火处理12 h后对板坯进行铣面,铣面之后扁锭厚度达6 mm。采用和6 mm厚铸轧板坯相同的轧制和中间退火工艺条件,将扁锭轧成厚度为0.8 mm的薄板。铸轧板和常规轧制板的最终成品退火条件均为(250 ℃,2 h)。

表1 AZ31镁合金的化学成分

Table 1 Chemical composition of AZ31 magnesium alloy (mass fraction, %)

拉伸实验选用退火后的AZ31镁合金铸轧板和常规轧制板。拉伸试样轴向平行于轧制方向,试样标距尺寸为30 mm×5 mm×0.8 mm。拉伸试验在Gleebe1500D热模拟机上进行。变形温度分别为150、200、250、300、350和400 ℃,应变速率分别为 0.000 3、0.003、0.03和0.3 s-1。样品采用电阻加热至设定温度,加热速度为5℃/s,保温3 min后进行拉伸,拉伸至断裂后空冷至室温。根据载荷—位移数据计算获得真应力—真应变曲线。拉伸变形后的显微组织观察均选取真应变为0.2时试样的显微组织。在拉伸后试样断口附近制取试样,经过粗磨和抛光后,采用配方为1 mL硝酸+1 mL乙酸+1 g草酸+150 mL水的浸蚀剂显示其组织,在NEOPHOT32显微镜系统上进行显微组织观察。采用GB/T 6394—2002标准中的截距法测量试样显微组织的晶粒尺寸。

应变硬化指数n和应变速率敏感系数m分别根据式(1)和(2)计算:

2 结果与分析

2.1 高温塑性

2.1.1 真应力—真应变曲线

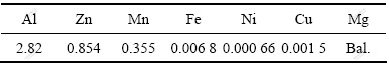

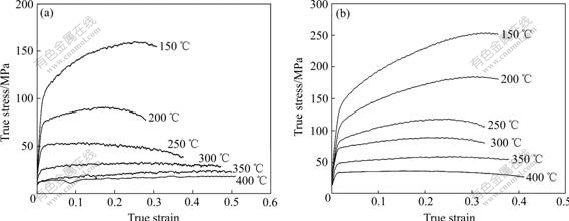

图1和图2所示分别为AZ31镁合金铸轧和常规轧制板的真应力—真应变曲线。由图1和图2可见,材料在拉伸开始阶段具有明显的加工硬化特征,随着应变的增加,应力达到最大值,之后进入稳态流变阶段,此时应力基本不随应变的增加而变化,即材料出现稳态流变特征。应变速率越大,变形温度越低,则真应力—真应变曲线稳态阶段的应变越少。当应变速率一定时,随着变形温度的升高,峰值应力和峰值应变均降低。当变形温度一定时,随着应变速率的增加,峰值应力和峰值应变均增加。

相对于AZ31镁合金常规轧制板而言,AZ31镁合金铸轧板断裂前的总应变较大,其应力随着应变的增加逐渐达到最大值,而后随着应变的继续增加而缓慢降低。在变形温度低于300 ℃时不同应变速率条件下,铸轧板的峰值应力和峰值应变均大于常规轧制板的,且应力达到峰值应力后随着应变的增加很快下降,稳态流变阶段的应变较少。

图1 AZ31镁合金铸轧板的真应力—真应变曲线

Fig.1 True stress—true strain curves of cast-rolling AZ31 magnesium alloy sheet: (a)  =0.000 3 s-1; (b)

=0.000 3 s-1; (b)  =0.03 s-1

=0.03 s-1

图2 AZ31镁合金常规轧制板的真应力—真应变曲线

Fig.2 True stress—true strain curves of normal rolling AZ31 magnesium alloy sheet: (a)  =0.000 3 s-1; (b)

=0.000 3 s-1; (b)  =0.03 s-1

=0.03 s-1

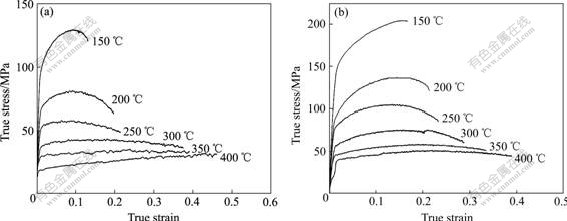

2.1.2 应变硬化指数

从图1和图2中的流变曲线可以看出,在低温和高应变速率变形条件下,AZ31镁合金板具有较大的应变硬化指数。当变形温度高于300 ℃时,板材的应变硬化指数较小,真应力很快达到最大值,随后进入稳态流变阶段。图3所示为AZ31镁合金铸轧板和常规轧制板在不同变形条件下的n值。随着变形温度的降低和应变速率的增加,n值不断增加。对于铸轧板,在变形温度为150 ℃、应变速率为0.3 s-1时,n值达到0.25。在相同变形条件下,铸轧板的n值均大于常规轧制板的。

图3 不同变形条件下AZ31镁合金铸轧和常规轧制板的应变硬化指数

Fig.3 Strain hardening exponent values of cast-rolling and normal rolling AZ31 magnesium alloy sheets deformed under different conditions

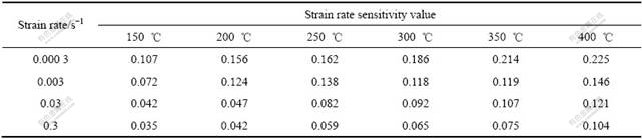

2.1.3 应变速率敏感系数

表2和表3所列分别为AZ31镁合金铸轧和常规轧制板不同变形条件下(ε=0.2)的应变速率敏感系 数。普通金属的应变速率敏感系数m≈0.02~0.2;当 m>0.3时,材料即表现出超塑性[12]。由表2和表3可见,AZ31镁合金板材的应变速率敏感系数随着变形温度的增加和应变速率的降低而增加。在相同的变形条件下,铸轧板的m值均大于常规轧制板,这是由于铸轧板的晶粒尺寸细小,变形更加均匀,从而提高 了板材的塑性。当变形温度为400 ℃、应变速率为0.000 3 s-1时,铸轧板的m值达到0.378,大于0.3,具有超塑性特征。

表2 不同变形条件下AZ31铸轧板的应变速率敏感系数

Table 2 Strain rate sensitivity values of cast-rolling AZ31 magnesium alloy sheet deformed under different conditions (ε=0.2)

表3 不同变形条件下AZ31常规轧制板的应变速率敏感系数

Table 3 Strain rate sensitivity values of normal rolling AZ31 magnesium alloy sheet deformed under different conditions (ε=0.2)

2.2 显微组织

2.2.1 组织演变

AZ31镁合金铸轧板和常规轧制板拉伸前的初始组织如图4所示。从图4可见,拉伸变形前,铸轧板和常规轧制板均为再结晶组织,由等轴晶组成,二者晶粒形状差别不大。铸轧板的初始组织比常规轧制板的细小均匀。铸轧板和常规轧制板的平均晶粒尺寸分别为6.5和9.2 ?m。

图4 AZ31镁合金板的初始组织

Fig.4 Initial microstructure of AZ31 magnesium alloy sheets: (a) Cast-rolling sheet; (b) Normal rolling sheet

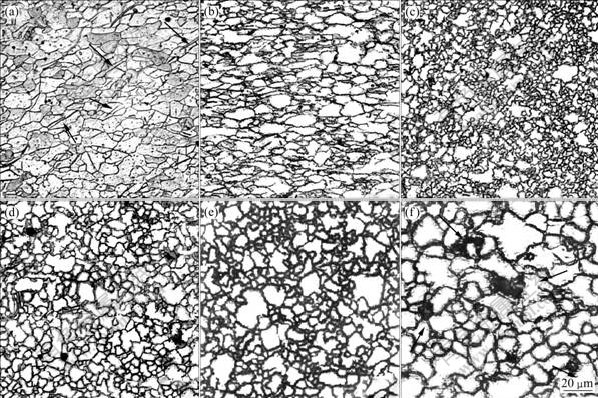

图5所示为不同变形条件下(ε=0.2)AZ31镁合金铸轧板的显微组织。当变形温度为150 ℃、应变速率为 0.3 s-1时,变形后的组织存在多边形化晶粒以及大量孪晶,如图5(a)所示,箭头所指为孪晶。当变形温度为150 ℃、应变速率为 0.000 3 s-1时,变形组织的晶粒较粗大,晶粒被拉长,发生局部流变失稳,如图5(b)所示。镁具有较低的层错能(60~78 mJ/m2)[13],大大低于铝的层错能(200 mJ/m2),因而镁合金的回复较为困难,在较低的温度下易于发生动态再结晶。当变形温度升高到200 ℃时,在低应变速率条件下AZ31镁合金发生动态再结晶,在大尺寸晶粒的周围分布着大量细小的再结晶晶粒,如图5(c)所示。随着变形温度的升高,小晶粒不断长大,逐渐取代初始大晶粒,动态再结晶进行得越来越充分。在250 ℃、0.000 3 s-1变形条件下,AZ31镁合金的柱面和锥面滑移系开动,位错的滑移、攀移、交滑移比低温时容易,动态再结晶的形核率增加,界面迁移能力增强,发生连续动态再结晶[14],其显微组织如图5(d)所示。

图5 不同变形条件下(ε=0.2)AZ31镁合金铸轧板的显微组织

Fig.5 Microstructures of cast-rolling AZ31 magnesium alloy sheet deformed under different conditions (ε=0.2): (a) 150 ℃, 0.3 s-1; (b) 150 ℃, 0.000 3 s-1; (c) 200 ℃, 0.000 3 s-1; (d) 250 ℃, 0.000 3 s-1; (e) 400 ℃, 0.3 s-1; (f) 400 ℃, 0.000 3 s-1

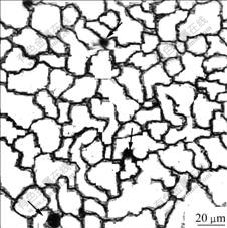

当变形温度达到400 ℃时,AZ31镁合金的动态再结晶进行得较为充分,晶粒尺寸较大,如图5(e)和(f)所示。当应变速率为0.000 3 s-1时,在三叉晶界处出现大量空洞,如图5(f)中箭头所示。图6所示为AZ31镁合金常规轧制板400 ℃、0.000 3 s-1变形条件下ε=0.2时的显微组织。

图6 AZ31镁合金常规轧制板在400 ℃、0.000 3 s-1变形条件下的显微组织

Fig.6 Microstructure of normal rolling AZ31 magnesium alloy deformed at 400 ℃ and 0.000 3 s-1 (ε=0.2)

AZ31镁合金在400 ℃、0.000 3 s-1变形条件下的变形机制主要是晶界滑移[15]。晶界滑移容易在晶界三叉处或材料增强相与基体的相界处产生应力集中,进一步变形会促使空洞或其它协调机制减缓晶界处的应力集中,进而延缓了断裂的产生,提高了变形能力[16]。在变形温度、应变速率和应变量一定的条件下,晶粒尺寸的减小使空洞尺寸、空洞体积分数、空洞密度均增加。在相同的变形条件下,铸轧板的晶粒尺寸小于常规轧制板,因此高温低应变速率变形条件下,相对于常规轧制板而言,铸轧板的空洞数量较多,尺寸较大。

2.2.2 晶粒尺寸

图7所示为不同变形条件下AZ31镁合金铸轧和常规轧制板的晶粒尺寸。在不同变形条件下,AZ31镁合金铸轧和常规轧制板的晶粒尺寸具有相似的变化趋势。在150 ℃变形时,AZ31镁合金在变形过程中仅发生基面滑移,不发生再结晶,产生大量孪晶,平均晶粒尺寸小于初始组织。当变形温度为200 ℃时,AZ31镁合金变在变形热的作用下发生动态再结晶,细小的再结晶晶粒和原始晶粒共存,平均晶粒尺寸较小。在250 ℃以上变形时,随着变形温度的增加,AZ31镁合金动态再结晶进行得越来越充分,晶粒尺寸随变形温度的升高而增大。AZ31镁合金铸轧和常规轧制板在高应变速率变形条件下的晶粒尺寸较小。这是由于在再结晶温度以下,高的应变速率降低了镁合金变形过程中晶粒间的协调性,产生大量孪晶,使平均晶粒尺寸较小;在再结晶温度以上时,低的变形速率使动态再结晶长大较充分,晶粒尺寸增大了。在不同变形条件下,AZ31镁合金铸轧板的晶粒尺寸均小于常规轧制板。

图7 不同变形条件下AZ31镁合金铸轧和常规轧制板的晶粒尺寸

Fig.7 Grain size of cast-rolling and normal rolling AZ31 magnesium alloy sheet deformed under different conditions

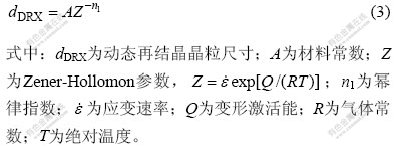

AZ31镁合金的动态再结晶晶粒尺寸同Z参数呈幂律关系[5]:

根据式(3)可得AZ31镁合金铸轧和常规轧制板的lgd—lgZ关系,如图8所示。由图8可见,在不同变形温度下,AZ31镁合金板的动态再结晶晶粒尺寸的对数同Z参数的对数呈良好的线性关系,其斜率n1为0.09~0.11。

图8 AZ31镁合金铸轧和常规轧制板的晶粒尺寸和Z参数的关系

Fig.8 Relationship between grain size and Z parameter of AZ31 magnesium alloy sheet: (a) Cast-rolling sheet; (b) Normal rolling sheet

3 结论

1) 2种AZ31镁合金板的流变曲线均在低温拉伸变形条件下具有明显的应变硬化特征;在高温变形条件下拉伸开始后应变硬化不明显,很快发生动态再结晶,进入稳态流变阶段。2种AZ31镁合金板的峰值应力和峰值应变均随着变形温度的降低和应变速率的增加而逐渐增大。

2) 2种AZ31镁合金板的应变硬化指数均随着变形温度的降低和应变速率的增加而增加;当温度为150 ℃、应变速率为0.3 s-1时,铸轧板的n值达到0.25;应变速率敏感系数m随着变形温度的增加和应变速率的降低而增加;当温度为400 ℃、应变速率为0.000 3 s-1时,铸轧板的m值达到0.378,具有超塑性特征;铸轧板的n值和m值均大于常规轧制板的。

3) AZ31镁合金板在低温变形过程中发生局部流变失稳,变形后的组织主要包括多边形化晶粒及孪晶;随着变形温度的升高,动态再结晶发生并进行得越来越充分;在高温低应变速率条件下,铸轧板中晶界滑移引起的空洞尺寸、体积分数和密度均大于常规轧制板。

4) 不同变形条件下铸轧板的晶粒尺寸均小于常规轧制板;晶粒尺寸和Z参数呈幂律关系,幂律指数为0.09~0.11。

REFERENCES

[1] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 8-10.

LI Wen-xian. Magnesium and magnesium alloys[M]. Changsha: Central South University Press, 2005: 8-10.

[2] 郭 强, 严红革, 陈振华, 张 辉. AZ31镁合金高温热压缩变形特性[J]. 中国有色金属学报, 2005, 15(6): 900-906.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Hot compression deformation behavior of AZ31 magnesium alloy at elevated temperature[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 900-906.

[3] 黄光胜, 汪凌云, 黄光杰, 卢志文, 宋美娟. AZ31镁合金高温本构方程[J]. 金属成形工艺, 2004, 22(2): 41-44.

HUANG Guang-sheng, WANG Ling-yun, HUANG Guang-jie, LU Zhi-wen, SONG Mei-juan. Constitute equation of AZ31 magnesium alloy for high temperature[J]. Metal Forming Technology, 2004, 22(2): 41-44.

[4] 汪凌云, 范永革, 黄光杰, 黄光胜. 镁合金AZ31B的高温塑性变形及加工图[J]. 中国有色金属学报, 2004, 14(7): 1068-1072.

WANG Ling-yun, FAN Yong-ge, HUANG Guang-jie, HUANG Guang-sheng. Plastic deformation at elevated temperature and processing maps of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1068-1072.

[5] KLIMANEK P, POTZSCH A. Microstructure evolution under compressive plastic deformation of magnesium at different temperatures and strain rates[J]. Mater Sci Eng A, 2002, 324: 145-150.

[6] FATEMI-VARZANEH S M, ZAREI-HANZAKI A, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy[J]. Mater Sci Eng A, 2007, 456: 52-57

[7] ISHIKAWA K, WATANABE, MUKAI T. High temperature compressive properties over a wide range of strain rates in an AZ31 magnesium alloy[J]. Journal of Materials Science, 2005, 40: 1577-1582.

[8] BEER A G, BARNETT M R. Influence of initial microstructure on the hot working flow stress of Mg-3Al-1Zn[J]. Mater Sci Eng A, 2006, 423: 292-299.

[9] MWEMBELA A, KONOPLEVA E B, MCQUEEN H J. Microstructural development in Mg alloy AZ31 during hot working[J]. Scripta Materialia, 1997, 37(11): 1789-1795.

[10] HELIS L, OKAYASU K, FUKUTOMI H. Microstructure evolution and texture development during high-temperature unaxial compression of magnesium alloy AZ31[J]. Mater Sci Eng A, 2006, 430: 98-103.

[11] SLOOFF A, ZHOU J, DUSZCZYK, KATGERMAN L. Constitutive analysis of wrought magnesium alloy Mg-Al4-Zn1[J]. Scripta Materialia, 2007, 57: 759-762.

[12] 杨觉先. 金属塑性变形物理基础[M]. 北京: 冶金工业出版社, 1988: 135-138.

YANG Jue-xian. Metal plastic deformation physical foundation[M]. Beijing: Metallurgical Industry Press, 1988: 135-138.

[13] MICHAEL M A, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys[M]. Ohio: ASM International Materials Park, 1999: 274.

[14] 娄花芬, 汪明朴, 唐 宁, 李 周, 郭明星, 雷 前. AZ31B镁合金的铸轧组织及其相关变形机制[J]. 中国有色金属学报, 2008, 18(9): 1584-1589.

LOU Hua-fen, WANG Ming-pu, TANG Ning, LI Zhou, GUO Ming-xing, LEI Qian. Microstructure of twin-roll cast AZ31B Mg alloy and its deformation mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1584-1589.

[15] SRINIVASN N, PRASAD Y V R K, RAMA RAO P. Hot deformation behavior of Mg-3Al alloy—A study using processing map[J]. Mater Sci Eng A, 2008, 476: 146-156.

[16] TERENCE G, LANGDON. Grain boundary sliding revisited: Developments in sliding over four decades[J]. Journal of Materials Science, 2006, 41: 597-609.

基金项目:国家科技支撑计划资助项目(2006BAE04B02)

收稿日期:2008-12-11;修订日期:2009-05-20

通信作者:李培杰,教授,博士;电话:010-62773639;E-mail: lipj@mail.thu.edu.cn

(编辑 李向群)