Trans. Nonferrous Met. Soc. China 26(2016) 1598-1606

Microstructure and phase precipitate behavior of Inconel 740H during aging

Yan GUO, Tai-jiang LI, Cai-xia WANG, Shu-fang HOU, Bo-han WANG

Xi’an Thermal Power Research Institute Co., Ltd., Xi’an 710032, China

Received 6 June 2015; accepted 11 April 2016

Abstract: The microstructure and phase precipitate behavior and their effects on the room temperature hardness and impact toughness of Inconel 740H aged at 750 °C for 10000 h were investigated by SEM, TEM and mechanical analysis. The as-received alloy shows a low hardness value of HB 168 and a highest toughness value of 96 J. After an aging treatment at 800 °C for 16 h and cooled in air (standard heat-treated condition), fine γ′ phase particles precipitate within the grains and small carbide particles are located at the grain boundaries. The hardness increases to HB 304 and the impact toughness decreases to 15 J after standard heat treatment. A maximum hardness value of HB 331 is achieved for the alloy aged at 750 °C for 300 h. With increasing the aging time from 300 to 10000 h, a decrease of the hardness and toughness is observed along with an enhanced quantity of M23C6 particles and the coarsening of γ′ phase.

Key words: Inconel 740H; aging; microstructure; phase precipitate

1 Introduction

The efficient ultra supercritical (USC) power plants, operating at steam temperatures of approximately 600 °C and pressures of 25-30 MPa, use high-strength ferritic and austenitic steels (P92, TP347HFG, Super304, TP310HNbN) for boiler and turbine components [1-3].

The growing demand for electricity and environmental concerns has sparked initiatives in the United States, Europe and Asia aimed at developing an advanced ultra supercritical (A-USC) with the target steam temperatures of 700-760 °C and pressures of approximately 35 MPa [4-6]. However, the increased operating parameters put more stringent requirements on the properties of candidate materials and cannot be met by conventional ferritic and austenitic steels. Consequently, there are efforts to replace these materials by Ni-based superalloys due to a combination of their excellent microstructural stability, high creep-rupture strength, high oxidation and hot corrosion resistance [7,8]. Ni-based superalloys have already found widespread applications in a number of critical technological areas, such as jet-engine turbines and power plants. Some superalloys including solid solution strengthened and age-hardened nickel-based alloys (617 [9-12], 617B [13,14], 740 [15-19], 740H [20-25]) were evaluated for using as steam turbine and boiler components under A-USC steam conditions.

Inconel 740 is a γ′-strengthened, precipitation- hardenable superalloy. Its desirable constituent phases, in addition to the FCC-structure γ matrix, are the FCC- ordered γ′ phase, MC carbides, and complex M23C6 carbides. Undesirable phases include the complex Si-rich G phase, and the DO24-ordered hexagonal Ni3Ti-based η phase [15-19]. Inconel 740H is a modified version of Inconel 740. Compared with Inconel 740, the mole ratio of Ti to Al in Inconel 740H is lowered in order to eliminate microstructure instabilities (G and η phases) found in Inconel 740 during thermal aging and creep [20-25]. Since Inconel 740H has only recently been developed, few studies concerning the microstructure evolution and phase precipitate behavior of 740H during a long term aging (10000 h) have been carried out so far on this material. In this work, the microstructure and phase precipitate behavior of 740H aged up to 10000 h at 750 °C are analyzed with respect to the hardness and impact toughness measurements at room temperature. The purpose of present work is to provide experimental data for the material selection of 700 °C ultra supercritical (USC) units in China.

2 Experimental

The chemical composition of 740H tube (d50.8 mm × 8 mm) is listed in Table 1.

Table 1 Chemical composition of 740H (mass fraction, %)

The as-received samples (solution-treated for 30 min at 1150 °C and then cooled in water) were marked by H0 and then followed by an aging treatment at 800 °C for 16 h and cooled in air (the standard heat-treated sample referred to as H1). The H1 samples were subsequently aged at 750 °C for 300, 1000, 3000, 5000 and 10000 h and referred to as H2, H3, H4, H5 and H6, respectively.

The hardness of the tested samples was measured with an HB-3000C Brinell hardness tester according to the requirement of GB/T 231.1-2009 and then the average value of hardness was obtained from the values of three testing points of the sample. The three V-notched charpy impact samples (55 mm × 10 mm × 5 mm) were tested at room temperature on a PKP450 impact testing machine according to the requirement of GB/T229-2007 and then the average value of impact absorbed energy was obtained from the values of three impact samples.

Metallographic samples were ground to 1000-grit and mechanically polished and then etched using a solution of HCl and HNO3 (the volume ratio of 3:1). Scanning electron microscopy (SEM) investigations were conducted using an FEI Quanta-400HV. Energy dispersive spectroscopy (EDS) micro-analysis was performed on an SEM.

The samples for transmission electron microscopy (TEM) were prepared as follows. A foil with about 500 μm in thickness was cut and mechanically ground to a thickness of 40 μm, from which the TEM disks with 3 mm in diameter were punched. Twin-jet electro- polishing was performed using a solution of 10% perchloric acid and 90% acetic acid below -20 °C, with a polishing current of approximately 30 mA. TEM observation was carried out on a JEM-200CX transmission electron microscope (TEM) operating at 200 kV. The phase identification was performed using the selected area electron diffraction (SAED) pattern.

3 Results

Figure 1 reveals the room temperature (RT) hardness under different conditions. The H0 sample had a low hardness value of HB 168 and then a remarkable increase of hardness for the H1 sample was observed. After that, the hardness of the alloy aged for 300 h (H2) reached a maximum value of HB 331. With an increase of aging time, the hardness decreased gradually to HB 307 (sample H6).

Fig. 1 Room temperature hardness of Inconel 740H under different conditions

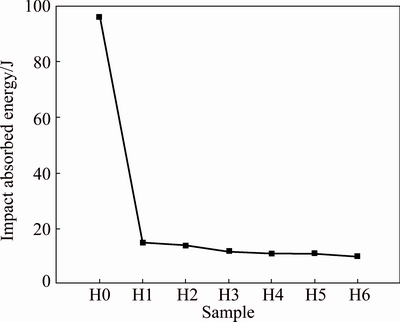

Fig. 2 Room temperature impact toughness of Inconel 740H (55 mm × 10 mm × 5 mm) under different conditions

Fig. 3 Room temperature impact fractured surfaces of H0 (a), H1 (b), H2 (c), H3 (d), H4 (e) and H5 (f) samples

Figure 2 shows the change of the RT impact absorbed energy under different conditions. The H0 sample had the highest impact absorbed energy (96 J) that is the characterization for the toughness. An obvious decline in toughness (15 J) was observed for the H1 sample and then a continuous decrease of toughness was visible.

Figure 3 shows the SEM images of the fractured surfaces after room temperature impact test of the alloys under different conditions. For the H0 sample, the fracture surface was predominantly of ductile nature revealed by the occurrence of large equiaxed dimples, presenting a trans-granular pattern, as shown in Fig. 3(a). As for the H1-H5 samples, the fractographs of the aged alloys indicated a clear brittle fracture with a localized mixed-mode behavior (Figs. 3(b)-(f)).

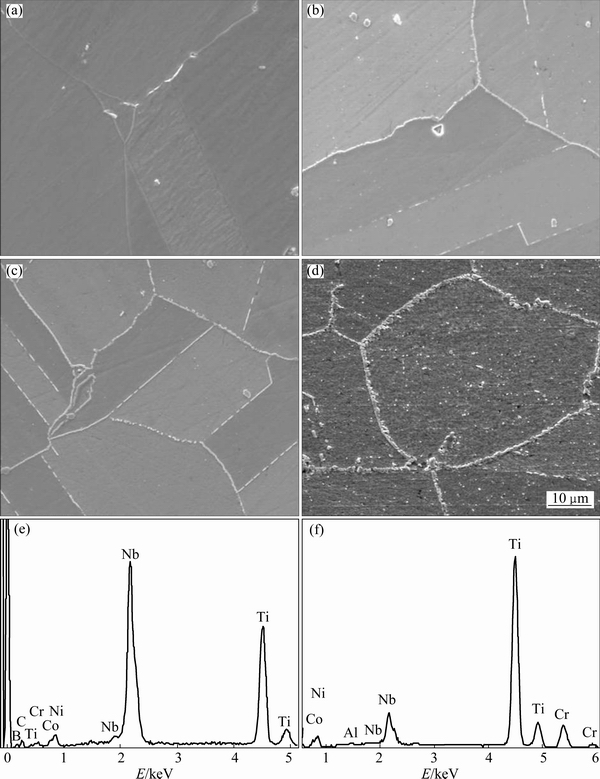

Fig. 4 SEM images of H0 (a), H1 (b), H2 (c), H6 (d) samples, and EDS analysis of (Nb, Ti)C (e) and TiN (f) in H6 sample

The microstructural evolution under different conditions was viewed by SEM (Fig. 4). Some large TiN particles (2.4-3.3 μm) rich in Ti (Fig. 4(f)) and (Nb,Ti)C particles (2.5-6.5 μm) rich in Nb and Ti (Fig. 4(e)) distributed within grains were detected in all samples (H0, H1, H2 and H6). As for the H1 and H2 samples, some precipitates were observed at grain boundaries. The amount of precipitates increased clearly after 10000 h aging (H6 sample), as shown in Fig. 4(d).

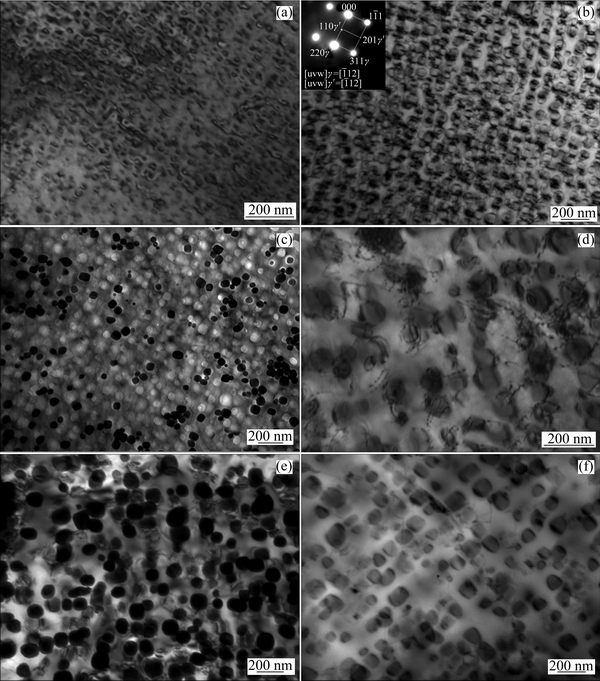

The TEM images and SAED pattern of intergranular precipitates under different conditions are shown in Fig. 5. For the H1 sample, γ′ phase particles with the sizes of 5-15 nm were visible in Fig. 5(a)). The sizes of γ′ phase particles were 30-70 nm (Fig. 5(b)), 30-90 nm (Fig. 5(c)), 60-140 nm (Fig. 5(d)), 60-180 nm (Fig. 5(e)), 70-220 nm (Fig. 5(f)) for H2, H3, H4, H5 and H6 samples, respectively. The TEM image of γ′ phase in the aged alloy has no remarkable change in shape in the process of aging. The spherical γ′ precipitates indicated strong coherency between γ′ phase and the γ matrix and a low degree of mismatch between the lattice parameters of both phases. The SAED pattern revealed that γ′ phase possessed an ordered FCC- structure with a lattice parameter of approximately 0.353 nm [25].

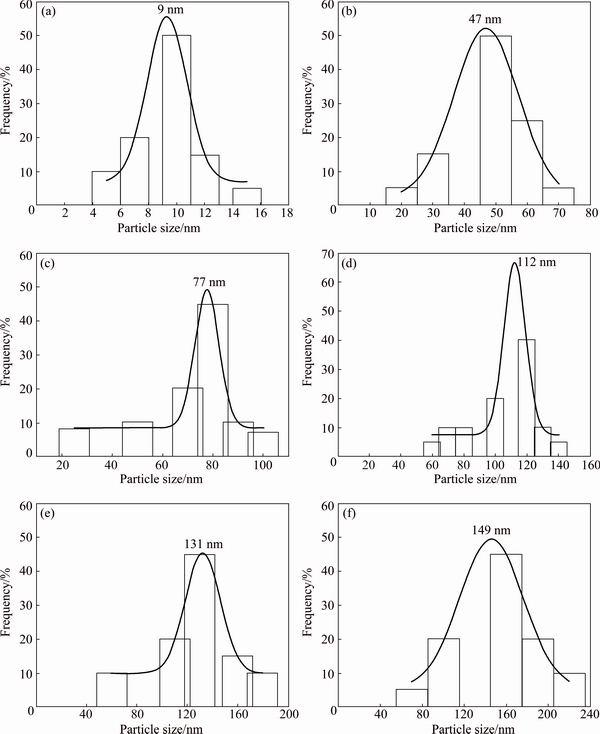

Figure 6 shows the particle size distribution of γ′ phase particles evaluated from more than five fields of view for the TEM images. Via a size fitting histogram with a Gaussian profile, the average sizes of γ′ phase particles in H1, H2, H3, H4, H5 and H6 samples were about 9, 47, 77, 112, 131 and 149 nm, respectively, which followed the theory of Ostwald ripening,

rt∝t1/3 (1)

where rt is the average radius of γ′ phases at time t. The results that rt has a linear relationship with t1/3 indicated the coarsening behavior of γ′ followed a diffusion controlled growth procedure.

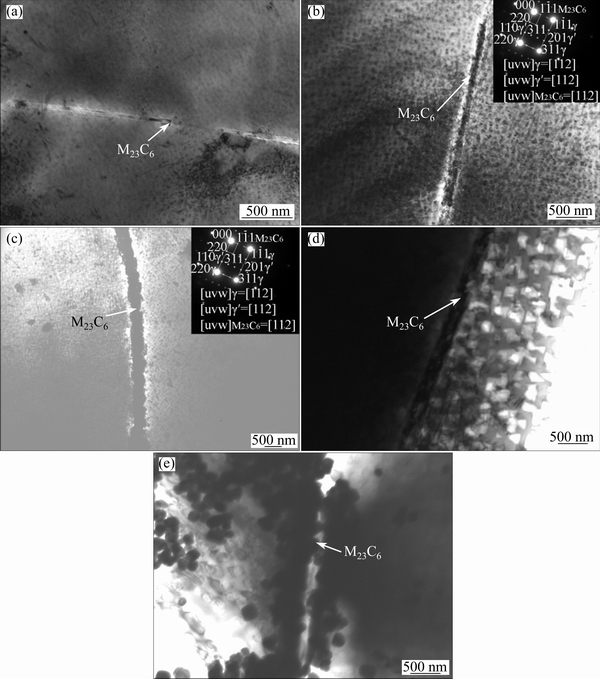

Figure 7 shows the TEM images and SAED patterns of intergranular precipitates under different conditions. Some carbide particles precipitated at the grain boundaries for the H1 sample. After aging for 300 h, an increased amount of M23C6 particles was clearly observed in Fig. 7(b). With prolonging the aging time, the agglomeration of M23C6 particles was visible at the grain boundaries (Figs. 7(d) and (e)).

Fig. 5 TEM images and SAED pattern of intragranular precipitates of H1 (a), H2 (b), H3 (c), H4 (d), H5 (e) and H6 (f) samples

4 Discussion

The as-received (H0) sample contained (Nb,Ti)C and TiN particles within grains. The distribution and size of the two phases took no change for the H1-H6 samples. The precipitates were a complex FCC-structure M23C6 with lattice parameters of 1.05-1.08 nm and an ordered FCC-structure γ′ phase with a lattice parameter of approximately 0.353 nm for the H1-H6 samples [25]. In general, the grain boundary carbides exhibited block- shape [26].

As the main contributors to strengthening and hardening effect in Ni-based superalloys, the morphology, size and chemical composition of γ′ precipitates are of primary importance for the Inconel 740H. The TEM images, together with SAED pattern showing typical superlattice reflections from γ′ precipitates for the H1-H6 samples are given in Fig. 5. No γ″ precipitates were detected from the TEM images and SAED pattern. The γ′ precipitates exhibited a spheroidal morphology despite of becoming slightly cuboidal after long time aging. In general, the γ′ precipitates exhibited a coarsening process during aging. As for the alloy aged for 300 h (H2), all γ′ precipitates remained below 70 nm in radius, whereas after that γ′ precipitates of sizes 30-100 nm were detected (H3). In the sample aged for 10000 h (H6), a small proportion of larger γ′ precipitates with sizes of more than 200 nm were detected. In the process of aging, it is indicative of the growth of γ′ phase particles with prolonging the aging time.

Fig. 6 Size distribution histogram and its Gaussian fit for γ′ phase particles in H1 (a), H2 (b), H3 (c), H4 (d), H5 (e) and H6 (f) samples

The aged alloys (H1-H6 samples) represented an enhanced RT hardness compared with the as-received sample (H0), which is correlated with the distribution and size of the precipitates and the relationship between the precipitates and the matrix phase. For example, the coherency between γ′ phase and the matrix was maintained during aging and resulted in a coherent stress for the aged alloy, thus giving rise to an enhanced hardness. On the other hand, the strengthening of the aged alloy also resulted from the precipitation of carbides as discrete particles both inside the grains and at the grain boundaries. The intra-granular carbides contributed to the strengthening effect by acting as barriers for dislocation motion and by stabilizing dislocations. The discrete nature of the grain boundary carbides was enhanced the hardness because it caused pinning of the boundary and decreased grain boundary sliding. The hardness of the H1 sample was HB 304 and then the hardness reached a maximum value of HB 331 for the H2 sample. With an increase of aging time, the hardness decreased from HB 331 (sample H2) gradually to HB 307 (sample H6). There probably was a critical value for the diameter of γ′ phase particles that gave the optimum hardness of Inconel 740H. When the diameter of γ′ precipitates was below the critical value, the hardness increased monotonically with an increase of precipitate size (samples H1 and H2); when the size was above the critical value, the hardness decreased with an increase of the precipitate size (samples H2 to H6).

Fig. 7 TEM images and SAED patterns of intergranular precipitates of H1 (a), H2 (b), H3 (c), H4 (d) and H5 (e) samples

The as-received alloy (H0 sample) exhibited the highest RT toughness revealed by dimple-ductile fracture. An obvious loss in RT toughness occurred predominately due to the carbides formed at the grain boundaries for the H1 sample. The grain boundaries were weakened by the grain boundary carbides and the separation occurred by the decohesion of carbide/matrix interface that was the initiation site for fracture. Hence, cracks may mainly take place at the grain boundaries during the impact test. On the other hand, the precipitation strengthening of γ′ phase of the aged alloys limited plastic deformation to the area nearby the grain boundaries, resulting in the occurrence of crack at the grain boundaries, which was an another important factor for the decrease of RT toughness. After aging, the toughness value decreased slightly with increasing the aging time and took no substantially change for the samples (H2-H6) possible due to the unchanged distribution of precipitates at intra- and inter-granular sites, which was manifested by the unchanged fracture surface (Fig. 3).

5 Conclusions

1) The precipitates were M23C6 carbide located inside the grains and at the grain boundaries and the γ′ phase dispersed within the grains for the H1-H6 samples.

2) During aging, the distribution of the grain boundary carbides took no obvious change. The coherency between the γ′ precipitates and the matrix was maintained and the coarsening behavior of γ′ precipitates followed a diffusion controlled growth procedure. Prolonging the aging time induced the growth of precipitates both at the grain boundaries and inside the grains.

3) There probably existed a critical value for the mean diameter of γ′ precipitates that gave the optimum hardness of Inconel 740H. When the diameter of γ′ precipitates was below the critical value, the hardness increased monotonically with increasing the precipitate size; when the size was above the critical value, the hardness decreased with the increase of precipitate size.

4) A loss of room temperature impact toughness of the aged alloy was evident.

5) The aged alloy represented good stabilities of hardness and toughness during aging.

References

[1] GUO Yan, LIN Lin, HOU Shu-fang. Microstructure of domestic TP310HCbN steel after high temperature creep-rupture test [J]. Electric Power, 2012,45(10): 42-47. (in Chinese)

[2] GUO Yan, JIA Jian-min, HOU Shu-fang, TANG Li-ying, LIN Lin. Steam oxidation behavior of domestic TP347H FG steel [J]. Corrosion Science and Protection Technology, 2011, 23(6): 505-509.

[3] CHI Cheng-yu, DONG Jian-xin, LIU Wen-qing, XIE Xi-shan. 3DAP investigation of precipitation behavior of Cu-rich phase in super 304H heat resistant steel [J]. Acta Metallurgica Sinica, 2010, 46(9): 1141-1146. (in Chinese)

[4] GUAN S, GUI C Y. A newly developed wrought Ni-Fe-Cr based superalloy for advanced ultra-supercritical power plant applications beyond 700 °C [J]. Acta Metallurgica Sinica, 2015, 28(9): 1083-1088.

[5]  KOPP R. Wrought Ni-base superalloys for steam turbine applications beyond 700 °C [J]. Advanced Engineering Materials, 2003, 5(7): 469-483.

KOPP R. Wrought Ni-base superalloys for steam turbine applications beyond 700 °C [J]. Advanced Engineering Materials, 2003, 5(7): 469-483.

[6] Sauders J, Monteriro M, Rizzo F. The oxidation behavior of metals and alloys at high temperatures in atmospheres containing water vapor: A review [J]. Progress in Materials Science, 2008, 53(5): 775-837.

[7] LIU Li-rong, JIN Tao, LIU Jin-lai, SUN Xiao-feng, HU Zhuang-qi. Effect of ruthenium on γ′ precipitation behavior and evolution in single crystal superalloys [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 14-22.

[8] JAHANGIRI M R, ARABI H, BOUTORABI S M A. Comparison of microstructural stability of IN939 superalloy with two different manufacturing routes during long-time aging [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1717-1729.

[9] Gariboldi E,Cabibbo M, Spigarelli S.Investigation on precipitation phenomena of Ni-22Cr-12Co-9Mo alloy aged and crept at high temperature [J]. International Journal of Pressure Vessels and Piping, 2008, 85(1-2): 63-71.

[10] Rahman S, Priyadarshan G, Raja K S, NESBITT C, MISRA M. Investigation of the secondary phases of alloy 617 by scanning Kelvin probe force microscope [J]. Materials Letter, 2008, 62(15): 2263-2266.

[11] Guo Yan, Wang Bo-han, Hou Shu-fang. Aging precipitation behavior and mechanical properties of Inconel 617 superalloy [J]. Acta Metallurgica Sinica (Engl Lett), 2013, 26(3): 307-312.

[12] Wu Q, Song H, SWINDERMAN R W, SHINGLEDECKER J P, VASUDEVAN V K. Microstructure of long-term aged IN617 Ni-base superalloy [J]. Metallurgical and Materials Transactions A, 2008, 39(11): 2569-2585.

[13] Tytko D, Choia P P, Klower J, KOSTKA A, INDEN G. Microstructural evolution of a Ni-based superalloy (617B) at 700 °C studied by electron microscopy and atom probe tomography [J]. Acta Materialia, 2012, 60(4): 1731-1740.

[14] Guo Yan, ZHANG Zhou-bo, ZHOU Rong-can, HOU Shu-fang, WANG Bo-han. Microstructure and mechanical properties of alloy 617B [J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1106-1113.

[15] Zhao S Q, XIE X S, Smith G D, Patel S J. Research and improvement on structure stability and corrosion resistance of nickel-base superalloy INCONEL alloy 740 [J]. Materials and Design, 2006, 27(10): 1120-1127.

[16] Zhao S Q, Xie X S, Smith G D, PATEL S J. The corrosion of INCONEL alloy 740 in simulated environments for pulverized coal-fired boiler [J]. Materials Chemistry and Physics, 2005, 90(2): 275-281.

[17] Evans N D, Maziasz P J, Swindeman R W, Smith G D. Microstructure and phase stability in INCONEL alloy 740 during creep [J]. Scripta Materialia, 2004, 51(6): 503-507.

[18] Zhao S Q, Jiang Y, Dong J X, XIE X S. Experimental investigation and thermodynamic calculation on phase precipitation of INCONEL 740 [J]. Acta Metallurgica Sinica (Engl Lett), 2006, 19(6): 425-431.

[19] Shingledecker J P, Evans N D, Pharr G M. Influences of composition and grain size on creep-rupture behavior of Inconel alloy 740 [J]. Materials Science and Engineering A, 2013, 578: 277-286.

[20] BECHETTI D H, DUPONT J N, DEBARBADILLO J J, BAKER B A. Homogenization and dissolution kinetics of fusion welds in INCONEL alloy 740H [J]. Metallurgical and Materials Transaction A, 2014, 45: 3051-3063.

[21] BECHETTI D H, DUPONT J N, deBARBADILLO J J D,BAKER B A, WATANABE M. Microstructural evolution of INCONEL alloy 740H fusion welds during creep [J]. Metallurgical and Materials Transaction A, 2014, 46: 1-17.

[22] Wang Jue, Dong Jian-xin, ZHANG Mai-cang, XIE Xi-shan. Hot working characteristics of nickel-base superalloy 740H during compression [J]. Materials Science and Engineering A, 2013, 566: 61-70.

[23] Chong Yan, Liu Zheng-dong, GODFREY Andy, LIU Wei, WENG Yu-qing. Microstructure evolution and mechanical properties of Inconel 740H during aging at 750 °C [J]. Materials Science and Engineering A, 2014, 589: 153-164.

[24] Xie Xi-shan, Zhao Shuang-qun, Dong Jian-xin, ZHANG Mai-cang. Structural stability and improvement of Inconel alloy 740 for ultra supercritical power plants [J]. Journal of Chinese Society of Power Engineering, 2011, 31(8): 638-641. (in Chinese)

[25] GUO Yan, ZHOU Rong-can, ZHANG Hong-jun, ZHANG Zhou-bo, HOU Shu-fang, WANG Bo-han. Microstructure and precipitates of alloy 740H [J]. Proceedings of the CSEE, 2015, 35(17): 4439-4444.

[26] YU Zhu-huan, LIU Lin, ZHANG Jun. Effect of carbon addition on carbide morphology of single crystal Ni-based superalloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(2): 339-345.

镍基合金740H时效过程中的显微组织与相析出行为

郭 岩,李太江,王彩侠,侯淑芳,王博涵

西安热工研究院有限公司,西安 710032

摘 要:借助扫描电镜、透射电镜和力学性能分析研究镍基合金740H在750 °C时效10000 h过程中的显微组织和相析出行为及其对室温硬度和冲击性能的影响。供货态镍基合金740H的硬度低至HB 168,最高冲击吸收能量为96 J。经800 °C标准热处理16 h后,晶内析出细小 γ' 颗粒,晶界析出少量碳化物,硬度提高到HB 304,冲击吸收能量降至15 J。当合金在750 °C时效300 h时,硬度达到最大值HB 331。随着时效时间由300 h延长至 10000 h,硬度和冲击吸收能量均降低,晶界碳化物M23C6数量明显增多,γ'相尺寸粗化。

关键词:镍基合金740H;时效;显微组织;相析出

(Edited by Mu-lan QIN)

Foundation item: Project (TN-15-TYK05) supported by the Research and Development Fund of Thermal Power Research Institute (TPRI), China; Project (2012AA050501) supported by the National High-tech Research and Development Program of China

Corresponding author: Yan GUO; Tel: +86-29-82002773; E-mail: gy197704@163.com

DOI: 10.1016/S1003-6326(16)64266-8