文章编号:1004-0609(2015)08-2099-09

Inconel 601镍基高温合金激光焊焊缝的显微组织

敖三三1,罗 震1, 2,单 平1,步贤政1,刘为东1

(1. 天津大学 材料科学与工程学院,天津 300072;

2. 高新船舶与深海开发装备协同创新中心,上海 200240)

摘 要:对3.0 mm厚的Inconel 601镍基合金激光焊后焊接接头的显微组织进行研究。结果表明:凝固后焊缝金属仍呈奥氏体相,其相组成由奥氏体基体γ相、γ′相(Ni3Al为主)以及碳化物相(Cr23C6)组成。同时,熔池金属以交互结晶的方式优先依附在半熔化状态的母材晶粒表面生长。另外,在焊缝金属中观察到以胞状和树枝状为主的亚结构,亚结构中存在凝固亚晶界、凝固晶粒边界和迁移晶粒边界。

关键词:Inconel 601合金;镍基高温合金;激光焊;亚结构;显微组织

中图分类号:TG456.7 文献标志码:A

Microstructure of Inconel 601 nickel-based superalloy laser welded joint

AO San-san1, LUO Zhen1, 2, SHAN Ping1, BU Xian-zheng1, LIU Wei-dong1

(1. School of Materials Science and Engineering, Tianjin University, Tianjin 300072, China;

2. Collaborative Innovation Center of Advanced Ship and Deep-Sea Exploration, Shanghai 200240, China)

Abstract: The welded joint microstructure of 3.0 mm-thickness Inconel 601 superalloy was analyzed. The results show that the phase composition of the welded joint consists of austenite matrix γ phase, γ′ phase (Ni3Al-based) and carbide phase (Cr23C6), which is similar with the metal phase composition. And the molten pool metal grows up in the form of interaction crystallization, which is prior to attach to the semi-molten state of the metal surface. The cellular and dendritic substructures are observed in the welded joint microstructures. Solidification sub-grain boundary (SSGB), solidification grain boundary (SGB) and migrated grain boundary (MGB) exist in the substructure.

Key words: Inconel 601 alloy; nickel-based superalloy; laser welding; substructure; microstructure

镍基合金是高温合金中应用最广、高温强度最高的一类合金[1-3]。而Inconel 601合金作为镍基高温合金中的一种,由于具有组织稳定、工作温度高、耐腐蚀性能好等诸多优点,已被广泛应用于能源电力、石油化工以及航空航天等关键技术领域[4-5]。同时,Inconel 601镍基合金在这些领域中的应用已逐步从原来的铸造结构件向焊接结构件转变[6]。然而,由于Inconel 601合金中存在多种固溶强化元素[5, 7],使得镍基高温合金在焊接过程中极易出现焊缝组织偏析、脆性相析出以及焊接热裂纹等缺陷。此外,该合金具有导热性低、液态金属黏性强、合金元素容易氧化等特点[7],使得焊缝成型较差、熔深较浅[8]。如采用传统的钨极惰性气体保护焊对Inconel 601镍基高温合金施焊时,焊缝熔深很浅,而采用多层多道焊,则焊接效率低,同时增加了焊缝的缺陷敏感性[9]。同时,Inconel 601合金的焊接热裂纹倾向较大,采用增大焊接热输入的办法不但不能增加焊缝熔深,反而容易使焊缝中产生微裂纹,降低焊接结构的使用寿命[10]。因此,需要采用一种热输入较小、能量密度较高的焊接方法来完成Inconel 601镍基高温合金结构件的焊接。激光焊接作为一种能量密度高[11]、焊接熔深大[12]、焊接热输入小[13-14]的焊接方法,特别适用于镍基高温合金的焊接[10]。

然而,采用激光焊接对Inconel 601合金结构件进行连接的研究报道极少,目前,学术界对镍基高温合金的焊接性研究大部分工作集中在Inconel 718合金[15-17]、Inconel 690合金[18]和Inconel 738合金[19]这 几种常用镍基高温合金。

RAM等[15]系统研究了Inconel 718合金激光焊接接头的显微组织和接头强度特性。他们采用脉冲Nd-YAG固体激光器对2 mm厚的Inconel 718进行焊接。对焊后的接头分别采用3种不同的热处理方式,最后分别对3种不同热处理方式焊接接头的显微组织和拉伸强度进行分析对比。结果表明,热处理方式后接头的抗拉强度不同。即采用直接时效处理的焊接接头强度要稍微低于母材强度;采用980 ℃固溶处理的接头强度也低于母材强度,但是比直接时效处理的接头强度有所提高。而采用1080 ℃时效处理的接头强度同母材强度很接近,但是其晶粒变大,性能也相应降低。同时,他们也进一步研究了Inconel 718激光焊接接头的高温力学性能[16]。

ZHANG等[17]对激光熔敷后的Inconel 718高温合金的接头抗拉强度进行了系统研究。采用5 kW的大功率光纤激光器对Inconel 718合金进行激光熔敷,熔敷后工件热处理后在室温进行拉伸强度试验。实验结果表明:母材和熔敷层的抗拉强度和屈服强度都高于标准值,但是其室温韧性却低于标准值。他们系统分析了工件的断裂机理。

同时,TUCKER等[18]也系统研究了激光焊接速度和离焦量对Inconel 690合金焊接接头中气孔形成的影响机理。他们采用X射线法对接头中的气孔进行定量分析。通过大量实验,得到了接头中气孔数量同焊接速度和离焦量之间的工艺窗口,为今后Inconel 690合金激光焊接工艺参数的优化提供了基础数据。

此外,EGBEWANDE等[19]也对Inconel 738合金激光焊接的可焊性进行了研究。分析了不同焊前热处理条件下的Inconel 738镍基高温合金的CO2激光焊接接头显微组织,结果表明:在产生晶界液化现象最少的热处理状态下焊接时焊缝热影响区裂纹最多,产生晶间液化现象较多的热处理条件下焊接时热影响区的裂纹敏感性较小。

尽管Inconel 601和Inconel 718、Inconel 690等同属于镍基高温合金,但由于合金元素含量不同,其物理和化学性能存在很大差异。因此,Inconel 718、Inconel 690等这些常用合金的激光焊接参数在一定程度并不能直接用于Inconel 601合金的焊接上。所以,必须对Inconel 601合金激光焊接工艺过程进行研究。同时,从所检索到的文献资料来看,对Inconel 601合金激光焊接的研究很少。随着Inconel 690合金焊接结构件的广泛应用,对其焊接性的研究也显得尤为重要。

鉴于此,本文作者将重点研究Inconel 601镍基高温合金激光焊后焊接接头的熔池金属凝固过程、相组成以及显微组织和亚结构,为今后Inconel 601镍基高温合金焊接接头力学性能、抗腐蚀性能的分析提供基础数据和理论支撑。

1 实验

1.1 实验设备及材料

采用GSI公司生产的JK2003SM型Nd:YAG激光器进行焊接,聚焦透镜的焦距为160 mm,利用多轴数控加工机床实现激光束与工件之间的相对运动。

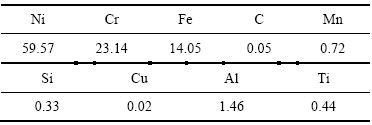

实验材料为德国ThyssenKrupp公司生产的Inconel 601镍基高温合金,供货状态为经过酸洗处理的3 mm厚固溶态板材。该合金的化学成分如表1所示。

表1 Inconel 601镍基高温合金的化学成分

Table 1 Chemical composition of Inconel 601 (mass fraction, %)

1.2 实验参数

通过大量激光焊工艺试验,确定最优焊接参数如下:激光功率P=1600 W,焊接速度v=4 mm/s,离焦量Δf=-0.5 mm,保护气为工业纯Ar,气流量为20 L/min。

1.3 实验方法

1) 金相分析

参照ASTM E3-01标准制备试样。采用饱和 FeCl3盐酸溶液对焊缝进行侵蚀后,通过OLYMPUS光学显微镜对焊缝显微组织进行观察。

2) 物相分析

按要求将焊缝加工成相应的块状试样,采用Rigaku D/max 2500v/pc型X射线衍射仪进行物相分析。

3) 扫描电镜分析

采用JSM-6700F型场发射扫描电子显微镜对金相试样进行分析。通过能谱仪(EDS)对焊缝微区、析出物以及氧化产物的化学组成和分布进行分析。

4) 透射电镜分析

将焊缝金属用砂纸上逐级打磨,用离子减薄制备TEM试样。采用JEOL透射电镜对焊缝的显微亚结构、沉淀相形貌以及分布情况进行观察。

5) 显微硬度测试

采用MHV200型维氏显微硬度仪来测量焊缝的显微硬度,试验载荷为0.98 N,加载时间10 s。

2 结果与分析

2.1 Inconel 601母材的显微组织

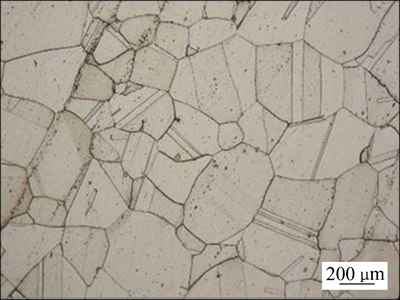

本研究中所使用的Inconel 601镍基高温合金的金相组织如图1所示。

图1 Inconel 601镍基高温合金的金相组织

Fig. 1 Metallograph of Inconel 601 nickel-based superalloy

从图1可以看出,Inconel 601镍基高温合金具有典型的全奥氏体等轴晶组织,平均晶粒尺寸为130~150 μm。合金金相组织中存在大量的孪晶组织,晶界比较平直。此外,该合金奥氏体基体上还弥散分布着很多的黑色颗粒,同时还有少量的黄褐色块状颗粒存在于晶粒内部和晶界处。

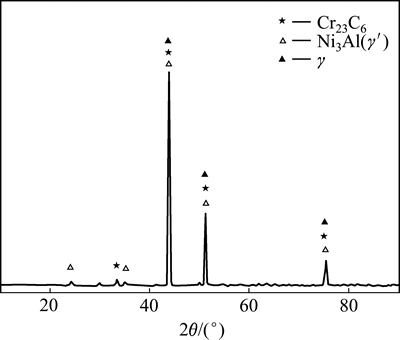

为了进一步确定Inconel 601镍基高温合金母材的相组成,对该合金母材试样进行了X射线衍射分析,其XRD谱如图2所示。

图2 Inconel 601镍基高温合金的XRD谱

Fig. 2 XRD pattern of Inconel 601 nickel-based superalloy

从图2可以看出,Inconel 601镍基高温合金的组成相主要有γ相、γ′相以及Cr23C6碳化物相。

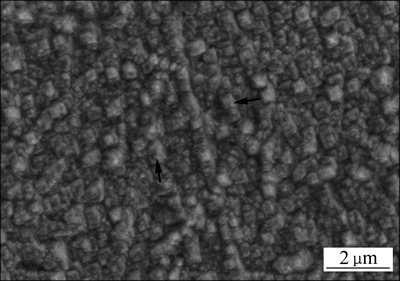

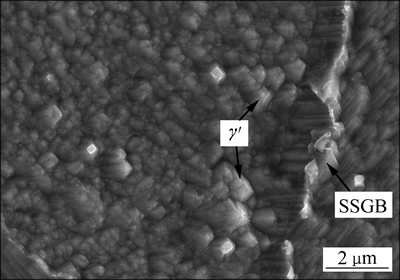

γ′相是镍基高温合金中一种重要的金属间相,其主要成分为Ni3Al和Ni3Ti,其中Ni原子可以被Cr和Mo等原子替代,其晶体结构与γ相基体同为面心立方结构。通常,γ′相是沉淀强化高温合金中的主要强化相。图3所示为Inconel 601镍基高温合金中的γ′相形貌。

图3 Inconel 601镍基高温合金中γ′相形貌

Fig. 3 Morphology of γ′ phase in Inconel 601 nickel-based superalloy

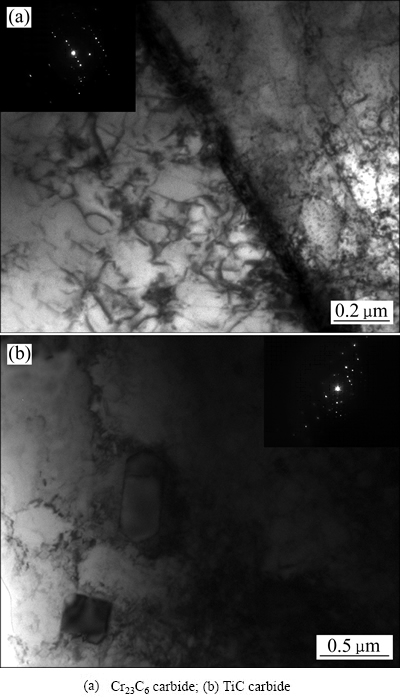

由于C元素在固溶体中的含量很低,因此极易形成碳化物。碳化物是镍基高温合金中一种常见的析出相。Inconel 601合金中的碳主要有两种形式:MC型碳化物和M23C6型碳化物。其中M23C6型碳化物以Cr23C6为主,主要沿奥氏体晶界出现,如图4(a)所示;而MC型碳化物以TiC为主,通常以块状颗粒的形式出现在奥氏体晶粒中,如图4(b)所示。

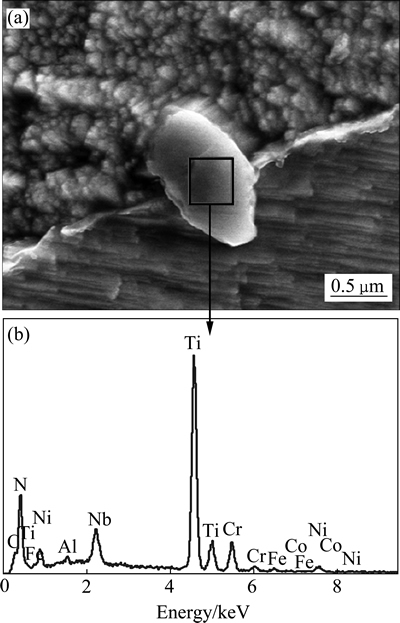

由于Inconel 601镍基高温合金中含有1.46%(质量分数)的Al和0.44%的Ti,在非真空冶炼过程中,合金中不可避免地会出现少量的氮化物和氧化物颗粒,但这些杂质相的颗粒较小,通常尺寸在几百个纳米到几微米之间,并且含量较少,因此,一般不会对合金性能产生不良影响。图5所示为Inconel 601镍基高温合金中的氮化物形貌及EDS谱。图6所示为Inconel 601镍基高温合金中氧化物颗粒形貌及EDS谱。由图5和图6可 知,该合金中的氮化物主要为TiN,氧化物杂质主要为Al2O3,颗粒大小在1 μm左右。

图4 Inconel 601合金母材中的碳化物形貌

Fig. 4 Morphologies of carbide in Inconel 601 nickel

Inconel 601镍基高温合金中氮化物和氧化物颗粒的熔点较高(TiN熔点为2950 ℃,Al2O3熔点为2050 ℃),在焊接过程中它们通常以固相形态存在于焊接熔池中[17]。当熔池金属凝固时,这些颗粒可以作为天然的形核剂,促进液态金属的非均匀形核,从而达到细化焊缝晶粒的效果。

2.2 Inconel 601焊接接头显微组织

激光焊接实验后,得到的Inconel 601镍基高温合金焊接接头横截面形貌特征以及各部分显微组织如图7所示。

从图7(a)中可以明显看到,激光焊接接头同样由焊缝(Weld metal, WM)、焊接热影响区(Heat-affected zone, HAZ)和母材(Base metal, BM) 3个主要部分构成。只是与传统弧焊接头不同的是,由于激光焊接过程中的功率密度较高,焊接热输入较小,因此,在激光焊接头中的焊接热影响区的范围较小,大约为150~200 μm,如图7(b)所示。图7(c)所示为激光焊接接头焊缝边缘位置的组织,该区域主要以柱状晶为主。逐步往焊缝中心位置观察发现,此时晶粒主要为等轴晶组织,如图7(d)所示。

图5 Inconel 601镍基高温合金中的氮化物形貌及EDS谱

Fig. 5 Morphology of nitride in Inconel 601(a) and EDS pattern of TiN(b)

图6 Inconel 601镍基高温合金中氧化物颗粒形貌及EDS谱

Fig. 6 Morphology of oxide in Inconel 601(a) and EDS pattern of Al2O3(b)

图7 Inconel 601合金激光焊缝的显微组织

Fig. 7 Microstructures of Inconel 601 laser weld seam

2.3 焊缝熔合区显微组织及其亚结构

图8所示为Inconel 601镍基高温合金焊缝晶粒内部的显微组织。从图8可以看出,Inconel 601合金的焊缝凝固模式为全奥氏体凝固模式,结晶凝固时的初始析出相为奥氏体相,焊缝熔合区中存在大量的黑色沉淀相,沉淀相的数量要明显多于母材的(见图1)。这是由于该合金中含有大量的合金元素和固相杂质,在凝固过程中这些合金元素容易在晶界和亚晶界处析出,加上此类元素在奥氏体中的扩散能力较差,因此最终保留在焊缝金属中。同时,还可以观察到:在焊缝熔合线(Fusion line)与热影响区(HAZ)之间还存在着一个白亮的半熔化区域(Partially melt zone),这个区域的母材金属在焊接过程中处于半熔化状态,是焊缝金属凝固时外延生长的基底,该区域通常在焊缝与母材熔化温度相差不大的情况下出现[18]。

图8 Inconel 601焊缝边缘凝固显微组织

Fig.8 Solidification microstructure of Inconel 601 seam

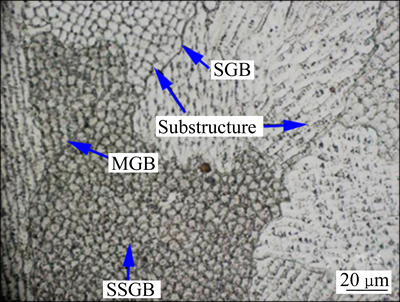

Inconel 601合金的接头在凝固过程中形成的亚结构(主要为胞状亚结构和树枝状亚结构)如图9所示。这些亚结构的边界包括凝固亚晶界(Solidification sub-grain boundary, SSGB)、凝固晶粒边界(Solidification grain boundary, SGB)和迁移晶粒边界(Migrated grain boundary, MGB)。

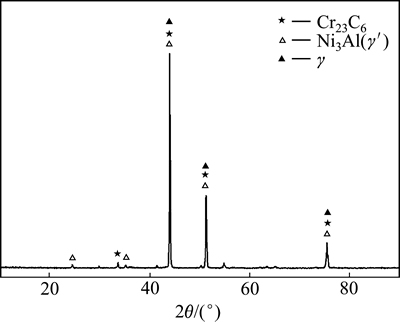

2.4 焊缝金属的相组成分析

图10所示为Inconel 601合金接头的XRD谱。从图10可以看到,焊缝中的相组成与合金母材类似,主要有奥氏体基体γ相、以Ni3Al为主的γ′相以及碳化物相(Cr23C6),这说明该合金的焊缝金属保持母材原有的奥氏体相,只是焊缝中的奥氏体显微形貌与母材的有所不同。

从图10还可以发现:焊缝金属XRD谱中γ′相和碳化物相的衍射峰强度与母材中的相比略有增强(见图2),这是由于焊接过程中熔池内的液态金属冷却速度较快,焊缝金属中溶质元素偏析较为严重,造成焊缝中γ′相和碳化物相析出较多。

图11所示为Inconel 601合金激光焊缝金属中的γ′相分布。由图11可以发现,γ′相在SSGB附近的析出比在晶胞内部析出的多,这是因为先结晶析出的晶胞轴中Al、Ti等溶质元素含量较少,而随后凝固晶胞边界处Al、Ti等溶质元素含量则较高,因此,以Ni3Al为主的γ′相在晶胞边界处析出比在晶胞轴上析出多。

图9 Inconel 601焊缝中心处亚结构边界

Fig. 9 Sub-structure boundary of Inconel 601 weld seam

图10 Inconel 601镍基高温合金焊缝的XRD谱

Fig. 10 XRD pattern of Inconel 601 nickel-based weld seam

图11 Inconel 601镍基高温合金焊缝金属内的γ′相

Fig. 11 Morphology of γ′ phase in Inconel 601 weld seam

另外,焊缝金属中溶质元素的偏析使得焊缝中的碳化物相与母材中的相比也略有增多。图12所示为 合金焊缝中Cr23C6型和TiC型碳化物相的TEM像。

图12 Inconel 601镍基高温合金焊缝中碳化物形貌

Fig. 12 Morphologies of carbide in Inconel 601 weld seam

3 讨论

3.1 Inconel 601激光焊缝形成过程

焊接接头的形成必然伴随着熔池液态金属的凝固过程。根据凝固理论可知,液态金属凝固结晶的过程是一个形核和晶核长大的过程,其中形核可分为均匀形核和异质形核。通常来说,均匀形核只有在液态金属极纯净,液体中无任何固相杂质的理想情况下才会发生。而对于焊接接头来讲,熔池液态金属的形核主要以异质形核为主。均匀形核所需要的形核功( )和异质形核所需要的形核功(

)和异质形核所需要的形核功( )的表达式分别如式(1)和(2)所示:

)的表达式分别如式(1)和(2)所示:

(1)

(1)

(2)

(2)

式中: 和

和 分别为均匀形核和异质形核所需要的形核功;

分别为均匀形核和异质形核所需要的形核功; 为单位面积的表面能;Tm为液态金属理论结晶温度;Lm为熔化潜热;

为单位面积的表面能;Tm为液态金属理论结晶温度;Lm为熔化潜热; 为过冷度;

为过冷度; 为晶核与基底的浸润角。

为晶核与基底的浸润角。

由式(1)和(2)可以看出,均匀形核和异质形核的形核功 和

和 之间相差一个系数,当浸润角

之间相差一个系数,当浸润角 为0°时结晶所需要的形核功最小,此时结晶所形成的新相与基底之间可以完全润湿,说明两相之间晶体结构相似,新形成的晶粒几乎可以沿着原有晶粒表面生长。

为0°时结晶所需要的形核功最小,此时结晶所形成的新相与基底之间可以完全润湿,说明两相之间晶体结构相似,新形成的晶粒几乎可以沿着原有晶粒表面生长。

在激光焊接过程中,焊接熔池周围热影响区处的母材晶粒处于半熔化状态,而这些半熔化状态的母材晶粒与凝固所生成的新相之间的晶体结构最为相似,形核时所需要的形核功最小,可以作为熔池中液态金属形核的良好基底。因此,焊接熔池在形核过程中总是优先依附于这些处于半熔化状态的母材晶粒表面,并以柱状晶的形式向焊缝中心生长,在熔合线处与母材形成共同的晶粒,即所谓的交互结晶、外延生长。

从图7(c)可以明显看到:Inconel 601镍基高温合金激光焊缝在凝固结晶过程中所形成的柱状晶与母材晶粒为同一个晶粒,二者之间保持着良好的共格关系,这表明其凝固方式为交互结晶,并通过外延生长的模式形成。同时,由于晶粒的长大还要受过冷度的影响,而垂直于焊缝熔合线的方向上散热最快,温度梯度最大,因此,焊缝边缘柱状晶区的生长总是沿着这个方向优先长大,其他方向上晶粒的生长则受到抑制。

另外,在焊缝中心处还可以发现有少量的等轴晶组织(见图7(d))。这是由于随着焊缝边缘柱状晶的生长,焊接熔池中原来处于过热状态的液态金属经过散热的作用几乎全部降到熔点以下,满足了形核过程对过冷度的要求,同时在液态金属中固相杂质的影响下,焊接熔池中剩余的液态金属开始形核。而此时,由于金属的散热没有了方向性,各个方向的过冷度几乎相同,依附于固相质点形成的晶核可以在液态金属中自由生长,其生长速度在各个方向上相差不多,最终长大形成等轴晶组织。

3.2 Inconel 601激光焊缝亚结构形成过程

通常认为,晶粒内部亚结构的出现与液态金属内部成分偏析所造成的成分过冷有关。对于Inocnel 601镍基高温合金激光焊接来说,由于焊接熔池的冷却速率较快,焊缝中的成分偏析更为明显,先结晶析出的晶胞中Al和Ti等元素的含量较低,而后结晶的晶胞边界处Al和Ti的含量则较高,从而造成晶胞边界与晶胞内部的成分偏析。晶胞与晶胞之间的边界就形成了凝固亚晶界。

除了凝固亚晶界以外,在该合金焊缝凝固组织中还存在其他两种形式的边界,即凝固晶粒边界(Solidification grain boundary, SGB)和迁移晶粒边界(Migrated grain boundary, MGB)(见图9)。SGB边界是亚晶粒束与亚晶粒束之间的边界,金属凝固结晶时杂质元素以及低熔点溶质元素也常常在此富集,因此,SGB边界处最容易出现焊接凝固裂纹。MGB边界的形成则是全奥氏体凝固模式中的普遍现象,通常认为MGB边界的形成可以使结晶凝固时生成的SGB边界变得平直而降低其能量,从而引起晶界迁移的驱动力降低,这种迁移晶界往往带有原来SGB晶界的大角度位向差。

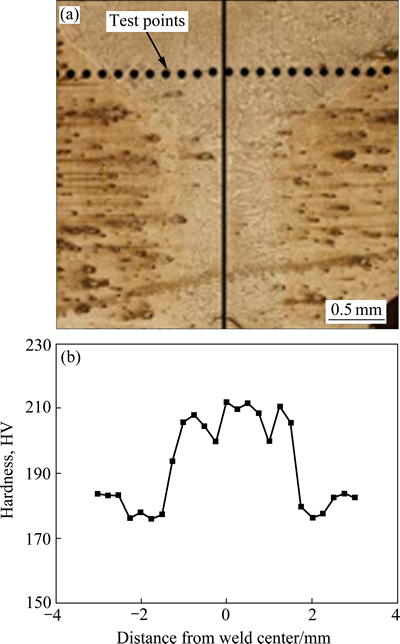

3.3 Inconel 601激光焊接头显微硬度

图13所示为Inconel 601镍基高温合金激光焊接接头的显微硬度分布。从图13可以看出,对于Inconel 601合金,母材的硬度为183 HV左右;焊缝区域的硬度处于193~210 HV之间,比母材硬度稍高,而热影响区的硬度则在177 HV左右。造成这种现象的主要原因是焊缝金属在冷却凝固过程中,不同的区域所产生的组织不一样。焊缝中心处出现了等轴晶组织(见图7(d)),因此,其硬度较高;而热影响区晶粒粗大,因而硬度也相对降低。

图13 Inconel 601合金激光焊接头形貌及硬度分布

Fig. 13 Morphology(a) and hardness distribution(b) of butt joint by laser welding for Inconel 601 alloy

4 结论

1) 对3 mm厚Inconel 601镍基高温合金,通过选择合适的激光焊工艺参数,得到的焊接接头热影响区大小为150~200 μm。

2) 对于Inconel 601镍基高温合金激光焊,焊缝金属的相组成与母材的相组成类似,均由奥氏体基体γ相、γ′相(Ni3Al为主)以及碳化物相(Cr23C6)组成,但相对于母材焊缝金属中的γ′相和碳化物相析出较多。

3) 存在于焊缝熔合线与热影响区之间的白亮半熔化区域是焊缝金属凝固时外延生长的基底。熔池金属优先依附在半熔化状态的母材晶粒表面,以交互结晶的方式生长。

4) 凝固过程中焊缝金属中形成了以胞状亚结构和树枝状亚结构为主的亚结构,亚结构中存在凝固亚晶界、凝固晶粒边界和迁移晶粒边界。

5) Inconel 601镍基高温合金中的TiN和Al2O3颗粒在焊接过程中以固态形式存在于焊接熔池中,这些颗粒作为天然的形核剂,促进了液态金属的非均匀形核,从而达到细化焊缝晶粒的效果。

6) 对于Inconel 601镍基高温合金的激光焊接头,由于焊缝凝固后形成的组织不同,使得焊缝区的硬度在193~210 HV之间,而热影响区硬度则约为177 HV。

REFERENCES

[1] 唐中杰, 郭铁明, 付 迎, 惠 枝, 韩昌松. 镍基高温合金的研究现状与发展前景[J]. 金属世界, 2014, 1: 36-40.

TANG Zhong-jie, GUO Tie-ming, FU Ying, HUI Zhi, HAN Chang-song. Research present situation and the development prospect of nickel-based superalloy[J]. Metal World, 2014, 1: 36-40.

[2] 倪 莉, 张 军, 王 博, 刘 林, 傅恒志. 镍基高温合金设计的研究进展[J]. 材料导报, 2014, 28(3): 1-6.

NI Li, ZHANG Jun, WANG Bo, LIU Lin, FU Heng-zhi. Progress in alloy design of nickel-based superalloys[J]. Materials Review, 2014, 28(3): 1-6.

[3] 田 宁, 田素贵, 于惠臣, 孟宪林. DZ125镍基合金的显微组织与蠕变行为[J]. 中国有色金属学报, 2014, 24(5): 1232-1240.

TIAN Ning, TIAN Su-gui, YU Hui-chen, MENG Xian-lin. Microstructures and creep behavior of DZ125 nickel-based superalloy[J]. The Chinese Journal Nonferrous Metals, 2014, 24(5): 1232-1240.

[4] DAS N. Advances in nickel-based cast superalloys[J]. Transactions of the Indian Institute of Metals, 2010, 63(2/3): 265-274.

[5] KWIECIEN M, MAJTA J, DZIEDZIC D. Shear deformation and failure of explosive welded Inconel-microalloyed steels bimetals[J]. Archives of Civil and Mechanical Engineering, 2014, 14(1): 32-39.

[6] 梁艳峰, 董晟全, 丁 宏, 李高宏. 不锈钢薄壁铸件壳型成形工艺研究[J]. 铸造技术, 2010, 31(7): 906-909.

LIANG Yan-feng, DONG Sheng-quan, DING Hong, LI Gao-hong. Study on shaping process for thin wall stainless steel casting by shell mould casting process[J]. Poundry Technology, 2010, 31(7): 906-909.

[7] BUSCAIL H, PERRIER S, JOSSE C. Oxidation mechanism of the Inconel 601 alloy at high temperatures[J]. Materials and Corrosion, 2011, 62(5): 416-422.

[8] LIN T S, LI H X, HE P, YANG X, HUANG Y D, LI L, HAN L. Effect of bonding parameters on microstructures and properties during TLP bonding of Ni-based super alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2112-2117.

[9] 李亚江, 夏春智, 石 磊. 国内镍基高温合金的焊接研究现状[J]. 现代焊接, 2010, 7: 1-4.

LI Ya-jiang, XIA Chun-zhi, SHI Lei. Domestic present research status of the nickel-based superalloy welding[J]. Modern Welding, 2010, 7: 1-4.

[10] HENDERON M B, ARRELL D, LARSSON R, HEOBEL M, MARCHANT G. Nickel based superalloy welding practices for industrial gas turbine applications[J]. Science and Technology of Welding and Joining, 2004, 9(1): 13-21.

[11] ZHAO P Z, LIU J, CHI Z D. Effect of Si content on laser welding performance of Al-Mn-Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2208-2213.

[12] 占小红, 陈 洁, 陶 汪, 杨志斌, 魏艳红, 陈彦宾, 欧文敏. 新型铝合金薄板对接激光焊接头性能[J]. 焊接学报, 2012, 12: 37-40, 114-115.

ZHAN Xiao-hong, CHEN Jie, TAO Wang, YANG Zhi-bin, WEI Yan-hong, CHEN Yan-bin, OU Wen-min. Performance of laser welding joint for the new aluminum thin plate butt[J]. Transactions of the China Welding Institution, 2012, 12: 37-40, 114-115.

[13] 高向东, 杨永琛, 张艳喜. 激光焊熔池图像三维形态恢复算法分析[J]. 焊接学报, 2013, 11: 5-8.

GAO Xiang-dong, YANG Yong-shen, ZHANG Yan-xi. Algorithm analysis of the laser welding pool image restoration[J]. Transactions of the China Welding Institution, 2013, 11: 5-8.

[14] GAO X D, WEN Q, KATAYAMA S. Analysis of high-power disk laser welding stability based on classification of plume and spatter characteristics[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3748-3757.

[15] RAM G D J, REDDY A V R, RAO K P, REDDY G M, SUNDARD J K S. Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds[J]. Journal of Materials Processing Technology, 2005, 167(1): 73-82.

[16] RAM G D J, REDDY A V, RAO K P, REDDY G M. High temperature mechanical properties of Inconel 718 pulsed Nd-YAG laser welds[J]. Materials at High Temperatures, 2006, 23(1): 29-37.

[17] ZHANG Y N, CAO X J, WANJARA P, MEDRAJ M. Tensile properties of laser additive manufactured Inconel 718 using filler wire[J]. Journal of Materials Research, 2014, 29(17): 2006-2020.

[18] TUCKER J D, NOLAN T K, MARTIN A J, YOUNG G A. Effect of travel speed and beam focus on porosity in alloy 690 laser welds[J]. JOM, 2012, 64(12): 1409-1417.

[19] EGBEWANDE A T, BUCKSON R A, OJO O A. Analysis of laser beam weldability of Inconel 738 superalloy[J]. Materials Characterization, 2010, 61(5): 569-574.

(编辑 龙怀中)

基金项目:国家自然科学面上基金资助项目(51275342);国家自然科学青年基金资助项目(51405335);中国博士后特别资助项目(2014T70212)

收稿日期:2014-11-14;修订日期:2015-05-18

通信作者:罗 震,教授,博士;电话:13302055307;E-mail: lz @tju.edu.cn