DOI:10.19476/j.ysxb.1004.0609.2018.02.04

挤压态Mg-Dy-Cu合金板材的显微组织及时效硬化行为

毕广利1,袁利桃1,李元东1,姜 静1,韩宇翔1,蒋春宏2,马 颖1

(1. 兰州理工大学 材料科学与工程学院 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050;

2. 兰石铸造有限公司,兰州 730050)

摘 要:采用X射线衍射仪、金相显微镜、扫描电镜、透射电镜及显微硬度计等研究挤压Mg-2Dy-0.5Cu(摩尔分数,%)合金板材的显微组织及时效硬化行为。结果表明:铸态合金主要由α-Mg枝晶、分布在枝晶间片层状的18R-LPSO相以及少量不规则的MgDy3颗粒相组成。挤压后,合金发生动态再结晶,粗大的LPSO相碎化并沿挤压方向排列,少量细小片层状的14H-LPSO相在再结晶的α-Mg晶粒内析出。随着时效时间的增加,14H-LPSO相的体积分数逐渐增加并粗化,合金的硬度增加且在72 h达到峰值。合金峰值硬度的产生主要归结为高体积分数14H-LPSO相的析出强化。

关键词:Mg-Dy-Cu合金板材;LPSO相;显微组织;时效行为

文章编号:1004-0609(2018)-02-0241-08 中图分类号:TG146.2 文献标志码:A

镁合金具有低的密度、高的比强度、比刚度和易于回收等特点,部分镁合金已被广泛应用于航空航天、汽车和3C产品等领域[1]。然而,由于传统的镁合金在室温下低的抗拉强度和有限的伸长率限制了其发展和应用[2-3]。因此,开发新型高强度、高韧性的镁合金至关重要。

最近的研究表明[4-6],含长周期堆垛有序结构(LPSO)的Mg-Zn-RE (RE为稀土元素,主要包括Y、Gd和Dy等)合金显示了优异的室温及高温力学性能。KAWAMURA等[4]利用粉末冶金法制备Mg97Zn1Y2合金在室温的拉伸屈服强度为600 MPa,伸长率为5%。合金优异的拉伸性能主要归结为晶粒细化和LPSO相强化。目前,已报道的LPSO相结构主要包括6H、14H、18R、10H和24R,其中14H和18R较为常见[7-8]。18R-LPSO相是一种高温亚稳相,热处理后可转变成14H-LPSO相[9]。同时,LPSO相的结构、类型、尺寸、分布和体积分数等因素影响LPSO相强化效果,影响合金的力学性能。研究结果表明[10-11],热挤压+等温时效可有效的细化晶粒,改变LPSO相的类型,提高LPSO相的体积分数,并进一步提高合金的力学性能。LIU等[10]研究了挤压Mg-7Y-4Gd-0.5Zn-0.4Zr合金在250 ℃等温时效的析出行为。研究结果表明,该合金挤压后,晶粒明显细化,晶内出现14H-LPSO相,在250 ℃时效25 h出现时效硬化峰值,该峰值的出现主由于时效过程中β'相以及14H- LPSO相的析出强化。LENG等[11]研究挤压态的Mg-9RY-4Zn合金的时效硬化行为。研究结果显示:峰值态合金在室温和250 ℃的最大抗拉强度、屈服强度及伸长率分别为285 MPa、276 MPa、8.6%和243 MPa、316 MPa、16.3%。如此优异的力学性能主要是由于再结晶晶粒内高体积分数的14H-LPSO相和大量堆垛层错的共同强化。

课题组的研究表明[12],挤压+时效后的Mg-Dy-Zn合金显示了较高的高温力学性能,300 ℃时合金的最大抗拉强度、屈服强度及伸长率分别为260 MPa、245 MPa、36%。合金优异的高温力学性主要由于稳定的显微组织和LPSO相的析出强化。然而,利用高熔点元素进行合金化可形成高温稳定的LPSO相,进一步提高合金的高温力学性能。过渡元素Cu与Zn位于同一周期,具有高的熔点,并且由Cu形成的LPSO相也分别在铸态的 Mg97Y2Cu1[13]和Mg96.8Dy2.2Cu1[14]合金中发现。课题组前期的研究显示[15],与铸态Mg-Dy-Zn合金相比,铸态Mg-Dy-Cu合金具有较高的力学性能,其室温的最大抗拉强度、屈服强度及伸长率分别为170 MPa、110 MPa和12.7%。因此,为了进一步促使LPSO相弥散分布,提高LPSO相的耐热性,本文作者制备挤压态Mg-Dy-Cu合金板材,并研究了合金在等温时效过程中的组织演变和时效硬化行为,为开发新型耐热稀土镁合金奠定理论基础。

1 实验

实验合金的名义成分为Mg-2Dy-0.5Cu(摩尔分数,%)合金。将纯Mg、纯Cu和Mg-20Dy(质量分数,%)中间合金分别放入石墨坩埚中,在熔盐覆盖剂的保护下利用电阻炉对坩埚进行加热,当温度升高到750 ℃后,待金属完全熔化,均匀搅拌10 min,使合金元素充分混合,然后将炉内温度降到720 ℃,静置30 min后,将合金液注入直径为85 mm,长度为350 mm的水冷模具中,得到d 85 mm 的合金锭。车削合金锭表面,得到d 80 mm 的合金锭,在360 ℃,挤压比为17: 1的条件下进行挤压。将挤压合金板材用线切割机制备成10 mm×10 mm×10 mm的立方块试样,随后在Al-708P型电阻炉中进行250 ℃的时效处理。

利用Olympus-BX51型光学显微镜、D/MAX-2500 PC型X射线衍射仪(XRD)、Quanta Feg450型扫描电子显微镜(SEM),Tecnai G2 F20型透射电子显微镜(TEM)对合金的物相和晶体结构进行观察和分析。合金的金相试样经粗磨、细磨、抛光后在苦味酸溶液(2.75 g苦味酸+45 mL乙醇+5 mL蒸馏水+ 2.5 mL乙酸)下腐蚀,腐蚀后用2%(体积分数)的HNO3和酒精混合液再次清洗去除腐蚀产物。透射试样经细磨、抛光成为厚度约为30 μm的薄片,再经离子减薄仪进行减薄,制备成直径为3 mm的薄膜样品。合金中LPSO相的体积分数以及长宽通过Image-Pro Plus 6.0软件测量,每个数值的测量至少选取了10张SEM像进行统计,并取平均值。硬度测试在HV-100型显微硬度计上进行,载荷3 N,保载时间为15 s。每个压痕均覆盖基体和第二相,且每个试样测10个硬度值,取其平均值。

2 结果和讨论

2.1 显微组织

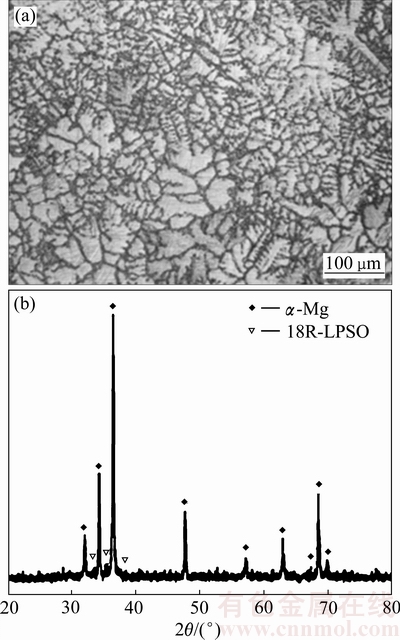

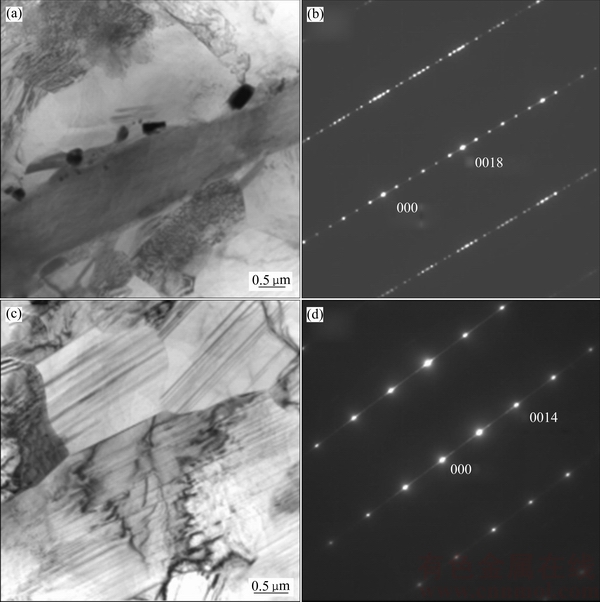

图1所示为铸态合金的光学显微组织和XRD谱。由图1(a)可知,铸态合金主要由α-Mg枝晶和分布在枝晶内的第二相组成。铸态合金的XRD谱显示合金主要为α-Mg和18R-LPSO相的衍射峰,如图1(b)所示。图2所示为铸态合金的扫描组织。合金的第二相主要由分布在枝晶间的片层状相以及少量位于晶内的颗粒相组成。表1的EDS分析结果显示,片层状相(如图2中B区)的平均化学成分为Mg-4.5Dy-3.7Cu (摩尔分数,%)。根据先前的研究[15],这种片层状相是具有18R-LPSO结构的Mg12DyCu相,其具有密排六方 (HCP)晶体结构,晶格常数分别为a=0.321 nm,c= 4.86 nm。这种18R-LPSO相也在铸态的Mg97.5Zn0.5Dy2合金[16]和Mg97Zn1Y2合金[17]中报道,不规则颗粒相(如图2中C区)平均的化学成分为Mg-75Dy(摩尔分数,%),其化学成分中Mg与Dy的摩尔比为1:3。因此,确定该颗粒相应为MgDy3相,这种相的形成主要是由于合金在凝固过程中Mg和Dy原子的偏聚形成的富含Dy的固溶体,并且在后续的挤压和时效过程中依然存在。但由于其数量较低,因此,在XRD谱中没有检测到该相的衍射峰。

图1 铸态合金的光学显微组织和XRD谱

Fig. 1 Optical microstructure(a) and XRD pattern(b) of as-cast alloy

图2 铸态合金的SEM像

Fig. 2 SEM image of as-cast alloy

表1 图2中颗粒相的EDS分析结果

Table 1 EDS results of particles shown in Fig. 2

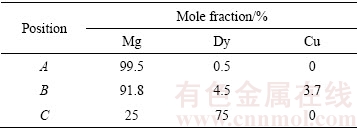

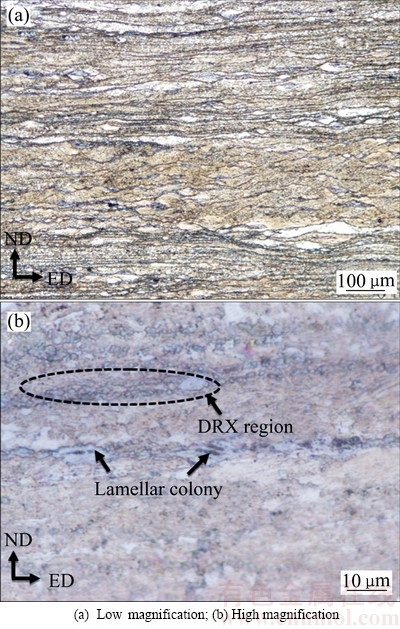

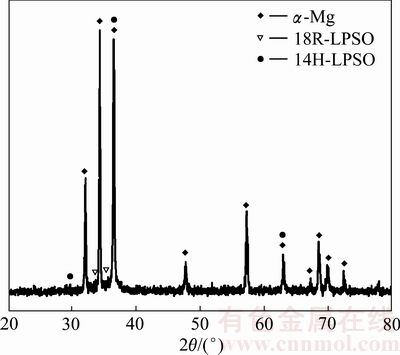

图3所示为挤压态合金的光学显微组织。铸态合金中的Mg3Dy和18R-LPSO相在挤压过程中被碎花并沿挤压方向分布形成挤压带,如图3(a)。挤压过程中合金部分区域发生动态再结晶,晶粒明显细化[18-19],形成再结晶区,如图3(b)。挤压后合金的平均晶粒尺寸为1.8 μm。图4为挤压态合金的SEM像。由图4可知,合金经挤压后其组织除了α-Mg基体,晶界的片层状相和立方体颗粒MgDy3相以外,还出现了一种晶内的片层状相。为了进一步确定晶界片层状相和晶内片层状相的结构,图5显示了两种片层状相的TEM像以及对应的SAED谱。图5(a)显示了分布在晶界处的片层相,由该相的SAED谱可知(见图5(b)),从(0001)面到(0002)面对应衍射斑点的间距被 5个衍射斑点平分,因此,该相为18R LPSO结构[20]。图5(c)显示了分布在晶内的片层相,由该相的SAED谱可知(见图5(d)),从(0000)面到(0002)面对应衍射斑点的间距被13个衍射斑点平分,因此,该相为14H LPSO结构,具有密排六方(HCP)结构,晶格常数分别为a=0.325 nm,c=3.694 nm[7, 20]。图6所示为挤压态合金的XRD谱。由图6可知,除了铸态α-Mg和18R-LPSO相的衍射峰外,合金中还出现14H-LPSO相的衍射峰,这与图5(d)的SAED结果相一致。

图3 挤压态合金的光学显微组织

Fig. 3 Optical microstructure of extruded alloy

图4 挤压态合金的SEM像

Fig. 4 SEM image of extruded alloy

2.2 时效硬化行为

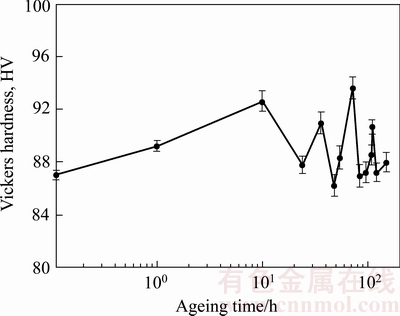

图7所示为挤压态合金在250 ℃的时效硬化曲线。由图7可知,挤压合金的硬度随时效时间的增加而先增加后降低。挤压合金(时效时间为0)的最初硬度为87 HV。在72 h,合金达到时效峰值,峰值硬度为94 HV,相比挤压态合金,挤压峰值态合金的硬度提高了8%。在150 h,合金硬度降到88 HV。

图5 挤压峰值态合金中片状相的TEM像及相应的SAED谱

Fig. 5 TEM images((a), (b)) and corresponding SAED patterns((c), (d)) of lamellar phases in peak-aged extruded alloy

图6 挤压态合金的XRD谱

Fig. 6 XRD pattern of extruded alloy

图7 挤压态合金在250 ℃的时效硬化曲线

Fig. 7 Age-hardening curve of extruded alloy at 250 ℃

图8 挤压态合金时效过程中的XRD谱

Fig. 8 XRD patterns of extruded alloy during aging process

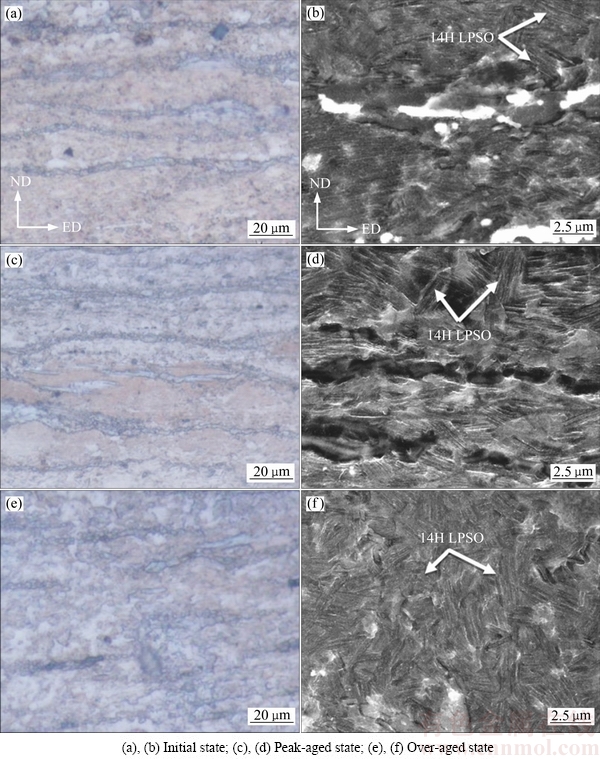

图8所示为挤压态,挤压峰值态和挤压过时效态合金的XRD谱。由图8可知,14H-LPSO相的衍射峰随时效时间的增加而增加,这表明该相的体积分数逐渐增加。此外除α-Mg、18R-LPSO相和14H-LPSO相的衍射峰并没有发现其它相的衍射峰,这说明合金在时效的过程中没有新相的形成。图9所示为挤压态、挤压时效峰值态以及挤压过时效态的光学显微组织。由图9(a)、(c)和(e)可知,随着时效时间的增加,挤压合金中再结晶区域的面积增加,合金的晶粒尺寸也略微增加。挤压态和挤压时效峰值态合金的平均晶粒平均尺寸分别为1.8和2.1 μm。时效150 h,挤压态合金的平均晶粒尺寸增加到10.8 μm。同时,由图9(b)、(d)和(f)可以看出,合金在时效的过程中再结晶区晶粒内析出14H-LPSO相逐渐增加,该相在挤压态、挤压时效峰值态和挤压过时效态的体积分数分别为35%、54%和80%。然而随着时效时间的增加,14H-LPSO相的形貌也逐渐发生改变。如图9(b)、(d)和(f)所示,在时效初期(时效0 h),14H-LPSO相的平均长度(l)和宽度(d)分别为2.25和 0.26 μm;在时效峰值态(72 h)LPSO相的长、宽略微增加(l=2.37 μm,d=0.25 μm); 在时效150 h,其平均长度和宽度明显增加,分别为4.01 μm和1.37 μm,表明该相在时效过程中发生粗化。研究表明,14H-LPSO相的析出可有效的阻碍位错运动,提高合金的力学性能[14]。本合金在时效72 h时,晶内析出大量细小片层状的14H-LPSO相,且合金的平均晶粒尺寸几乎不变。因此,高体积分数14H-LPSO相的析出强化和晶粒细化导致合金时效硬化行为的产生。然而,合金在时效150 h时,尽管LPSO相的体积分数增加,但平均晶粒尺寸也明显增大且析出的14H LPSO相发生严重粗化。由晶粒粗化和LPSO相粗化所导致的弱化作用高于高体积分数LPSO相引起的强化作用。因此,合金在时效150 h时显示较低的硬度值。

图9 挤压态合金在时效过程中的显微组织

Fig. 9 Microstructures of extruded alloy during aging process

2.3 14H-LPSO相形成机理

目前,合金中14H-LPSO 相的形成存在两种机理:1) 18R-LPSO相原位转变[21];2) 过饱和α-Mg固溶体的析出[22-23]。本研究中14H-LPSO 相的形成主要是因热挤压和时效导致过饱和α-Mg固溶体析出的结果,其中14H-LPSO相的形成包括两个阶段:第一阶段是在合金挤压过程中形成,第二阶段是在合金时效过程中析出。先前的研究表明[24-25],LPSO 相的形成需要同时满足堆垛序和化学序,即LPSO相的形成需要堆垛层错的存在及固溶原子的扩散。铸态合金因Dy和Cu的添加导致合金中产生大量的堆垛成错。同时,热挤压过程中合金的化学成份偏析消除,增加了Dy和Cu元素在镁中达到的固溶度[26]。另外,热挤压可以产生位错集中并在位错的周围产生局部的应变区,这种应变区增加了Dy和Cu原子的扩散速率,促进了LPSO相化学序的形成[10],当合金中的Dy和Cu原子扩散到堆垛层错上,当结构序和化学序同时满足时,14H-LPSO相便在挤压合金的再结晶晶粒内析出,如图5(c)所示。LIU等[26]研究挤压Mg-Y-Zn合金在时效过程中14H-LPSO相的析出过程:α-Mg'(SSSS)→α-Mg+14H-LPSO,其中α-Mg'(SSSS)指为过饱和固溶体,α-Mg为固溶体接近平衡状态。从图9(b)、(d)和(f)可以看出,14H-LPSO相是在α-Mg晶粒内形成,表明挤压态合金在时效过程中该相的形成与过饱和α-Mg固溶体的分解相关。此外,合金在时效过程中,由于枝晶界处的18R-LPSO相是一种亚稳相,部分Dy和Cu将由18R-LPSO相向镁基体中扩散,形成过饱和的α-Mg基体,当Dy和Cu原子在堆垛层错的界面的摩尔比为2:1时,基体内14H-LPSO相将在镁基体中析出。随着时效时间的增加,合金中析出的14H-LPSO相的体积分数增加,然而18R-LPSO相逐渐减少,晶粒内析出的14H-LPSO相沿着α-Mg基体的c轴生长而粗化[27],如图9(b)、(d)和(f)所示。因此,前者的硬化作用略高于后者的软化作用,导致合金在时效过程中显示了较低的时效硬化行为。

3 结论

1) 铸态合金主要由α-Mg枝晶,分布在枝晶间片层状的18R-LPSO相以及少量的MgDy3颗粒相组成。挤压后,合金发生动态再结晶,晶粒明显细化,合金的平均晶粒尺寸为1.8 μm。片层状18R-LPSO相被挤碎并沿挤压方向形成挤压带,同时少量细小片层状的14H-LPSO相在动态再结晶的α-Mg晶粒内析出。

2) 挤压态合金在250 ℃时效的过程中,随着时效时间的增加,14H-LPSO相在α-Mg晶粒内逐渐析出,体积分数增加且粗化,合金的硬度先增加后降低。合金在72 h达到时效峰值,其硬度为94 HV,相比挤压态,峰值态合金的硬度提高了8%。时效峰值硬度的产生主要归结为高体积分数14H-LPSO相的析出强化。

REFERENCES

[1] 王敬丰, 黄秀洪, 谢飞舟, 黄 崧, 侯 帆, 潘复生. 轧制工艺对Mg-Gd-Y-Zn-Mn合金中LPSO相及其组织性能的影[J]. 中国有色金属学报, 2016, 26(8): 1588-1596.

WANG Jing-feng, HUANG Xiu-hong, XIE Fei-zhou, HUANG Song, HOU Fan, PAN Fu-sheng. Influences of rolling processes on LPSO phase, microstructure and property of Mg-Gd-Zn-Mn alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1588-1596.

[2] LUO Xiao-mei, BI Guang-li, JIANG Jing, LI Ming, LI Rong-guang, LI Yuan-dong, MA Ying, HAO Yuan. Compressive anisotropy of extruded Mg-Dy-Zn alloy sheet[J]. Transactions of Nonferrous of Metals Society of China, 2016, 26(2): 390-397.

[3] 刘 庆. 镁合金塑性变形机理研究进展[J]. 金属学报, 2010, 46(11): 1458-1472.

LIU Qing. Research process on plastic deformation mechanism of Mg alloys[J]. Acta Metall Sinica, 2010, 46(11): 1458-1472.

[4] KAWAMURA Y, HAYASHI K, INOUE A, MASUMOTO T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa[J]. Materials Transaction, 2001, 42(7): 1172-1176.

[5] BI G L, LI Y D, ZANG S J, ZHANG J B, MA Y, HAO Y. Microstructure, mechanical and corrosion properties of Mg-2Dy-xZn (x=0, 0.1, 0.5 and 1at.%) alloys[J]. Journal of Magnesium and Alloys, 2014, 2(1): 64-67.

[6] LI J C, HE Z L, FU P H, WU Y J, PENG L M, DING W J. Heat treatment and mechanical properties of a high-strength cast Mg-Gd-Zn alloy[J]. Materials Science and Engineering A, 2016, 651: 745-752.

[7] MATSUDA M, II S, KAWAMURA Y, IKUHARA Y, NISHIDA M. Variation of long-period stacking order structures in rapidly solidified Mg97Zn1Y2 alloy[J]. Materials Science and Engineering A, 2005, 393: 269-274.

[8] ZHU Y M, WEYLAND M, MORTON A J, OH-ISHI K, HONO K, NIE J F. The building block of long-period structures in Mg-RE-Zn alloys[J]. Scripta Materialia, 2009, 60(11): 980-983.

[9] ITOI T, SEIMIYA T, KAWAMURA Y, HIROHASHI M. Long period stacking structures observed in Mg97Zn1Y2 alloy[J]. Scripta Materialia, 2004, 51(2): 107-111.

[10] LIU K, ZHANG J H, TANG D X, ROKHLIN L L, ELKIN F M, MENG J. Precipitates formed in a Mg-7Y-4Gd-0.5Zn-0.4Zr alloy during isothermal ageing at 250 ℃[J]. Materials Chemistry and Physics, 2009, 117: 107-112.

[11] LENG Z, ZHANG J H, ZHU T L, WU R Z, ZHANG M L, LIU S J, SUN J F, LI Zhang. Microstructure and mechanical properties of Mg-(6,9)RY-4Zn alloys by extrusion and aging[J]. Materials and Design, 2013, 52: 713-719.

[12] BI G L, FANG D Q, ZHAO L, LIAN J S, JIANG J, JIANG Z H. An elevated temperature Mg-Dy-Zn alloy with long period stacking ordered phase by extrusion[J]. Materials Science and Engineering A, 2011, 528(10/11): 3609-3614.

[13] KAWAMURA Y, KASAHARA T, IZUMI S, YAMASAKI M. Elevated temperature Mg97Y2Cu1 alloy with long period ordered structure[J]. Scripta Materialia, 2006, 55: 453-456.

[14] ZOU G D, CAI X C, FANG D Q, WANG Z, ZHAO T S, PENG Q M. Age strengthening behavior and mechanical properties of Mg-Dy based alloys containing LPSO phases[J]. Materials Science and Engineering A, 2015, 620: 10-15.

[15] BI G L, LUO X M, JIANG J, ZHANG Y G, XU J J, CHEN J M, LI Y D, MA Y. Effect of Zn, Cu, and Ni addition on microstructure and mechanical properties of as-cast Mg-Dy alloys[J]. China Foundry, 2016, 13(1): 54-58.

[16] 毕广利, 李元东, 黄晓峰, 陈体军, 马 颖, 郝 远. Zn含量对铸态Mg-Dy合金显微组织 和力学性能的影响[J]. 中国有色金属学报, 2015, 25(4): 875-882.

BI Guang-li, LI Yuan-dong, HUANG Xiao-feng, CHEN Ti-jun, MA Ying, HAO Yuan. Effect of Zn addition on microstructure and mechanical properties of as-cast Mg-Dy alloy[J]. The Chinese Journal of Nonferrous Metal, 2015, 25(4): 875-882.

[17] 刘 欢, 薛 峰, 白 晶, 周 健, 孙扬善. 高温退火对铸态和挤压态Mg97Y2Zn1合金中长周期有序结构形态的影响[J]. 金属学报, 2013, 49(10): 1255-1263.

LIU Huan, XUE Feng, BAI Jing, ZHOU Jian, SUN Yang-shan. Effect of high temperature annealing on morphology of long period stacking ordered structures in as-cast and extruded Mg97Y2Zn1 alloy[J]. Acta Metallurgica Sinica, 2013, 49(10): 1255-1263.

[18] ZHANG Y, ZENG X Q, LIU L F, LU C, ZHOU H T, LI Q, ZHU Y P. Effect of yttrium on microstructure and mechanical properties of hot-extruded Mg-Zn-Y-Zr alloys[J]. Materials Science and Engineering A, 2004, 373(1/2): 320-327.

[19] YANG Z, GUO Y C, LI J P, HE F, XIA F, LIANG M X. Plastic deformation and dynamic recrystallization behaviors of Mg-5Gd-4Y-0.5Zn-0.5Zr alloy[J]. Materials Science and Engineering A, 2008, 485(1/2): 487-491.

[20] 付丽丽, 邱克强, 任英磊, 李荣德. 热处理对Mg81Ni8Zn5Y6合金中长周期结构的影[J]. 中国有色金属学报, 2016, 26(7): 1414-1419.

FU Li-li, QIU Ke-qiang, REN Ying-lei, LI Rong-de. Effect of heat treatment on long-period stacking ordered structure of Mg81Ni8Y6 alloy[J]. The Chinese Journal of Nonferrous Metal, 2016, 26(7): 1414-1419.

[21] ZHU Y M, MORTON A J, NIE J F. Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys[J]. Acta Materialia, 2012, 60(19): 6562-6572.

[22] WU Y J, ZENG X Q, LIN D L, PENG L M, DING W J. The microstructure evolution with lamellar 14H-type LPSO structure in an Mg96.5Gd2.5Zn1 alloy during solid solution heat treatment at 773 K[J]. Journal of Alloy and Compounds, 2009, 477(1/2): 193-197.

[23] ZHANG X L, WANG Z H, DU W B, LIU K, LI S B. Microstructure and mechanical properties of Mg-13Gd-5Er-1Zn-0.3Zr alloy[J]. Materials and Design, 2014, 58: 277-283.

[24] ABE E, KAWAMURA Y, HAYASHI K, INOUE A. Long-period ordered structure in a high-strength nanocrystalline Mg-1 at% Zn-2 at% Y alloy studied by atomic-resolution Z-contrast STEM[J]. Acta Materialia, 2002, 50(15): 3845-3857.

[25] DING W J, WU Y J, PENG L M, ZENG X Q, YUAN G Y, LIN D L. Formation of 14H-type long period stacking ordered structure in the as-cast and solid solution treated Mg-Gd-Zn-Zr alloys[J]. J Mater Res, 2009, 24: 1842-1854.

[26] LIU H, BAI J, YAN K, MA A, JIANG J H. Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg-Y-Zn alloys during annealing at 773 K[J]. Materials and Design, 2016, 93: 9-18.

[27] BI G L, JIANG J, ZHANG F, FANG D Q, LI Y D, MA Y, HAO Y. Microstructure evolution and properties of Mg-Dy-Zn alloy during cooling after solution treatment[J]. Journal of Rare Earths, 2016, 34(9): 931-936.

Microstructures and age-hardening behavior of extruded Mg-Dy-Cu alloy sheet

BI Guang-li1, YUAN Li-tao1, LI Yuan-dong1, JIANG Jing1, HAN Yu-xiang1, JIANG Chun-hong2, MA Ying1

(1. State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals, School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China;

2. Lanshi Foundry Co., Ltd., Lanzhou 730050, China)

Abstract: The microstructure and age-hardening behavior of an extruded Mg-2Dy-0.5Cu (mole fraction, %) alloy sheet were investigated by X-ray diffractometer, optical microscopy, scanning electron microscopy, transmission electron microscopy and microlardness tester. The microstructures of the as-cast alloy mainly consist of α-Mg dendrites, the 18R-long period stacking ordered (LPSO) phase distributes among α-Mg dendrites and a small number of MgDy3 particle phases. After extrusion, dynamic recrystallization (DRX) occurs and fine microstructure is obtained during extrusion. Some coarse 18R-LPSO phases are crushed and distributed along the hot extrusion direction. Moreover, few fine lamellar 14H-LPSO phases precipitate in DRX α-Mg grains. With the increase of aging time, the volume fraction of 14H-LPSO phase gradually increases and the phases coarsen, the hardness of the alloy increases and reaches a peak at 72 h, which is mainly attributed to the precipitation strengthening of the high volume fraction of 14H-LPSO phase.

Key words: Mg-Dy-Cu alloy sheet; LPSO phase, microstructure; aging behavior

Foundation item: Projects(51301082, 51464031) supported by the National Natural Science Foundation of China

Received date: 2016-11-02; Accepted date: 2017-05-08

Corresponding author: BI Guang-li; Tel: +86-931-2973564; E-mail: glbi@163.com

(编辑 李艳红)

基金项目:国家自然科学基金青年基金资助项目(51301082,51464031)

收稿日期:2016-11-02;修订日期:2017-05-08

通信作者:毕广利,副教授,博士;电话:0931-2973564;E-mail: glbi@163.com