文章编号:1004-0609(2015)-07-1822-10

一次时效温度对新型高强耐蚀GH925合金显微组织和力学性能的影响

石照夏1,颜晓峰1,段春华1,周江波2,何云华2,赵明汉1

(1.钢铁研究总院 高温材料研究所,北京 100081;

2.攀钢集团江油长城特殊钢有限公司,江油 621700)

摘 要:为了研究一次时效温度对新型高强耐蚀GH925合金显微组织和力学性能的影响,利用热力学计算软件Thermo-Calc对合金中可能析出的平衡相及相组成进行计算并分析,采用超高分辨率场发射扫描电镜及附带能谱仪、扫描电镜和金相显微镜对合金中的析出相和冲击断口形貌进行观察。结果表明:一次时效温度对GH925合金中σ相和γ′相的析出行为影响显著;一次时效温度升高不仅会促进σ相在晶界上的大量析出并向晶内生长,而且会引起γ′相的粗化,导致合金强度和韧性降低;晶界σ相引起的脆化效应是导致沿晶断裂的根本原因。

关键词:耐蚀合金;GH925合金;一次时效温度;力学性能;显微组织

中图分类号: TG113.25 文献标志码:A

Effects of primary aging temperature on microstructures and mechanical properties of new corrosion-resistant alloy GH925 with high strength

SHI Zhao-xia1, YAN Xiao-feng1, DUAN Chun-hua1, ZHOU Jiang-bo2, HE Yun-hua2, ZHAO Ming-han1

(1. High Temperature Materials Research Institute, Central Iron and Steel Research Institute, Beijing 100081, China;

2. Pangang Group Jiangyou Changcheng Special Steel Co., Ltd., Jiangyou 621700, China)

Abstract: In order to study the effect of primary aging temperature on the microstructures and mechanical properties of a new corrosion-resistant alloy GH925, the precipitated equilibrium phases and their compositions were calculated and analyzed by Thermo-Calc software, and the precipitated phases and impact fracture morphology were observed by ultra high resolution field emission scanning electron microscopy (FESEM) and energy dispersive spectrometry (EDS), scanning electron microscopy (SEM) and metallographic microscopy. The results show that the primary aging temperature has significant effect on the precipitation behaviors of σ phase and γ′ phase. The increase of primary aging temperature not only promotes the precipitation of a large number of σ phase at the grain boundary and its growth to the inner of the grain, but also leads to the coarsening of γ′ phase, giving rise to the decreases of strength and toughness. The root reason for the intergranular fracture is the embrittlement effect caused by σ phase at the grain boundary.

Key words: corrosion-resistant alloy; GH925 alloy; primary aging temperature; mechanical property; microstructure

随着深海油气开采和舰船等海洋业的迅速发展,日益严苛的工况环境对作为结构材料的耐蚀合金在耐高温、高压、强腐蚀等性能方面提出了更高要求[1-2]。GH925合金作为一种含Mo、Cu、Al、Ti的Ni-Fe-Cr系时效硬化型耐蚀高温合金,是在Incoloy 825合金成分基础上通过增加Al、Ti含量发展而来,其国外对应牌号为Incoloy 925[3]。Cr、Mo和Cu等改善抗氧化性和还原性介质腐蚀能力的元素添加及固溶+时效处理后Ni3(Al,Ti)型γ′相的析出,使该合金除具有高强度外,还具有良好的抗点蚀、缝隙腐蚀和抗Clˉ应力腐蚀开裂能力,并兼具优异的耐氧化、耐氢气泡腐蚀、耐晶间腐蚀等特点,在海洋领域具有广阔的应用前景,特别适合用作同时含有高CO2、H2S、Clˉ及单质S的深海油气开采和高Clˉ含量海水等严苛腐蚀环境中的承力构件[4-5]。

由于GH925合金是我国自主仿制的新型高强耐蚀合金,目前国内尚未开展相关研究工作,可借鉴的Ni-Fe-Cr系耐蚀合金相关研究主要集中于028、G3、825等传统耐蚀合金的平衡相析出行为、热处理和热加工等方面。孟凡国等[6]通过对镍基耐蚀合金028平衡相的析出行为研究,得到该合金在变形及长期时效过程中主要存在的析出相为呈颗粒状和针状分布的σ相,该相的存在会显著降低合金的抗腐蚀性能;罗坤杰等[7]、包耀宗等[8]以及孟凡国等[9]通过对G3、825、028等合金高温变形特性及变形后组织特征的研究,建立了合金的热变形本构模型,确定了适宜的热加工温度范围。国外关于Incoloy 925合金的报道较少,仅限于合金的析出相特征及在特定介质中的耐腐蚀性能研究。MANNAN等[10]在模拟油田环境中Incoloy 925合金的慢应变速率应力腐蚀试验中发现,该合金中的析出相分布状态会显著影响其耐腐蚀性能,当析出相在晶界上呈连续分布则会降低其抗应力腐蚀开裂性能。还有报道[11]指出,Incoloy 925合金因具有优良的抗氢脆性能,已成为可替代Monel K-500合金用于海军多种装备中紧固件等构件的优选材料。

对于时效强化型镍基高温合金,热处理制度的选取会通过改变析出相的种类、数量和形貌特征,进而影响合金的力学和耐腐蚀性能[12],然而,目前有关热处理工艺对GH925合金显微组织特征和力学性能方面的研究鲜见报道。本文作者在对GH925合金性能优化热处理工艺的研究中发现,该合金的力学性能对热处理制度、尤其是一次时效温度极为敏感,只有选择合适的一次时效温度才能获得合金良好的塑韧性匹配。因此,对该合金进行热处理、显微组织特征和力学性能关联性的系统研究具有重要意义。鉴于此,本文作者通过研究GH925合金的析出相特征以及不同一次时效处理温度对显微组织和力学性能的影响,可为该类合金的热处理工艺优化提供参考依据。

1 实验

合金采用真空感应+电渣重熔(VIM+ESR)双联工艺冶炼,锭型为d 360 mm,经锻造及热轧至d 70 mm圆棒,其化学成分如表1所列。在轧棒2/3半径处取样,经固溶处理后,分别进行如下制度的两级时效热处理:740/750 ℃,保温后炉冷至615 ℃,保温后空冷。将热处理后的样品加工成标准拉伸试样、“U”型缺口冲击试样和硬度试样,测试其室温力学性能。

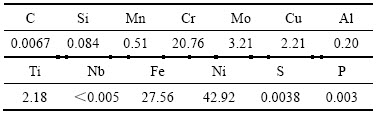

表1 GH925合金的化学成分

Table 1 Chemical compositions of GH925 alloy (mass fraction, %)

在与上述力学性能试样相同的取样位置上取样进行显微组织观察。对金相表面首先采用机械研磨和机械抛光,随后在20% H2SO4+80% CH3OH(体积分数)溶液中进行电解抛光,操作电压为20~30 V,抛光时间约为20 s,之后在150 mL H3PO4+10 mL H2SO4+15 g CrO3溶液中进行电解浸蚀,操作电压为3~5 V,电解时间3 s左右。采用OLYMPUS GX71金相显微镜、JEOL JSM 7800F超高分辨率场发射扫描电子显微镜和附带能谱仪、JEOL JXA 8530F场发射电子探针观察合金显微组织特征。采用JEOL JSM 6480LV型扫描电子显微镜观察冲击断口特征。

使用冶金和材料热力学计算软件Thermo-Calc与相应的镍基高温合金数据库对合金中平衡相的析出规律进行热力学模拟计算。将表1所列合金成分和温度参数作为Thermo-Calc软件的输入条件,计算得到可能的平衡析出相及各相的元素组成。

2 结果与分析

2.1 合金热力学平衡相图

为研究GH925合金的显微组织特征,首先采用Thermo-Calc软件计算了合金中可能存在的平衡相及其析出温度和析出量,计算结果如图1所示。可以看出,合金的平衡相主要有基体γ相、γ′相、MC和M23C6碳化物以及η相和σ相等金属间化合物。合金对应的初熔和终熔温度分别为1313和1389 ℃,凝固温度范围为76 ℃。1130~1313 ℃之间只存在γ相,当温度低于1130 ℃时,开始从γ基体中析出富Ti的一次MC型碳化物,析出温度范围较宽,为858~1130 ℃。在MC析出温度范围下限温度附近,即859 ℃开始析出富Cr的M23C6型碳化物。当温度降至986 ℃后,开始析出η相。热力学计算结果表明,固溶温度为980 ℃的平衡态组织中会有γ相、MC碳化物和少量η相。当温度降至883 ℃,开始析出σ相,其析出温度范围较宽,为466~883 ℃,572 ℃为其峰值析出温度,相应的α-Cr相在低于此温度时开始析出。在σ相析出温度范围的下限温度 (467 ℃) 附近开始析出Laves相。热力学计算得到的γ′相开始析出温度仅为415 ℃。这是由于热力学计算时,在较高温度形成的MC和η相消耗了大量γ′相形成元素Al和Ti,且合金中γ′相形成元素Al含量仅为0.2%,导致计算时参与形成γ′相的Al、Ti含量极低,γ′相析出缓慢,因此,计算得到的γ′相析出温度远低于实验得到的结果(593~816 ℃)[3]。

表2所列为各平衡相析出量达到最大时对应的温度及其平衡成分。从表2可以看出,Ni、Fe、Cr为GH925合金基体γ相的主要形成元素;Ti为MC型碳化物的主要形成元素,MC中还含有极少量的Mo、Cr及痕量Fe、Ni;低Al、高Ti含量促进η相在较高温度析出;σ相中含有较多Cr、Fe和Mo,并含有少量Ni,含量按照Cr、Fe、Mo、Ni的顺序递减,但σ相中的Fe和Ni含量比基体中的Fe和Ni含量低;Cr和Mo是M23C6的主要形成元素,其中Cr含量高达基体中Cr含量的3倍;γ′相中C含量极低(0.0067%),因此,平衡相中MC和M23C6碳化物含量均非常低,基本在10-4数量级;此外,GH925合金中含有大量Cr,并含有少量Mo,因此促进了α-Cr相和Laves相的析出。

2.2 合金时效处理后的组织演变

图2(a)~(d)所示分别为GH925合金热轧态、固溶态和经不同一次时效温度的两级时效处理后的金相显微组织。从图2(a)可以看出,热轧态等轴晶粒细小但不均匀,尺寸为8~48 μm,基体组织为单相γ,部分晶粒内有孪晶,晶界和晶内析出物稀少。从图2(b)可以看出,固溶处理后,晶界非常干净,晶粒明显长大,尺寸为15~180 μm,晶内仅有少量弥散分布的颗粒状析出相。从图2(c)和(d)可以看出,固溶并经不同一次时效温度的两级时效处理后,晶粒尺寸接近,与固溶态相比均未发生明显改变,但时效处理后,晶界和晶内出现大量析出相,且750 ℃时效试样中析出相的数量明显多于740 ℃时效试样的。

图1 GH925合金平衡相析出量与温度的关系及局部放大图

Fig. 1 Relationship between precipitation amounts of equilibrium phases and temperatures for GH925 alloy (a) and its partial magnification (b)

表2 GH925合金平衡相最大析出量、对应温度及平衡成分

Table 2 Calculated maximum precipitation amount, temperatures and compositions of equilibrium phases in GH925 alloy

图2 不同状态GH925合金的金相显微组织

Fig. 2 Metallographic microstructures of GH925 alloy in different states

图3所示为不同状态GH925合金扫描电镜显微组织。从图3(a)可以看出,合金经锻造及热轧后,晶界和晶内有少量颗粒状析出相。表3所列为图3(a)中析出相和基体的EDS能谱分析结果。可以看出,热轧态合金中晶界和晶内尺寸较大的块状析出相主要为富Ti的MC型碳化物,结合热力学计算结果可知,MC碳化物的形成温度范围较宽,因此,在锻造、热轧及后续冷却过程中都有可能形成。小颗粒状析出相较基体明显富Mo和Ti。MC碳化物在高温下是不稳定的,它会通过下列反应分解成M6C或M23C6碳化物[13]:

MC+γ→M6C(M23C6)+γ′ (1)

温度是促进MC碳化物分解的重要因素,在800 ℃以下,即使经过数千小时的长期热暴露,MC的分解也甚微;但在900 ℃以上长时间保温后,MC不稳定;1000~1100 ℃范围时,MC碳化物转变速率最快。本研究中GH925合金热加工时经历了MC迅速分解的温度范围,由此确定富Mo和Ti的颗粒状析出应为M6C型碳化物。此外,晶界上还有极少量不连续分布的小颗粒状析出相,但颗粒尺寸极小,采用能谱分析的方法无法确定其组成。由于合金中Cr含量较高,且含有一定量的C,结合热力学计算,此类分布于晶界的小颗粒析出相应为M23C6碳化物。总体而言,由于合金中C含量低,因此碳化物较少,这与热力学计算结果是一致的。从图3(b)可以看出,固溶处理后晶界平直干净,小颗粒析出相已完全固溶,仅极少量MC碳化物残留。此外,在固溶态试样中未观察到η相和σ相,说明采取的固溶制度可使η相和σ相完全回溶到γ基体中,为后续时效过程中γ′相的充分析出奠定了基础。从图3(c)和(d)可以看出,经过两级时效处理后,晶界上析出针状和片层状析出相,并向晶内生长,经750 ℃时效后析出量显著增多,且分布密度增大。由能谱分析可知(见表4),析出相主要含有Cr、Mo、Fe和Ni元素,且Cr含量是基体中Cr含量的2倍,Mo含量是基体中Mo含量的4倍,而Fe、Ni含量相对基体中Fe、Ni含量减少,Ni含量减少尤为明显。

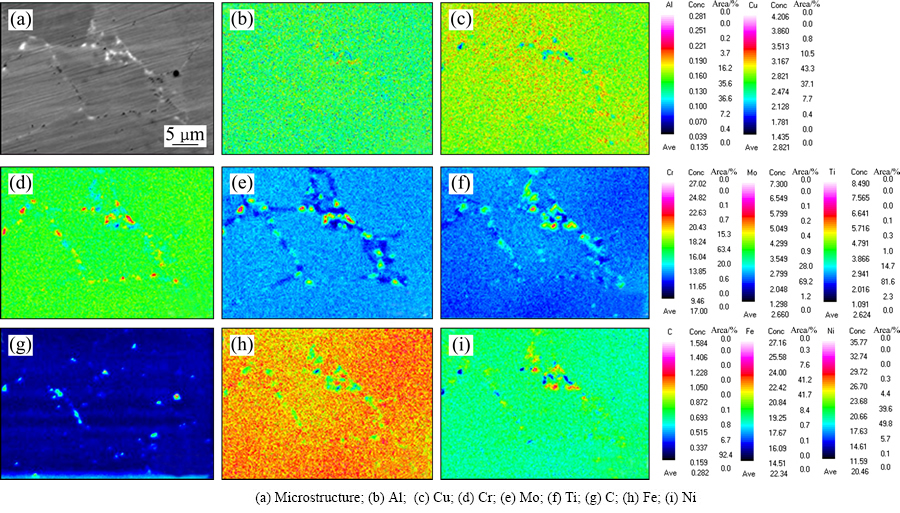

为了进一步确定时效后析出相的种类,采用电子探针分析了一次时效温度为740 ℃的GH925合金中析出相的元素面分布,如图4所示。通过分析背散射形貌可以看出,晶界上有两种不同的析出相,一种为尺寸较大的白亮片层相,另一种为尺寸较小的黑色颗粒相。元素面分布结果表明,片层状析出相主要富Cr和Mo,且较基体严重贫Fe和Ni,而小颗粒状析出相主要富C和Ti。由此确定GH925合金充分固溶后经两级时效处理在晶界析出的片层状析出相为σ相,其晶体结构为体心四方晶系,每个晶胞有30个原子,晶格常数是a=b=0.880 nm,c=0.460 nm[14-15]。由于750 ℃较740 ℃更接近σ相的鼻尖析出温度[3],因此,750 ℃时效后会析出数量更多的σ相。弥散分布的小颗粒相富Ti和C,为在较高温度形成的一次MC。

图3 不同状态GH925合金的扫描电镜显微组织

Fig. 3 SEM microstructures of GH925 alloy in different states

表3 图3(a)中热轧态GH925合金析出相的成分能谱分析结果

Table 3 EDS results of compositions of precipitated phases in hot-rolled GH925 alloy shown in Fig. 3(a)

表4 时效态GH925合金析出相成分能谱分析结果

Table 4 EDS results of compositions of precipitated phases in aged GH925 alloy

图5所示为不同状态GH925合金中的γ′相形貌。从图5(a)可以看出,热轧态γ′相呈球形,尺寸范围为11~25 nm,平均尺寸约为17 nm。图5(b)中,在740 ℃进行一次时效及后续二次时效后,γ′相从过饱和固溶体中均匀析出,尺寸较热轧态γ′相明显细化,尺寸范围为4~20 nm,平均尺寸约为10 nm,且呈球状。这是由于热轧态γ′相在轧后冷却过程中不同温度下析出,且在随后冷却过程中有不同程度的长大,因此,尺寸较大且不均匀。从图5(c)可以看出,进行750 ℃的一次时效及后续二次时效后,γ′相明显长大,尺寸范围为15~38 nm,平均尺寸约为26 nm。由此可知,时效温度提高10 ℃会导致γ′相迅速粗化,平均尺寸增大2倍之多。

图6所示为将固溶态GH925合金进行740 ℃、300 h时效处理后的显微组织。从图6(a)可以看出,经过740 ℃、300 h时效时效处理后,晶界和晶粒内部有大量析出相,部分晶界已被析出相完全覆盖。从图6(b)和(c)可以看出,晶界片层状的析出相为σ相,晶内γ′相尺寸范围为29~63 nm,平均尺寸约为46 nm,较750 ℃两级时效后的γ′相尺寸增大近2倍。由此可知,在740 ℃进行300 h时效一方面会促进晶界σ相的大量析出及其向晶内的生长,此外还会导致γ′强化相的明显粗化。因此,为避免σ相的大量析出和γ′的粗化,除应控制一次时效温度外,还应控制合理的时效时间,这也是今后研究的重点之一。

图4 一次时效温度为740 ℃时GH925合金析出相的形貌及元素面分布

Fig. 4 Microstructure and element distributions of precipitations in GH925 alloy primary aged at 740 ℃

图5 不同状态下GH925合金的FESEM像

Fig. 5 FESEM images of GH925 alloy in different states

图6 固溶态GH925合金进行740 ℃、300 h时效处理后的金相组织和FESEM像

Fig. 6 Metallographic image (a) and FESEM images ((b), (c)) of GH925 alloy aging at 740 ℃ for 300 h after solid-solution treatment

2.3 合金时效处理后的力学性能

图7所示为固溶态GH925合金经不同一次时效温度处理后的室温力学性能。可以看出,一次时效温度从740 ℃提高到750 ℃后,合金的抗拉强度(Rm)、屈服强度(Rp0.2)、伸长率(A)、断面收缩率(Z)、冲击韧性(Aku)及硬度(HB)均降低,其中屈服强度和冲击韧性的降低尤为明显。

图7 固溶态GH925合金经不同一次时效温度处理后的室温力学性能

Fig. 7 Mechanical properties at room temperature for GH925 alloy aged at different primary aging temperatures after solid-solution treatment

高温合金在热处理处理过程中主要发生以下两方面的变化,其一为晶粒尺寸的改变,其二为析出相的种类、数量、形貌和分布的变化[16-17]。镍基合金的力学性能在很大程度上取决于γ′强化相的数量和形貌。本研究中,时效温度较低时,析出均匀细小且数量较多的γ′相。且随时效温度的升高,γ′相逐渐变大,颗粒数量变少。这主要是由于时效过程中,金属原子通过空位等缺陷扩散并形核,时效温度越高,溶质原子扩散越快,析出相长大所需时间越短,溶质原子析出时易聚集,越有利于相的析出和长大,故最终导致析出相颗粒比较大,数量少[18]。镍基合金中典型的γ′相点阵常数与基体相近,并与基体共格,在基体中能呈细小颗粒状均匀析出。在变形过程中,第二相粒子阻碍位错的运动,同时对位错起钉扎作用,从而提高了合金的位错密度及变形抗力,产生显著的强化作用[19]。较多的γ′相数量、细小而弥散分布的γ′相形貌达到的强化效果最佳,而较大较少的γ′相会使合金的强化作用降低。因此,对GH925合金而言,采用740 ℃的一次时效温度更有利于获得高强度。

高温合金的冲击韧性随σ相和μ相等在晶界的大量析出而显著下降已成为共识。如前所述,一方面,σ相与γ基体的晶体结构完全不同,σ相在晶界以非共格方式析出,而且点阵常数大,与γ基体保持有较高的界面能,另外一方面,σ相本身硬而脆,形变不易与基体协调。所以在应力作用下σ相与γ基体相界面容易成为裂纹源,直接影响合金的冲击韧性[20]。由此可知,在晶粒尺寸相同的情况下,若晶界析出的σ相数量越多,则σ相覆盖晶界的程度越大,导致合金的脆化程度就愈严重。通常认为冲击韧性随晶粒尺寸的细化而升高。本研究中,一次时效温度从740 ℃升至750 ℃后,晶粒尺寸相近,但由于时效温度的升高加快了合金元素成分扩散性,导致析出物成形快且迅速增大[21]。因此,晶界上σ相的大量析出及其分布密度的增大是导致GH925合金冲击韧性大幅下降的根本原因。

图8所示为固溶态GH925合金经不同一次时效温度处理后的室温冲击断口形貌。从图8可以看出,合金的断裂基本为沿晶断裂,晶粒表面粗糙,与740 ℃时效后冲击断口相比,750 ℃时效后断口晶界裂纹较多,韧窝小而少,且明显变浅。时效断口主要为脆性沿晶断裂,这主要是由晶界和晶内大量脆性析出物所致。脆性相为σ相,其强度远低于材料本身强度,因而弱化了晶界,当材料受外界拉应力时,脆性相首先破裂,产生脆性沿晶断裂,影响了材料的塑性与韧性[22]。因此,当一次时效温度升至750 ℃时,晶界以及晶内脆性析出相的大量析出显著降低了合金的冲击韧性。此外,晶粒尺寸的不均匀性是导致冲击韧性波动较大的主要原因。综上所述,采用740 ℃的一次时效温度有利于GH925合金获得高强度及良好的塑韧性匹配。

图8 固溶态GH925合金经不同一次时效温度处理后室温冲击试样的断口形貌

Fig. 8 Fracture morphologies of impact specimens at room temperature for GH925 alloy aged at different primary aging temperatures after solid-solution treatment

3 结论

1) GH925合金平衡相热力学计算结果与组织观察结果基本符合,表明合金的主要平衡析出相为γ相、η相、一次MC碳化物、σ相、γ′相和M23C6碳化物等。

2) GH925合金在热轧、固溶处理、两级时效处理以及长期时效过程中存在不同种类和数量的析出相。时效处理后弥散析出的γ′相为合金的主要强化相,晶界析出相主要为富Cr和Mo的σ相,呈针状和片层状,并向晶内发展。

3) 一次时效温度对GH925合金晶粒度无显著影响,但较高的一次时效温度会导致晶界和晶内脆性σ相的大量析出以及主要强化相γ′相的明显粗化;在740 ℃进行300 h时效后,σ相析出量增大,γ′相严重粗化;一次时效温度的升高导致合金的力学性能下降,屈服强度和冲击韧性的下降尤为明显;随一次时效温度增加而发生的冲击韧性显著降低与晶界脆性析出相的变化密切相关。

4) GH925合金的冲击断口呈现典型的沿晶断裂特征;随一次时效温度升高,晶界上脆性σ相数量增多,分布密集程度提高,导致合金脆化程度愈严重。

REFERENCES

[1] 谢锡善, 董建新, 胡尧和, 张麦仓, 郑 磊. 铁镍基高温耐蚀合金的研究与发展[J]. 世界钢铁, 2009, 9(1): 50-55.

XIE Xi-shan, DONG Jian-xin, HU Yao-he, ZHANG Mai-cang, ZHENG Lei. Research and development of iron-nickel-based superalloy corrosion resistant alloy[J]. World Steel, 2009, 9(1): 50-55.

[2] 郭 婧, 耿志宇, 董建新, 张麦仓. 镍基耐蚀825合金的组织特征及热力学计算[J]. 稀有金属材料与工程, 2012, 41(11): 1929-1934.

GUO Jing, GENG Zhi-yu, DONG Jian-xin, ZHANG Mai-cang. Microstructure characteristics and thermodynamic calculation of Incoloy 825[J]. Rare Metal Materials and Engineering, 2012, 41(11): 1929-1934.

[3] GANESAN P, CLATWORTHY E F, HARRIS J A. Development of a time-temperature transformation diagram for alloy 925[J]. Corrosion, 1988, 44(11): 827-835.

[4] MCOY S A, PUCKETT B C, HIBNER E L. High performance age hardenable nickel alloys solve problems in sour oil and gas service[EB/OL]. http://www.specialmetals.com.

[5] LEMKE T F, HARRIS J A. High-alloy materials for offshore applications[C]//Offshore Technology Conference, Houston, Texas, 1983: 71-72.

[6] 孟凡国, 董建新, 张麦仓, 姚志浩. 镍基耐蚀合金028平衡相的析出行为[J]. 中国有色金属学报, 2014, 24(2): 432-440.

MENG Fan-guo, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. Precipitation behavior of equilibrium phases in nickel-based corrosion resistant alloy 028[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 432-440.

[7] 罗坤杰, 张麦仓, 王宝顺, 董建新. Hastelloy G-3合金热变形特性研究[J]. 稀有金属材料与工程, 2011, 40(4): 605-609.

LUO Kun-jie, ZHANG Mai-cang, WANG Bao-shun, DONG Jian-xin. Research on hot deformation behavior of Hastelloy G-3 alloy[J]. Rare Metal Materials and Engineering, 2011, 40(4): 605-609.

[8] 包耀宗, 董 瀚, 苏 杰, 雍岐龙, 王黎辉, 李明志. 耐蚀合金G3、G3-Z和825热加工性的研究[J]. 特殊钢, 2009, 30(5): 1-3.

BAO Yao-zong, DONG Han, SU Jie, YONG Qi-long, WANG Li-hui, LI Ming-zhi. A study on hot workability of corrosion resistance alloy G3, G3-Z and 825[J]. Special Steel, 2009, 30(5): 1-3.

[9] 孟凡国, 董建新, 张麦仓, 姚志浩. 028合金热变形行为及加工图[J]. 材料热处理学报, 2014, 35(7): 1-8.

MENG Fan-guo, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. Hot deformation behavior and processing map of 028 alloy[J]. Transactions of Materials and Heat Treatment, 2014, 35(7): 1-8.

[10] MANNAN S, HIBNER E, PUCKETT B. Physical metallurgy of alloys 718, 725, 725HS, 925 for service in aggressive corrosive environments[C]//NACE International. Houstom: Corrosion, 2003, 03126-1-12.

[11] HIBNER E L, SHOEMAKER L. A new generation of high strength, corrosion-resistant superalloy products for marine fasteners and hardware—A summary report[C]//NACE International. Houstom: Corrosion, 2004, 04287-1-17.

[12] 赵双群, 谢锡善. 一种新型镍基高温合金长期时效后的组织和性能[J]. 金属学报, 2003, 39(4): 399-404.

ZHAO Shuang-qun, XIE Xi-shan. Properties and microstructure after long-term aging at different temperatures for a new nickel base superalloy[J]. Acta Metallurgica Sinica, 2003, 39(4): 399-404.

[13] 姚志浩, 董建新, 张麦仓, 郑 磊. GH864合金显微组织与力学性能的关联性[J]. 稀有金属材料与工程, 2010, 39(9): 1565-1570.

YAO Zhi-hao, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei. Relationships between microstructures and properties for GH864 superalloy[J]. Rare Metal Materials and Engineering, 2010, 39(9): 1565-1570.

[14] PAN Yong, QIU Cai-an. Phase diagrams and σ-phase precipitation in some stainless steels[J]. Transactions of Nonferrous Metals Society of China, 1995, 5(2): 76-80.

[15] HCRTZMAN S. High alloying stainless steels[J]. Scandinavian Journal of Metallurgy, 1996, 15(4): 140-142.

[16] 李 阳, 李 莎, 王 岩. 固溶处理对GH4700镍基合金管组织及力学性能的影响[J]. 特殊钢, 2013, 34(3): 64-66.

LI Yang, LI Sha, WANG Yan. Effect of solid solution treatment on structure and mechanical properties of nickel base alloy GH4700[J]. Special Steel, 2013, 34(3): 64-66.

[17] SHARGHI-MOSHTAGHIN R, ASGARI S. The influence of thermal exposure on the γ′ precipitates characteristics and tensile behavior of superalloy IN-738LC[J]. Journal of Materials Processing Technology, 2004, 147(343/350): 343-350.

[18] 陈 琪, 陈雅文, 孔凡亚. 热处理对超大变形量 GH2132合金力学性能的影响[J]. 材料热处理技术, 2012, 41(20): 184-188.

CHEN Qi, CHEN Ya-wen, KONG Fan-ya. Effects of heat treatment on mechanical properties of GH2132 alloy with large deformation[J]. Materials and Heat Treatment, 2012, 41(20): 184-188.

[19] 张 云, 曹富荣, 林开珍, 李宝绵, 周 舸, 丁 桦. GH4742高温合金的动态再结晶行为[J]. 中国有色金属学报, 2013, 23(11): 3091-3099.

ZHANG Yun, CAO Fu-rong, LIN Kai-zhen, LI Bao-mian, ZHOU Ge, DING Hua. Dynamic recrystallization behavior of GH4742 superalloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(11): 3091-3099.

[20] 陈国良, 谢锡善, 倪克仕, 徐志超, 王 迪. 铁基高温合金中μ相和σ相引起的晶界脆化[J]. 金属学报, 1981, 17(1): 1-9.

CHEN Guo-liang, XIE Xi-shan, NI Ke-shi, XU Zhi-chao, WANG Di. Brittle grain boundary caused by the μ phase and σ phase in iron-based superalloy[J]. Acta Metallurgica Sinica, 1981, 17(1): 1-9.

[21] 赵雪会, 白真权, 冯耀荣, 魏 斌, 尹成先, 王敬忠. 热处理温度及析出相对镍基合金腐蚀性能的影响[J]. 材料热处理学报, 2012, 33(8): 39-44.

ZHAO Xue-hui, BAI Zhen-quan, FENG Yao-rong, WEI Bin, YIN Cheng-xian, WANG Jing-zhong. Effects of heat treatment and precipitated phase on corrosion resistance of Ni-based alloy[J]. Transactions of Materials and Heat Treatment, 2012, 33(8): 39-44.

[22] CHASTELL D J, FLEWITT P E J. The formation of the sigma phase during long term high temperature creep of type 316 austenitic stainless steel[J]. Materials Science and Engineering: A.B, 1979, 38(2): 153-162.

(编辑 龙怀中)

收稿日期:2014-12-15;修订日期:2015-05-22

通信作者:石照夏,工程师;博士;电话:010-62183360;E-mail:zxshiustb@163.com