DOI: 10.11817/j.issn.1672-7207.2018.10.025

岩溶地基改性注浆材料力学性能及其孔隙结构特征

宋国壮1,王连俊1,张艳荣1,郭颖1,曹元平2

(1. 北京交通大学 土木建筑工程学院,轨道工程北京市重点实验室,北京,100442;

2. 中铁第一勘察设计院集团有限公司,陕西 西安,710000)

摘要:为了制备高速铁路岩溶地基加固工程及高性能水泥基材料,研制一种改性高聚物即水泥基(HPC)注浆材料,对其与常规水泥浆液(Blank)、水泥-水玻璃(C-S)的力学性能及体积稳定性等进行室内试验对比分析;运用压汞测试技术(MIP)探究其硬化后浆体微观组构与宏观力学性能间的本质关联性。研究结果表明:在28 d龄期下,Blank,C-S和HPC试件单轴抗压强度与龄期为7 d的相比分别增大77%,20%和78%,体积损失率分别为18.3%,4.9%和1.2%;聚合物体系的协调效应减小了传统水泥基注浆材料体积失稳及因单掺速凝剂导致后期强度发展缓慢的缺陷;复合掺用多高聚物显著降低了硬化水泥浆体内部孔隙直径即孔径,使孔径分布趋于细化;在28 d龄期下,不同体系的HPC浆体抗压强度与材料内部孔隙率、阈值孔径均呈指数关系,与平均孔径呈线性负相关,揭示其孔隙结构分布特征可有效反映HPC浆体力学性能的变化规律,降低孔径有利于提升其力学性能。

关键词:高聚物;抗压强度;体积收缩;孔隙结构;孔径分布

中图分类号:U213.14;U214.18 文献标志码:A 文章编号:1672-7207(2018)10-2568-08

Mechanical stability and pore structures of modified grouting material in karst foundation

SONG Guozhuang1, WANG Lianjun1, ZHANG Yanrong1, GUO Ying1, CAO Yuanping2

(1. Beijing Key Laboratory of Track Engineering, School of Civil Engineering,Beijing Jiaotong University, Beijing 100442, China;

2. China Railway First Survey and Design Institute Group Ltd., Xi’an 710000, China)

Abstract: A modified high polymers cement-based(HPC) grouting material was developed and the differences between that and conventional cement paste(Blank), cement-silicate(C-S) on mechanical properties and dimension stability were analyzed to consolid foundation on high speed railway and prepare materials with high performance cementitious materials. The relationship between microstructure and macroscopic mechanical properties of HPC was investigated using mercury penetration(MIP). The results show that the compressive strength of Blank, C-S and HPC specimen at 28 d increase by 77%, 20% and 78%, respectively, compared with those at 7 d, and the dimension losses are 18.3%, 4.9% and 1.2%, respectively, which indicates that the dimension stability and mechanical property at late stage of traditional cementitious grouting material can be improved by the synergy effect of polymers system. The pore size of hardening cement paste reduces obviously and the pore radius distribution tends to thin with multiple high polymers. There presents exponential relationship is presented between internal porosity, threshold pore diameter and the compressive strength of different HPC pastes at 28 d, which has negative linear correlation with average pore diameter. The above mentioned solutions reveal that the mechanical properties of HPC can be reflected by the distribution characteristics of pore structure, and which can be improved by decreasing the pore radius.

Key words: high polymer; compressive strength; dimension shrinkage; pore structure; pore size distribution

注浆技术是我国北部煤矿采空区及西南岩溶地区的高速铁路工程对复杂地基采用的最广泛的加固手段。其原理是将注浆溶液通过一定压力注入岩体中,浆液通过填充、渗透、挤密等方式与岩体胶结,从而改善工程岩体的力学性能,以提高其稳定性和整体性。材料作为注浆治理技术的重要组成部分,直接影响注浆治理效果及被充填介质的服役性能。对于深部地下工程,注浆材料需具备堵水与加固的双重性能,流变时间可根据需要进行调控且凝结硬化后具有良好的强度、抗渗性及体积稳定性等耐久性能[1-2]。目前常见的注浆材料主要有普通水泥、水泥-水玻璃及化学类材料等。传统水泥基注浆材料普遍存在流动度不可控、可泵期不易调节等流变性能方面的缺陷,且硬化结石体早期强度高,后期强度增大缓慢;而普通水泥浆在扩散过程中的高析水性及水泥-水玻璃浆体硬化进程中自收缩等导致体积损失,必然会对其充填效果及充填介质的服役性能造成劣化影响[3-6]。水泥基注浆材料经凝结硬化后,形成了典型的多孔介质,其孔隙结构对强度、弹性模量、抗渗性、抗腐蚀性等宏观性能影响显著[7-9]。目前,存在很多水泥基材料强度与孔隙率之间关系的半经验公式,如幂函数、指数、对数和线性关系式[10],这些公式往往仅对试验数据进行线性回归,缺乏必要的理论支持。为此,本文作者通过大样本、长周期室内试验研制出一种改性高聚物-水泥基注浆材料(HPC),对其与普通水泥浆液、水泥-水玻璃在力学性能及体积稳定性等方面的性能差异进行对比分析。利用压汞测试(MIP)等研究手段,从亚微观角度探究高聚物体系物理化学效应下孔隙结构特征对硬化后水泥浆体力学性能的影响规律,旨在揭示改性水泥基注浆材料宏观性能与微观组构间的本质关联,为高性能水泥基注浆材料的性能优化提供理论依据与试验参考。

1 试验

1.1 原材料

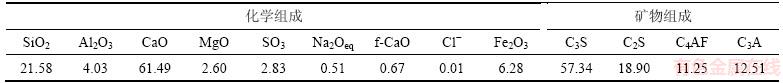

1) 水泥。水泥(C)为中国建筑材料研究院依据 GB 8076—1997监制的混凝土外加剂性能检测专用基准水泥(细度为0.5%,比表面积为341 m2/kg),其化学及矿物组分如表1所示。

2) 水玻璃。水玻璃(S)为山西华凯伟业有限公司生产,硅酸盐质量分数为40%,密度为1.38 g/cm3。

3) 高聚物体系。① 速凝剂,为清华大学建筑材料研究所合成的Na2O-AI2O3-H2O稳定胶体体系,主要成分为偏铝酸钠(SA),固体质量分数为65%。② 聚羧酸高效减水剂(Sp),其固体质量占溶液总质量的40%。③保水剂,由北京汉力淼新技术有限公司提供,其主要成分为高吸水树脂(SAP),粒径为180~420 μm。

1.2 试验方案

各高聚物体系试样组分及掺量如表2所示。试样采用水泥基注浆浆液常规水灰比0.8:1;其中m(S)/m(C),m(SA)/m(C),m(Sp)/m(C)和m(SAP)/m(C)分别为水玻璃、偏铝酸钠、聚羧酸及高吸水性树脂的折固质量与水泥质量之比;水的质量为各聚合物所含水与拌合水质量之和。

1.3 试样制备与测试

1) 试样制备。水泥浆液试样按参照GB/T 50080—2016“普通混凝土拌合物性能试验方法标准”规定的方法进行,将称量的速凝剂、减水剂先后倒入水泥胶砂搅拌机中,加入水泥和拌合水,均以125 r/min的转速搅拌2 min;将SAP颗粒倒入搅拌锅,以62 r/min的转速搅拌2 min。由于SAP具有一定的引气效应,导致搅拌后试样中含有大量气泡,需对试样进行多次振捣,使气泡悬浮出浆液表面。

表1 基准水泥化学及熟料矿物组成(质量分数)

Table 1 Chemical and mineral composition of cement %

表2 各试样体系组分(质量分数)及其配合比

Table 2 Formulation of different test systems and its matching %

2) 抗压强度。成型模具长、宽、高分别为70.7,70.7和70.7 mm,成型后立即用塑料保鲜薄膜覆盖,标准养护24 h后拆模,并在温度为(20±2) ℃、相对湿度大于95%的养护室中养护至规定龄期。测试时采用位移加载控制,加载速率为2 mm/min。正式加载前预加载3次,预压力为0.1 MPa,使试块与试验机加载接触面接触良好。抗压强度以3个平行试样的平均值为试验结果。

3) 体积稳定性。参照GB/T 50080—2016“普通混凝土拌合物性能试验方法标准”将复合浆体倒入250 mL量筒内。浆体析水后,用移液管将析水吸出并测量其体积,试验观察时间为60 min,测量间隔为10 min。而后将试样制备成长×宽×高为70.7 mm× 70.7 mm×70.7 mm的立方体试块,养护24 h后拆膜,移入干燥养护室内养护。将养护24 h后试块体积作为初始体积,并在温度为(25±2) ℃、相对湿度为(50±5)%的恒温恒湿实验室中连续原位测试变形14 d。在每组配合比下制备3个平行试块,以保证测量结果的重复性。

4) MIP测试。将养护至规定龄期(养护方式与前述的相同)的水泥试块置于无水乙醇中浸泡24 h以中止水化,而后置于(60±2) ℃的烘箱干燥至恒质量。破取新鲜断面,采用AUTOSCAN-33压汞仪对其进行孔结构参数测试。观察前应对试样表面进行喷金处理。

2 试验结果及分析

2.1 不同注浆材料力学性能对比分析

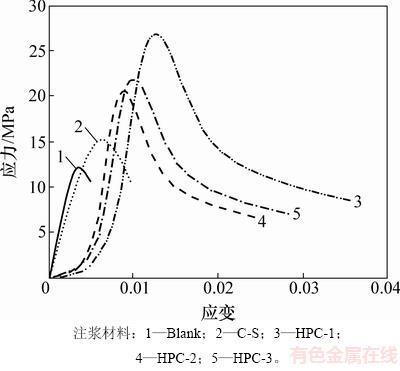

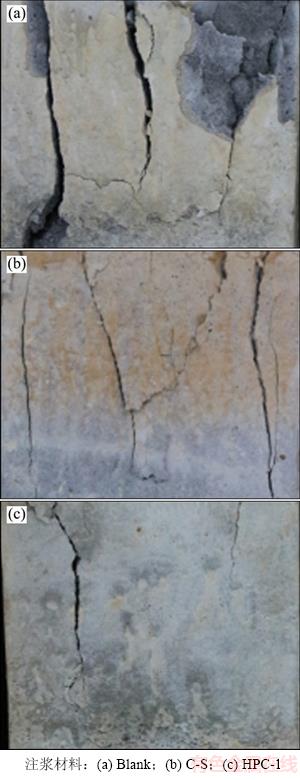

单轴受压状态下的应力-应变关系可有效反映材料在各受力阶段的变形特点及破坏进程,其包含的力学性能指标是进行构件设计及非线性分析的重要参数[11-12]。试验得到的7 d龄期下不同材料立方体试样抗压应力-应变关系曲线(由荷载-变形曲线计算得到)及其破坏形式分别如图1和图2所示。

从图1及图2可见:Blank试样和C-S试样在达到峰值应力时发生完全脆性破坏,破坏形态表现为若干斜向贯通的裂缝破坏面,故仅能得到峰值应力前的应力-应变曲线;而改性试样受压时出现了完整的应变软化和强度残余阶段,且在应变软化阶段才出现1条自上端面向下延伸的竖向非贯通裂纹;达到峰值应力后,随着应变提高至较大值,改性样仍存有一定的残余强度,这表明在多高聚物的协调效应下,改性水泥基材料的压缩延性明显比常规水泥净浆和水泥-水玻璃的好。

图1 7 d龄期下不同注浆材料的应力-应变关系曲线

Fig. 1 Stress-strain curves of different grouting materials at 7 d

图2 破坏形态

Fig. 2 Failure modes

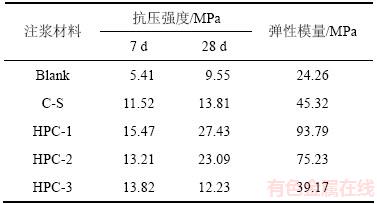

抗压强度是水泥基材料最重要的力学性能指标,而弹性模量反映了材料所受应力与产生应变之间的关系,是计算结构变形、裂缝开展和温度应力所必需的参数之一。取应力-应变曲线中1/3峰值应力与初始应力(本研究取0.5 MPa)的割线斜率定义为弹性模量[13-15],各材料在不同龄期下的抗压强度及弹性模量见表3。

表3 各材料强度发展及弹性模量

Table 3 Strength development and elastic modulus of different materials

由表3可见:28 d龄期下Blank试样抗压强度较7 d增大77%;C-S试样后期强度变化较缓慢,强度增长率仅为20%;HPC-1试样在不同龄期下的抗压强度均达到最大值,强度增长率达78%,表明减水剂的掺入可有效克服单掺水玻璃等速凝剂导致传统水泥基注浆材料后期强度发展缓慢的缺陷。

Blank,C-S和HPC-1这3种注浆材料弹性模量分别为24.26,45.32和93.37 MPa,表明HPC-1试样刚度明显比Blank及C-S试样的高。综上所述,聚合物的协调效应使改性水泥基注浆材料力学性能显著增强。

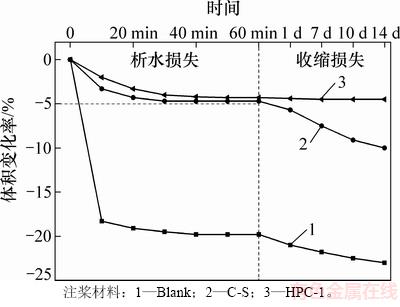

2.2 水泥基注浆材料体积稳定性

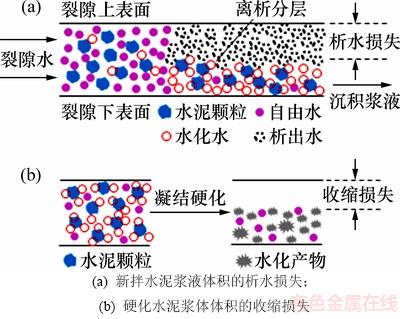

水泥基材料在富水裂隙岩体注浆中的体积稳定性关系到其充填效应及堵水效果,并对充填介质的服役性能产生重要影响。传统水泥基注浆材料的体积失稳机制主要包括2方面:一是高水灰比水泥浆液在地下水及水泥颗粒重力作用下引起浆水离析分层,从而导致体积的析水损失;二是速凝类浆液早期过快的水化反应消耗大量拌和水,硬化后水化不足而导致材料收缩变形,其失稳示意图如图3所示。

水泥基材料的体积稳定性受水灰比、化学外加剂的使用及其掺量、养护条件、方式等多因素影响[16]。对流态期内不同水泥基注浆浆液析水率及硬化后体积的收缩变形进行试验研究,其经时变化趋势如图4所示。从图4可见:10 min时Blank试样体积变化率接近-20%,其体积的析水损失较严重;而60 min时C-S浆液和HPC-1浆液体积变化率均小于-5%,达到稳定性浆液标准[17]。由于高聚物体系中高分子吸水树脂较高的比表面积能够不断吸附水分子并对其进行表面包裹,而达到吸液饱和状态的SAP分子与部分水泥颗粒搭接形成桥架效应,这种骨架结构网能够持续吸附游离水,增大了其渗出浆体的难度。SAP的“储水”作用使流态期内HPC浆液体积的析水损失显著降低。

图3 传统注浆材料体积失稳示意图

Fig. 3 Schematic diagrams of traditional grouting materials with dimensional instability

达到凝结硬化状态后,Blank试样和C-S试样分别由于早期失水严重以及水玻璃作用下过快的水化反应消耗大量的拌和水,表现为一定的收缩变形。而HPC浆液养护中后期储存于SAP高分子饱和结构中的拌和水被释放并参与水化反应,生成的水化产物堆积于水泥浆基体,使得固相及表观体积保持稳定。

图4 水泥基注浆材料体积损失经时曲线

Fig. 4 Dimensional loss-time curves of different cement-based materials

研究表明,高吸水树脂的“水库”作用可有效调节体系内部有效水灰比及湿度分布,并维持养护水的供给平衡,对于改善水泥基注浆材料的体积稳定性作用显著。

2.3 硬化水泥基注浆材料孔隙结构特征分析

硬化后水泥基注浆材料孔隙结构特征是反映其密实度的重要指标,同时也对其抗渗性、抗腐蚀性以及强度、干缩、徐变等性能有显著影响,本文从孔径分布、平均孔径、孔隙率等参数对不同体系硬化水泥基材料孔隙结构特征的差异进行研究,以揭示其与宏观性能的本质关联。结合文献[18-22],将孔尺寸分布分为4个区间:凝胶孔(<10 nm)、细毛细孔[10~50) nm、毛细孔[50,1 000) nm、大孔(>1 000 nm)。其中,凝胶孔为凝胶以及其与其他水泥产物之间的孔;毛细孔源于硬化浆体中未被水化产物填充的原充水空间;而大孔包括浆体拌和过程中夹带的气体以及SAP等表面活性剂引入的孔。28 d时不同材料试样孔径分布微分曲线及水泥基材料孔隙结构特征参数分别见图5和表4。

图5 28 d时不同材料试样孔径分布微分曲线

Fig. 5 Pore distribution differential curves of different specimens at 28 d

由图5及表4可以看出:C-S试样孔径特征峰较Blank明显向凝胶孔及细毛细孔区间偏移,凝胶孔与毛细孔比率之和为89.34%,高于Blank试样的84.39%。其中,凝胶孔分布比率由26.25%增至39.07%,表明SA使孔径在一定程度上细化。但过快的水化反应导致后期水化产物生成不足,原充水空间未被足够填充,这是C-S体系后期强度发展缓慢且表现出一定干燥收缩变形的原因。随着Sp的加入,HPC-2体系凝胶孔区间区间内形成2个特征峰,凝胶孔与细毛细孔分布比率之和增至47%,这表明Sp的“解絮-分散”效应保证了浆体内部水分充足,且确保了养护过程中外部环境的水分持续供应给浆体中未反应的水泥颗粒,而被分散的水泥颗粒经反应后产生的水化产物将一部分较大毛细孔隙填充,使其孔径显著减小,孔结构密实度明显提高。SAP的掺入使HPC-1体系凝胶孔数量进一步提升,其区间内出现3个特征峰,凝胶孔及细毛细孔分布比率之和增至最大值54.38%,这是由于SAP的“释水”效应可有效提高硬化浆体后期的水化程度。但大孔区间内进汞量明显提高,其分布比率由4.78%增至17%,这是SAP分子释放水后形成了尺寸较大的空孔所致;加之Sp对孔结构密实程度提高,孔径分布呈现由毛细孔向两极分化的趋势。少量离散的大孔对孔结构的劣化效应并不明显,决定孔结构密实度及孔隙率的依然是基体中占主体地位的凝胶孔及细毛细孔,故HPC-1体系下硬化浆体后期强度进一步提高。

当SAP质量分数增至0.5%时(HPC-3),孔径分布明显由凝胶孔和细毛细孔向粗毛细孔和大孔区间内偏移,大孔分布比率增至最大值32.98%。这表明过量饱和SAP高分子释放水分后,经过水泥硬化干燥造成失水塌缩留下的空孔使孔隙率明显增大,浆体后期强度显著降低。图6所示为掺入过量SAP后断面微观形貌,过量SAP分子释放水分后会在浆体中留下一系列形状不规则(受SAP凝胶形状控制)的大尺寸孔隙,其尺寸为200~600 μm。

表4 28 d龄期下水泥基材料孔隙结构特征参数及分布

Table 4 Parameters and distribution of pore of cementitious materials at 28 d

图6 过量SAP下HPC浆体SEM图像

Fig. 6 SEM image of HPC with overdose of SAP

结合表4中28 d龄期下各体系试样孔隙结构特征参数,以Blank试样为基准样,各体系下平均孔径从大至小依次为Blank,HPC-3,C-S,HPC-2和 HPC-1,这与表3中28 d龄期下强度的试验结果相反,即28 d龄期下硬化水泥浆体抗压强度与体系内部平均孔径呈负相关。这初步揭示了硬化后改性水泥基材料微观组构与宏观力学性能间存在本质关联,平均孔径可有效反映HPC浆体抗压强度的变化特征。

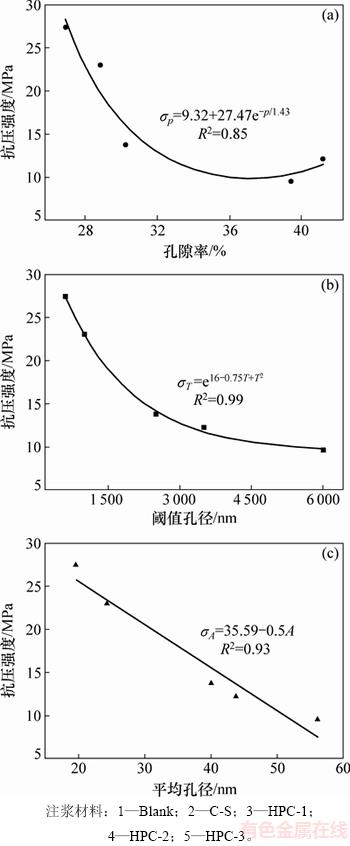

3 HPC浆体力学性能与孔隙结构特征关联研究

基于各材料试样的抗压强度和孔隙结构测试结果,将28 d龄期、不同高聚物体系下HPC试样抗压强度与相应孔结构特征参数绘制成散点图,并对抗压强度与特征参数的关系进行拟合,拟合曲线见图7。从图7可见:在28 d龄期下,硬化HPC浆体抗压强度与孔隙率、阈值孔径呈指数关系,拟合相关系数R2分别为0.85和0.99,这与张艳荣等[22-24]提出的混凝土强度与总孔隙率关系的半经验公式相一致。硬化HPC浆体抗压强度与平均孔径呈线性负相关,R2为0.93,即硬化HPC浆体抗压强度随平均孔径的增大而呈线性降低,这表明降低孔径有利于提升其力学性能。

为进一步讨论不同孔径对HPC浆体抗压强度的影响,借鉴水泥浆体抗压强度和孔隙率之间的线性回归方程[25]以及本研究的试验结果,进一步建立了如下式所示的改性水泥基材料抗压强度与不同孔径分布比率之间的关系式:

(1)

(1)

式中:σ为抗压强度;P<10 nm,P10~1 000 nm和P>1 000 nm分别为孔径小于10 nm,10~1 000 nm和大于1 000 nm的分布比率;σ0为平均孔径为0 mm时的抗压强度;系数a,b和c表示不同孔径对抗压强度的影响系数。经拟合得到σ0=73.65 MPa,a=-2,b=96.3,c=115。

图7 HPC浆体孔结构特征参数与抗压强度的关系

Fig. 7 Relationship between compressive strength and pore characteristic parameters of HPC

式(1)表明不同孔径区间对改性水泥基材料力学性能的影响不同:孔径区间小于10 nm 的凝胶孔对硬化HPC浆体抗压强度影响最小,而孔径区间为10~1 000 nm和大于1 000 mm的孔对强度的影响更为显著。这表明采用降低孔径的措施有利于提高改性水泥基注浆材料的力学强度。

4 结论

1) 通过单轴受压时HPC试样获得包括应变软化和强度残余阶段的应力-应变全曲线。达到峰值应力后,当应变增长至较大值时,仍存有一定的残余强度;HPC试样的压缩延性及弹性模量明显比Blank和C-S的高。在28 d龄期下,Blank,C-S和HPC试件单轴抗压强度较7 d龄期分别增大77%,20%和78%,高聚物体系的协调效应克服了单掺水玻璃等速凝剂导致水泥基注浆材料后期强度发展缓慢的缺陷。

2) 由于流变期和水化进程中的高析水和干燥收缩,在14 d龄期下,Blank和C-S试样体积损失率分别为18.3%和4.9%;改性试样体积收缩呈现先增大后减小的趋势,体积损失率仅为1.2%。复合使用速凝剂、减水剂及适量高吸水树脂对于改善水泥基注浆材料的体积稳定性作用显著。

3) 在28 d龄期下,各体系材料试样平均孔径从大至小的试样依次为Blank,HPC-3,C-S, HPC-2和 HPC-1,这与强度试验的测试结果呈负相关,初步揭示了硬化后改性水泥基材料微观组构与宏观力学性能间存在本质关联,平均孔径可有效反映HPC浆体抗压强度的变化特征。

4) 在28 d龄期下,硬化HPC浆体抗压强度与孔隙率、阈值孔径均呈指数关系,与平均孔径呈线性关系,表明降低孔径有利于提升其力学性能。孔径分布区间对改性水泥基注浆材料力学性能的影响具有差异性:孔径小于 10 nm 的凝胶孔对硬化HPC浆体抗压强度影响最小,而孔径为10~1 000 nm和大于1 000 mm的凝胶孔对浆体强度的影响更显著。

参考文献:

[1] 李利平, 李术才, 张庆松, 等. 一种新型高分子注浆材料的试验研究[J]. 岩石力学与工程学报, 2010, 29(增1): 3150-3156.

LI Liping, LI Shucai, ZHANG Qingsong, et al. Experimental study of a new polymer grouting material[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(Supp1): 3150-3156.

[2] 沙飞, 刘人太, 李术才, 等. 运营期渗漏水隧道注浆材料适用性[J]. 中南大学学报(自然科学版), 2016, 47(12): 4163-4172.

SHA Fei, LIU Rentai, LI Shucai, et al. Application on different types of cementitious grouts for water-leakage operational tunnels[J]. Journal of Central South University(Science and Technology), 2016, 47(12): 4163-4172.

[3] 沈凡, 黄绍龙, 孙政, 等. 水性环氧树脂-水泥-乳化沥青复合胶结体系的硬化机理[J]. 中南大学学报(自然科学版), 2012, 43(1): 105-110.

SHEN Fan, HUANG Shaolong, SUN Zheng, et al. Hardening mechanism of waterborne epoxy-cement-emulsified asphalt bonding system[J]. Journal of Central South University(Science and Technology), 2012, 43(1): 105-110.

[4] 李召峰, 李术才, 刘人太, 等. 富水破碎岩体注浆加固材料试验研究与应用[J]. 岩土力学, 2016, 37(7): 1937-1946.

LI Shaofeng, LI Shucai, LIU Rentai, et al. Development of the grouting material for reinforcing water-rich broken rock masses and its application[J]. Rock and Soil Mechanics, 2016, 37(7): 1937-1946.

[5] 刘彦伟, 程远平, 李国富. 高性能注浆材料研究与围岩改性试验[J]. 采矿与安全工程学报, 2012, 29(6): 821-826.

LIU Yanwei, CHENG Yuanping, LI Guofu. Research on high performance grouting material and improving surrounding rock mass strength[J]. Journal of Mining & Safety Engineering, 2012, 29(6): 821-826.

[6] 裴向军, 张佳兴, 王文臣, 等. SJP注浆浆液水化进程与流变特性研究[J]. 岩土工程学报, 2017, 39(2): 201-209.

PEI Xiangjun, ZHANG Jiaxing, WANG Wenchen, et al. Study of hydration process and rheological properties of SJP time-varying slurry[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(2): 201-209.

[7] 张宇, 金祖权, 张云升. 不同方式养护高强水泥基材料孔表面积分形维数与孔结构的关系[J]. 硅酸盐学报, 2017, 45(2): 249-253.

ZHANG Yu, JIN Zuquan, ZHANG Yunsheng. Relationship between pore surface fractal dimension and pore structure of high strength cementitious materials cured by different methods[J]. Journal of the Chinese Ceramic Society, 2017, 45(2): 249-253.

[8] 谢超, 王起才, 李盛, 等. 不同水灰比、养护条件下混凝土孔结构、抗压强度与分形维数之间的关系[J]. 硅酸盐通报, 2015, 34(12): 3695-3702.

XIE Chao, WANG Qicai, LI Sheng, et al. Relations of pore fractal dimension to pore structure and compressive strength of concrete under different water to binder ratio and curing condition[J]. Bulletin of the Chinese Ceramic Society, 2015, 34(12): 3695-3702.

[9] 傅强, 郑克仁, 谢友均, 等. 水泥乳化沥青砂浆孔体积的分形特征[J]. 硅酸盐学报, 2013, 41(11): 1551-1557.

FU Qiang, ZHENG Keren, XIE Youjun, et al. Fractal characteristic of pore volume of cement and asphalt mortar[J]. Journal of the Chinese Ceramic Society, 2013, 41(11): 1551-1557.

[10] 金南国, 金贤玉, 郭剑飞. 混凝土孔结构与强度关系模型研究[J]. 浙江大学学报(工学版), 2005, 39(11): 1680-1684.

JIN Nanguo, JIN Xianyu, GUO Jianfei. Relationship modeling of pore structure and strength of concrete[J]. Journal of Zhejiang University (Engineering Science), 2005, 39(11): 1680-1684.

[11] 徐世烺, 蔡向荣, 张英华. 超高韧性水泥基复合材料单轴受压应力-应变全曲线试验测定与分析[J]. 土木工程学报, 2009, 42(11): 79-85.

XU Shilang, CAI Xiangrong, ZHANG Yinghua. Experimental measurement and analysis of axial compressive stress-strain curve of ultra high toughness cementitious composites[J]. China Civil Engineering Journal, 2009, 42(11): 79-85.

[12] 熊良宵, 刘慈军. 海水侵蚀后水泥砂浆的单轴动态力学性能研究[J]. 岩石力学与工程学报, 2013, 32(12): 2481-2488.

XIONG Liangxiao, LIU Cijun. Dynamic mechanical properties of cement mortar after corroded by sea water[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(12): 2481-2488.

[13] 田青, 邓德华, 彭建伟. 水泥-沥青胶凝材料的弹性模量与组成参数的关系[J]. 中国铁道科学, 2016, 37(2): 1-7.

TIAN Qing, DENG Dehua, PENG Jianwei. Relationship between elastic modulus and composition parameters of cement-asphalt cementitious material[J]. China Railway Science, 2016, 37(2): 1-7.

[14] 郑新国. 反压成型高聚物注浆材料膨胀特性及其固结体力学性能研究[J]. 中国铁道科学, 2017, 38(1): 9-15.

ZHENG Xinguo. Expansion characteristics of polymer grouting material cured under pressure and mechanical properties of its consolidated body[J]. China Railway Science, 2017, 38(1): 9-15.

[15] 余自若, 秦鑫, 安明喆. 活性粉末混凝土的常规三轴压缩性能试验研究[J]. 中国铁道科学, 2012, 33(2): 38-42.

YU Ziruo, QIN Xin, AN Mingzhe. Experimental research on the conventional triaxial compressive properties of reactive powder concrete[J]. China Railway Science, 2012, 33(2): 38-42.

[16] 韩松, 涂亚秋, 安明喆, 等. 活性粉末混凝土早期收缩规律及其控制方法[J]. 中国铁道科学, 2015, 36(1): 40-47.

HAN Song, TU Yaqiu, AN Mingzhe, et al. The shrinkage of reactive powder concrete in early age and its control methods[J]. China Railway Science, 2015, 36(1): 40-47.

[17] 单仁亮, 杨昊, 张雷, 等. 水泥稳定浆液配比及适用条件研究[J]. 煤炭工程, 2014, 46(12): 97-100.

SHAN Renliang, YANG Hao, ZHANG Lei, et al. Research on proportion and application conditions of cement stable slurry[J]. Coal Engineering, 2014, 46(12): 97-100.

[18] 张国防, 王培铭. E/VC/VL三元共聚物对水泥砂浆孔结构和性能的影响[J]. 建筑材料学报, 2013, 16(1): 111-114, 120.

ZHANG Guofang, WANG Peiming. Effects of ethylene/vinyl chloride/vinyl laurate redispersible terploymer on pore structure and properties of cement mortar[J]. Journal of Building Materials, 2013, 16(1): 111-114, 120.

[19] 刘小华, 权娟娟, 张郁. 孔结构特征对高掺量矿渣水泥的力学性能影响[J]. 硅酸盐通报, 2014, 33(6): 1505-1509.

LIU Xiaohua, QUAN Juanjuan, ZHANG Yu. Effect of pore structure characteristics on mechanical properties of high-slag cement[J]. Bulletin of the Chinese Ceramic Society, 2014, 33(6): 1505-1509.

[20] 熊蓉蓉, 龙广成, 谢友均, 等. 矿物掺合料对蒸养高强浆体抗压强度及孔结构的影响[J]. 硅酸盐学报, 2017, 45(2): 175-181.

XIONG Rongrong, LONG Guangcheng, XIE Youjun, et al. Influence of mineral admixtures on compressive strength and pore structure of steam-cured high-strength cement paste[J]. Journal of the Chinese Ceramics Society, 2017, 45(2): 175-181.

[21] ZHANG Yanyong, KONG Xiangming. Influences of superplasticizer, polymer latexes and asphalt emulsions on the pore structure and impermeability of hardened cementitious materials[J]. Construction and Building Materials, 2014, 53: 392-402.

[22] 张艳荣. 水泥-化学外加剂-水分散体系早期微结构与流变性[D]. 北京: 清华大学土木工程系, 2014: 175-194.

ZHANG Yanrong. Study on the microstructure and rheological properties of cement-chemical admixtures-water dispersion system at early stage[D]. Beijing: Tsinghua University. School of Civil Engineering, 2014: 175-194.

[23] TANG Luping. A study of the quantitative relationship between strength and pore-size distribution of porous materials[J]. Cement and Concrete Research, 1986(1): 87-96.

[24] KUMAR R, BHATTACHARJEE B. Porosity pore size distribution and in situ strength of concrete[J]. Cement and Concrete Research, 2003, 33(2): 155-164.

[25] 熊蓉蓉, 龙广成, 谢友均, 等. 矿物掺合料对蒸养高强浆体抗压强度及孔结构的影响[J]. 硅酸盐学报, 2017, 45(2): 175-181.

XIONG Rongrong, LONG Guangcheng, XIE Youjun, et al. Influence of mineral admixtures on compressive strength and pore structure of steam-cured high-strength cement paste[J]. Journal of the Chinese Ceramic Society, 2017, 45(2): 175-181.

(编辑 陈灿华)

收稿日期:2017-12-04;修回日期:2018-03-05

基金项目(Foundation item):国家自然科学基金资助项目(U1234211);黔张常铁路科研开发计划项目(KCL14107530)(Project(U1234211) supported by the National Natural Science Foundation of China; Project(KCL14107530) supported by the Research and Development of Science and Technology of the Qianzhangchang Railway)

通信作者:宋国壮,博士研究生,从事复杂地质环境下高速铁路地基处理与沉降控制等研究;E-mail:14115340@bjtu.edu.cn