DOI: 10.11817/j.issn.1672-7207.2021.02.001

高炉炉缸区焦炭石墨化过程中多尺度孔隙结构的变化规律

胡中杰1, 2,吴胜利1,曹银平2,王臣2,周恒1

(1. 北京科技大学 冶金与生态工程学院,北京,100083;

2. 宝山钢铁股份有限公司炼铁厂,上海,201900)

摘要:在不同加热温度下(1 100~1 600 ℃)模拟高炉炉缸区焦炭的石墨化过程,利用真空排水法及氮气吸附法考察不同石墨化程度焦炭的多尺度孔隙结构演变过程。研究结果表明:二次加热后的焦炭中孔隙结构丰富且复杂,随着二次加热温度的升高,焦炭的显气孔率、比表面积、孔容积及微孔数量呈规律性变化,可分为3个过程:即1 100≤ t <1 200,1 200≤ t <1 400和1 400≤ t <1 600 ℃,且在温度低于1 400 ℃时灰分析出主导焦炭孔隙结构变化,大于1 400 ℃时则主要受焦炭石墨化的影响;同时,不同石墨化程度焦炭的吸附脱附曲线均存在交叉点,且2条曲线不重合形成了“滞后环”,基于滞后回线原理分析认为焦炭石墨化后的气孔结构多呈“毛囊”状;在焦炭石墨化过程中,内部灰分逐渐熔化析出至基质表面的迁移行为是导致出现上述规律的原因。

关键词:焦炭;石墨化;多尺度;孔隙结构;滞后环

中图分类号:TF526 文献标志码:A

文章编号:1672-7207(2021)02-0331-08

Variation of multi-scale pore structure during graphitization of coke in a blast furnace hearth

HU Zhongjie1, 2, WU Shengli1, CAO Yinping2, WANG Chen2, ZHOU Heng1

(1. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing,Beijing 100083, China;

2. Ironmaking Plant, Baoshan Iron & Steel Co. Ltd., Shanghai 201900, China)

Abstract: The graphitization processes of coke in the hearth of blast furnace were simulated at different heating temperatures from 1 100 ℃ to 1 600 ℃. The evolutions of multi-scale pore structure of coke with different graphitization degrees were investigated by the vacuum drainage and nitrogen adsorption method. The results show that the pore structure of coke after reheating is abundant and complex as well. With the increase of the reheating temperature, the apparent porosity, specific surface area, pore volume and microporous quantity of coke change regularly, which can be divided into three stages, i.e., 1 100≤ t <1 200, 1 200≤ t <1 400 and 1 400≤ t < 1 600) ℃. Moreover, the ash precipitation plays the leading role on the pore structure change of coke below 1 400 ℃. Once the temperature is higher than 1 400 ℃, the pore structure will be mainly affected by the graphitization process of coke. Besides, there are crossing points existed in the adsorption and desorption curves of coke with different graphitization degrees. The two curves do not coincide and thus forms a "hysteresis loop". Based on the principle of hysteresis loop, it can be deduced that the pore structure of graphitized coke mostly appeares as a shape of "hair follicle". It is the inner ash migration to the surface of coke substrates during the graphitization process that leads to the above law.

Key words: coke; graphitization; multi-scale; pore structure; hysteresis loop

焦炭是炼铁过程中能量流的主要载体[1],保障含铁炉料的还原及熔化;在高炉炉缸区焦炭是唯一以固态形式存在的物料,其气孔结构是炉缸区煤气流上升及渣铁滴落的重要通道。焦炭的气孔主要源自焦化过程中挥发性气体的析出,气体析出的不同状态形成了宏观的开气孔和闭气孔[2-4],焦炭的气孔划分目前尚未有统一标准,一般认为孔径小于1 μm的孔均为微气孔。前人针对气孔率及孔隙结构与焦炭热态强度的关系进行了深入研究,金慧军等[5]认为随着气孔率增加,焦炭溶损反应更为剧烈,反应后强度随之降低。焦炭的溶损反应主要发生在0.03~1 μm之间,中孔与微孔直接影响内扩散区域的溶损反应[6-10]。目前人们针对焦炭在炉缸高温区孔隙结构演变的研究较少,焦炭在高炉内经熔损反应、高温热应力及碱金属侵蚀后,粒度大幅降解,且高温作用下焦炭微晶结构渐趋有序化接近石墨的层间距[11-13],不同尺寸的孔隙结构也会随之变化。本文作者采用可控温马弗炉为主体模拟高炉炉缸区焦炭的石墨化过程,借助真空排水法、氮气吸附法及SEM扫描电镜重点研究石墨化过程中焦炭的显气孔率、比表面积、孔径分布等多尺度孔隙结构的特征参数,从微观形貌上研究孔隙结构的变化规律。

1 实验

1.1 实验原料

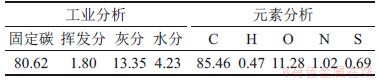

本实验选用的是现场高炉生产中所用的焦炭,其工业分析及元素分析见表1。

表1 高炉焦炭的工业分析与元素分析结果(质量分数)

Table 1 Industrial analysis and elemental analysis of BF coke %

1.2 实验方法

结合高炉内不同区域炉温及炼焦温度将烘干脱水后的焦炭在氮气保护下,分别加热到1 100~1 600 ℃后恒温0.5 h,其中氮气的流量为2 L/min。

目前,测量焦炭的孔隙结构方法较多[14-17],根据气孔孔径不同,主要采用真空排水法及图像分析法测定显气孔率、大气孔孔径及分布,采用压汞法测定中孔孔径,采用氮气吸附法测定焦炭中的微孔孔径。与其他方法相比,真空排水法操作简便,同时由于焦炭的石墨化过程会使微孔闭合,因此,本实验分别采用真空排水法与氮气吸附法(77 K)来测定焦炭不同孔径孔隙结构的特征参数,用SEM观察目标温度下不同石墨化程度的焦炭形貌,以从形态上解释孔隙结构的变化规律。

2 结果与讨论

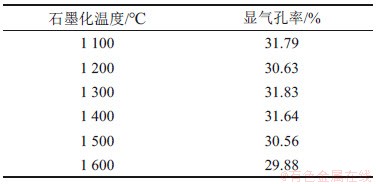

2.1 焦炭宏观显气孔率的测定分析

焦炭是一种多孔碳质材料,根据气孔的不同形态将气孔率分为显气孔率及总气孔率。本实验采用真空排水法测定不同石墨化程度焦炭的显气孔率;将实验试样去除表面粉尘后,于150 ℃下干燥4 h,开启真空泵,当剩余压力小于或等于2.666 kPa时,关闭抽气阀,停泵。测得实验结果如表2所示。

表2 不同石墨化温度下焦炭的显气孔率

Table 2 Apparent porosity of coke at different graphitization temperatures

焦炭进入炉缸高温区后,其灰分会在1 300 ℃左右开始析出并挥发[18],焦炭内部原有的闭塞气孔随之打开;但同时随着二次加热温度的升高,焦炭的石墨化程度加深,其微晶结构中的层面间距d002不断减小,碳素有序性增强导致焦炭的微孔闭合,孔隙合并。由表2可知,焦炭的显气孔率在1 200 ℃时略有降低,这是由于焦炭在高于炼焦温度时,内部熔点低的矿物开始熔化并通过气孔向表面流动;至1 400 ℃时显气孔率有所增大,这是由于灰分逐渐移出焦炭基质,此时灰分析出对气孔率的增大作用与石墨化度对气孔率的削减作用相互抵消;当温度升高至1 500 ℃时,焦炭内部的灰分挥发殆尽,石墨化程度进一步加深,导致显气孔率明显下降。

2.2 焦炭微观孔隙结构的测定分析

为进一步从微观尺度研究焦炭石墨化过程中孔隙结构的变化规律,将样品在110 ℃下干燥12 h,采用氮气吸附法在低温低压(温度T=77 K,压力p=127 kPa)条件下测定表2中6种试样的比表面积、孔容积及孔分布。其原理是将焦炭放入液态氮气中,改变外界压力时氮气会附着在焦炭的气孔表面上,测量不同的相对压力下氮气的吸附量,进而得到吸附与脱附的等温曲线,通常采用BET方程及BJH模型分析试样的比表面积及孔径分布[19-21]。

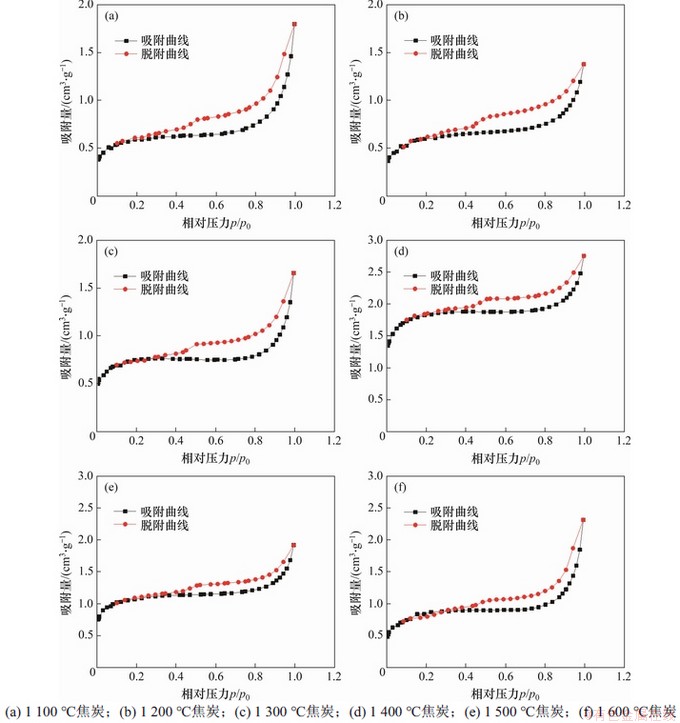

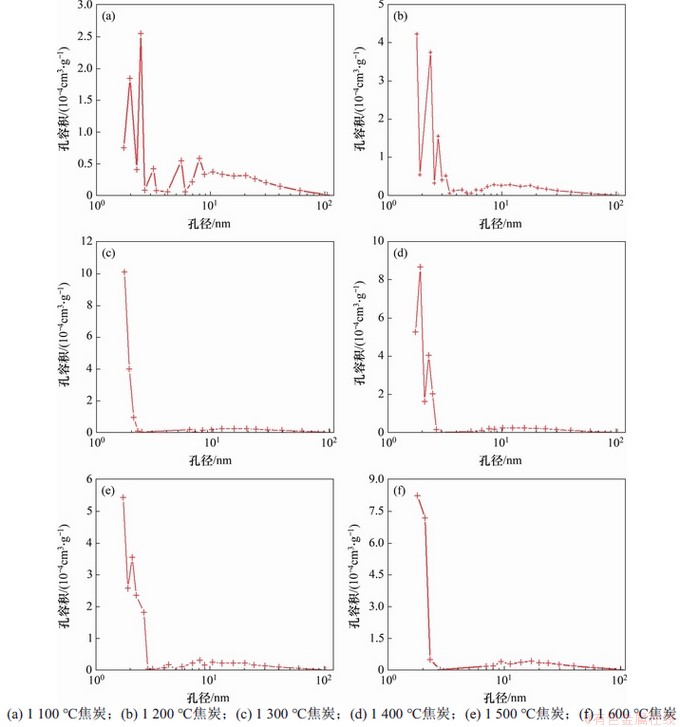

在77.4 K时测得的不同二次加热温度的等温吸附及脱附曲线如图1所示。

在吸附脱附等温线中,可以将相对压力划分为低压、中压、高压3段。在低压阶段,吸附等温曲线上升较快,此阶段主要是微孔被填充,由图1可见:吸附等温线均出现不同程度上凸,说明6种焦炭试样中均有微孔,且微孔的数量不同,1 400 ℃焦炭样品的微孔最多;在高压阶段,各样品的吸附曲线上升趋势很快,可以看出焦炭之中存在着较多的大孔,其中当相对压力为1时,1 600 ℃焦炭氮的吸附量比1 500 °C焦炭氮的吸附量大,反映其大孔比例高。

图1 不同石墨化温度下焦炭的吸附与脱附曲线

Fig. 1 Adsorption and desorption curves of coke at different graphitization temperatures

根据BDDT理论[22]及图1,6种试样的吸附曲线均属于Ⅳ型特征等温线,吸附过程中由于毛细管凝聚作用使N2分子在低于常压下冷凝填充了介孔孔道,毛细凝结在孔壁上的环状吸附膜液面上进行,而脱附则是从孔口的球形弯月液面开始,从而导致吸脱附等温线不相重合形成了“滞后环”。根据滞后回线原理可以判断焦炭的气孔结构多呈“毛囊”状。同时,本实验中各样品的脱附等温曲线出现了Harris拐点(在p/p0在0.4~0.5范围内脱附曲线出现的拐点,其中,p为被吸附气体在吸附温度下平衡时的压力,Pa;p0为饱和蒸汽压力,Pa;C为与吸附热有关的常数),是因为相对压力增加时氮气在焦炭内部孔隙表面产生多层吸附或毛细凝聚,在氮气重新解吸释放过程中出现了交叉吸附-脱附曲线相交的结果。

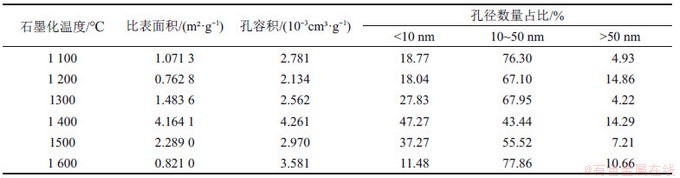

由BET方程(式(1))及BJH理论可计算出焦炭的比表面积、孔容积及孔径分布,如表3所示;孔容积分布如图2所示。

(1)

(1)

式中:V为吸附气体的总体积,m3;Vm为催化剂表面覆盖第一层时所需气体的体积,m3。

图2 不同石墨化温度下焦炭的孔径分布曲线

Fig. 2 Pore size distribution curves of coke at different graphitization temperatures

表3 不同石墨化温度焦炭的比表面积、孔容积及孔径分布

Table 3 Specific surface area, pore volume and pore size distribution of different cokes

分析表3及图2可以看出温度段随着二次加热温度的升高,焦炭的比表面积、孔容积及微孔数量呈规律性变化。二次加热温度t基本上可分为3个温度段:1 100≤ t <1 200,1 200≤ t <1 400和1 400≤t <1 600 ℃。在1 100≤ t <1 200 ℃,焦炭的比表面积及孔容积略有波动,在1 200≤ t <1 400 ℃,大孔占比先降低后升高,10~50 nm孔径数量占比降低了23.66%;在1 400≤ t <1 600 ℃温度区间,样品的比表面积急速下降,1 600 ℃焦炭试样的比表面积及孔径小于10 nm的孔的占比均约为1 400 ℃条件下试样的1/5。出现上述规律的原因是焦炭中含有约13%的灰分,在二次加热过程中灰分经历了由焦炭内部析出至表面进而挥发的过程,导致该过程中会反复出现堵孔,堵孔及闭合孔打开的现象;同时,随着温度的升高,焦炭的石墨化程度加深,碳原子排列有序性使内部微孔闭合,因此,在1 400 ℃以后发现焦炭的比表面积成倍速下降,孔容积及微孔数量也随之下降。

总体来看,在石墨化过程中,对焦炭孔隙结构的影响如下:低于1 400 ℃时灰分析出主导焦炭的孔隙变化,高于1 400 ℃时孔隙结构变化主要受焦炭石墨化的影响。

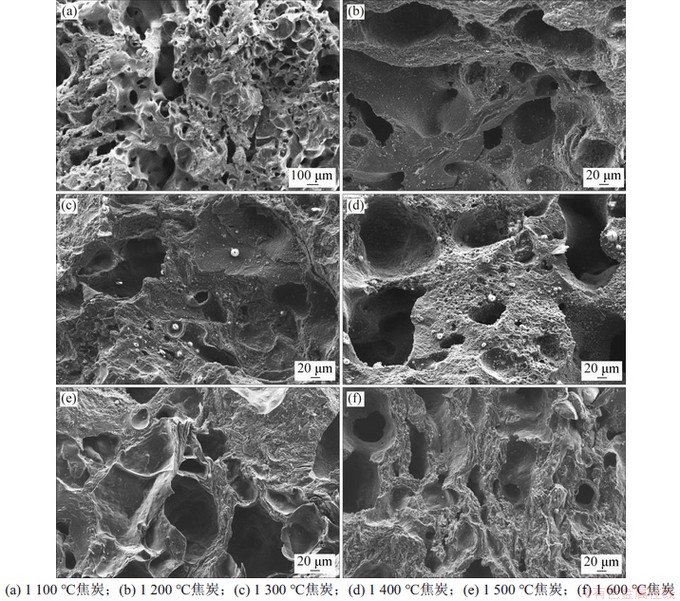

2.3 焦炭的扫描电镜形貌分析

为了深入分析焦炭的孔隙结构,采用SEM对不同石墨化温度下的焦炭进行观察,观察结果如图3所示。

图3 不同石墨化温度下焦炭的微观形貌

Fig. 3 Micro-morphology of coke sat different graphitization temperatures

由图3可以发现:随着二次加热温度的升高,焦炭在1 200 ℃时表面大气孔附近有白色矿物颗粒出现;当温度升至1 400 ℃时,焦炭内部矿物质逐渐迁移至基质表面,包裹焦炭形成小球体外形;当温度升至炉缸风口高温时,灰分矿物质挥发,焦炭石墨化程度逐渐加深,表面的气孔总量逐渐减少,大气孔数量减少,气孔变小,微孔闭合,焦炭的微观结构趋于有序。由此推测的焦炭中灰分在高炉炉缸区熔融并迁移至基质表面的过程与GORNOSTAYEV等[23]得出的结论一致。

3 结论

1) 焦炭试样在1 100~1 400 ℃时显气孔率波动较小,约为31%,高于1 400 ℃后由于石墨化作用,显气孔率开始下降。

2) 不同石墨化程度焦炭试验的氮气吸附曲线属于Ⅳ型特征等温线,且各试样的吸附脱附曲线均存在交叉点,说明焦炭内部孔隙结构发达且复杂,氮气在焦炭内部孔隙表面产生多层吸附或毛细凝聚,2条曲线不重合且形成了“滞后环”,根据滞后回线原理,可以判断焦炭石墨化后的气孔结果多呈“毛囊”状。

3) 随着加热温度的升高,焦炭的孔隙结构在3个温度阶段1 100≤ t <1 200,1 200≤ t <1 400和1 400≤ t <1 600 ℃呈现规律性变化。在温度低于1 400 ℃时,灰分析出主导焦炭孔隙变化,高于1 400 ℃时,孔隙结构变化主要受焦炭石墨化的影响。

4) 1 200 ℃时,焦炭表面大气孔附近开始出现白色矿物颗粒,1 400 ℃时,内部灰分矿物质大多析出至基质表面。随着焦炭的石墨化程度进一步加深,焦炭表面矿物质挥发,且气孔总量逐渐减少,大气孔数量减少,气孔变小,微孔闭合,焦炭的微观结构趋于有序。

参考文献:

[1] WANG Ping, WU Yu, MENG Qingmin, et al. Interaction reaction between the degradation of coke and the reduction of iron ore in oxygen blast furnace under hydrogen-enriched operation[J]. Ironmaking & Steelmaking, 2020, 47(3): 290-295.

[2] WANG Wei, DAI Bowen, XU Runsheng, et al. The effect of H2O on the reactivity and microstructure of metallurgical coke[J]. Steel Research International, 2017, 88(8): 1700063.

[3] 方觉, 王杏娟, 龚瑞娟, 等. 高炉块状带焦炭强度模拟研究[J]. 钢铁研究学报, 2007, 19(1): 12-15.

FANG Jue, WANG Xingjuan, GONG Ruijuan, et al. Simulative research on coke strength in lumpish section of blast furnace[J]. Journal of Iron and Steel Research, 2007, 19(1): 12-15.

[4] 徐万仁, 吴铿, 朱仁良, 等. 提高喷煤量对高炉风口焦性状的影响[J]. 钢铁, 2005, 40(2): 11-14.

XU Wanren, WU Keng, ZHU Renliang, et al. Influence of increasing PCI rate on characteristics of tuyere coke in blast furnace[J]. Iron and Steel, 2005, 40(2): 11-14.

[5] 金慧军, 傅永宁. 焦炭-CO2反应过程中孔隙结构的变化[J]. 煤化工, 1991, 19(1): 11-17.

JIN Huijun, FU Yongning. Changes in pore structure during coke-CO2 reaction[J]. Coal Chemical Industry, 1991, 19(1): 11-17.

[6] HILDING T, GUPTA S, SAHAJWALLA V, et al. Degradation behaviour of a high CSR coke in an experimental blast furnace: effect of carbon structure and alkali reactions[J]. ISIJ International, 2005, 45(7): 1041-1050.

[7] GUPTA S, SAHAJWALLA V, CHAUBAL P, et al. Carbon structure of coke at high temperatures and its influence on coke fines in blast furnace dust[J]. Metallurgical and Materials Transactions B, 2005, 36(3): 385-394.

[8] 马名杰, 张胜局, 闫燕, 等. 焦炭结构的研究进展[J]. 中国煤炭, 2006, 32(8): 54-56.

MA Mingjie, ZHANG Shengju, YAN Yan, et al. Research progress in coke structure[J]. China Coal, 2006, 32(8): 54-56.

[9] 郭瑞, 汪琦, 赵雪飞, 等. 焦炭反应性及反应后热性质及其检测方法[J]. 过程工程学报, 2013, 13(3): 512-518.

GUO Rui, WANG Qi, ZHAO Xuefei, et al. Reactivity and post-reaction properties of coke and their measurement[J]. The Chinese Journal of Process Engineering, 2013, 13(3): 512-518.

[10] 左海滨, 戎妍, 张建良, 等. 氧化钙对焦炭性能的影响[J]. 钢铁, 2014, 49(1): 7-12.

ZUO Haibin, RONG Yan, ZHANG Jianliang, et al. Effect of CaO on properties of coke[J]. Iron and Steel, 2014, 49(1): 7-12.

[11] 胡德生. 焦炭微晶结构特性研究[J]. 钢铁, 2006, 41(11): 10-12.

HU Desheng. Crystallite structure characteristics of coke[J]. Iron & Steel, 2006, 41(11): 10-12.

[12] SHI H, REIMERS J N, DAHN J R. Structure-refinement program for disordered carbons[J]. Journal of Applied Crystallography, 1993, 26(6): 827-836.

[13] 房永征, 曹银平, 金鸣林, 等. 添加无烟煤对焦炭微晶和气孔结构的影响[J]. 钢铁, 2006, 41(10): 16-18, 22.

FANG Yongzheng, CAO Yinping, JIN Minglin, et al. Effect of anthracite in coal blend on micro-crystal and pore structure of coke[J]. Iron & Steel, 2006, 41(10): 16-18, 22.

[14] 鞠付栋, 陈汉平, 杨海平, 等. 煤气化过程中焦炭的表面孔隙结构及其分形特征[J]. 中国电机工程学报, 2010, 30(8): 9-14.

JU Fudong, CHEN Hanping, YANG Haiping, et al. Characteristic surface pore structure and its fractal characteristics during coal gasification[J]. Proceedings of the CSEE, 2010, 30(8): 9-14.

[15] 邢德山, 阎维平. 用压汞法分析工业半焦的孔隙结构特征[J]. 华北电力大学学报(自然科学版), 2007, 34(5): 57-63.

XING Deshan, YAN Weiping. Analysis to pore structure of typical semi-cokes by mercury porosimetry[J]. Journal of North China Electric Power University(Natural Science Edition), 2007, 34(5): 57-63.

[16] 赵振国. 吸附作用应用原理[J]. 热能动力工程, 2005(6): 631.

ZHAO Zhengguo. Application principle of adsorption[J]. Thermal Energy Engineering, 2005(6): 631.

[17] 杨光智, 徐洋洋, 魏士政, 等. 焦炭高温加热下灰分及微孔结构研究[J]. 煤炭转化, 2015, 38(4): 54-57.

YANG Guangzhi, XU Yangyang, WEI Shizheng, et al. Study on ash content and micropore structure of coke after high temperature treatment[J]. Coal Conversion, 2015, 38(4): 54-57.

[18] 申俊华, 许娟, 李彦敏. BJH法测量粉末孔径的方法研究[J]. 工程技术:引文版, 2016(1): 184-185.

SHEN Junhua, XU Juan, LI Yanmin. BJH method for measuring pore size of powder[J]. Engineering Technology: Citation Version, 2016(1): 184-185.

[19] 郭文涛. 焦炭微观结构对其在高炉中反应行为与性能影响研究[D]. 北京: 北京科技大学钢铁冶金新技术国家重点实验室, 2016: 5-26.

GUO Wentao. The influence of the coke microstructure on the reaction behavior and performance in the blast furnace[D]. Beijing: University of Science and Technology Beijing. State Key Laboratory of Advanced Metallurgy, 2016: 5-26.

[20] GRIGORE M, SAKUROVS R, FRENCH D, et al. Coke gasification: the influence and behavior of inherent catalytic mineral matter[J]. Energy & Fuels, 2009, 23(4): 2075-2085.

[21] 张守玉, 吕俊复, 黎永, 等. 煤中矿物质对煤焦氧化的催化性能在热处理过程中的变化[J]. 燃烧科学与技术, 2005, 11(2): 137-141.

ZHANG Shouyu, LU Junfu , LI Yong, et al. Transition of the catalytic capability of minerals for the oxidation of coal-char during heat treatment[J]. Journal of Combustion Science and Technology, 2005, 11(2): 137-141.

[22] 何余生, 李忠, 奚红霞, 等. 气固吸附等温线的研究进展[J]. 离子交换与吸附, 2004, 20(4): 376-384.

HE Yusheng, LI Zhong, XI Hongxia, et al. Research progress of gas-solid adsorption isotherms[J]. Ion Exchange and Adsorption, 2004, 20(4): 376-384.

[23] GORNOSTAYEV S S, HARKKI J J. Mechanism of physical transformations of mineral matter in the blast furnace coke with reference to its reactivity and strength[J]. Energy & Fuels, 2006, 20(6): 2632-2635.

(编辑 刘锦伟)

收稿日期: 2020 -03 -26; 修回日期: 2020 -05 -26

基金项目(Foundation item):国家自然科学基金资助项目(51904023, 51804027);中央高校基本科研业务费资助项目(FRF-IC-19-004) (Projects(51904023, 51804027) supported by the National Natural Science Foundation of China; Project(FRF-IC-19-004) supported by the Fundamental Research Funds for the Central Universities)

通信作者:吴胜利,博士,教授,从事高炉炼铁新技术等研究; E-mail: wushengli@ustb.edu.cn

引用格式:胡中杰, 吴胜利, 曹银平, 等. 高炉炉缸区焦炭石墨化过程中多尺度孔隙结构的变化规律[J]. 中南大学学报(自然科学版), 2021, 52(2): 331-338.

Citation:HU Zhongjie, WU Shengli, CAO Yinping, et al. Variation of multi-scale pore structure during graphitization of coke in a blast furnace hearth[J]. Journal of Central South University(Science and Technology), 2021, 52(2): 331-338.